Patents

Literature

61results about How to "Improve temperature and pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic/inorganic composite hollow microspheres, and preparation method and application thereof

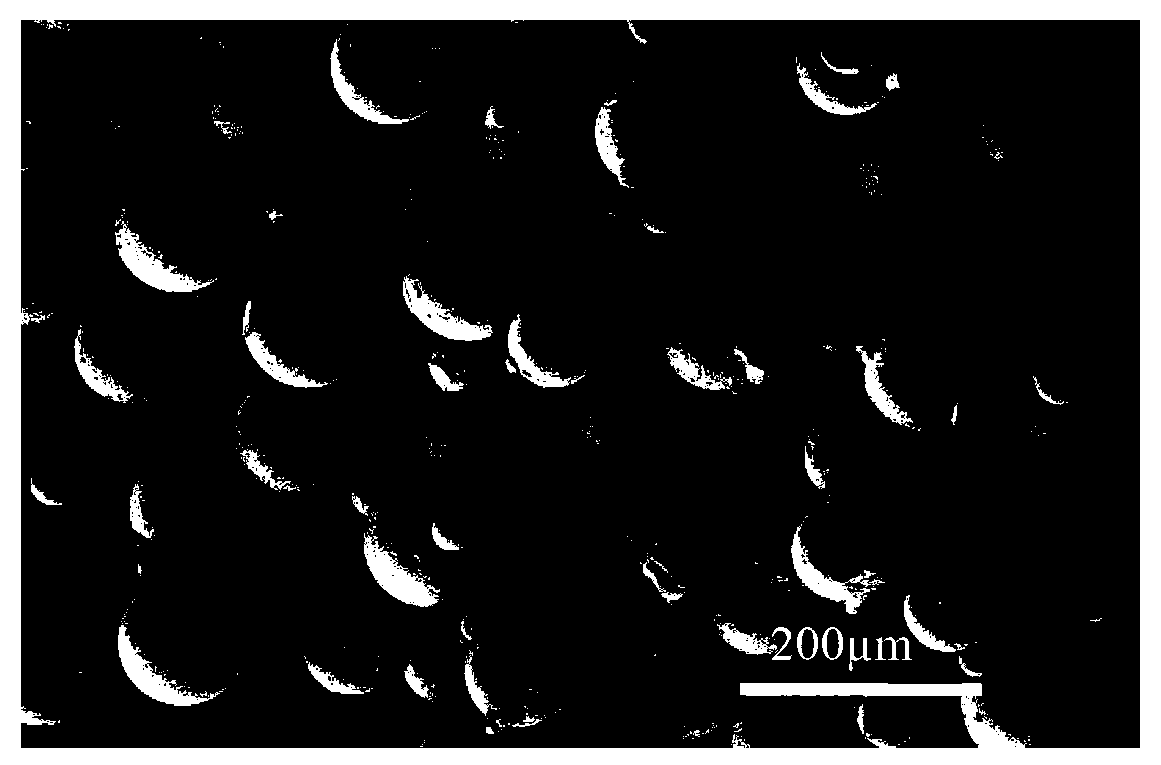

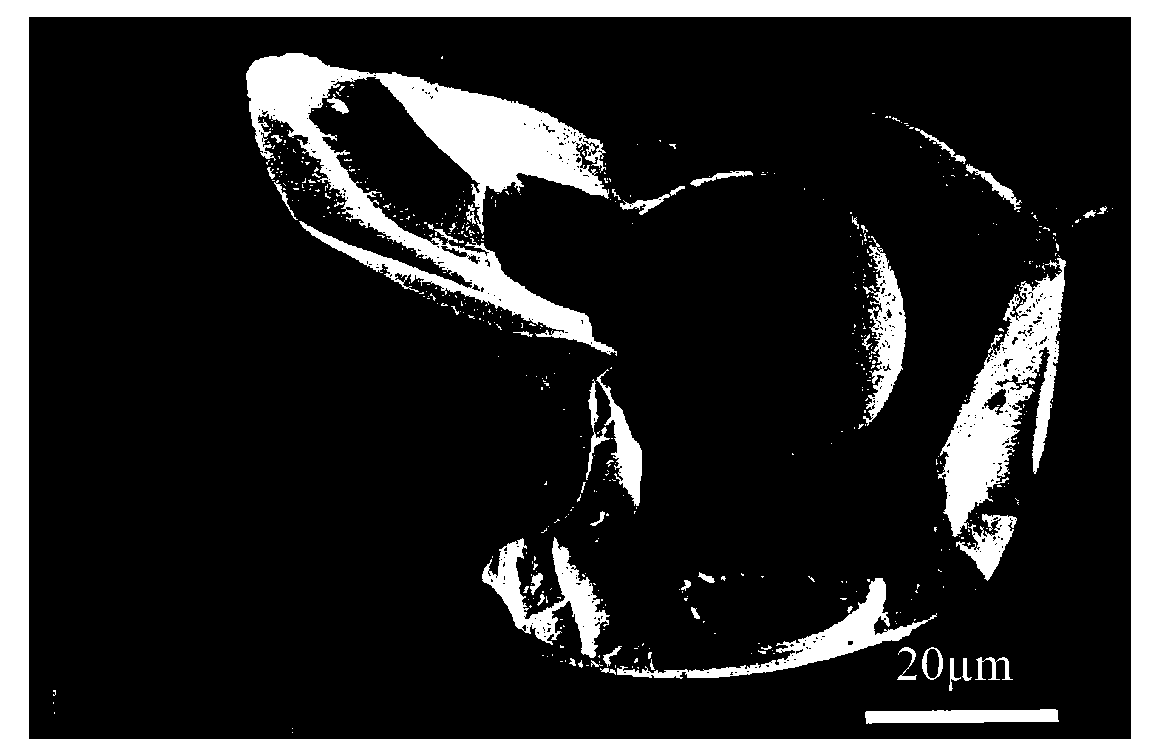

ActiveCN103387717AUniform particle sizeSmall particle sizeDrilling compositionMicroballoon preparationPolymer scienceMicrosphere

