Patents

Literature

51results about How to "Meet the actual needs of the site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire evacuation system and evacuation method thereof

ActiveCN104809832AImprove general performanceDisplay rich contentSignalling system detailsElectric transmission signalling systemsFire evacuationFire alarm system

The invention discloses a fire evacuation system and an evacuation method. The fire evacuation system comprises a fire evacuation acoustic-optical indicating system, an acoustic-optical power supply system, a fire parameter detection system, a control system and a fire alarm system; the fire evacuation acoustic-optical indicating system, the acoustic-optical power supply system and the control system and electrically connected mutually; the acoustic-optical power supply system continuously supplies power for a lamp assembly in the fire evacuation system; the control system controls the acoustic-optical power supply system to supply power for a voice prompt device in the fire evacuation acoustic-optical indicating system through a second power supply circuit and controls the luminance of the lamp assembly and acoustic-optical contents of the fire evacuation acoustic-optical indicating system through the control circuit; the fire parameter detection system and the control system are electrically connected to the fire alarm system through data transmission lines respectively. The fire evacuation system can provide different evacuation guidance for users at different floors according to point locations of fires and fire conditions of fire scenes and avoids the users from running to error channels or taking error actions and accordingly gets into danger.

Owner:联创时代(苏州)设计有限公司

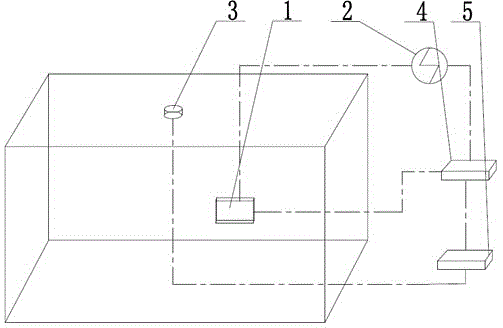

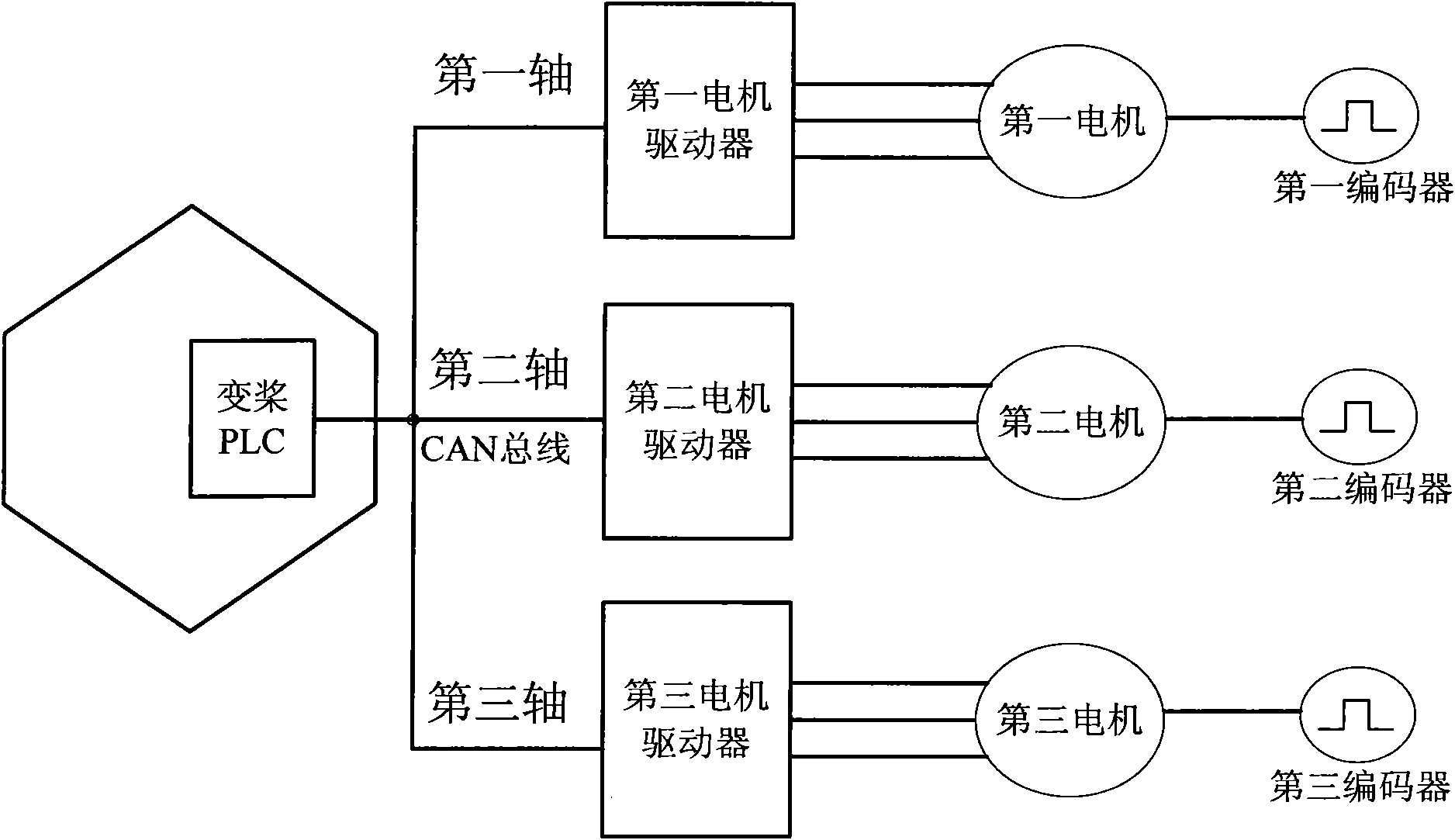

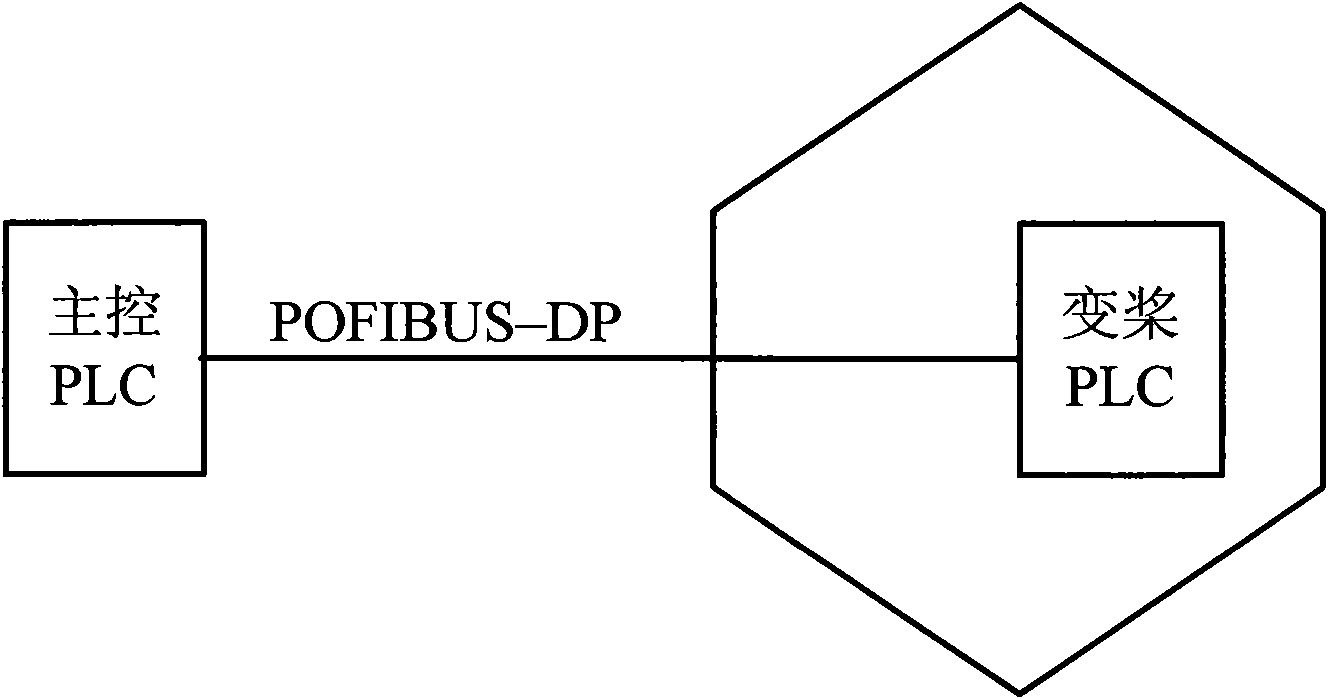

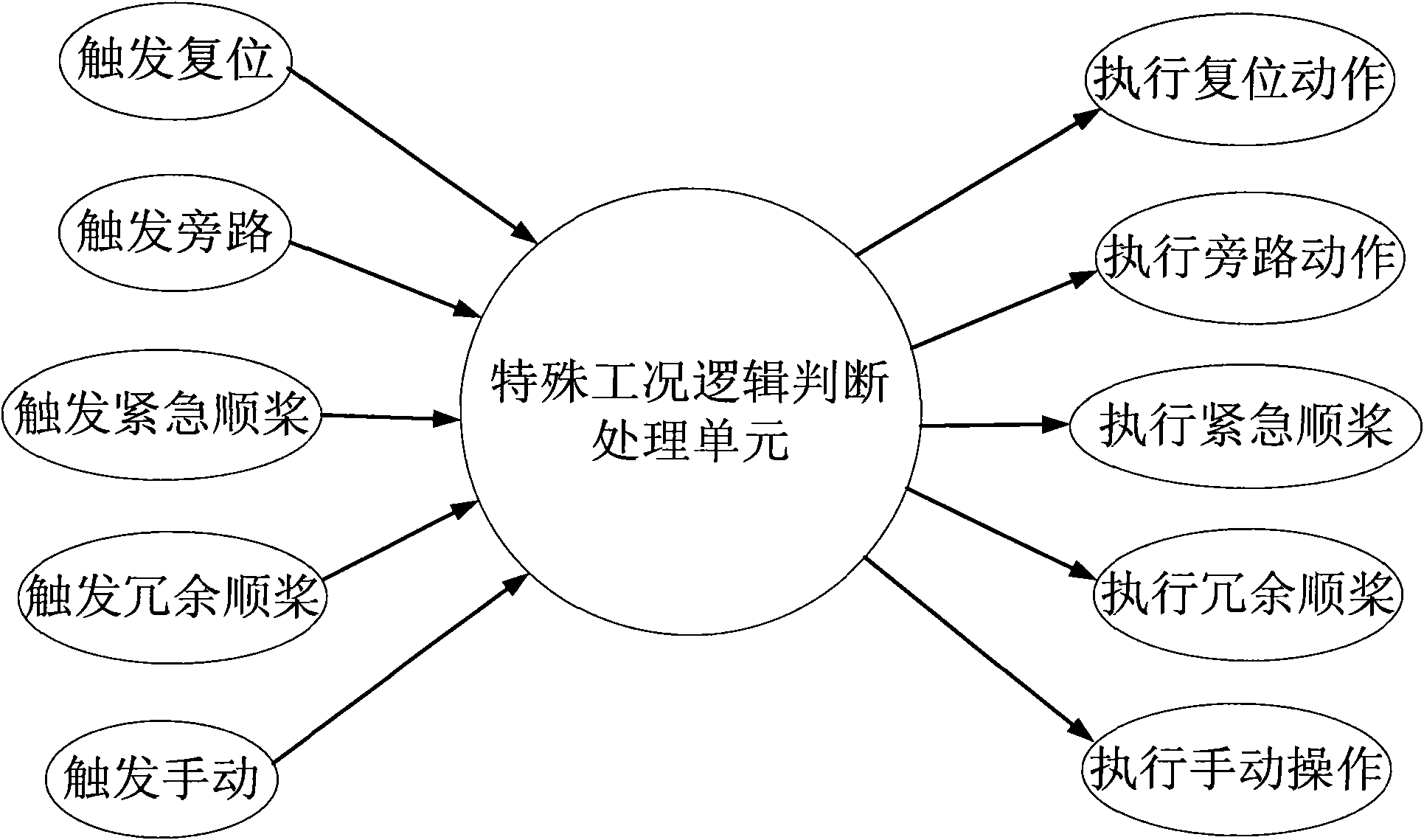

Active pitch control system of wind driven generator with special working condition processing logic

ActiveCN101975142AReduce Logical ComplexityImprove securityWind motor controlMachines/enginesWind drivenControl system

The invention relates to an active pitch control system of a wind driven generator, which realizes special working condition processing logic in a motor driver at the bottom layer of the active pitch control system and direct control on a blade angle. For various special working conditions possibly occurring in the site operation of the wind driven generator, a series of motion measures are adopted in the active pitch control system to ensure safety shut-down, corrective maintenance and normal power generation production of the wind driven generator. The active pitch control system of the wind driven generator with special working condition processing logic has the advantages of reliable safety and remarkable economic benefit.

Owner:GUAN HUADIAN TIANREN CONTROL EQUIP CO LTD

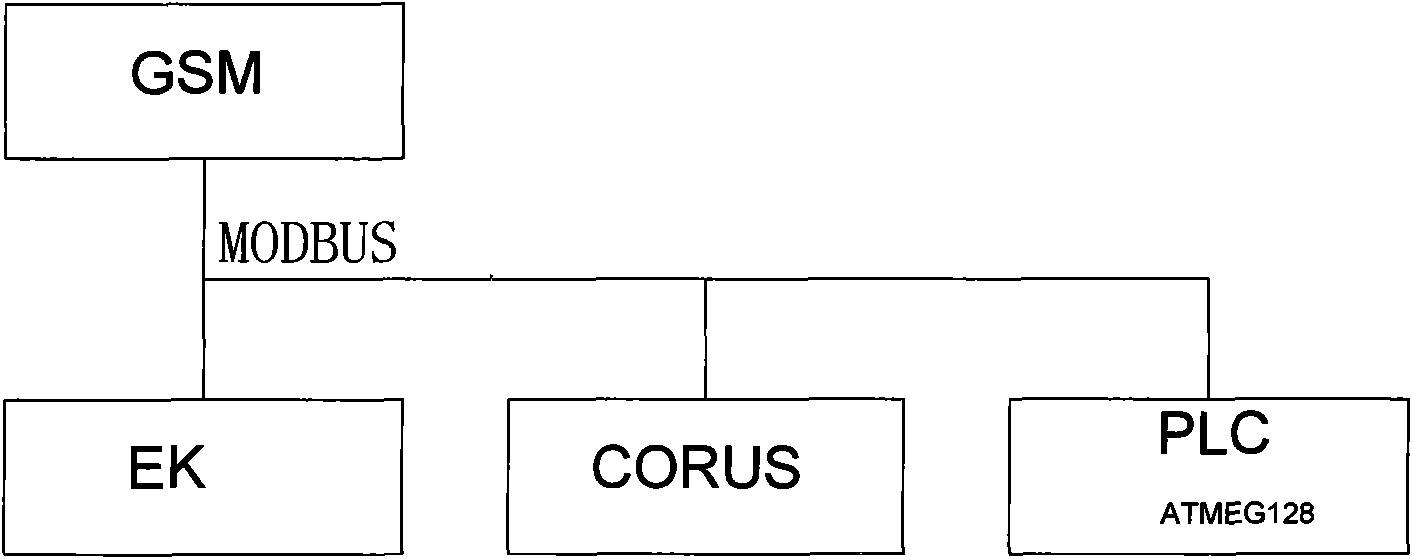

Coal gas remote meter reading system

InactiveCN101581591AResolve the case of incomplete packetsSolve the problem of free expansionError preventionVolume indication and recording devicesComplete dataNetwork packet

The invention discloses a coal gas remote meter reading system, which comprises a GSM main module and a collection flow meter instrument module EK, a collection flow meter instrument module CORUS, a PLC module and an isolated power supply module which are connected with the GSM main module, wherein the GSM main module encrypts based on a KEELOQ algorithm while performing GPRS / CDMA transmission, an instrument terminal needs to study with a host so as to communicate with the host, and in the studying process, the instrument terminal sends a serial number and an encryption key EN_KEY to the host, and the host generates a random number. The coal gas remote meter reading system has the advantages of adopting GPRS / CDMA to effectively perform remote transmission and using an encryption technique to successfully solve the problem of incomplete data packets in the process of the GPRS / CDMA transmission. Besides, the mode of power supply adopts power supply modules of an explosion-proof power supply and an intrinsically safe power supply module to flexibly satisfy on-site actual needs.

Owner:无锡虹叶腾文电子科技有限公司

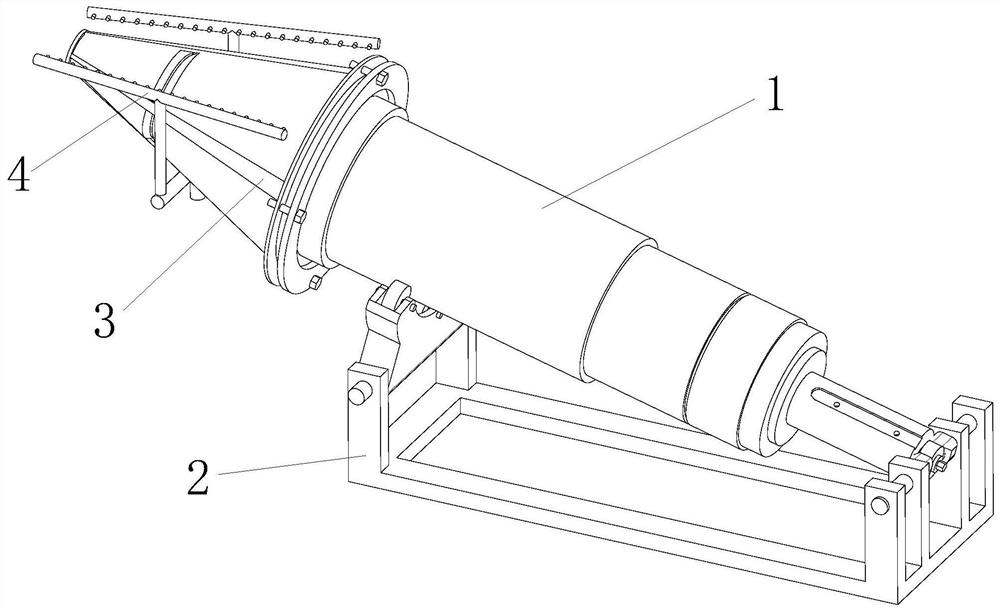

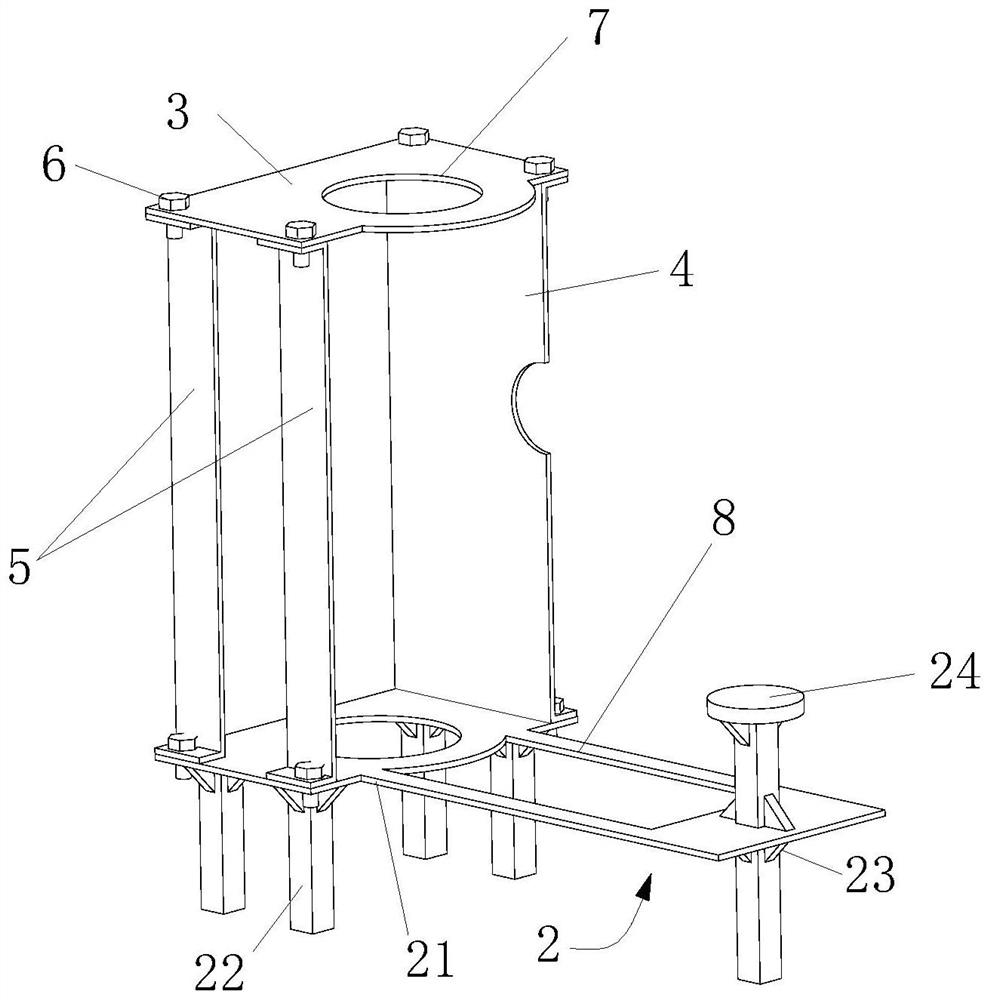

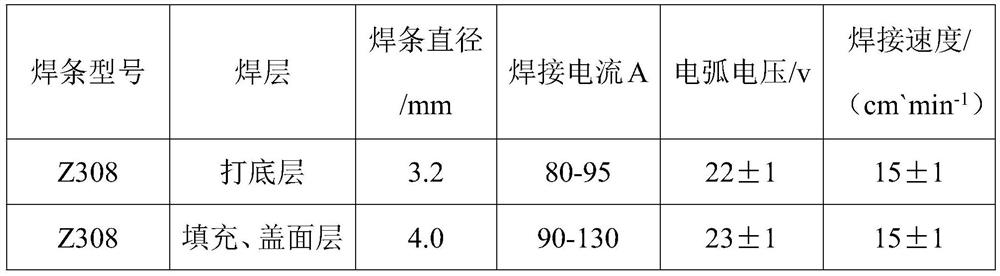

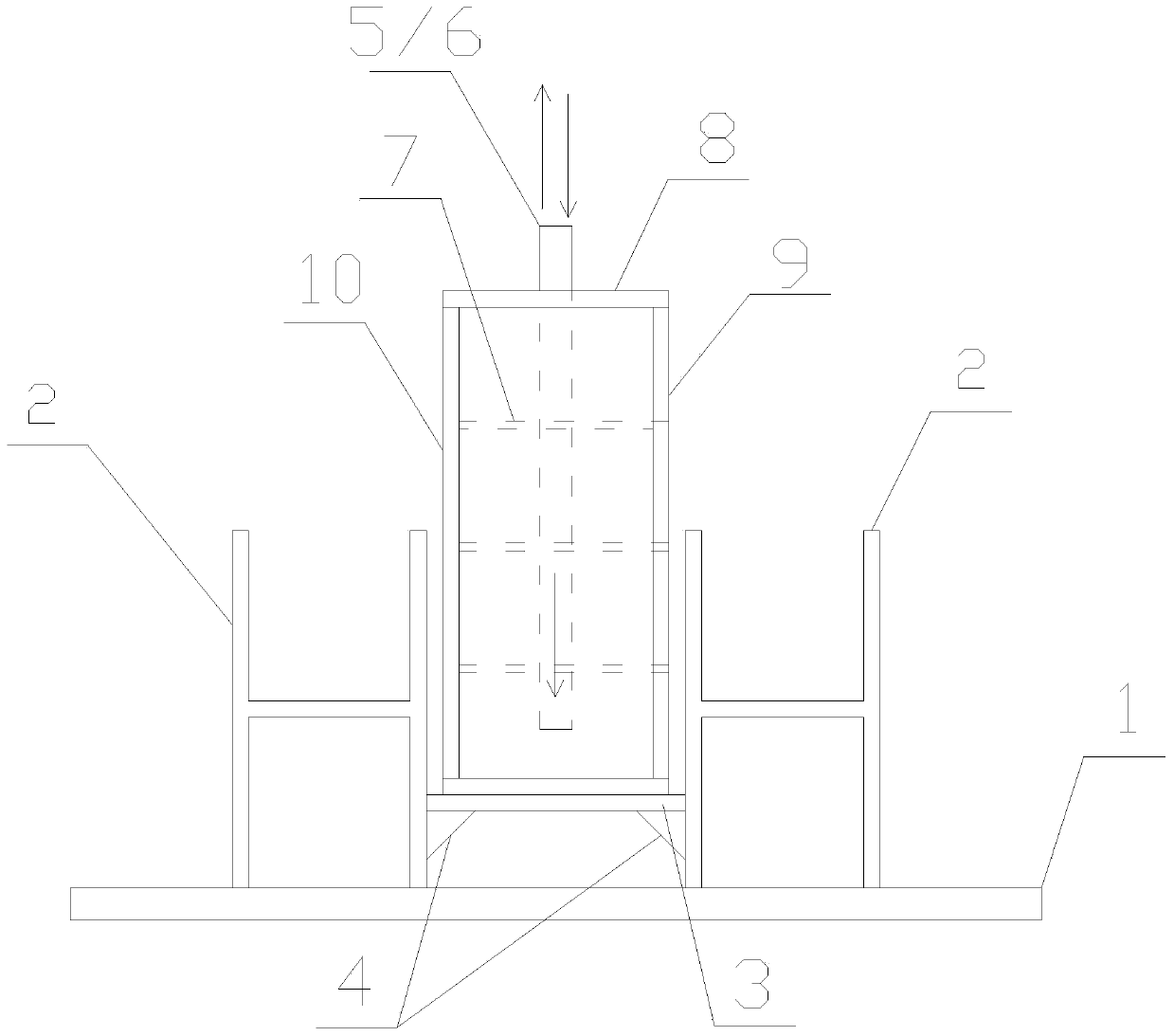

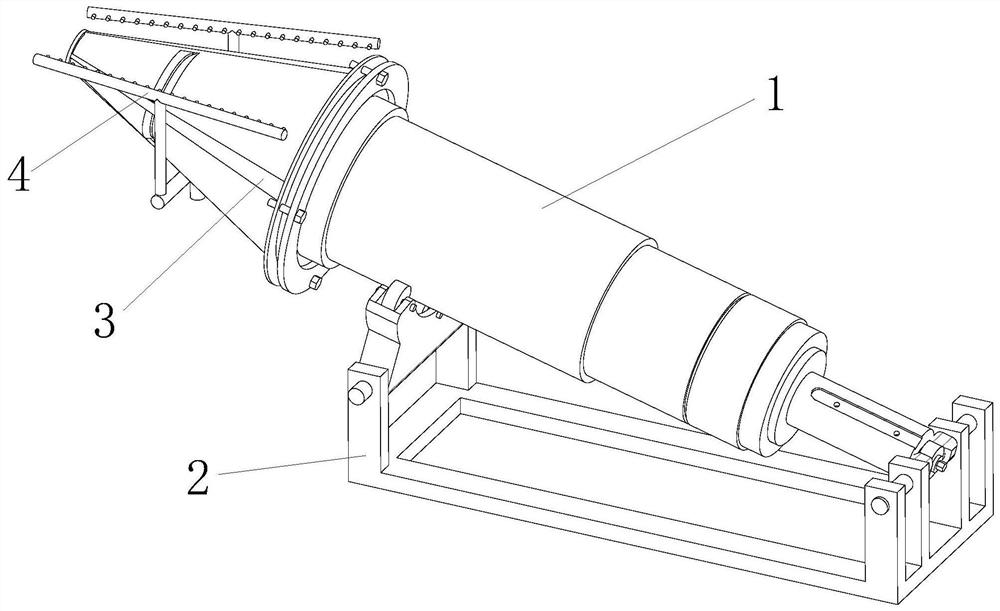

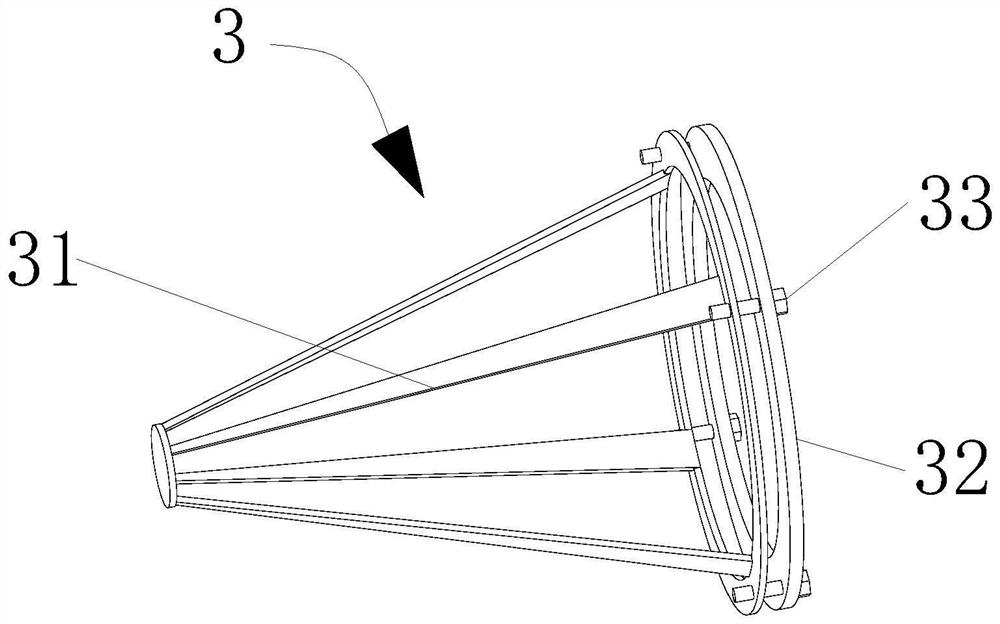

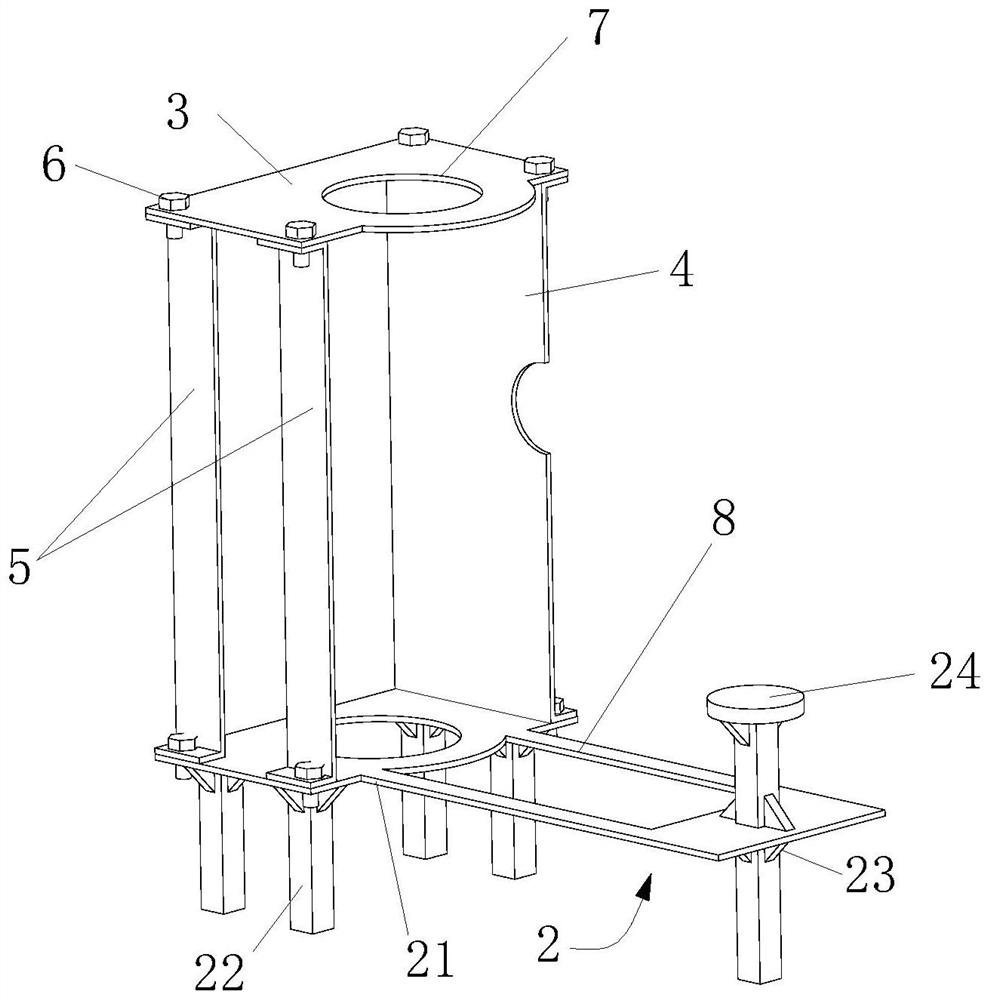

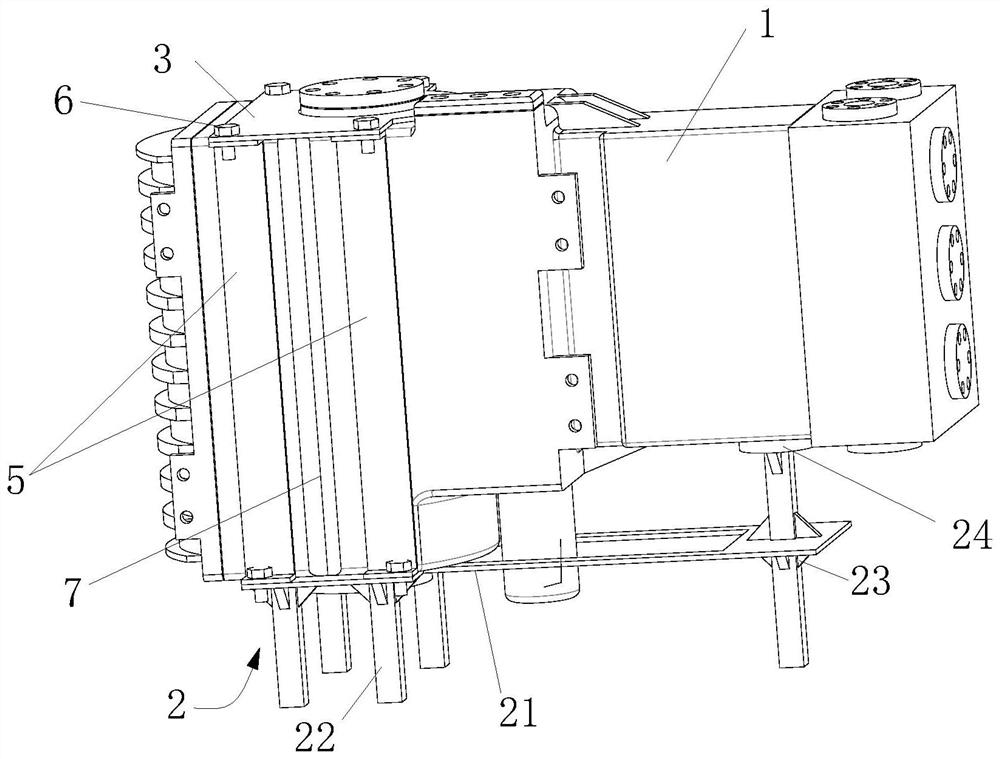

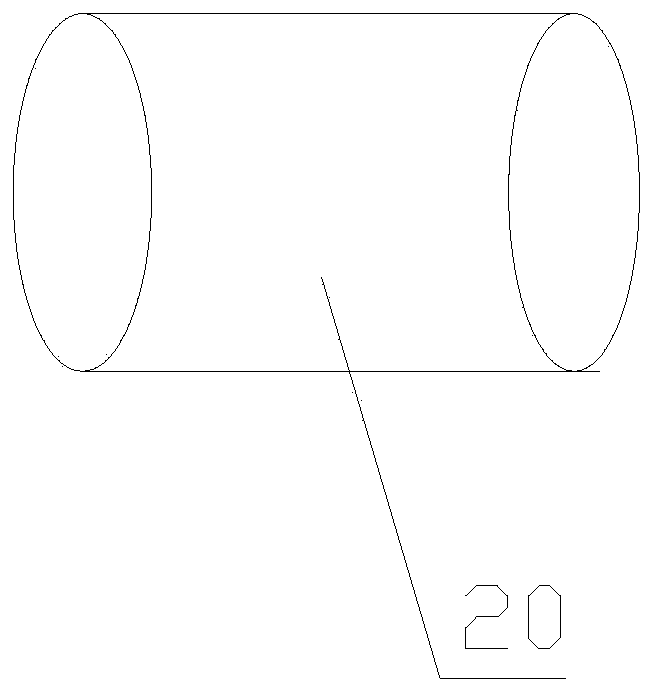

Welding device for fracture of large inclined roll shaft of ring rolling mill and repairing process of welding device

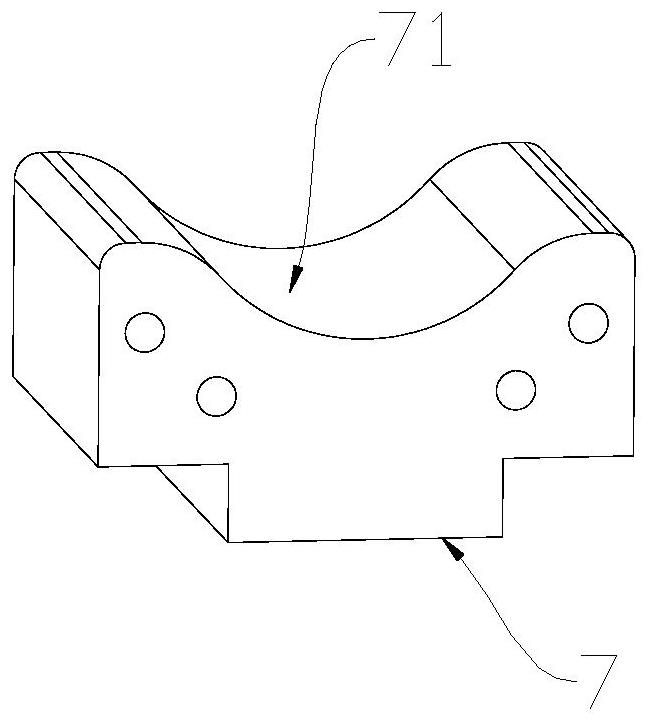

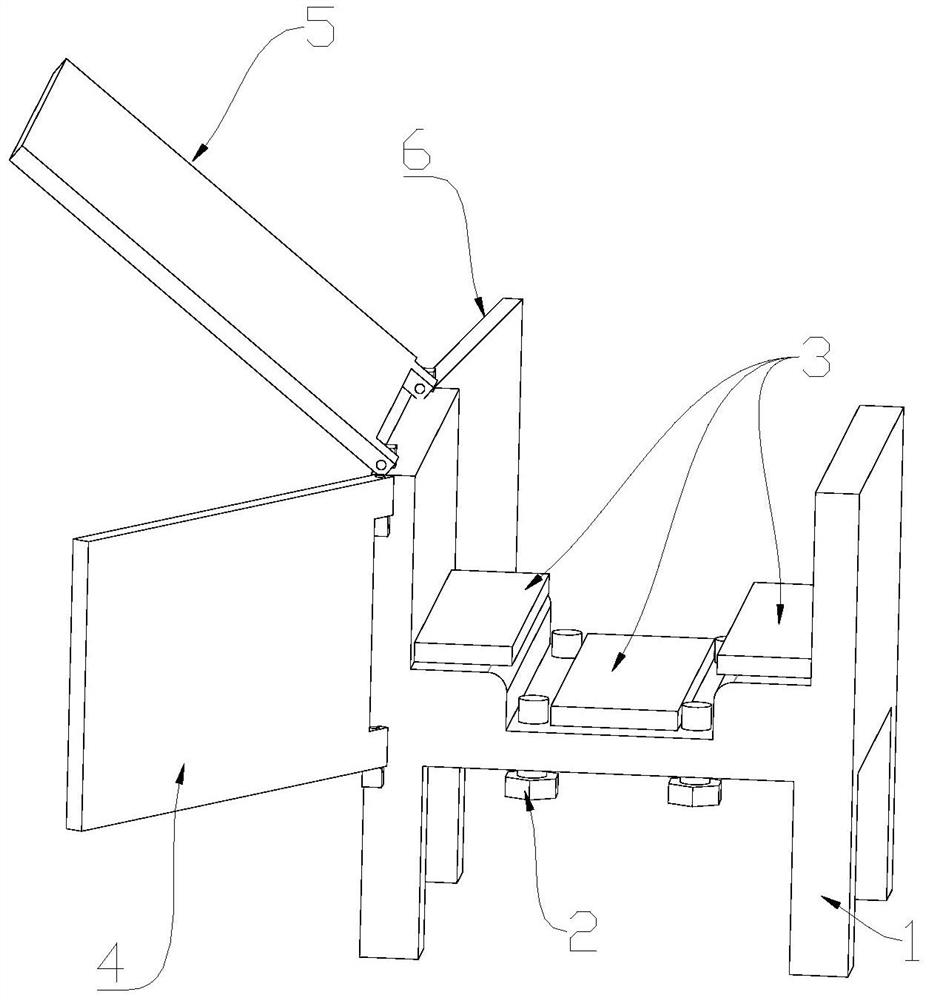

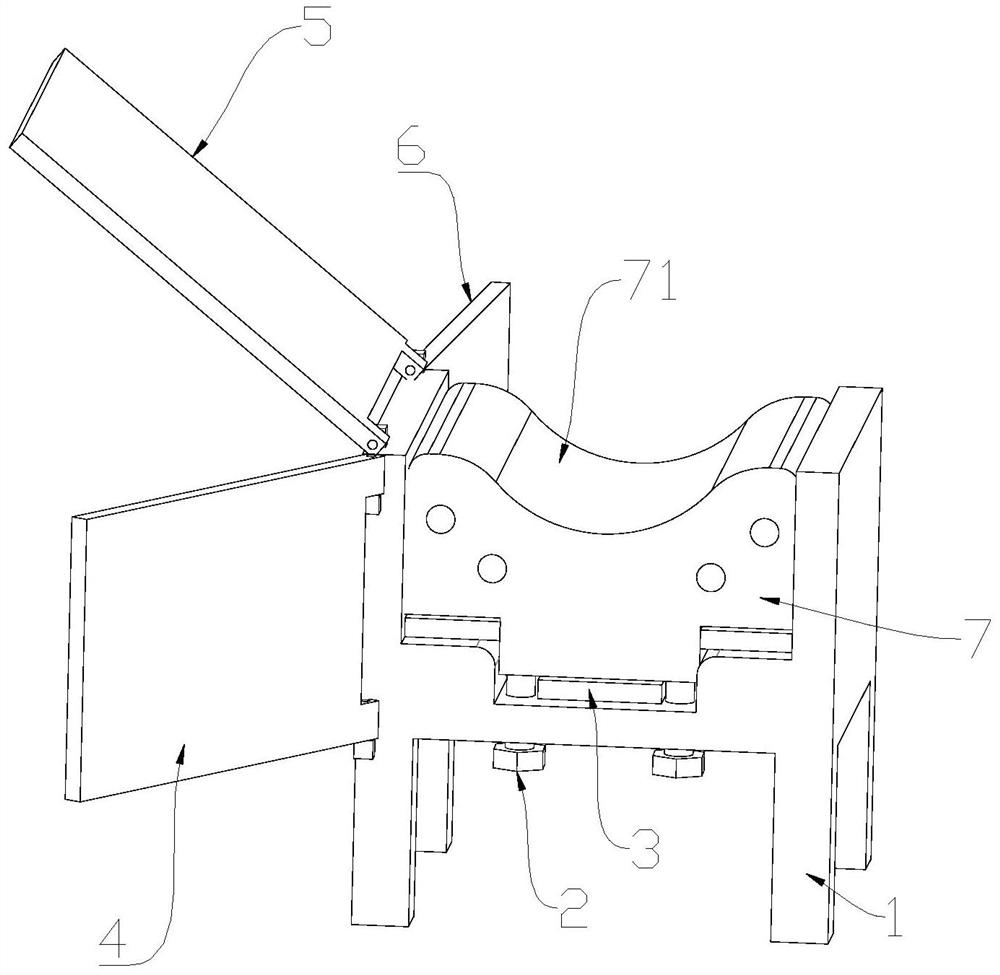

ActiveCN112935686ANovel structureCompact configurationWelding/cutting auxillary devicesAuxillary welding devicesFailure rateStructural engineering

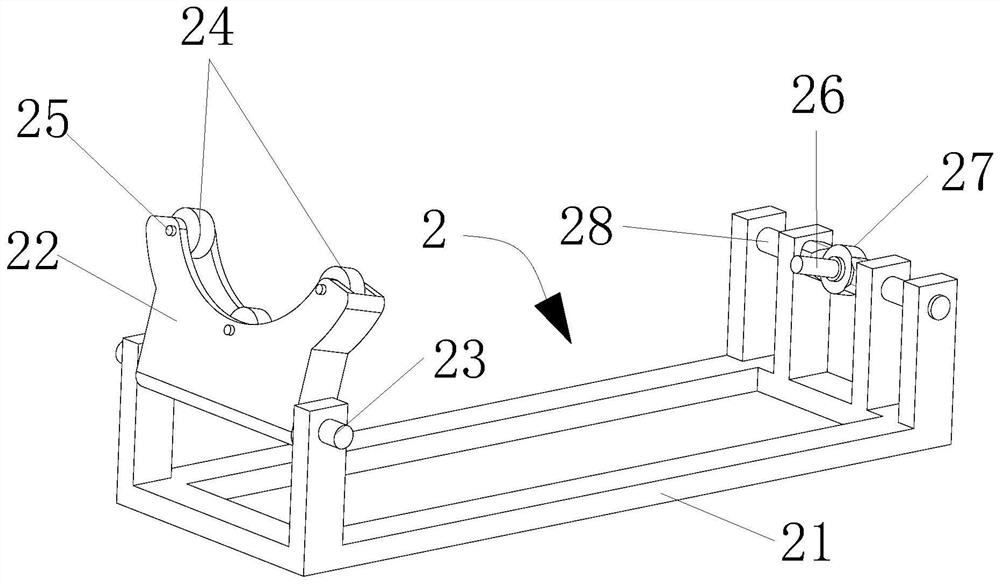

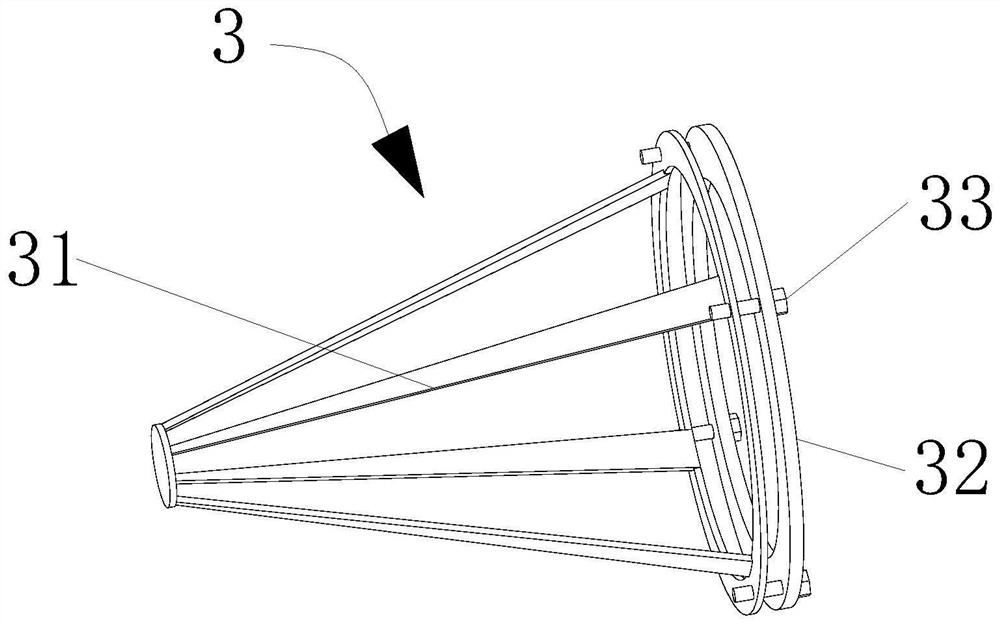

The invention discloses a welding device for fracture of a large inclined roll shaft of a ring rolling mill. The welding device comprises a structural part fixing support, a structural part assembling and fixing tool and a heating tool, wherein the structural part fixing support is used for obliquely placing the inclined roll shaft and enabling the inclined roll shaft to freely rotate on the structural part fixing support; the structural part assembling and fixing tool is used for assembling and fixing the fractured part of the inclined roll shaft and controlling the deformation amount in the welding process; and the heating tool is used for heating the fractured part of the inclined roll shaft. A welding repairing process based on the welding device for the fracture of the large inclined roll shaft of the ring rolling mill is further disclosed. Through the implementation of the device and the process, a large amount of maintenance time can be shortened, the maintenance cost is reduced, the failure rate and shutdown loss are reduced, and a guarantee is provided for reasonable grouping production.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