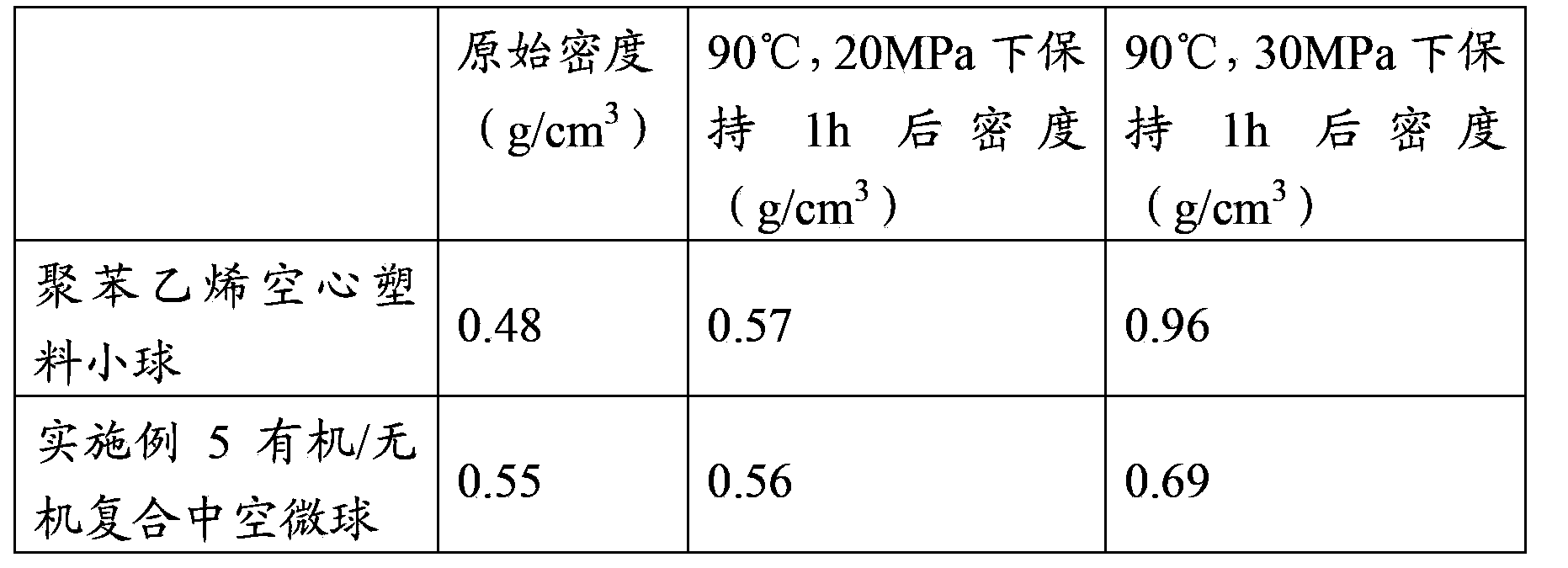

The invention relates to organic / inorganic composite hollow microspheres, and a preparation method and an application thereof. According to the invention, a part of hydrophobically modified inorganic nano-grade material is added into styrene monomer or styrene monomer dissolved with polystyrene; the mixture is uniform, and is adopted as an oil phase; the viscosity of the oil phase is controlled through controlling the concentration of polystyrene and the addition amount of the nano-grade material; and temperature resistance and pressure resistance of the hollow microspheres are improved through adding an inorganic nano-grade material. In a W1 / O / W2 triple emulsion, initiation and polymerization of the styrene monomer, precipitation hardening of polystyrene and the inorganic nano-grade material, and the like are realized, such that the organic / inorganic composite hollow microspheres with the hollow structure are formed.