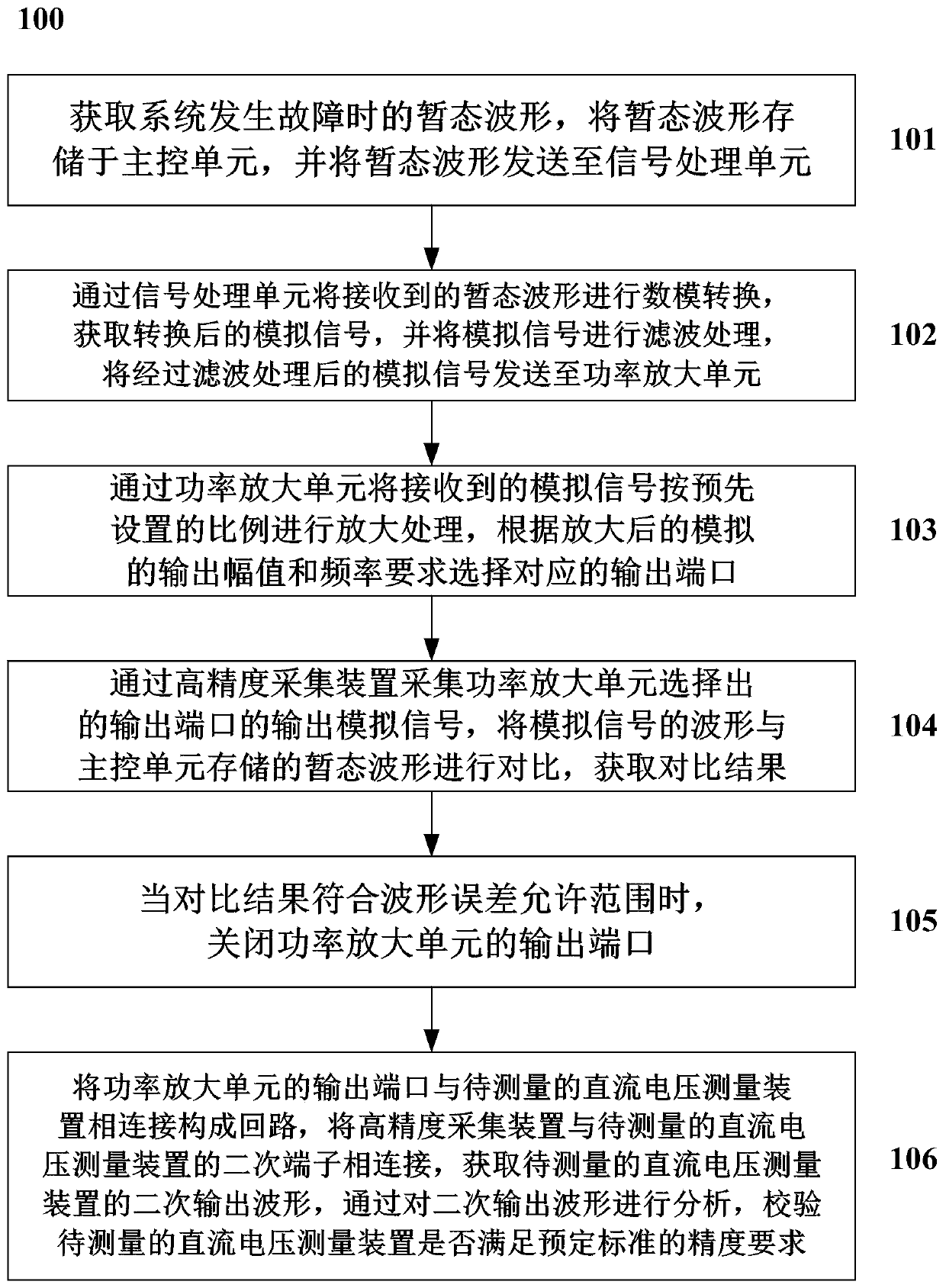

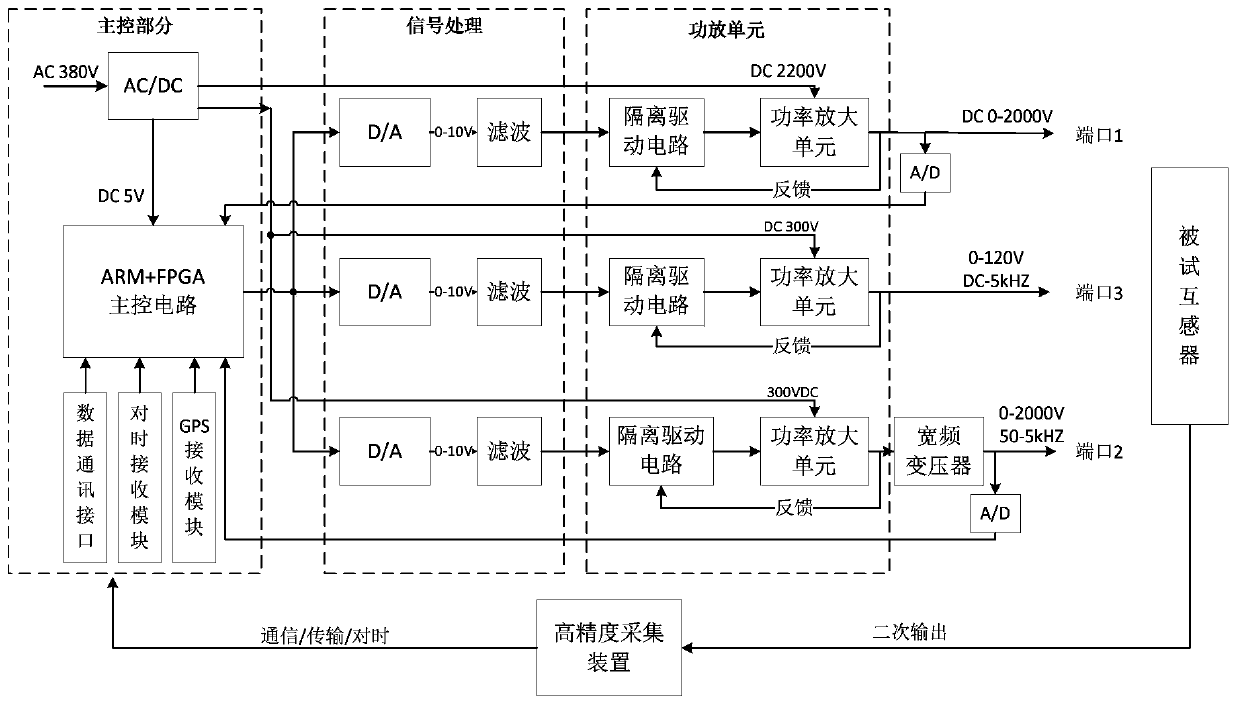

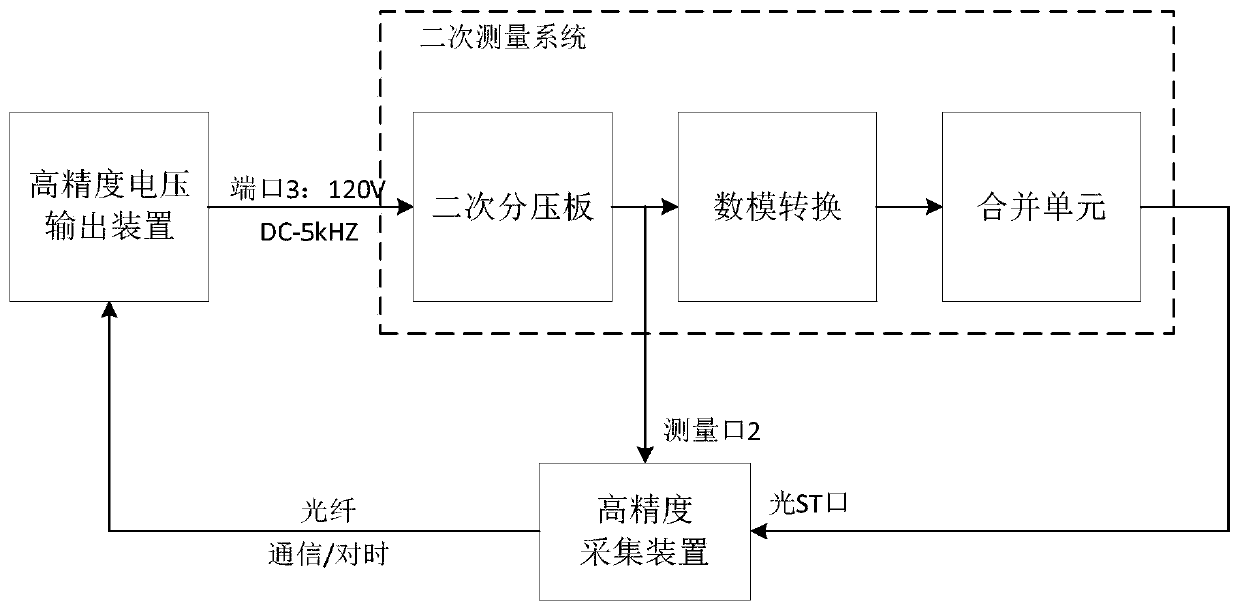

Method and system for carrying out field calibration on transient characteristics of direct-current voltage measuring device

InactiveCN111208466AInput flexibleMeet the actual needs of the siteElectrical measurementsTransient stateCurrent voltage

The invention discloses a method and a system for carrying out field calibration on the transient characteristics of a direct-current voltage measuring device. The method comprises the following steps: acquiring a transient waveform when a system has a fault, storing the transient waveform in a main control unit, performing digital-to-analog conversion on the transient waveform through a signal processing unit, and sending an analog signal subjected to filtering processing to a power amplification unit; amplifying the analog signal through the power amplification unit, and selecting a corresponding output port; collecting an output analog signal of the power amplification unit through a high-precision collection device, comparing the waveform of the analog signal with a transient waveformstored in the main control unit, and closing an output port of the power amplification unit when a comparison result conforms to a waveform error allowable range; and connecting an output port of thepower amplification unit to a direct-current voltage measuring device to be measured to form a loop, and connecting the high-precision acquisition device to a secondary terminal of the direct-currentvoltage measuring device to obtain a secondary output waveform of the direct-current voltage measuring device to be measured.

Owner:CHINA ELECTRIC POWER RES INST +2

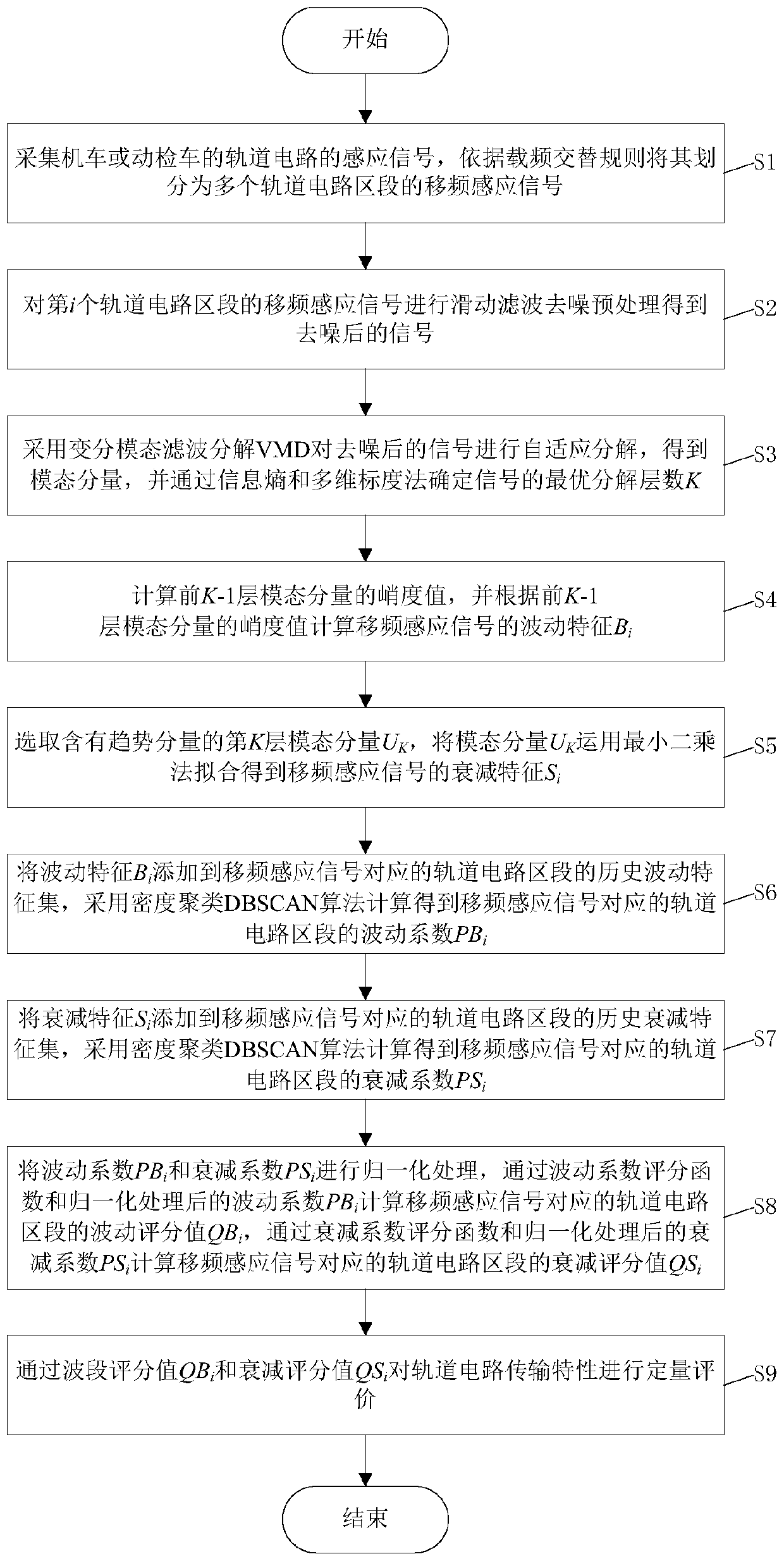

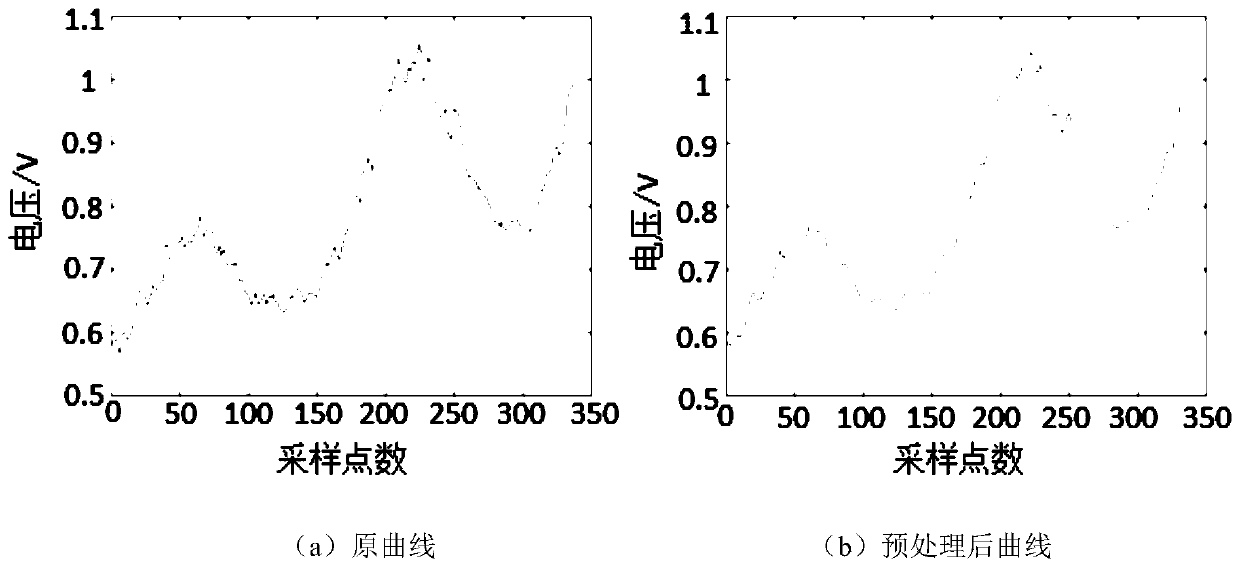

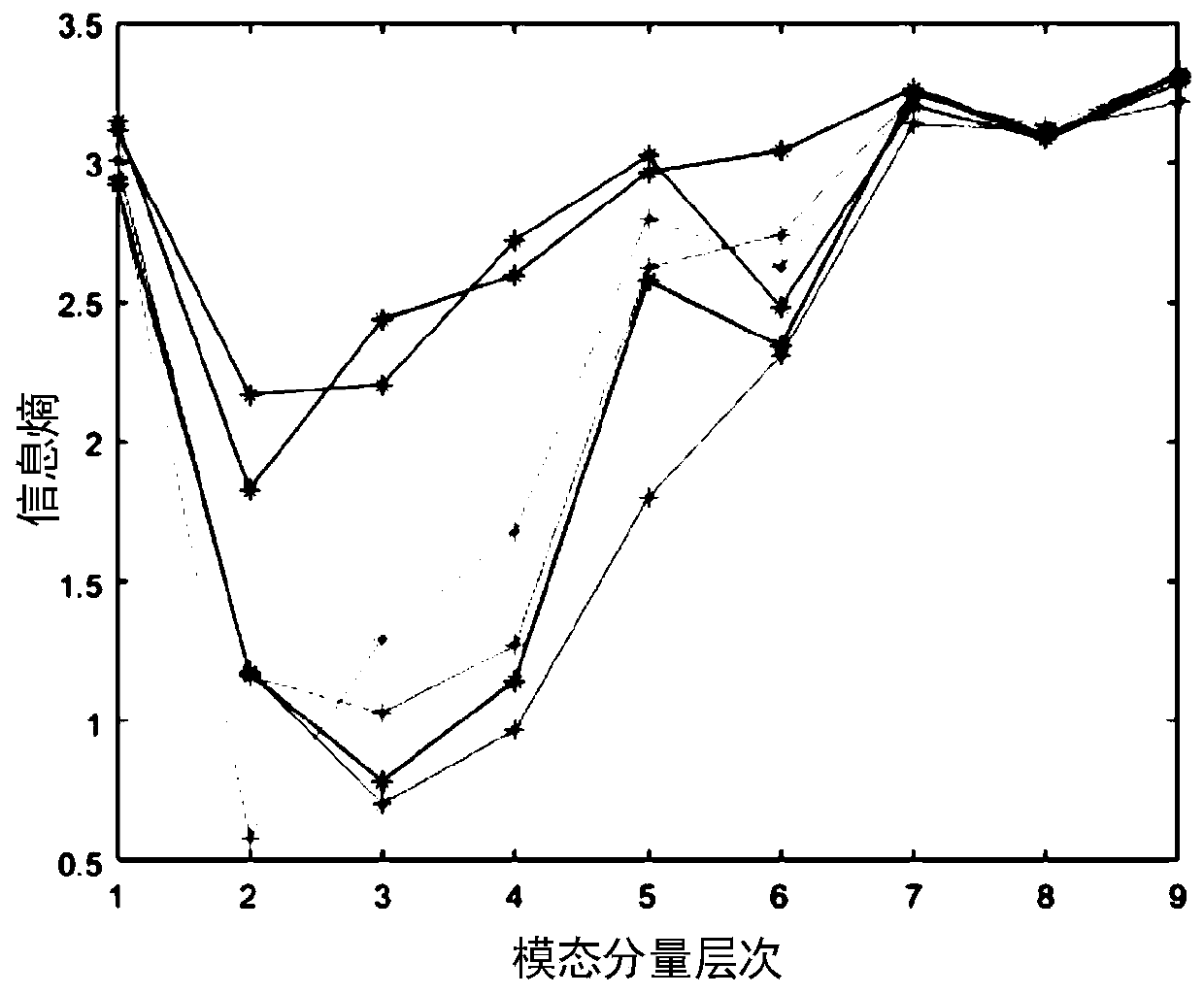

Track circuit transmission characteristic quantitative evaluation method based on variational mode decomposition

ActiveCN110533115AMeet the needs of transmission characteristic performance evaluationImprove applicabilityCharacter and pattern recognitionFault location by conductor typesVariational mode decompositionEngineering

The invention discloses a track circuit transmission characteristic quantitative evaluation method based on variational mode decomposition. According to the method, locomotive signals or track circuitinduction signals of a dynamic inspection vehicle are collected, transmission characteristics of a track circuit are obtained by using processing methods such as variational mode decomposition and the like, and then the transmission characteristics of the track circuit of each track section of the line are scored by an adaptive scoring function, so that visual quantitative evaluation of the transmission characteristics of the track circuit is completed. The method is good in applicability, and can meet the requirements for evaluating the transmission characteristic performance of the track circuit at present.

Owner:SOUTHWEST JIAOTONG UNIV

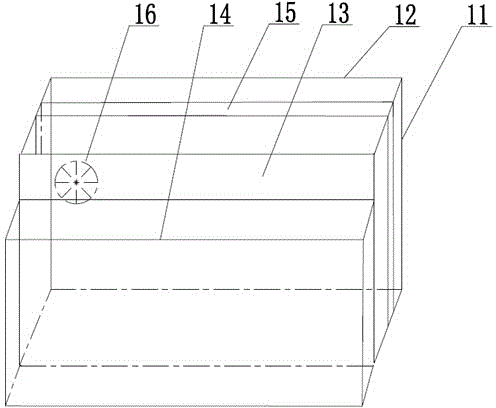

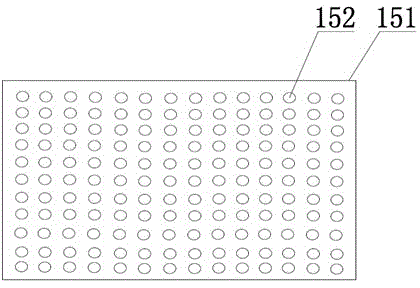

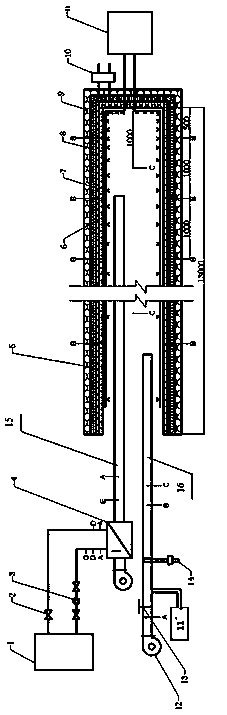

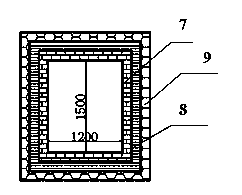

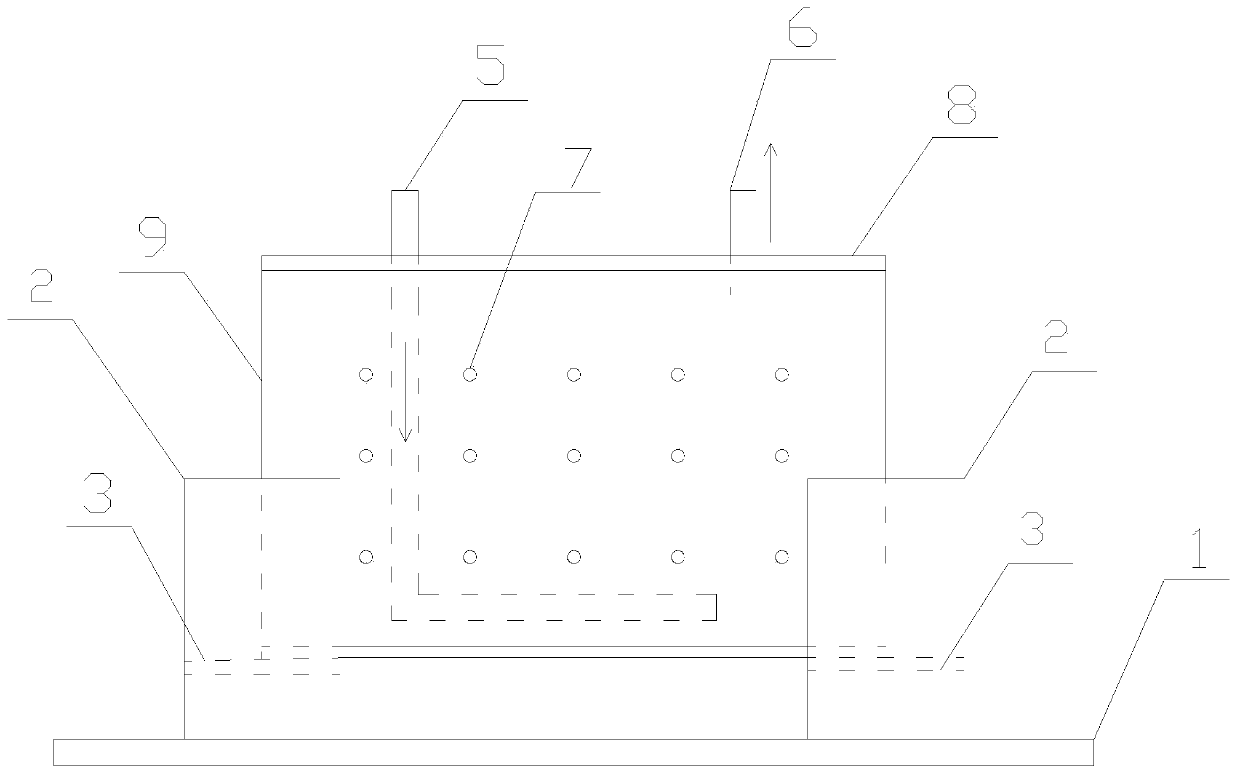

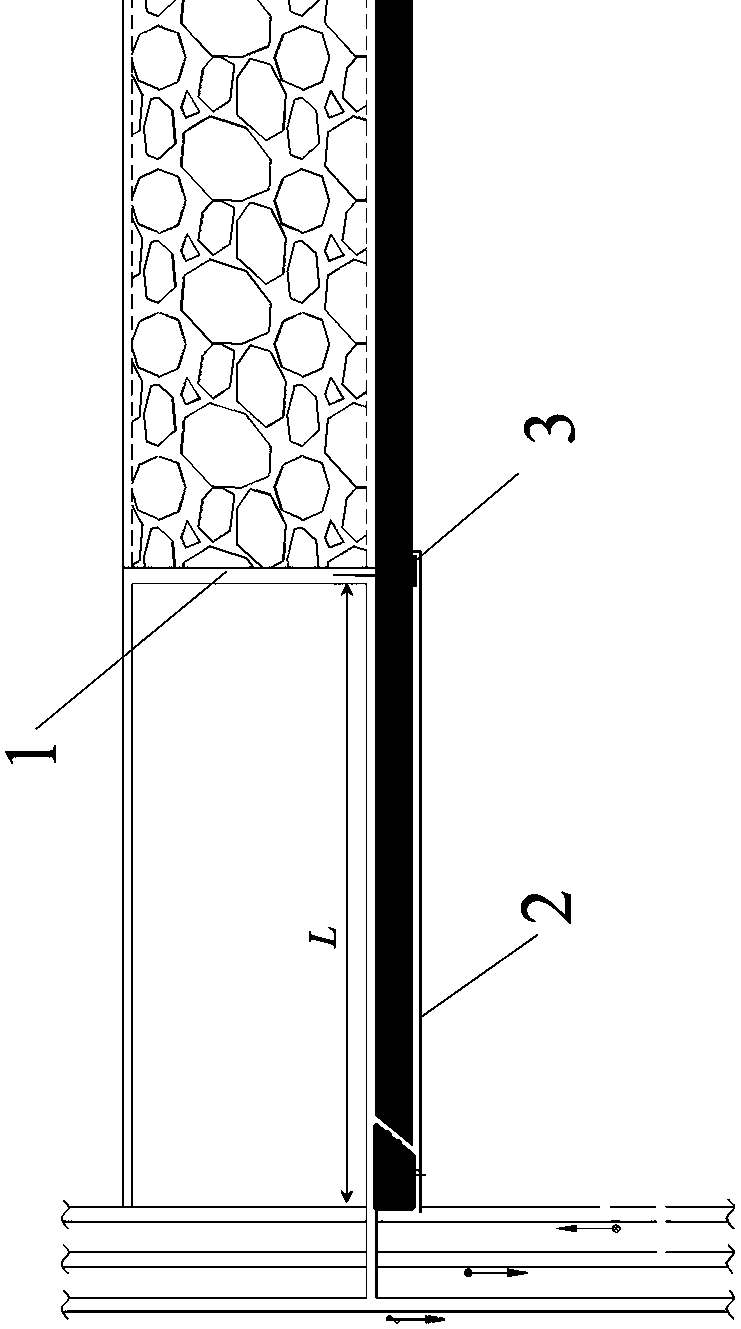

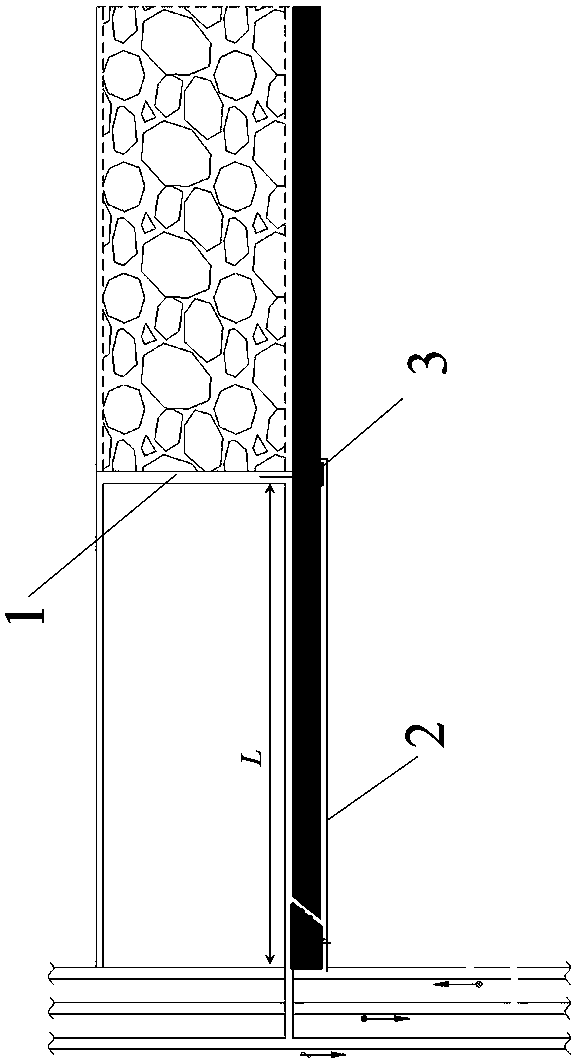

Heat and humidity exchange simulation testing system for non-coal solid mine deep mining excavation tunnel

The invention discloses a heat and humidity exchange simulation testing system for a non-coal solid mine deep mining excavation tunnel. A simulated tunnel is a rectangular grotto obtained through being scaled down according to a field practical blind excavation tunnel, the upper side, the lower side, the left side, the right side and one end of the rectangular grotto are sealed, a tunnel heat source simulation device consists of an electric heating film (5) and a heating control device (10), an in-tunnel humidity environment simulation device is formed by connecting a humidifier pipe (6) with a humidifier (11), an in-tunnel fresh air quality simulation device is formed by sequentially connecting a fan (12), a humidifier (11'), an electric heater (14) and a fresh air pipe (16), and a tunnel temperature reduction refrigeration simulation device consists of a refrigeration machine set (1), an air cooler (4) and a cold air pipe (15). The heat and humidity exchange simulation testing system has the advantages that the field real heat and humidity exchange environment is provided for researching heat and humidity exchange of air in the blind tunnel, the field simulation verification in a laboratory is realized on theoretical calculation results, and good practical significance popularization and application values are realized for solving the heat damage problem of the existing deep well mining.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

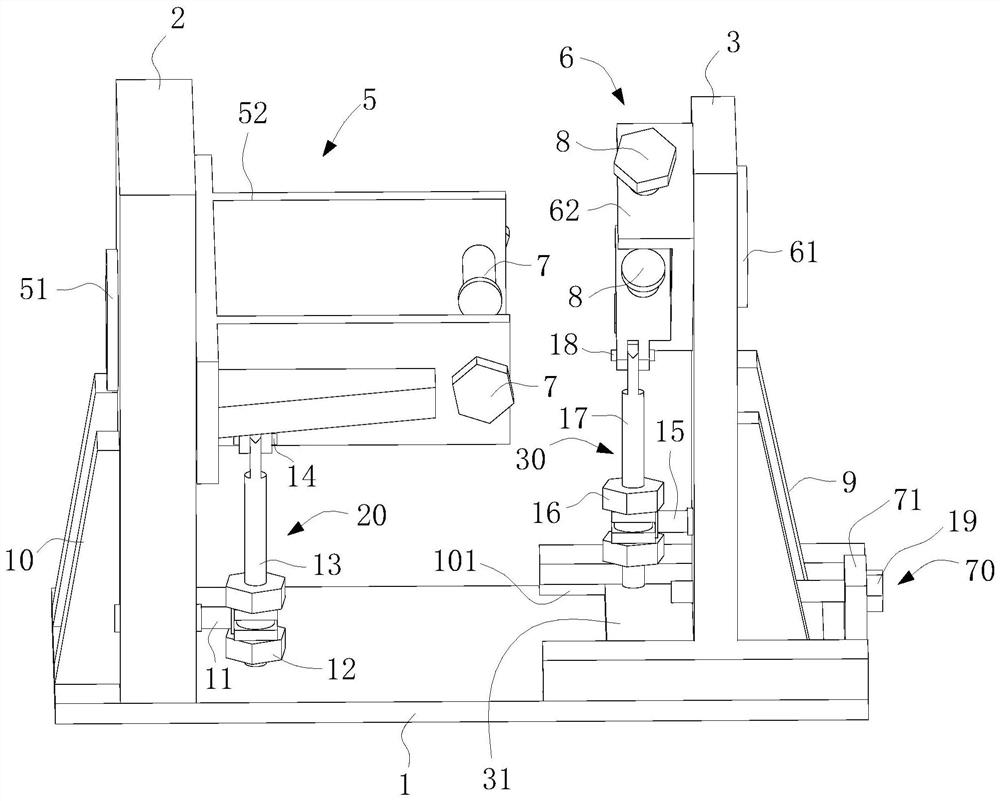

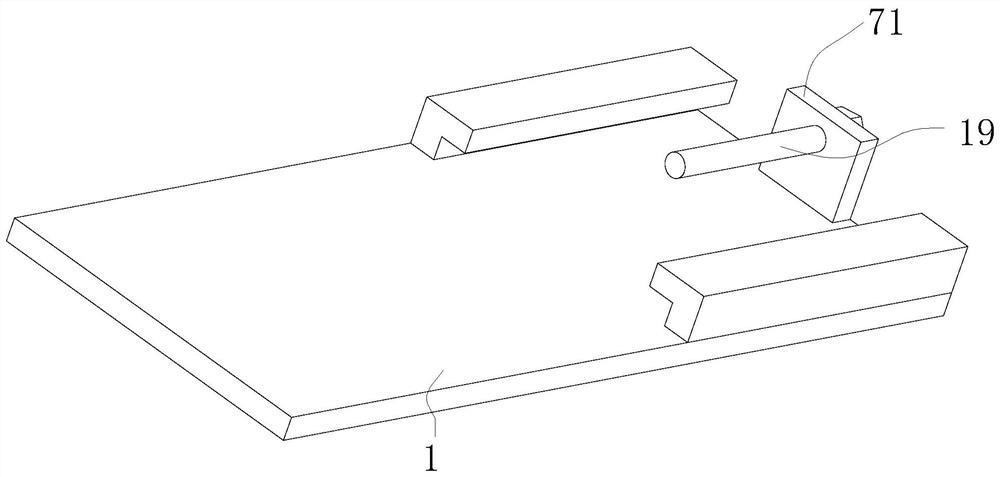

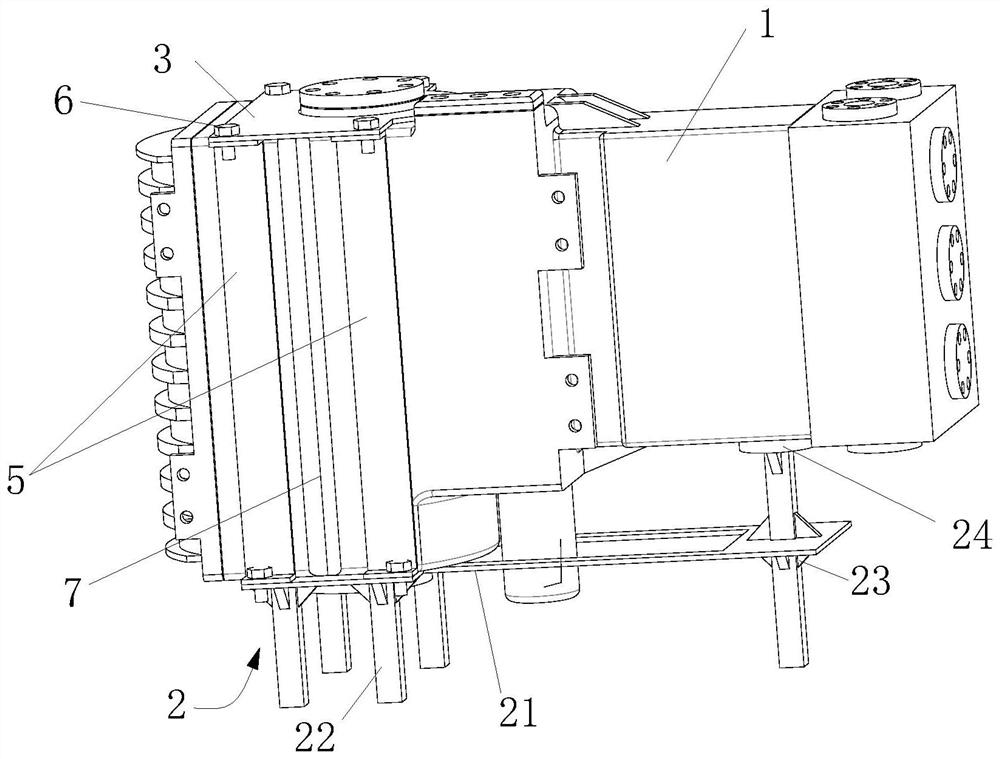

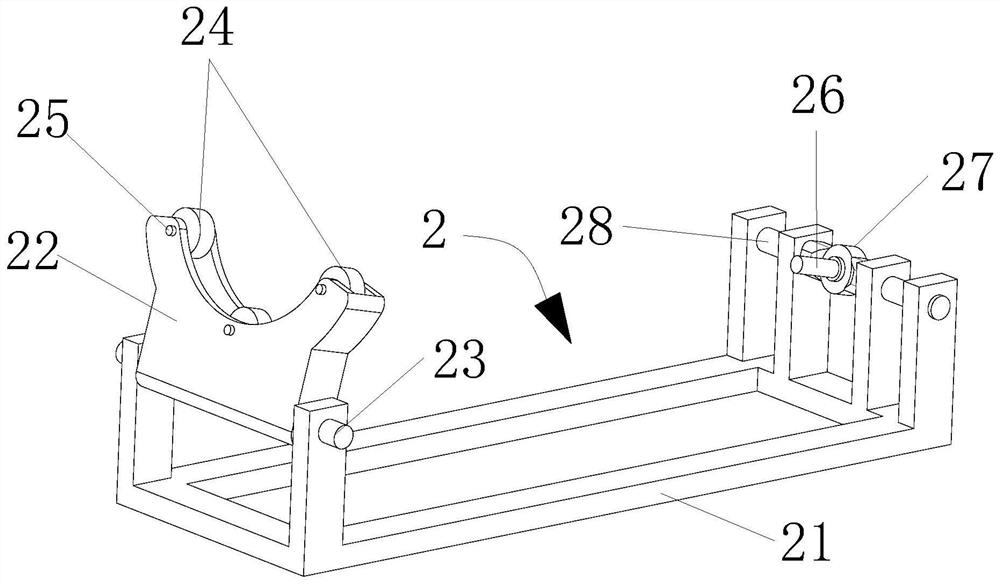

Welding device and repair process for fracture of large crankshaft of high-pressure pump body

PendingCN113210801ANovel and reasonable designSimple structureWelding/cutting auxillary devicesArc welding apparatusEngineeringMechanical engineering

The invention discloses a welding device for the fracture of a large crankshaft of a high-pressure pump body. The welding device comprises a structural part tool bottom plate. A left support is fixedly arranged on one side of the structural part tool bottom plate, a right support is slidably arranged on the other side of the structural part tool bottom plate, and a right support adjusting device is arranged between the right support and the structural part tool bottom plate. A left clamping fixing frame and a right clamping fixing frame are rotatably arranged on the left support and the right support respectively. A left fixing frame adjusting device is movably arranged between the left clamping fixing frame and the left support, and a right fixing frame adjusting device is movably arranged between the right clamping fixing frame and the right support. The invention further discloses a repair process for the fracture of the large crankshaft of the high-pressure pump body. By means of the welding device, welding repair of the fracture of the large crankshaft of the high-pressure pump body can be rapidly implemented, the purchase cost is reduced, the long-time procedure shutdown loss is reduced, and a guarantee is provided for reasonable production organization.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

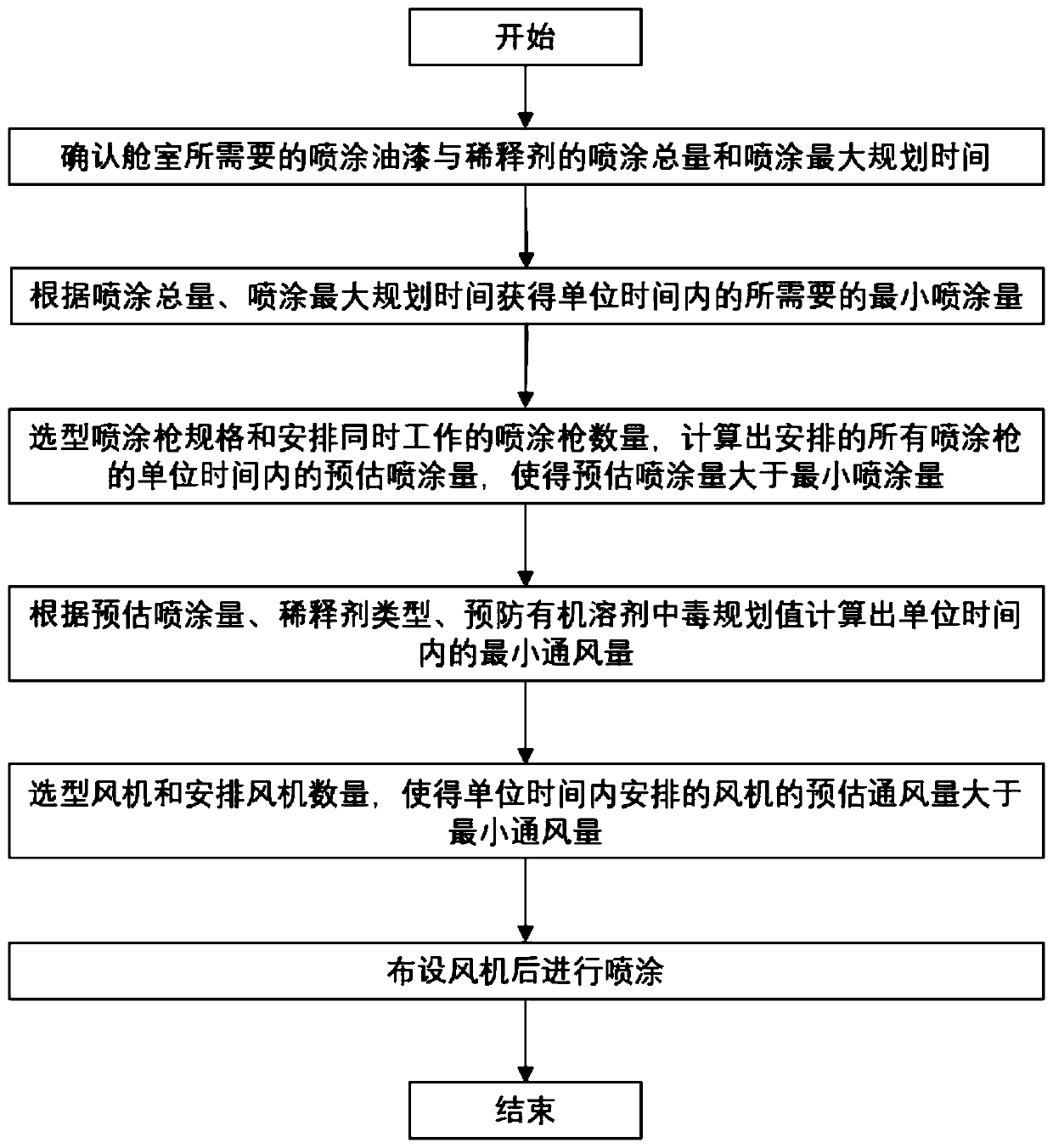

Ship cabin coating method

PendingCN111036511AMeet the actual needs of the siteLiquid surface applicatorsCoatingsOrganic solventMarine engineering

The invention discloses a ship cabin coating method. The method includes the steps that the total spraying amount and maximum spraying planning time of spraying oil paint and diluent needed by a cabinare confirmed; the minimum spraying amount required in unit time is acquired according to the total spraying amount and the maximum spraying planning time; the specifications of spray guns are selected, the number of the spray guns which operate at the same time is set, and the prediction spraying amount of all the set spray guns in unit time is calculated, so that the prediction spraying amountis larger than the minimum spraying amount; the minimum ventilation rate in unit time is worked out according to the prediction spraying amount, diluent type and organic solvent poisoning prevention planning value; the draught fan type is selected, the number of draught fans is set, and the prediction ventilation rate of the set draught fans in unit time is made to be larger than the minimum ventilation rate; and spraying is conducted after the draught fans are arranged. The ship cabin coating method has the beneficial effect that a ventilation rate calculation method which is more suitable for the field actual needs is formulated before spraying in accordance with the actual spraying portions, spraying paint and actual spray gun number.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

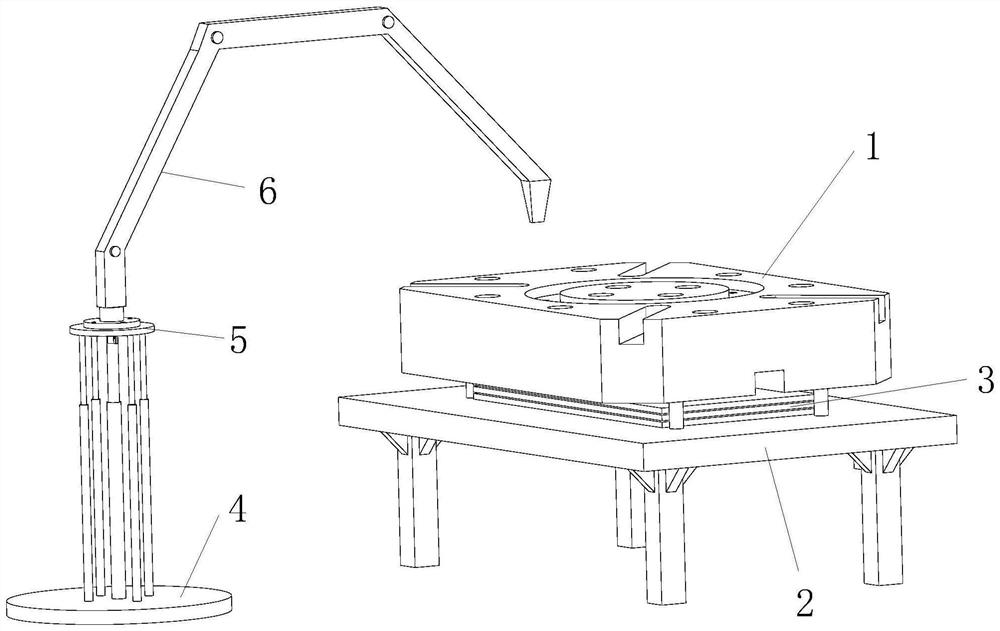

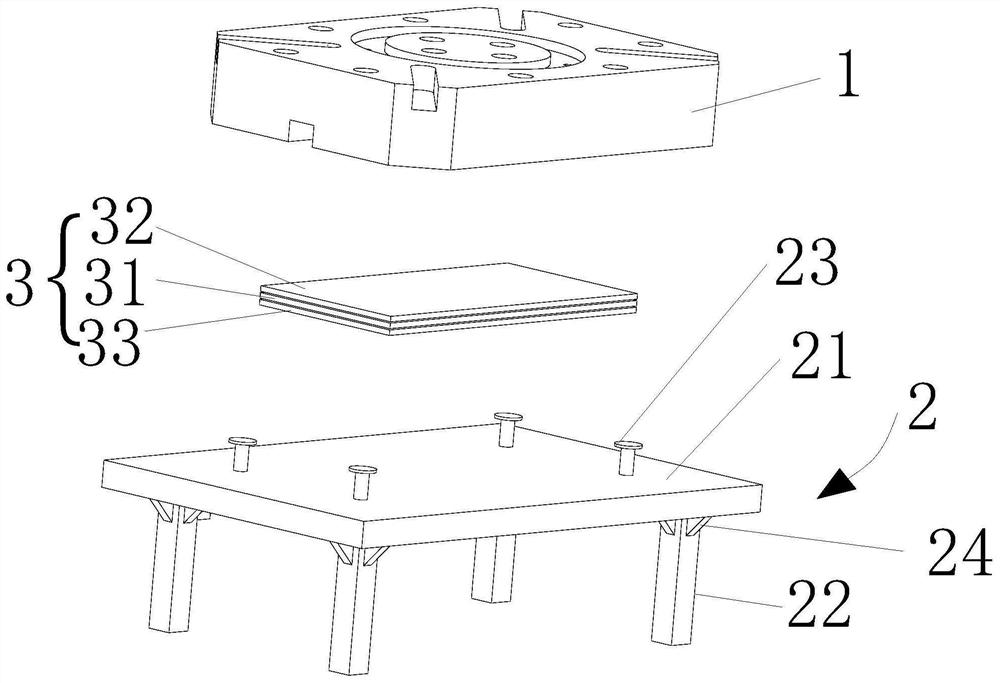

Repairing device for surface abrasion of large wheel fixing table base and repairing process

ActiveCN112935480AUniform rise in preheat temperatureImprove welding qualityArc welding apparatusRobot handStructural engineering

The invention discloses a repairing device for surface abrasion of a large wheel fixing table base. The repairing device comprises a welding robot, a structural part supporting platform, a heating device arranged on the structural part supporting platform, a mechanical arm base and a mechanical arm lifting adjusting device; the mechanical arm lifting adjusting device is movably arranged on the mechanical arm base and can lift for adjustment on the mechanical arm base; and a base of the welding robot is arranged on the mechanical arm lifting adjusting device. A repairing process based on the repairing device for the surface abrasion of the large wheel fixing table base is further disclosed. The repairing process is implemented, through welding verification, welding repair of the abrasion of the large wheel fixing table base can be rapidly implemented, the purchase cost is reduced, the long-time procedure shutdown loss is reduced, and a guarantee is provided for reasonably grouping and producing various domestic and overseas wheels.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

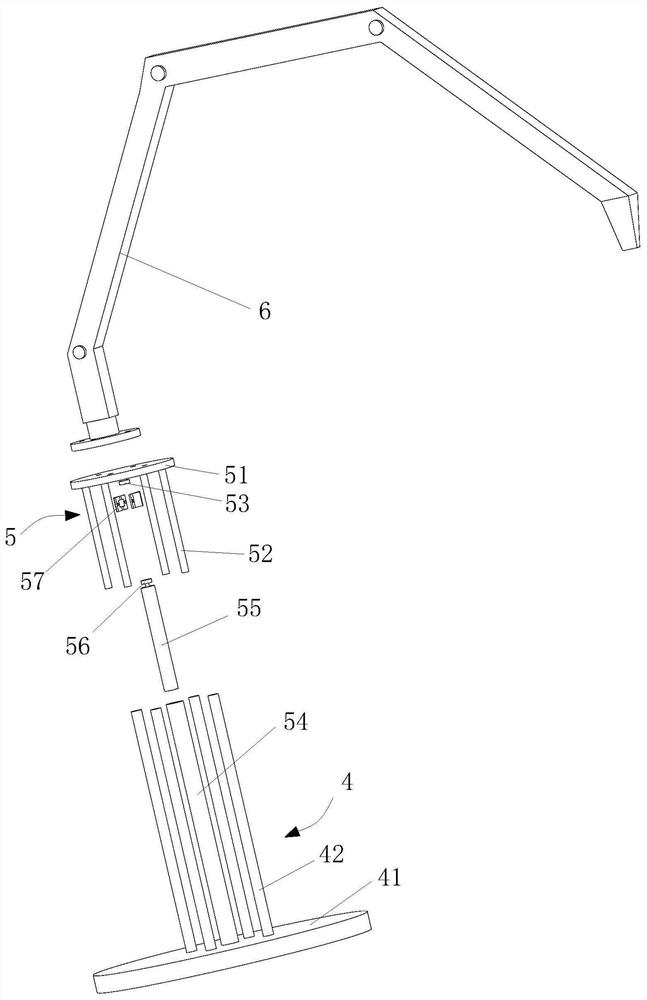

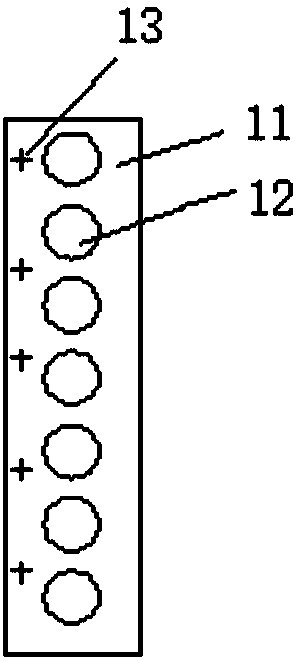

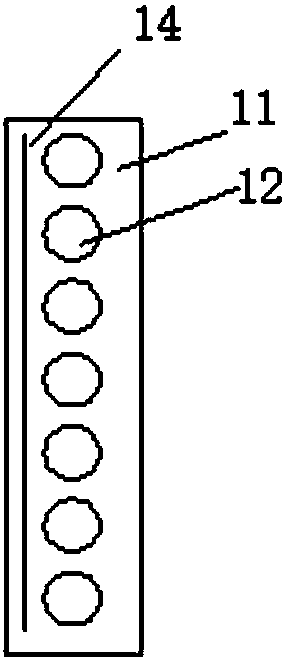

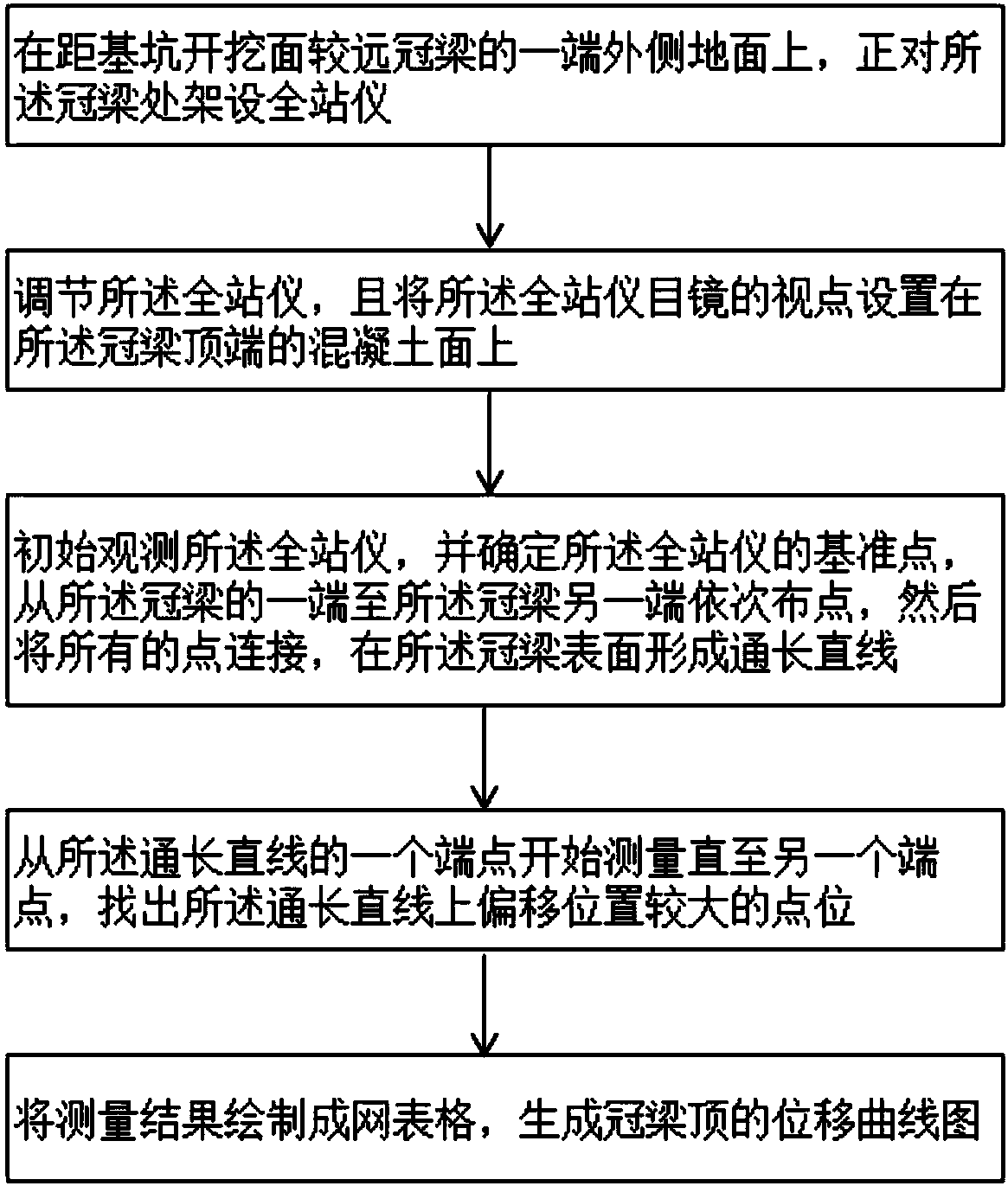

Top part horizontal displacement monitoring method for foundation pit support device

ActiveCN108362247AReduce bias due to operational factorsFlexible increase or decrease of monitoring pointsSurveying instrumentsEyepieceEngineering

The invention relates to a top part horizontal displacement monitoring method for a foundation pit support device. A total station is erected on the ground on the outer side of an end of a crown beamcomparatively far away from a pit excavation face and exactly facing the crown beam. The total station is adjusted and a sight point of an eyepiece of the total station is set on a concrete face on the top end of the crown beam. Initial observation is performed on the total station and reference points of the total station are determined; points are set in sequence from one end to the other end ofthe crown beam and are then connected together so as to form a long straight line on the surface of the crown beam. Measurement is started from one end point of the long straight line to the other end point of the long straight line and a point at the long straight line having comparatively large displacement is found. A measurement result is drawn in to a grid form and a displacement curve graphof the top of the crown beam is generated. The invention can reflect the horizontal displacement level of the crown beam directly. The method is simple and is time saving and labor saving.