Owner:CHINA PETROLEUM & CHEM CORP +1

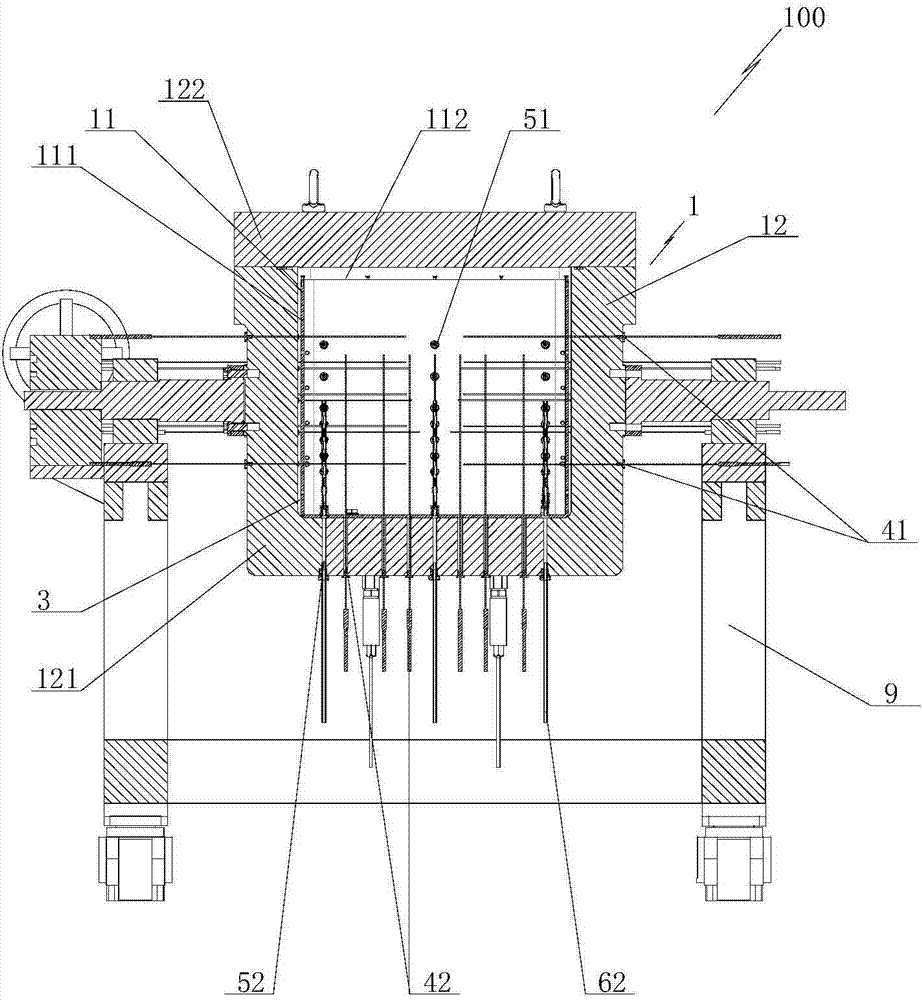