Owner:CHINA MCC20 GRP CORP

Welding device for crack of water tank of wheel dephosphorization electric reciprocating pump body and repairing process

ActiveCN112935472AImprove welding qualityLow investment costArc welding apparatusStructural engineeringMechanical engineering

The invention discloses a welding device for a crack of a water tank of a wheel dephosphorization electric reciprocating pump body. The welding device comprises a base, a back face connecting and fixing steel plate detachably arranged on the rear side of the upper surface of the base, two groove face fixing pull plates detachably arranged on the front side of the upper surface of the base at intervals, and an upper pressing plate detachably and fixedly connected with the back face connecting and fixing steel plate and the two groove face fixing pull plates. A repairing process of the welding device for the crack of the water tank of the wheel dephosphorization electric reciprocating pump body is further provided. The repairing process of the welding device for the crack of the water tank of the wheel dephosphorization electric reciprocating pump body is provided for solving the problems existing in the background technology. By applying the device and the process, welding repairing of the crack of the water tank of the electric reciprocating cast iron pump body can be rapidly implemented and completed, the purchase and maintenance cost is reduced, the long-time shutdown loss is reduced, and a guarantee is provided for reasonable grouping steel to produce various domestic and overseas wheels.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

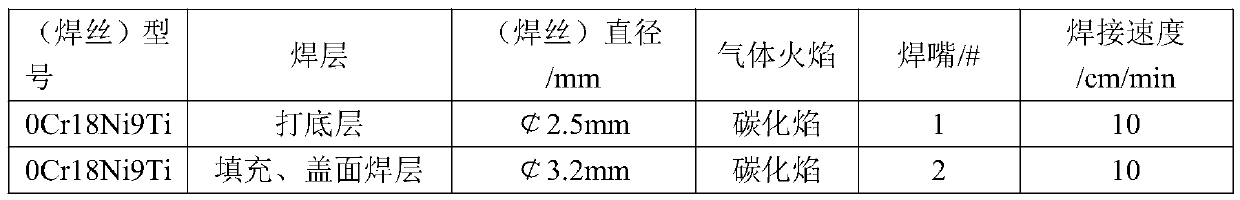

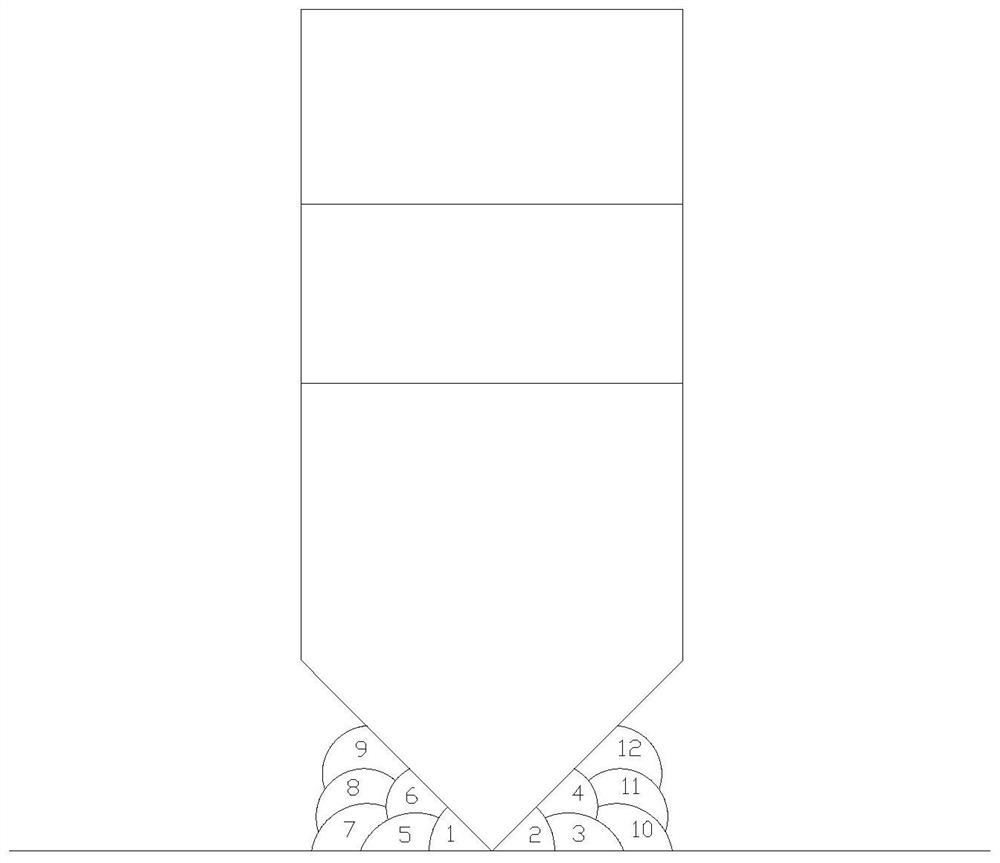

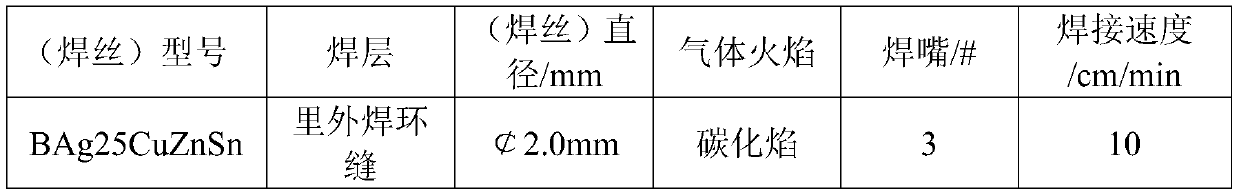

Large-scale heat-resistant steel heating furnace door manual gas welding repair device and repair process

PendingCN111360363AReduce downtime lossImprove welding qualityMeasurement of fluid loss/gain rateGas flame welding apparatusIngotHeating furnace

The invention discloses a large-scale heat-resistant steel heating furnace door manual gas welding repair device. A furnace door is of a cuboid hollow structure and comprises a furnace door front panel and a furnace door rear panel. A plurality of fixed rods are uniformly arranged inside the furnace door front panel and the furnace door rear panel. The large-scale heat-resistant steel heating furnace door manual gas welding repair device further comprises a rectangular fixed bottom steel plate, a pressure test water inlet pipe and a pressure test water outlet pipe. A plurality of sets of vertical H-steel supporting frames are arranged on the fixed bottom steel plate in bilateral symmetry. A transverse H-steel supporting frame with the height less than the vertical H-steel supporting framesis arranged between each set of the vertical H-steel supporting frames. The pressure test water inlet pipe and the pressure test water outlet pipe are arranged on the two sides of the interior of thefurnace door correspondingly. The pipe heads of one ends of the pressure test water inlet pipe and the pressure test water outlet pipe face upwards. The large-scale heat-resistant steel heating furnace door manual gas welding repair device is safe and easy to operate, stable in welding quality, low in investment cost and high in working efficiency, meets the actual demands on site, greatly reduces the maintenance cost, reduces shutdown loss during the process of heating an annular furnace and provides a guarantee for reasonable assembly production of various specifications of wheels and ringparts and heating steel ingots.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

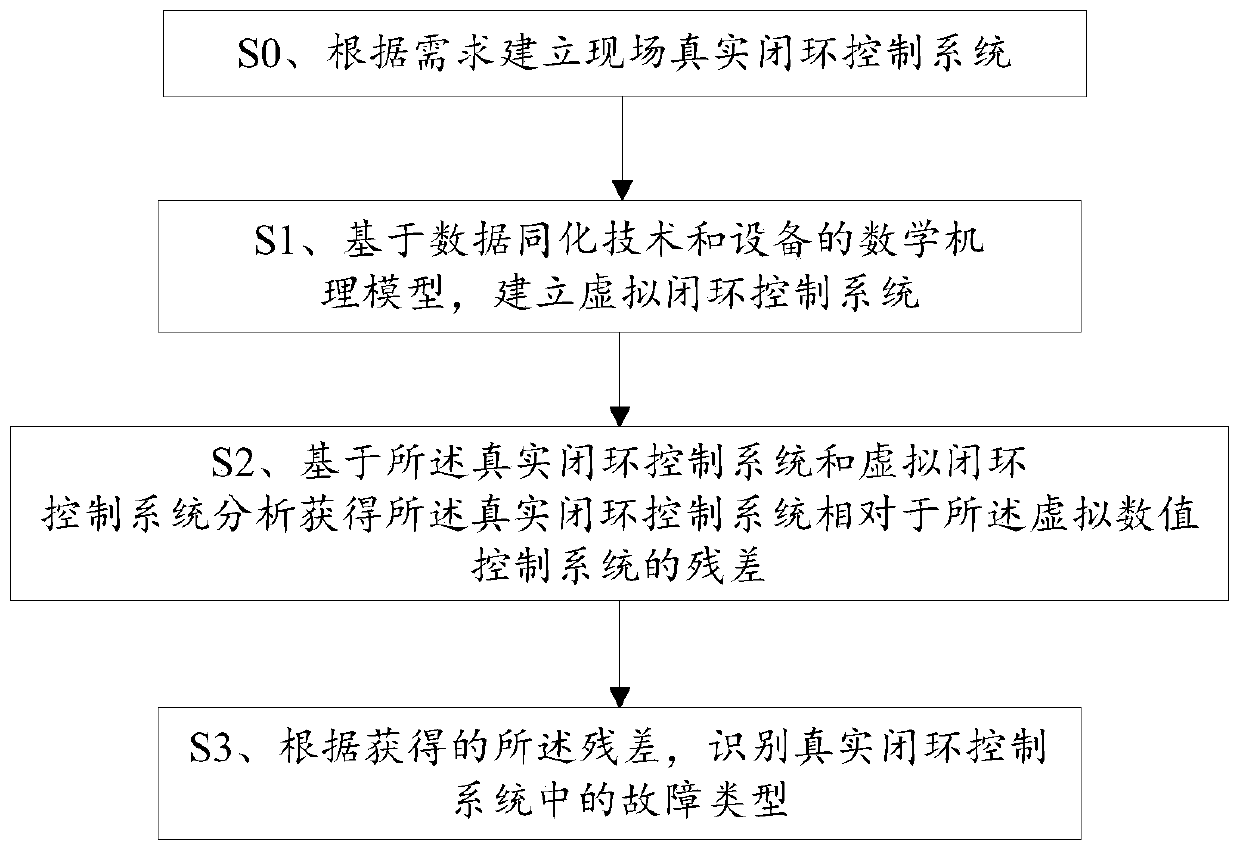

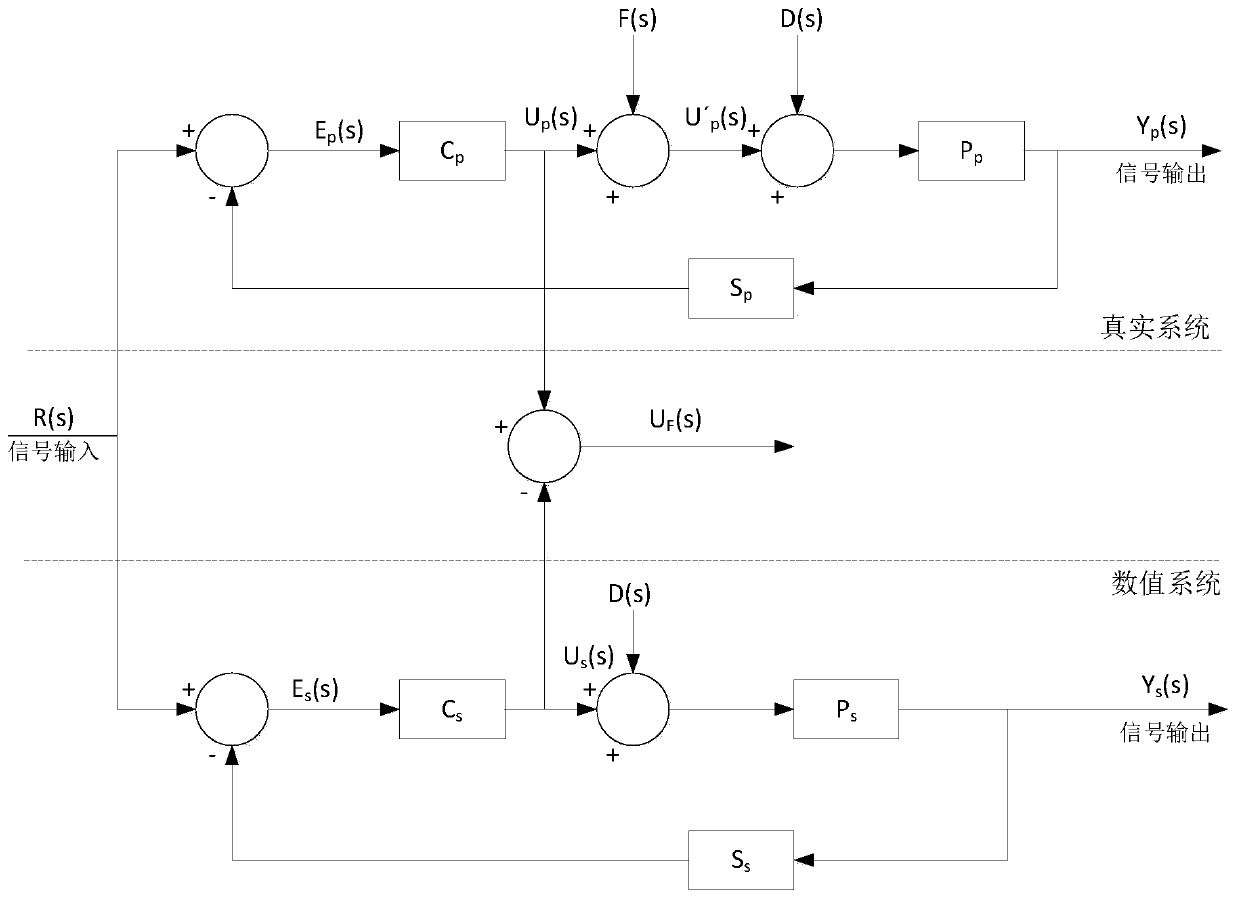

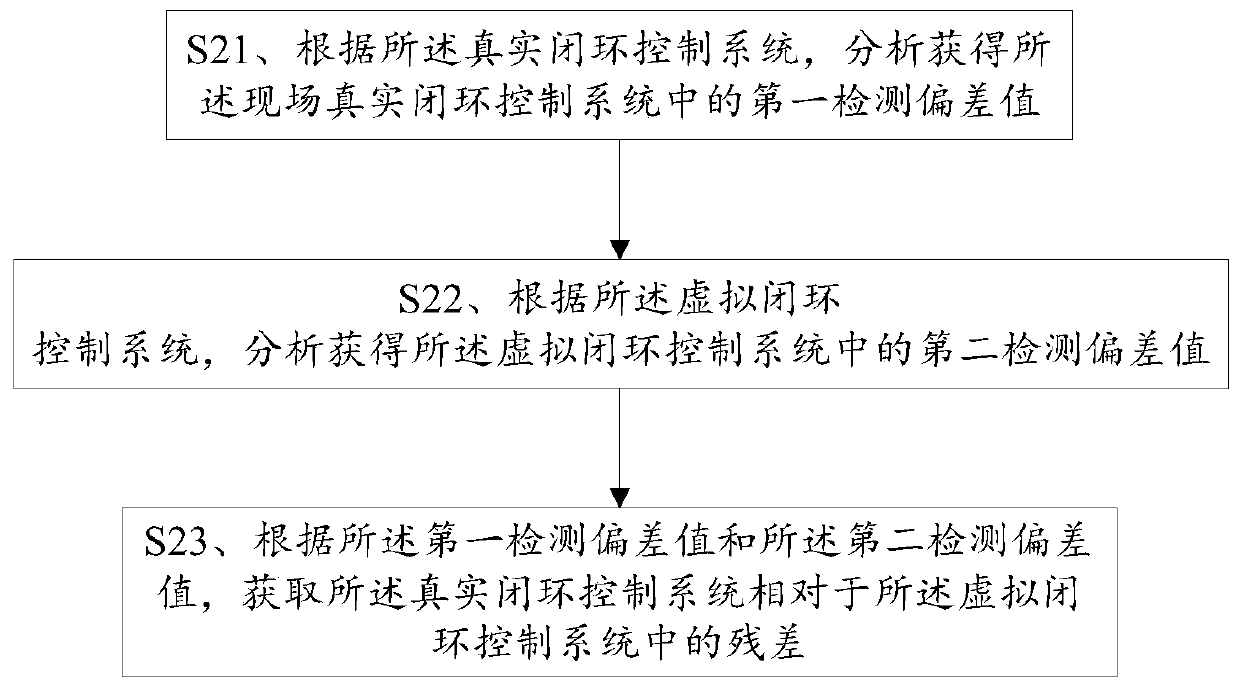

Closed-loop control system early failure detection and diagnosis method and closed-loop control system early failure detection and diagnosis system

ActiveCN110045716AImprove efficiencyAccelerateProgramme controlElectric testing/monitoringFailure typeData assimilation

The invention discloses a closed-loop control system early failure detection and diagnosis method, and the method comprises the following steps: S0, building an on-site real closed-loop control systemaccording to actual needs; S1, based on a data assimilation technology and a mathematical mechanism model of equipment, building a virtual closed-loop control system; S2, based on the real closed-loop control system and the virtual closed-loop control system, analyzing to obtain residual error of the real closed-loop control system relative to the virtual closed-loop control system; S3, accordingto the obtained residual error, identifying failure type in the real closed-loop control system. With the method and the system provided by the invention, technical problems of low accuracy of smallfailure diagnosis and difficulty in diagnosis in the prior art are solved, and the small failure in the closed-loop control system can be identified quickly and accurately.

Owner:中广核工程有限公司 +2

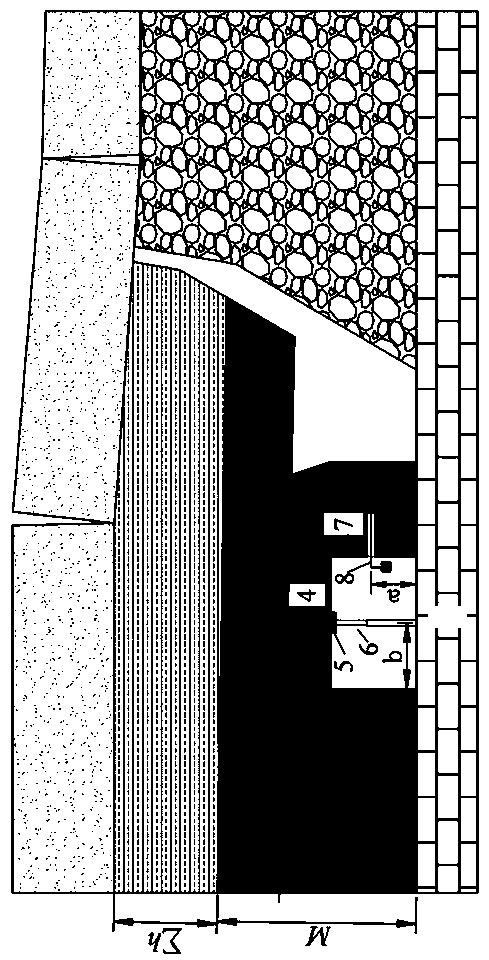

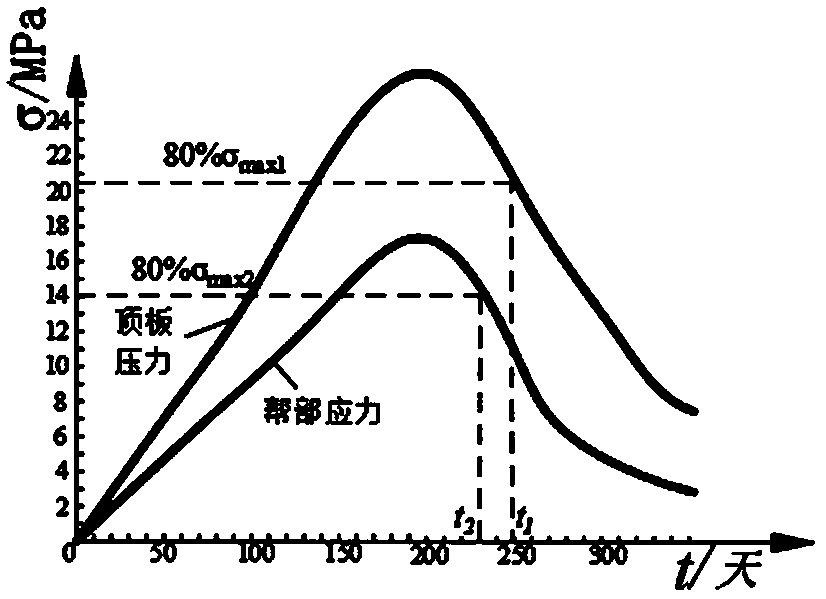

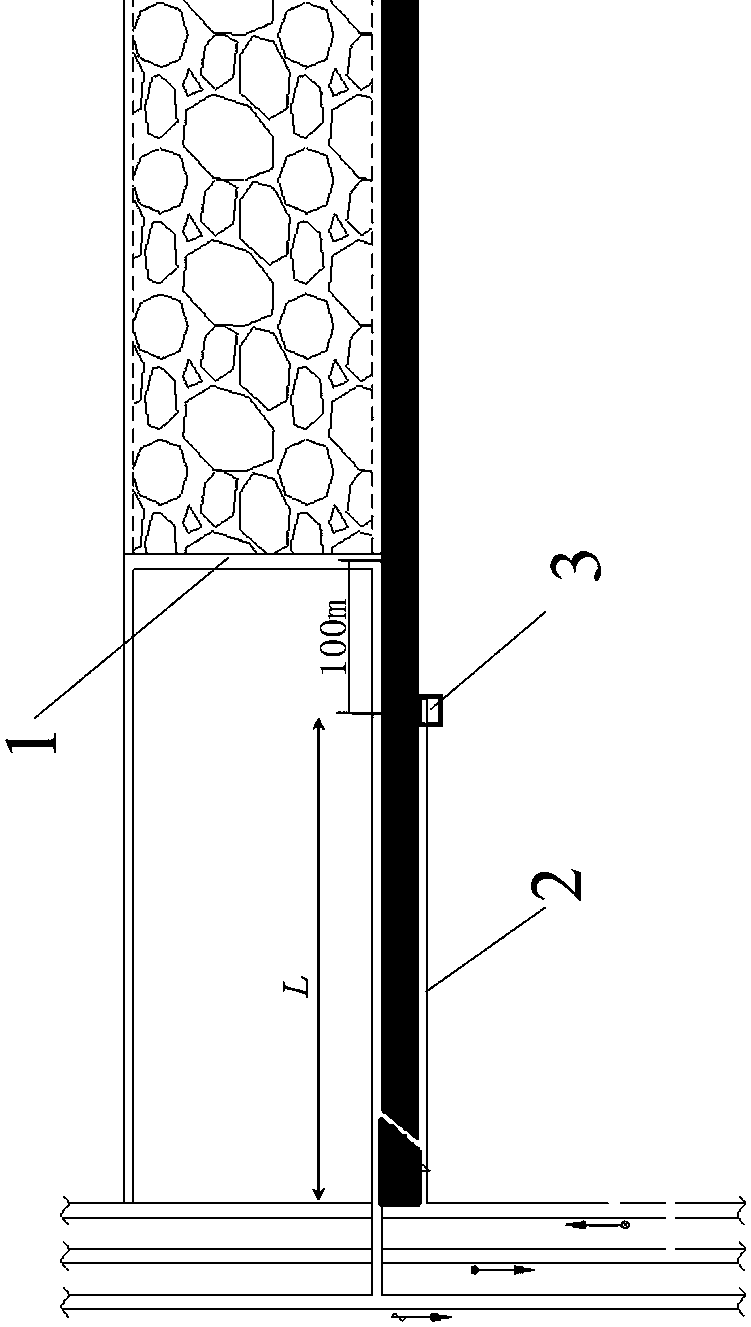

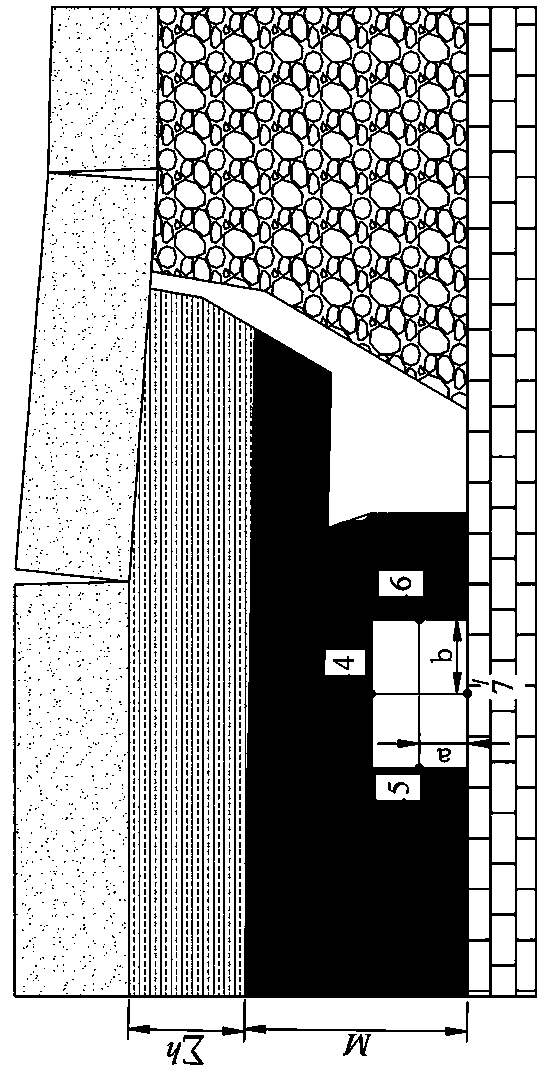

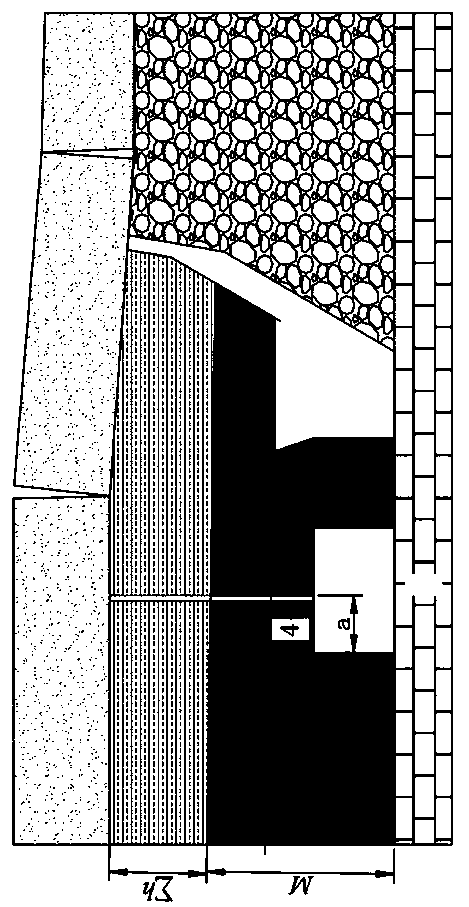

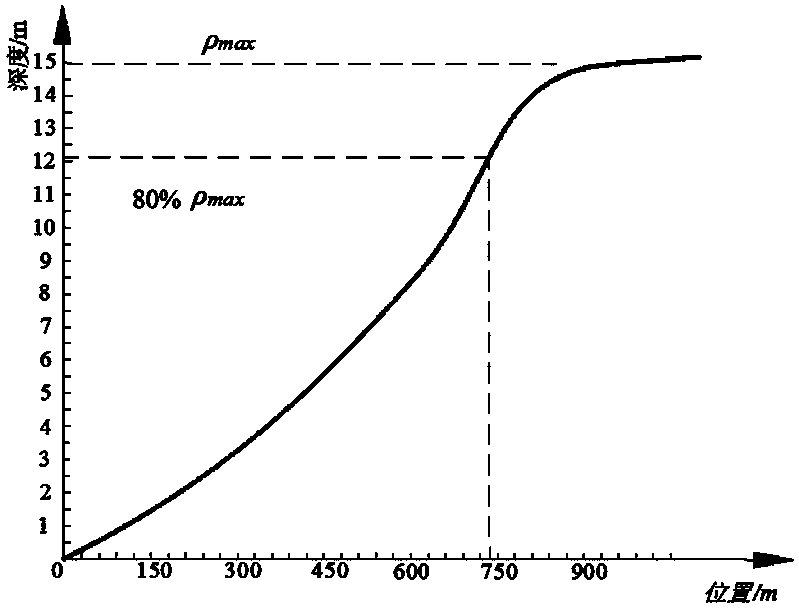

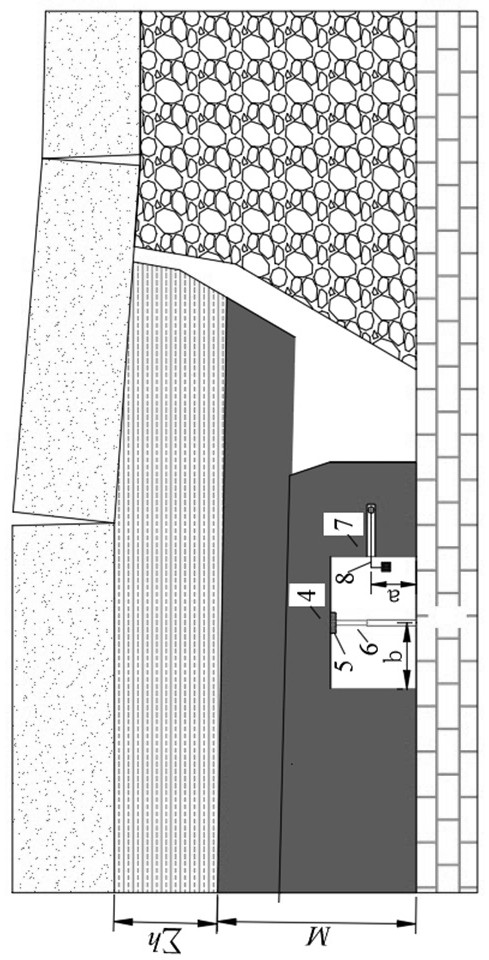

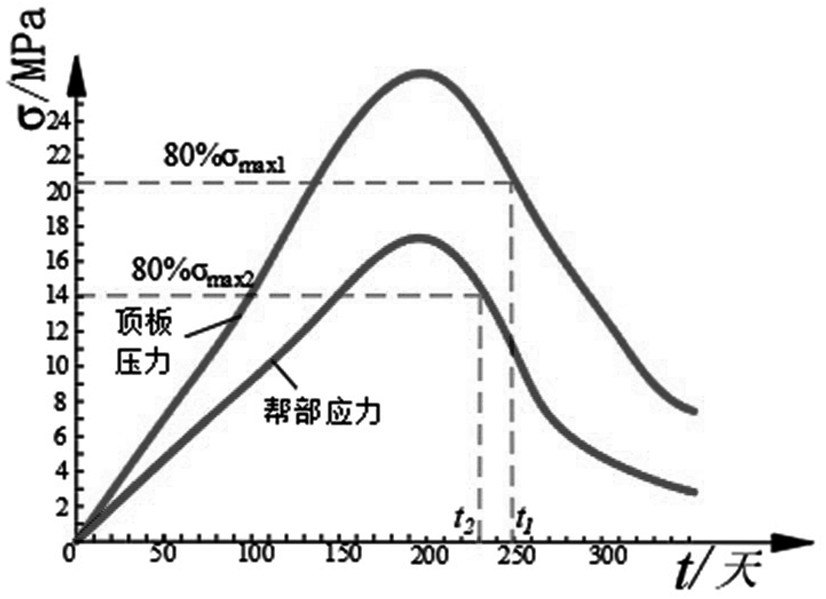

Superhigh seam gob-side entry driving tension succession quantitative solution method

ActiveCN110863828ASlow down the overburden settlement trendIn line with the actual situationUnderground miningSurface miningMining engineeringStructural engineering

The invention relates to a superhigh seam gob-side entry driving tension succession quantitative solution method. The method comprises the steps of (1) determining the gob-side entry driving excavation time T1 with the basic roof sinking amount as the index; (2) determining the reasonable excavation time T2 with the roadway surrounding rock stress variation as the time index; and (3) determining the reasonable gob-side entry driving excavation time T. Through the superhigh seam gob-side entry driving tension succession quantitative solution method, the basic roof sinking amount and the overlying strata movement stabilization time are obtained on the basis of taking full consideration of the difference of coal and rocks and are more in line with the on-site actuality, and the result is moreaccurate; the roadway surrounding rock stress variation is introduced as the additional index, and a double-index system of the gob-side entry driving excavation time is formed; 70% of the maximum basic roof sinking value and 80% of maximum stress serve as the evaluation indexes of the roadway excavation time; the weight ratios occupied by the maximum basic roof sinking value and the maximum stress are determined according to specific geological conditions, and the gob-side entry driving excavation time is obtained; and the safety and stability of gob-side entry driving surrounding rocks canbe ensured, the superhigh seam gob-side entry driving time can be effectively reduced, and normal excavation succession is guaranteed.

Owner:SHANDONG UNIV OF SCI & TECH

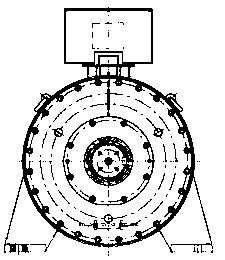

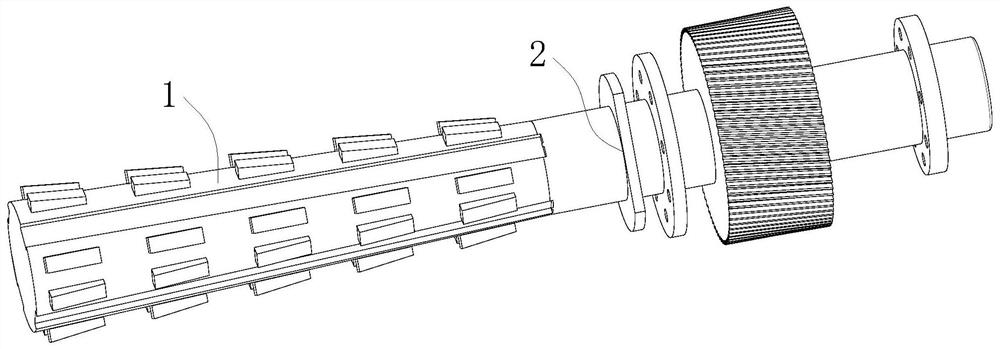

High-voltage permanent-magnet intelligent driving system for water-conservancy vertical shaft

PendingCN111181338AMeet the requirements of 10000V high voltage power supply conditionsSimple structureMagnetic circuit rotating partsCooling/ventillation arrangementControl engineeringPermanent magnet motor

The invention discloses a high-voltage permanent magnet intelligent driving system for a water-conservancy vertical shaft. The high-voltage permanent magnet intelligent driving system comprises a shell, a stator assembly, a rotor assembly and a high-power permanent magnet motor driver, the length-diameter ratio of a rotor is larger than or equal to 11 and smaller than or equal to 20, the rotor assembly comprises two rotor units which are coaxial with each other and arranged on the same rotor rotating shaft in a sleeving mode, a magnetism isolating partition plate is arranged between the two rotor units, and the two rotor units and the magnetism isolating partition plate abut against each other. The high-voltage permanent magnet intelligent driving system has the beneficial effects that thelong and thin structure low-speed large-torque high-pressure permanent magnet intelligent driving system suitable for the water conservancy vertical shaft environment is provided, and the problems that energy consumption is large, a speed reducer is prone to damage, the maintenance period is short, maintenance cost is high, driving system noise is large, vibration is large and vertical shaft space is limited are solved.

Owner:日照东方电机有限公司

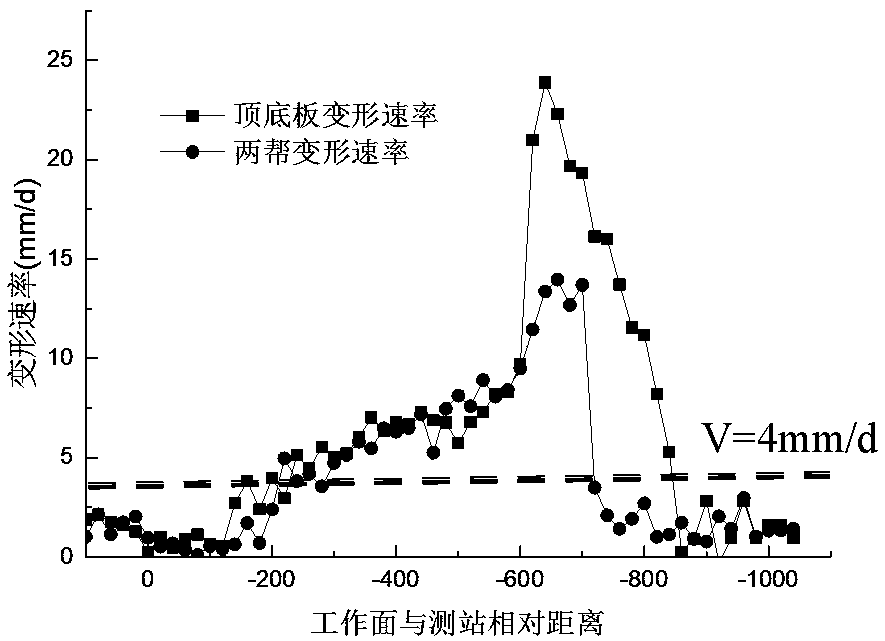

Extra-thick coal seam gob-side coal roadway digging time design method based on a double-index weight method

PendingCN111008758AThe result is accurateSlow down the overburden settlement trendResourcesComplex mathematical operationsCoalMining engineering

The invention relates to an extra-thick coal seam gob-side coal roadway digging time design method based on a double-index weight method. The method comprises the following steps: 1) determining gob-side roadway digging time T1 by taking basic roof subsidence as an index, 2) determining reasonable digging time T2 by taking roadway surrounding rock deformation rate as a time index; and 3) determining reasonable gob-side roadway digging time T. The basic roof subsidence and the overlying strata movement stabilization time are obtained on the basis of fully considering the difference of coal androck mass so that the field reality is better met and the result is more accurate; the roadway surrounding rock deformation rate is introduced as an additional index to form a double-index system of gob-side coal roadway digging time; 70% of the maximum basic roof subsidence value and the surrounding rock deformation rate (4mm / day) are proposed as evaluation indexes of the roadway digging time andthe weight ratio of the two is determined according to specific geological conditions, the gob-side roadway digging time is comprehensively obtained, the gob-side roadway surrounding rock safety andstability are guaranteed, the extra-thick coal seam gob-side roadway digging time is shortened and normal replacement of digging is guaranteed.

Owner:SHANDONG UNIV OF SCI & TECH

Dual-index method for quantitatively judging gob-side entry driving time of extra-thick coal seam

ActiveCN111042821ASlow down the overburden settlement trendIn line with the actual situationMining devicesTunnelsOverburdenMechanical engineering

The invention relates to a dual-index method for quantitatively judging gob-side entry driving time of an extra-thick coal seam. The dual-index method comprises the following steps: (1) determining gob-side entry driving time T1 by taking main roof subsidence as an index; (2) determining reasonable driving time T2 by taking entry surrounding rock fracture development depth as a time index; (3) determining the reasonable gob-side entry driving time T. The dual-index method obtains the main roof subsidence and overburden rock movement stability time on the basis of fully considering the difference between coal and a rock mass, and is more consistent with actual conditions on site and more accurate in result. The dual-index method introduces the entry surrounding rock fracture development depth as the additional index, so that a dual-index system for the gob-side entry driving time is formed. The dual-index method takes 70% of a maximum main roof subsidence value and 80% of a maximum fracture depth as evaluation indexes of the entry driving time, and determines the weight proportion of the maximum main roof subsidence value and the maximum fracture depth according to specific geological conditions so as to comprehensively obtain the gob-side entry driving time, thereby ensuring the safety and stability of surrounding rocks of a gob-side entry, reducing the gob-side entry driving time of the extra-thick coal seam, and guaranteeing normal replacement of mining and driving.

Owner:SHANDONG UNIV OF SCI & TECH

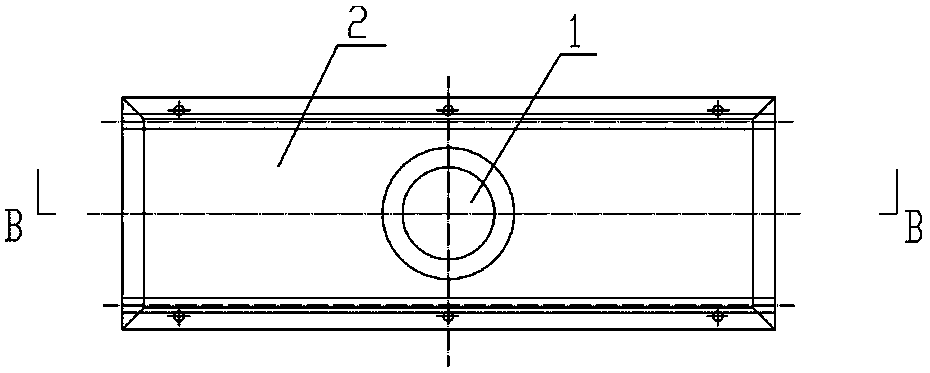

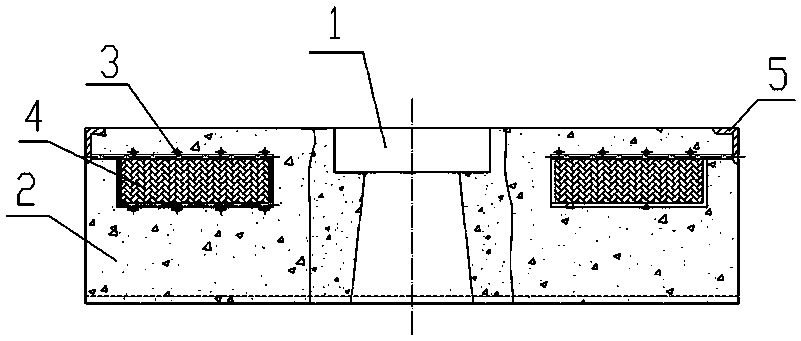

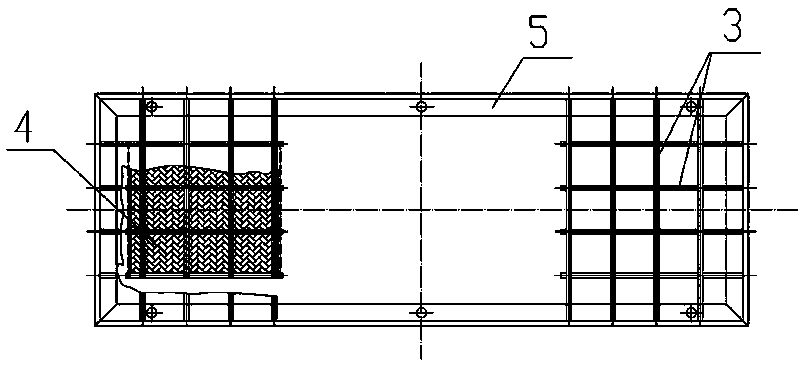

Composite heat-insulated furnace surface prefabricated block for aluminum anode carbon roasting furnace flue wall

ActiveCN105910441BMeet the actual needs of the siteReduce surface temperatureFurnace componentsInsulation layerFire resistance

The invention discloses a composite heat insulation type furnace face prefabricated block for an aluminum anode carbon roasting furnace flue wall. The composite heat insulation type furnace face prefabricated block comprises a prefabricated material pouring body which is of a cuboid structure and is provided with a fire jet opening in the middle, bearing nets and heat insulation layers, wherein the bearing nets and the heat insulation layers are sequentially and horizontally embedded into the portions, located on the two sides of the fire jet opening, of the upper portion of the prefabricated material pouring body from top to bottom. L-shaped reinforcing frames are pressed on the edge of the periphery of the upper surface of the prefabricated material pouring body in a buckled manner. The composite heat insulation type furnace face prefabricated block is a composite body composed of refractory castable, the L-shaped reinforcing frames, the bearing nets, the heat insulation layers and other materials, and the requirements for fire resistance, collision prevention, heat insulation performance, load-bearing performance and anti-skidding performance of the furnace face prefabricated block for the flue wall are met; and the refractory castable sintered bauxite with the high strength and high performance is adopted as a host material for the furnace face prefabricated block, so that the finished prefabricated block has high strength, micropores and the medium or high specific gravity and is high in performance. A manufacturing method of the composite heat insulation type furnace face prefabricated block is simple, the process parameters are easy to control, and high-temperature sintering is not needed; and the pouring material formula is changed for different portions, and the field actual requirements of different portions of the prefabricated block are met.

Owner:郑州汇特耐火材料有限公司

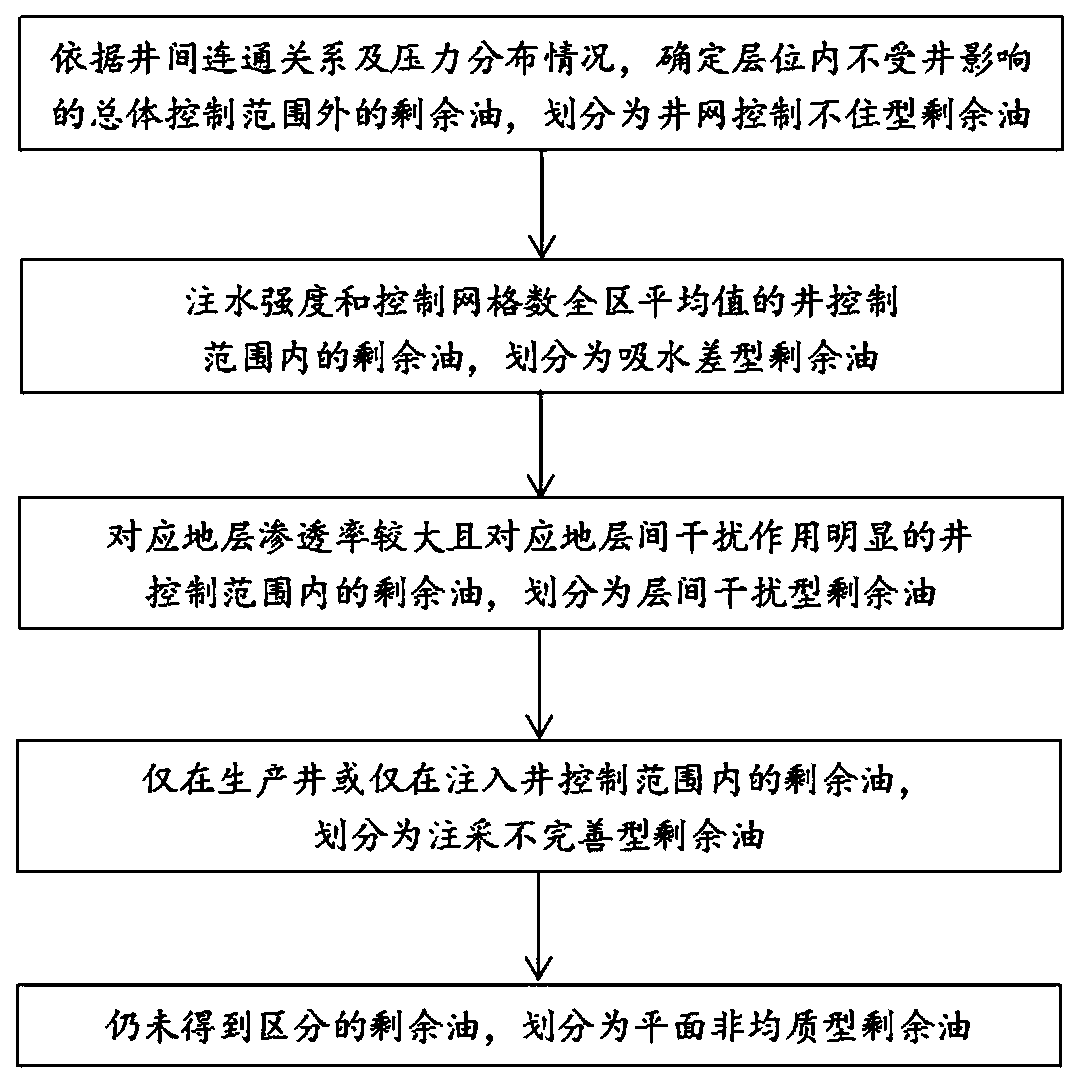

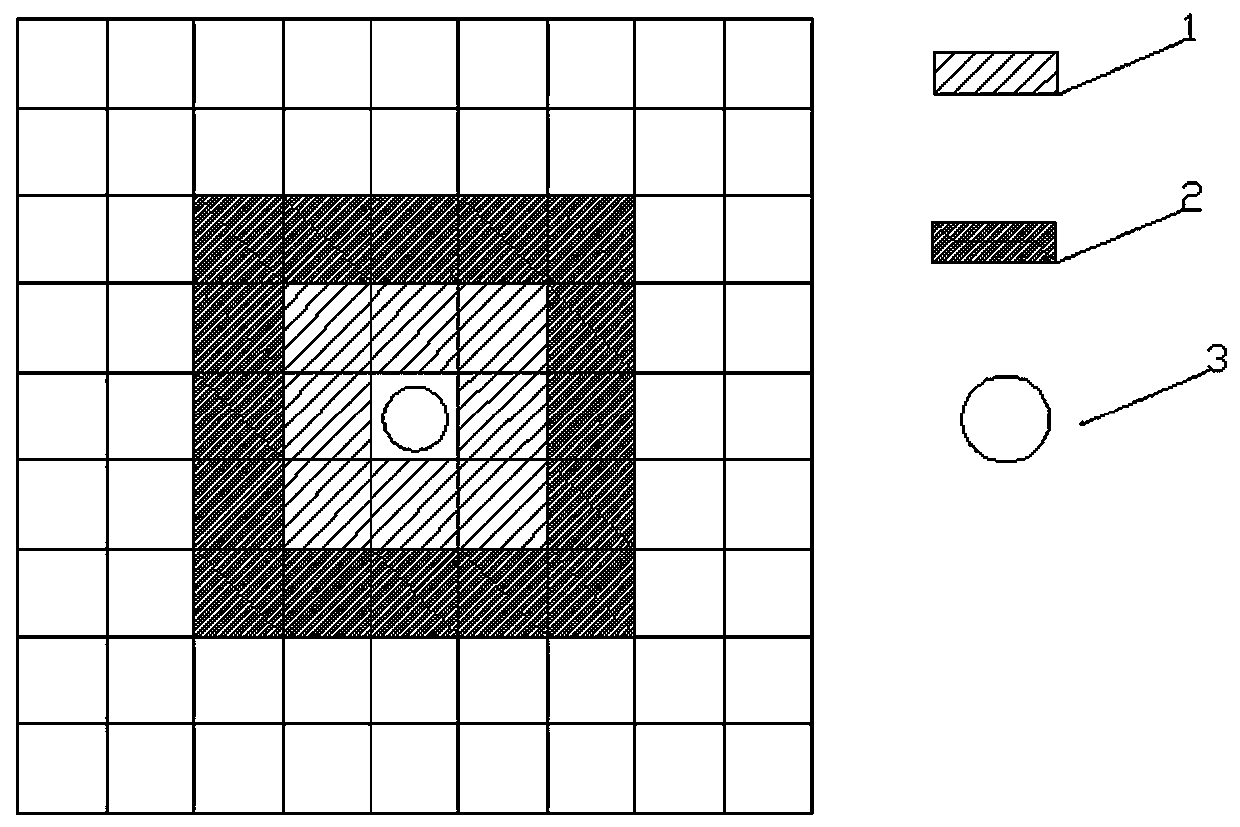

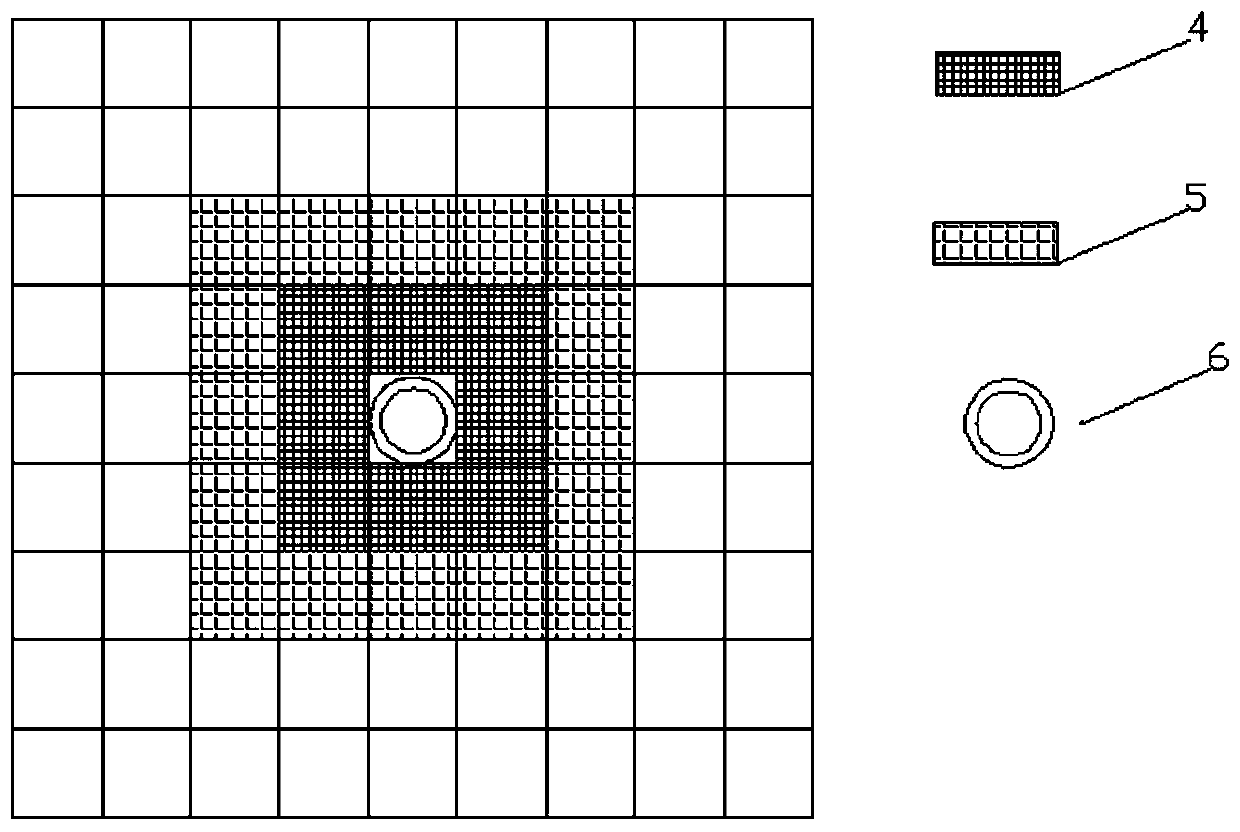

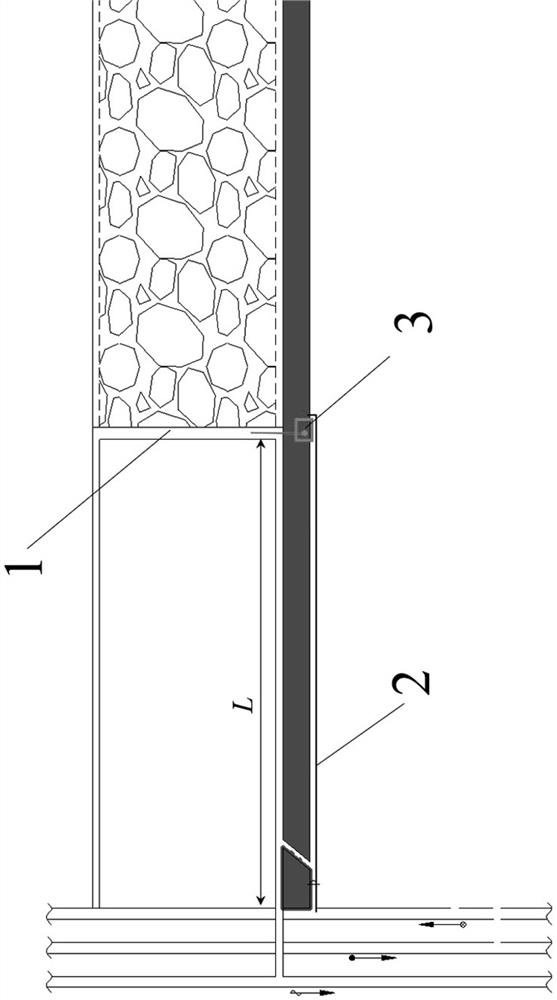

A method for quantitatively dividing remaining oil of an oil field in a high water cut period

ActiveCN109726946AMeet the actual needs of the siteEnhanced overall recoveryResourcesHorizonNetwork control

The invention belongs to the technical field of oil exploitation, and particularly relates to a method for quantitatively dividing remaining oil of an oil field in a high water cut period, which comprises the following steps of: 1, determining remaining oil outside an overall control range which is not influenced by a well in a horizon according to a well-to-well communication relationship and a pressure distribution condition, and dividing the remaining oil into well network control incapable remaining oil; 2, dividing the water injection intensity into water absorption difference type residual oil when the water injection intensity is smaller than the whole average water injection intensity and the single well control area is smaller than the average single well control area; 3, screening out one third of the production well and the injection well with higher corresponding stratum permeability, analyzing the liquid production amount and the water injection amount of the production well and the injection well, and dividing the liquid production amount of the corresponding stratum into interlayer interference type remaining oil if the liquid production amount of the corresponding stratum can reach half of the water absorption amount; 4, finding out residual oil only in the control range of the production well or the injection well, and dividing the residual oil into injection-production imperfect residual oil; 5, If after step 1-4, the remaining oil that has not been distinguished, classifying the remaining oil as a planar heterogeneous residual oil..

Owner:NORTHEAST GASOLINEEUM UNIV

A Quantitative Solution to the Tension Replacement of Gob-side Driving in Extra-thick Coal Seam

ActiveCN110863828BSlow down the overburden settlement trendIn line with the actual situationUnderground miningSurface miningMining engineeringStructural engineering

The present invention relates to a quantitative solution to tension replacement of gob-side roadway in extra-thick coal seams. 1) The time T of goaf-side roadway is determined by taking the basic roof subsidence as an index. 1 ,2) Taking the stress change of the roadway surrounding rock as the time index, determine the reasonable excavation time T 2 ,3) Determine the reasonable excavation time T of the gob-side roadway. The present invention obtains the basic roof subsidence and overlying rock movement stability time on the basis of fully considering the difference between coal and rock mass, which is more in line with the actual site and the result is more accurate; the stress change of the surrounding rock of the roadway is introduced as an additional index to form a The double-index system of the excavation time of gob-side roadway; 70% of the maximum basic roof subsidence value and 80% of the maximum stress are used as the evaluation index of roadway excavation time, and the weight ratio of the two is determined according to the specific geological conditions. The excavation time of the gob-side roadway can not only ensure the safety and stability of the surrounding rock of the gob-side roadway, but also effectively reduce the time of gob-side roadway excavation in extra-thick coal seams, and ensure the normal replacement of mining.

Owner:SHANDONG UNIV OF SCI & TECH

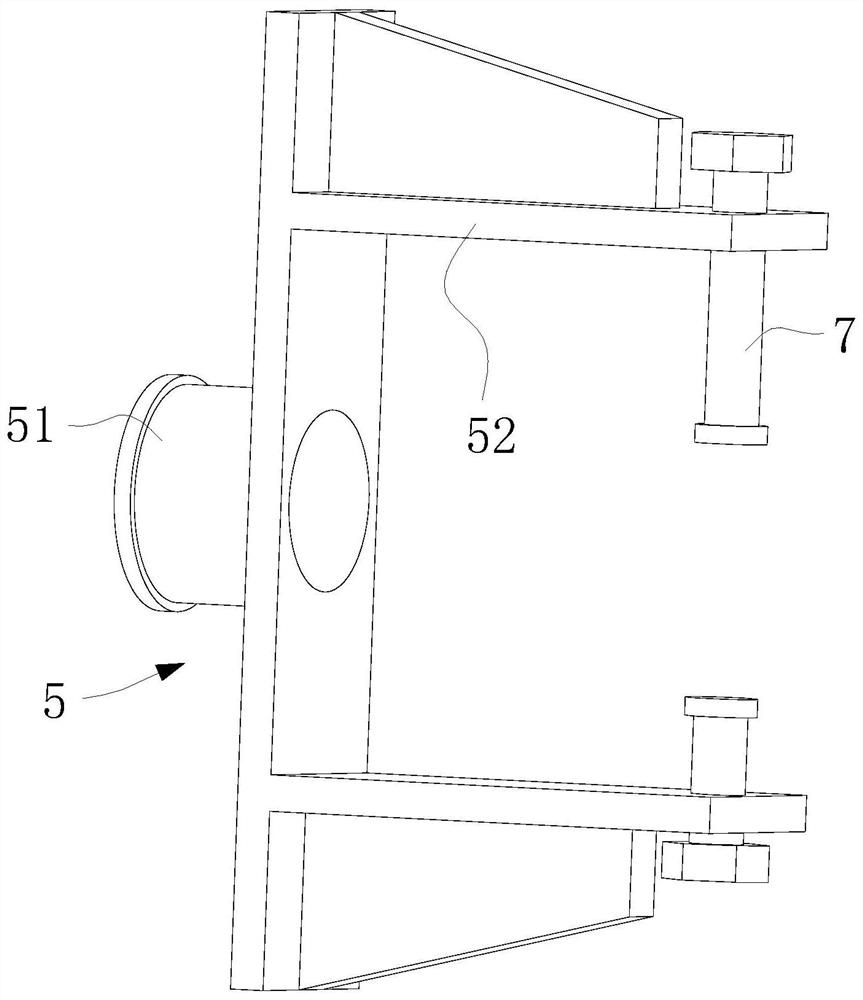

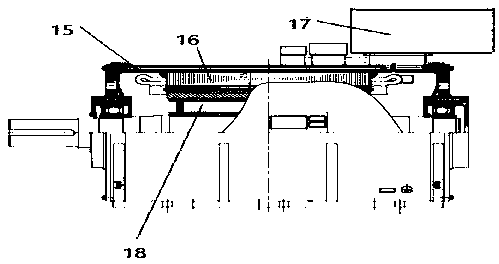

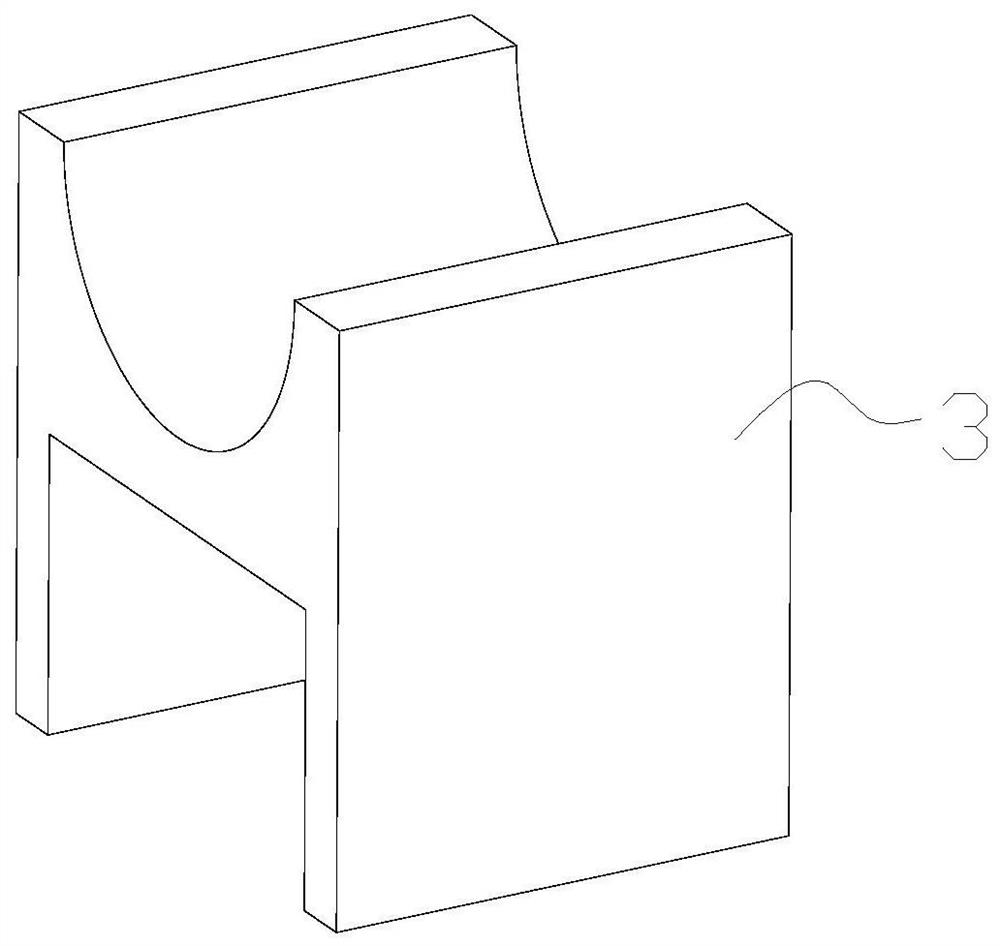

Welding auxiliary device and welding process for fractures of mandrel baffle plate of flat uncoiling machine

ActiveCN112958872ASimple structureEasy to manufactureWelding/cutting auxillary devicesAuxillary welding devicesSteel frameMechanical engineering

The invention discloses a welding auxiliary device and welding process for fractures of a mandrel baffle plate of a flat uncoiling machine. The device comprises a front end fixed support and a rear inclined end fixed support. The upper portion of the front end fixed support is in a circular arc shape. The rear inclined end fixed support comprises a body supporting steel frame, side wing supporting steel frames are fixedly arranged on the two sides of the body supporting steel frame correspondingly, and a supporting steel plate is rotationally arranged on the upper portion of the body supporting steel frame. The process for welding and repairing the fractured part of the mandrel baffle plate of the flat uncoiling machine by using the welding auxiliary device is further disclosed. The fractured part and the local chipping part of the mandrel baffle plate of the flat uncoiling machine are subjected to surfacing repair by using a multifunctional micro-arc additive manufacturing machine and welding repair by manual argon arc welding, the maintenance time is saved, the maintenance cost is reduced, the shutdown loss is reduced, and a guarantee is provided for reasonable production combination.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

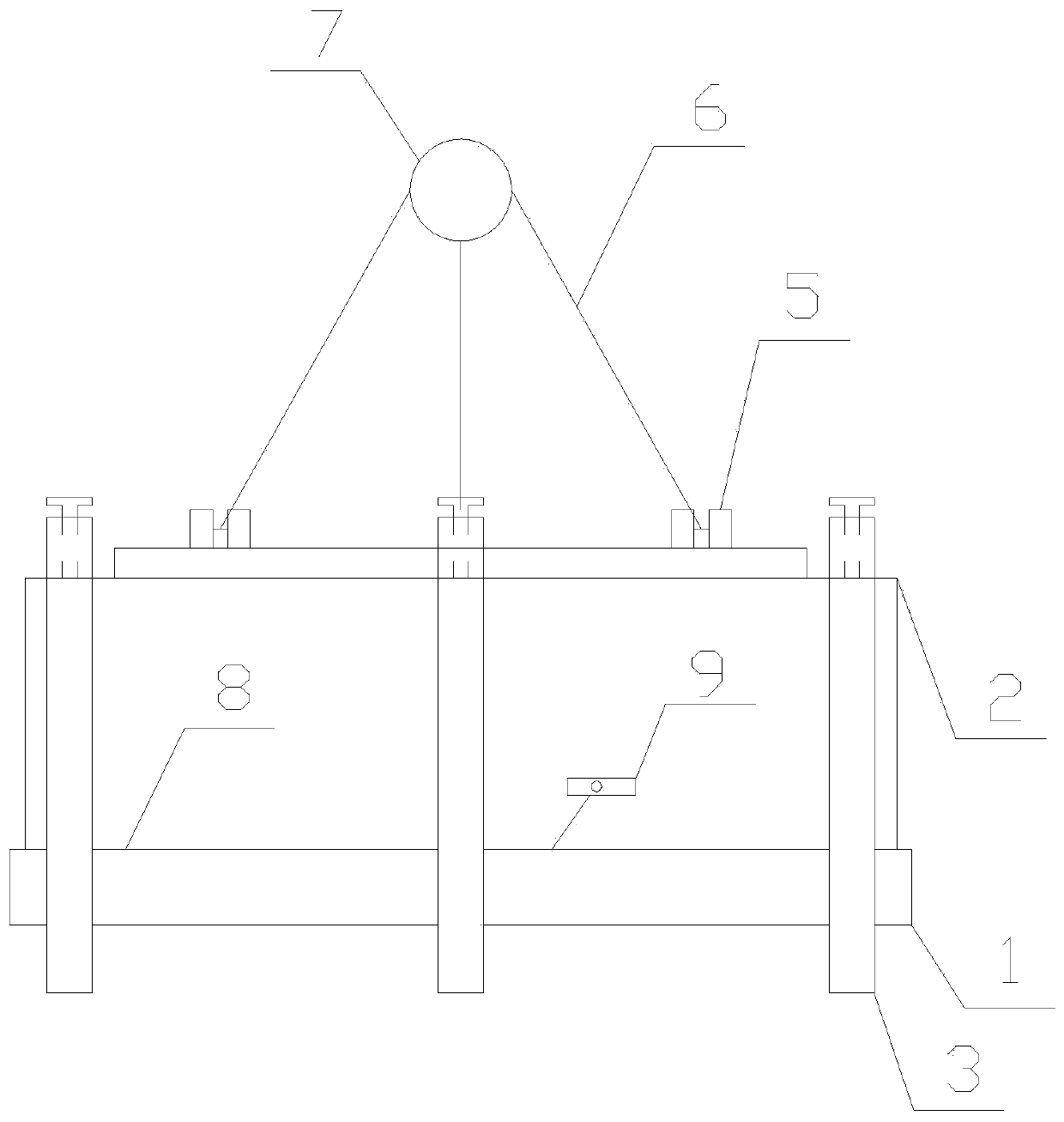

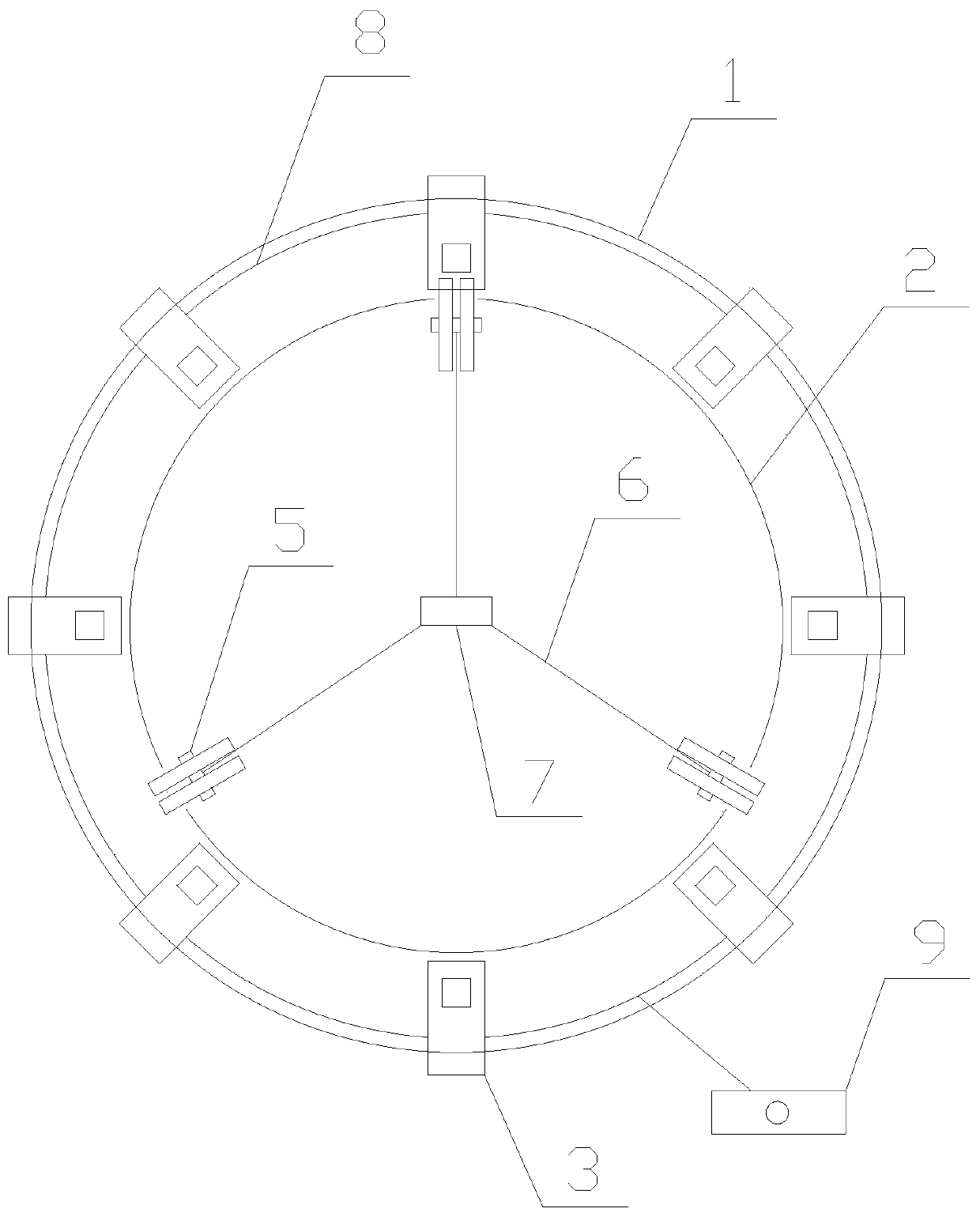

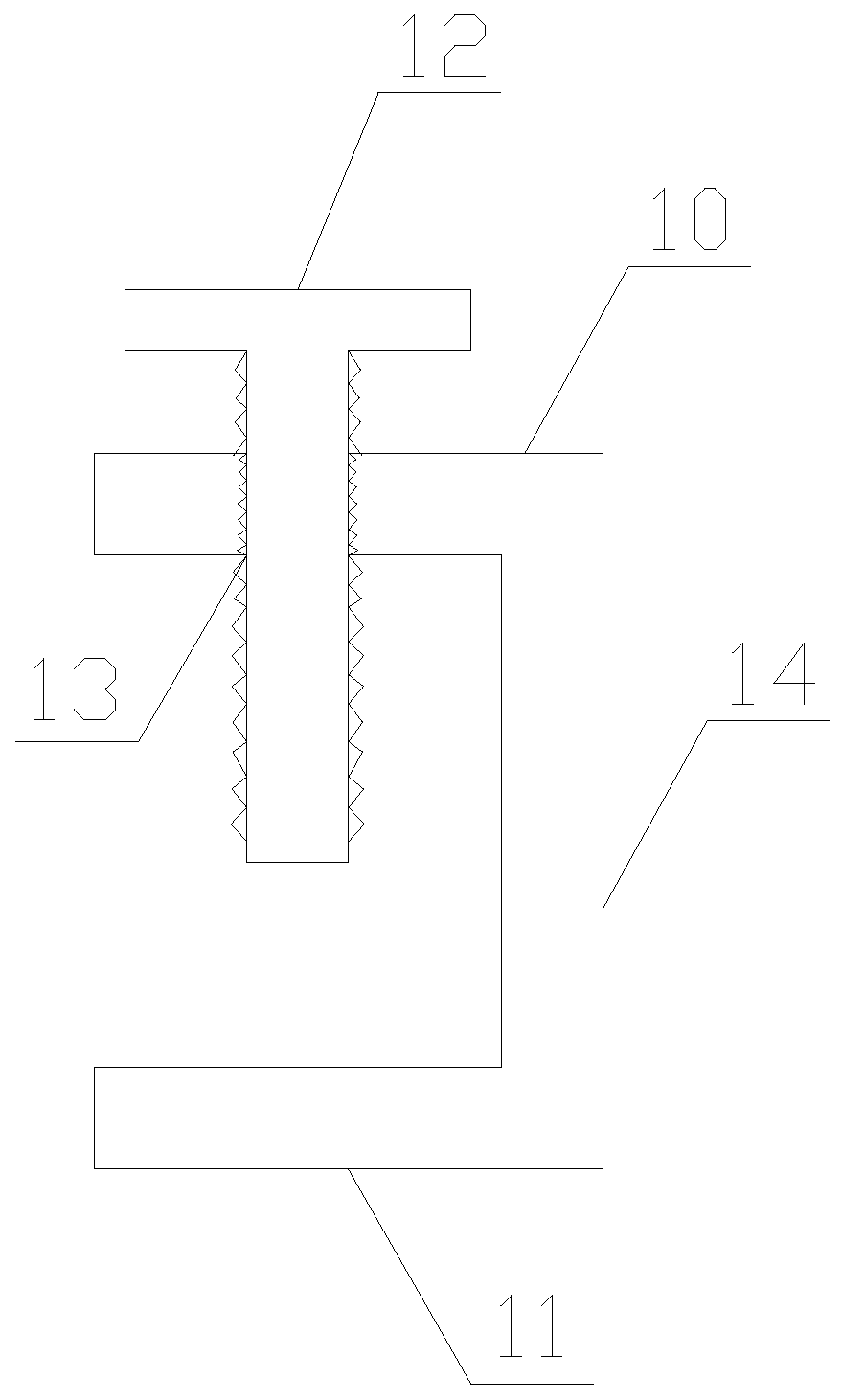

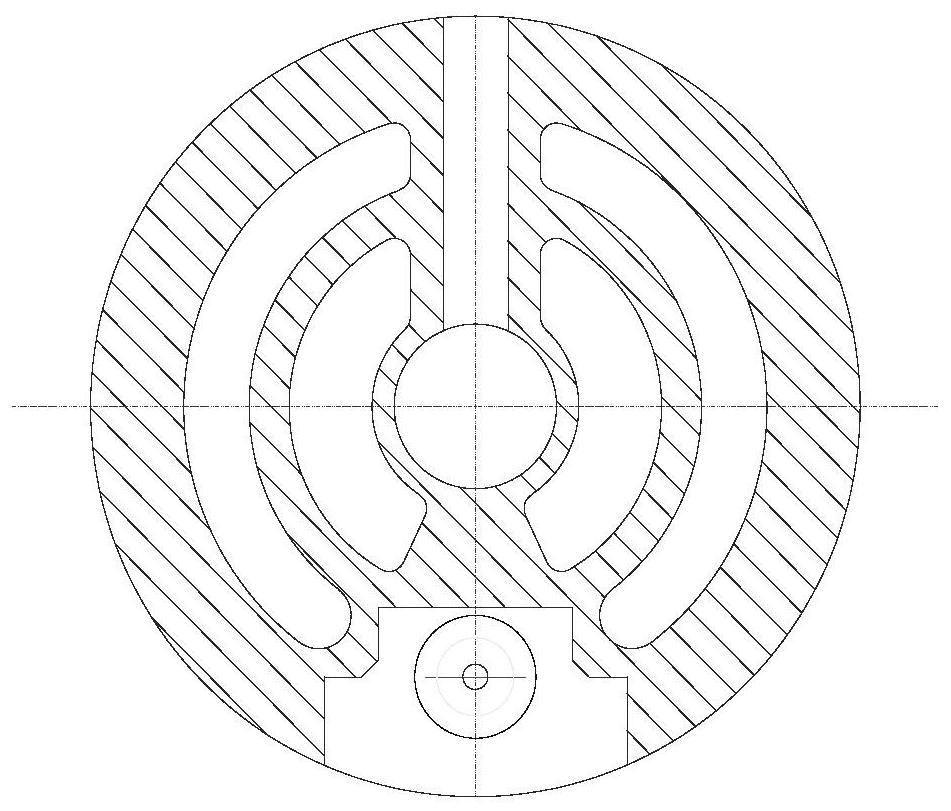

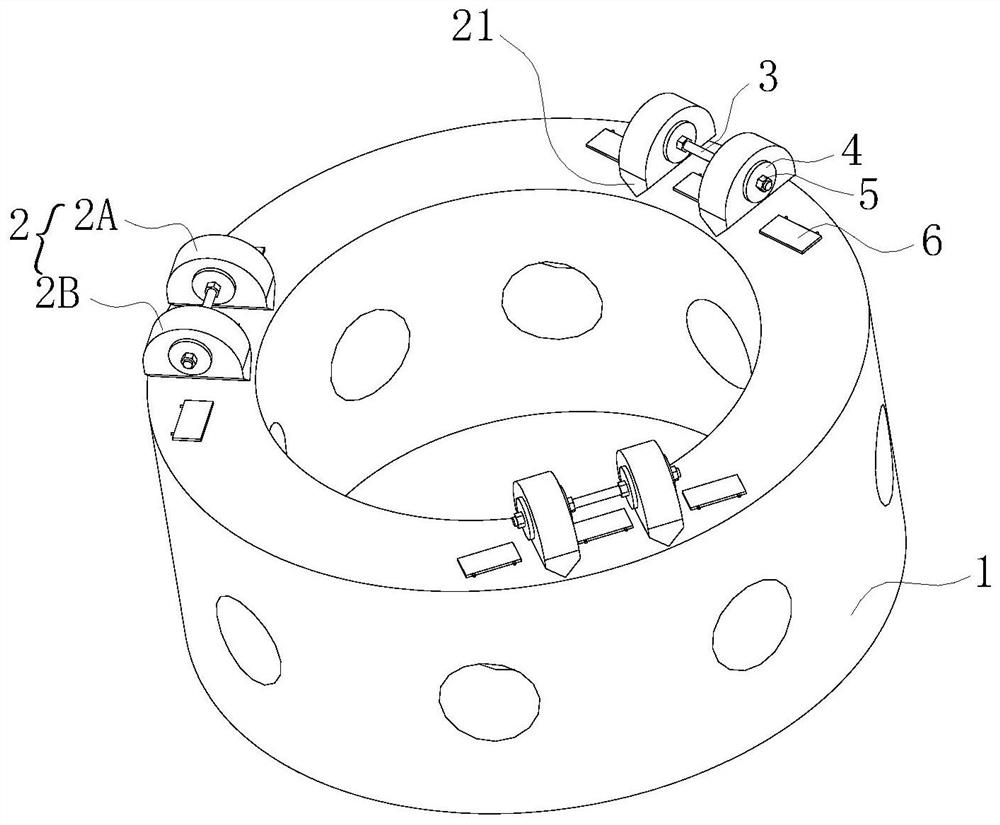

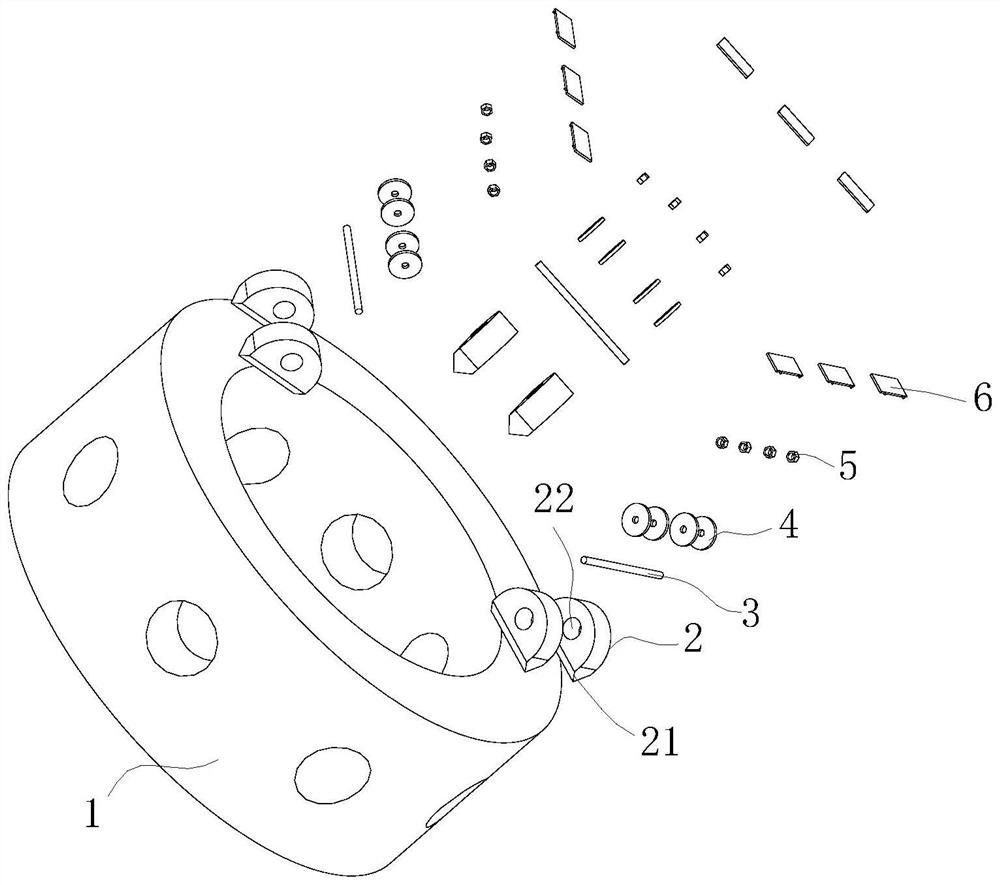

Bottom shell and welding seam assembly tool structure for electromagnetic chuck for hoisting and transporting wheel steel ingots and repair process for bottom shell and welding seam assembly tool structure

PendingCN111250826AImprove welding qualityLow investment costWelding/cutting auxillary devicesAuxillary welding devicesRepair timeIngot

The invention discloses a bottom shell and welding seam assembly tool structure for an electromagnetic chuck for hoisting and transporting wheel steel ingots and a repair process for the bottom shelland welding seam assembly tool structure. The tool structure comprises a circular bottom shell and an upper cover panel welded on the bottom shell, and further comprsies a welding gun, wherein a jointof the circular bottom shell and the upper cover panel defines a welding seam; a plurality of upper fixing devices are uniformly arranged on the upper surface of the upper cover panel; each upper fixing device is connected to a hoisting ring through a connecting chain; a plurality of hook head clamps are uniformly arranged along the periphery on the bottom shell and the upper cover panel; each hook head clamp comprises a hook head clamp body in the shape of U with an opening facing leftwards, the upper part and the lower part of the hook head clamp body are separately a hook head upper clamping plate and a hook head lower clamping plate, and a distance between the hook head upper clamping plate and the hook head lower clamping plate is equal to sum of height of the bottom shell and heightof the upper cover panel; a wire hole is formed in the hook head upper clamping plate; and a full-thread bolt which is adaptive to the wire hole is arranged in the wire hole. The bottom shell and welding seam assembly tool structure disclosed by the invention can perform online welding repair for fracture of the bottom shell on the electromagnetic chuck, saves maintenance time, reduces maintenance cost, reduces breakdown loss, and provides guarantee for reasonable assembly and production.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

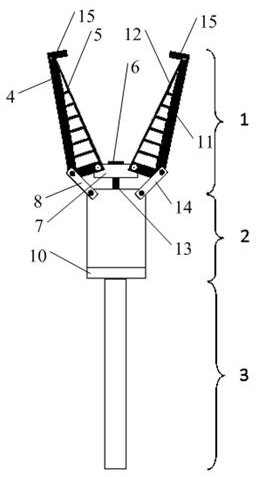

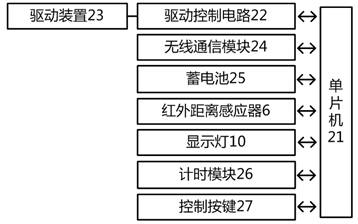

A fully automatic auxiliary branch-picking mechanism and method for tree-block removal

ActiveCN112655398BResolved technical issues where stuck frags could not be handledSolve the safety problem of smashing and injuring the wreckersCuttersCutting implementsStructural engineeringOverhead line

The present invention provides a fully automatic auxiliary branch-picking mechanism and branch-picking method for tree barrier cleaning, comprising: a grapple hook assembly, a host assembly and an insulating operating rod; the first grapple shell is fixed on the first claw hook inner lining; the second The grapple shell is fixed on the second grapple lining; the lifting platform is fixedly connected with the host assembly through the connecting rod; the first grapple shell is hinged with the host assembly through the first connecting piece; the second grapple shell is connected through the second connecting piece It is hinged with the host assembly; the first claw hook lining and the second grab hook shell are respectively hinged with the lifting platform; the host assembly is provided with a driving device for controlling the opening and closing of the grab hook assembly; The technical problem of stuck broken branches is solved, and at the same time, the safety problem of using non-specialized tools to cause high-altitude fall to injure the obstacle removal personnel is solved. The present invention plans obstacle-clearing lines according to needs, and sets obstacle-clearing positions according to actual conditions, and can also perform patrol inspection on overhead lines to ensure timely processing of obstacle-clearing work.

Owner:国网山东省电力公司昌邑市供电公司 +2

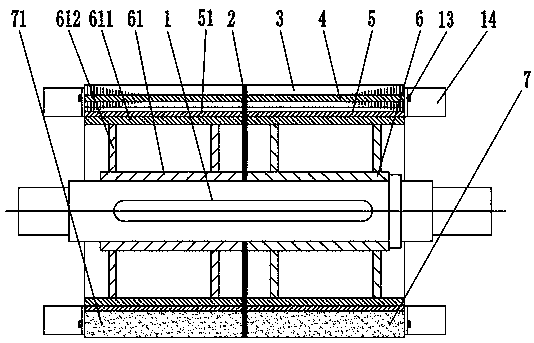

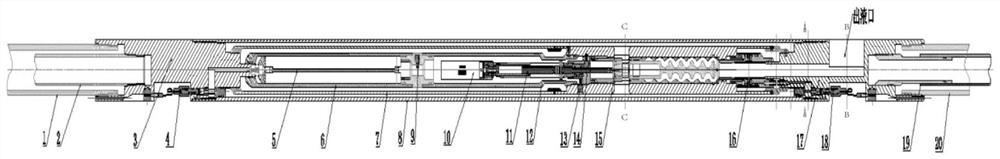

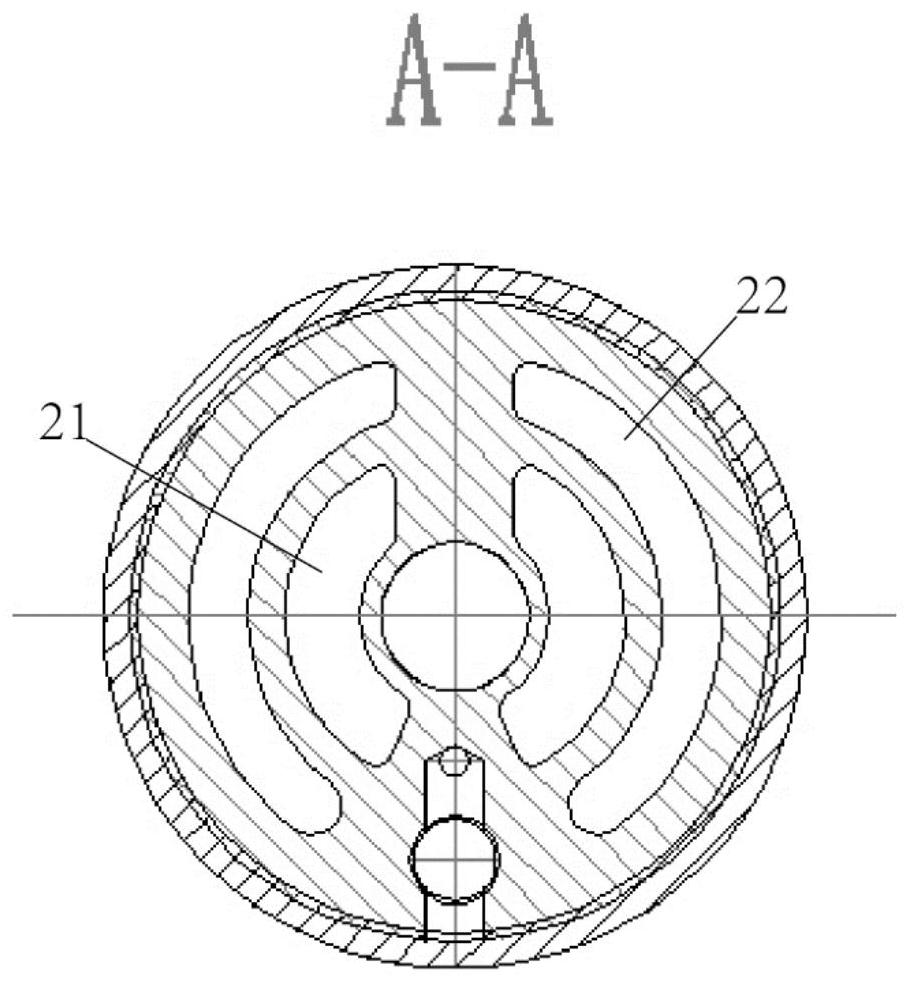

Double-medium layered injection flow control device and control method thereof

PendingCN114458259AWide flow rangeImprove temperature and pressure resistanceSurveyConstructionsReduction driveControl engineering

The invention provides a double-medium layered injection flow control device and a control method thereof.The lower portion of a connector is in threaded connection with the head end of an outer pipe, a control unit is connected with the tail end of an upper connector, the control unit is electrically connected with an adjustable flow assembly, and a control unit cabin used for protecting the control unit is arranged outside the control unit; an inner pipe is arranged between the control unit cabin and the outer pipe; the control unit is electrically connected with the motor and the speed reducer, the motor and the speed reducer are connected with the head end of the adjusting mechanism, the tail end of the adjusting mechanism is connected with the head end of the adjustable three-way valve, the adjustable three-way valve is arranged in the flow adjusting inner pipe, and the motor, the speed reducer and the adjusting mechanism are both arranged in the motor sealing cabin. The control device does not need to be tripped into an instrument for testing and allocation, is not limited by well deviation, and realizes real-time allocation of the injection rate.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A fracture welding repair process for large-scale inclined roll shaft of a ring rolling mill

ActiveCN112935686BNovel structureCompact configurationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention discloses a large-scale inclined roll shaft fracture welding device for a ring rolling mill. Fixing structure tooling is used for pairing and fixing the broken part of the inclined roller shaft and controlling the deformation amount during the welding process; and the heating tooling is used for heating the broken part of the inclined roller shaft. The invention also discloses a fracture welding repairing process for a large-scale inclined roll shaft of a ring rolling mill based on the welding device. Through the implementation of the present invention, a large amount of maintenance time can be shortened, the maintenance cost can be reduced, and the failure rate and downtime loss can be reduced, thereby providing a guarantee for rational production.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

A Welding Repair Process for Cracks in Water Tank of Electric Reciprocating Pump Body for Wheel Phosphorus Removal

ActiveCN112935472BImprove welding qualityLow investment costArc welding apparatusStructural engineeringProcess engineering

The invention discloses a water tank crack welding device for an electric reciprocating pump body for dephosphorization by wheels. The fixed draw plate on the groove surface and the fixed steel plate connected to the back side and the two fixed pull plates on the groove surface are respectively detachably connected and fixed upper pressing plate. The present invention also provides a repair process for the water tank crack welding device of the wheel dephosphorization electric reciprocating pump body. Aiming at the problems existing in the background technology, the present invention provides a repair process for the wheel phosphorus removal electric reciprocating pump body water tank crack welding device craft. The application of the present invention can quickly implement and complete the electric reciprocating cast iron pump body water tank crack welding repair, reduce procurement and maintenance costs, reduce long-term shutdown losses, and provide a guarantee for the reasonable assembly and rolling of steel to produce various domestic and foreign wheels.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

Converter backing ring body lug fixing assembly welding structure and welding process

ActiveCN112981037AWon't hurtSolve Welding ProblemsArc welding apparatusManufacturing convertersStructural engineeringMachining

The invention discloses a converter backing ring body lug fixing assembly welding structure. The welding structure comprises a converter backing ring body and three pairs of lugs evenly arranged along the circumference of the upper surface of the converter backing ring body, each pair of lugs comprises a first lug and a second lug, and shaft holes are formed in the centers of the first lugs and the centers of the second lugs; and the shaft holes corresponding to each pair of lugs are connected through a full-thread fixed connecting rod. The welding structure mainly aims at solving the problems that in the prior art, secondary machining or repairing of a pin shaft hole is prone to occurring in a traditional method that lifting lugs are arranged on a backing ring in a paired welding mode, and a backing welding method is time-consuming and prone to damaging the body structure condition during back gouging. By means of the welding structure, converter backing ring body lug fixing assembly welding can be rapidly completed, the quality is ensured, the effect is improved, and a guarantee is provided for follow-up accurate assembling.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

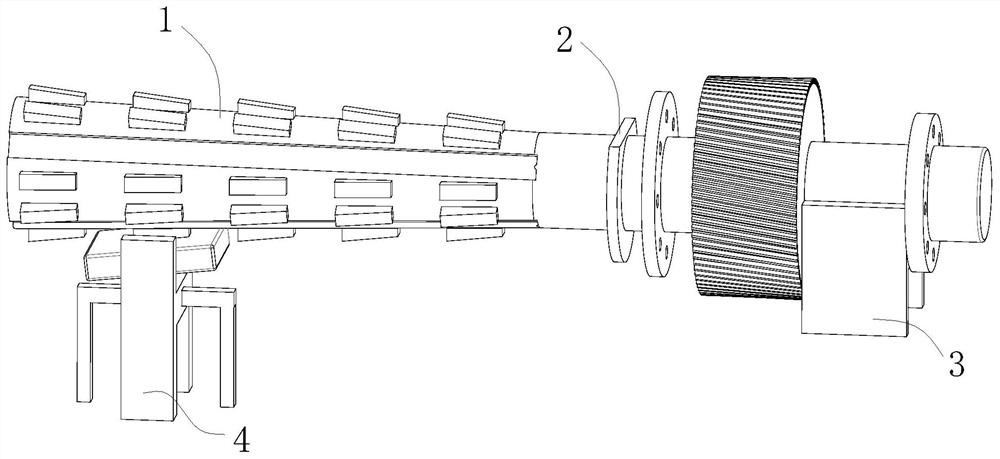

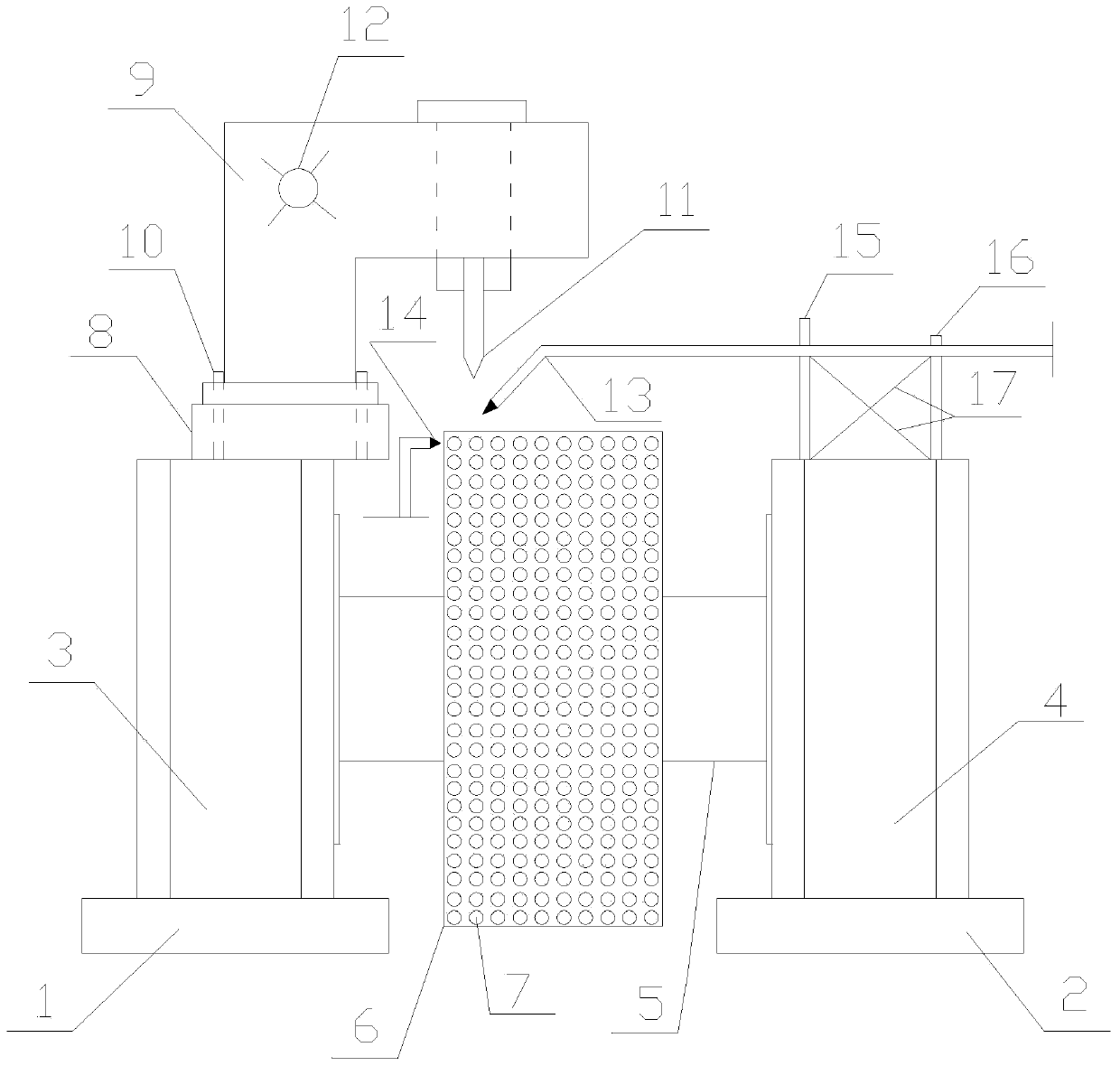

Stud embedding device on roller of mine high-pressure roller mill and repair welding process thereof

PendingCN111299958AReduce labor intensityImprove work efficiencyGas flame welding apparatusCouplingStructural engineering

The invention discloses a stud embedding device on a roller of a mine high-pressure roller mill and a repair welding process thereof. The high-pressure roller mill comprises a left side rack and a right side rack, wherein an extrusion roller is arranged on the left side rack and the right side rack through an universal coupling, a plurality of studs are evenly arranged on the outer side of the extrusion roller, a left side sleeper and a right side sleeper are arranged at the bottoms of the left side rack and the right side rack respectively, a stud embedding and drilling device is arranged atthe top of the left rack, a heating device is arranged on the right rack, and the stud embedding device further comprises a welding gun. The stud embedding device and the repair welding process thereof have the advantages of being safe, easy to operate, stable in welding quality, low in investment cost, high in working efficiency and capable of meeting actual field requirements, greatly reducing maintenance cost, reducing shutdown loss, reducing labor intensity of workers and providing guarantee for reasonable production assembly, and meanwhile, the stud embedding device on the roller of the mine high-pressure roller mill and the repair welding process provide scientific reference basis for online repair of other mine large workpieces.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

High-speed rail axle anvil die surface strengthening surfacing welding process

ActiveCN114393276AImprove work efficiencyImprove welding qualityWelding accessoriesStructural engineeringHeat conservation

The invention discloses a high-speed rail axle anvil die surface strengthening surfacing welding technology which is carried out through a simple welding auxiliary device, the welding auxiliary device comprises a structural part frame, the structural part frame comprises a bottom plate and side plates arranged at the two ends of the bottom plate, and supporting legs are arranged on the front side and the rear side of the bottom of each side plate; an adjusting lifting device is arranged on the bottom plate, and the upper surface of the adjusting lifting device is matched with the bottom of the high-speed rail axle anvil die and provided with a plurality of electric heating belts. A frame front movable heat preservation door, a frame rear movable heat preservation door and a frame heat preservation movable cover plate are movably arranged between the front ends and the rear ends of the two side plates and between the tops of the two side plates respectively. According to the method, the investment cost is low, field operation and maintenance are convenient, the repairing time is short, after surfacing repairing is conducted on the upper semicircular anvil die and the lower semicircular anvil die, it can be effectively guaranteed that the welding quality that the clamped red steel is not abraded, cracked, disengaged and the like due to uneven cold and hot and alternating loads in the periodic use process can be effectively guaranteed, and the rolling operation use requirement is met.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com