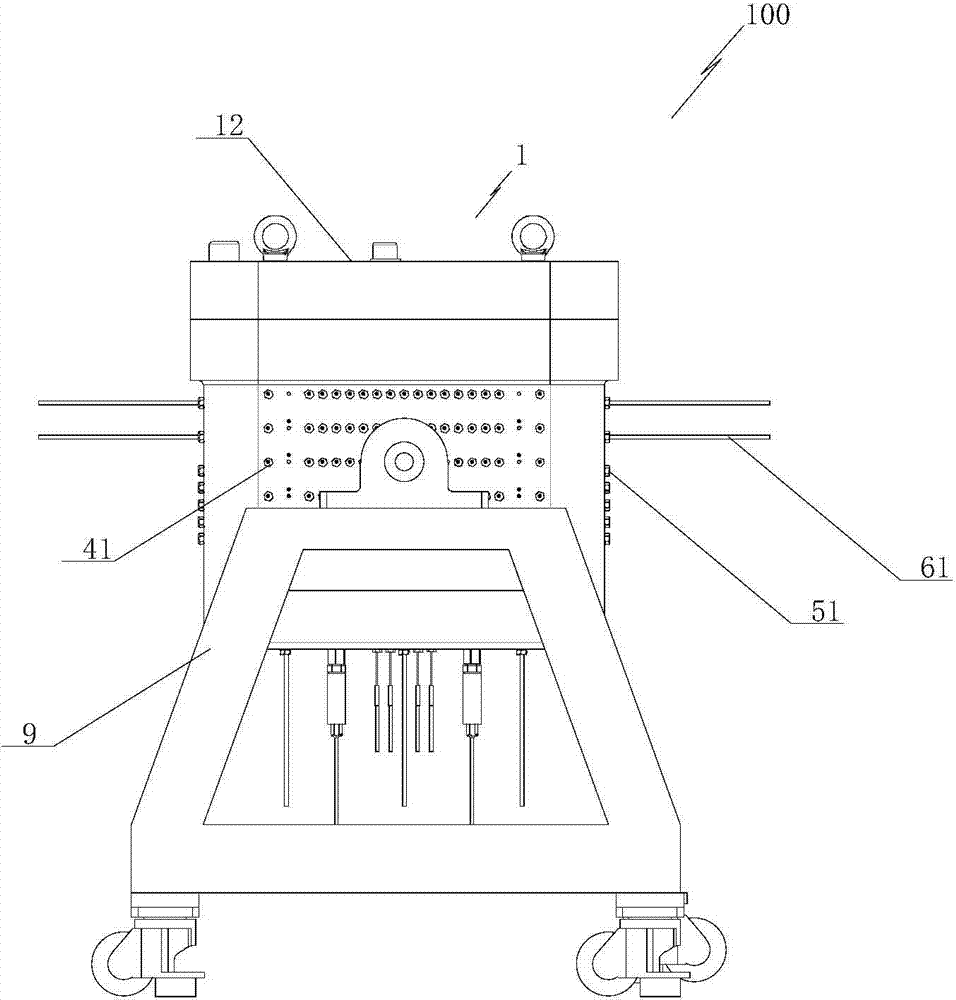

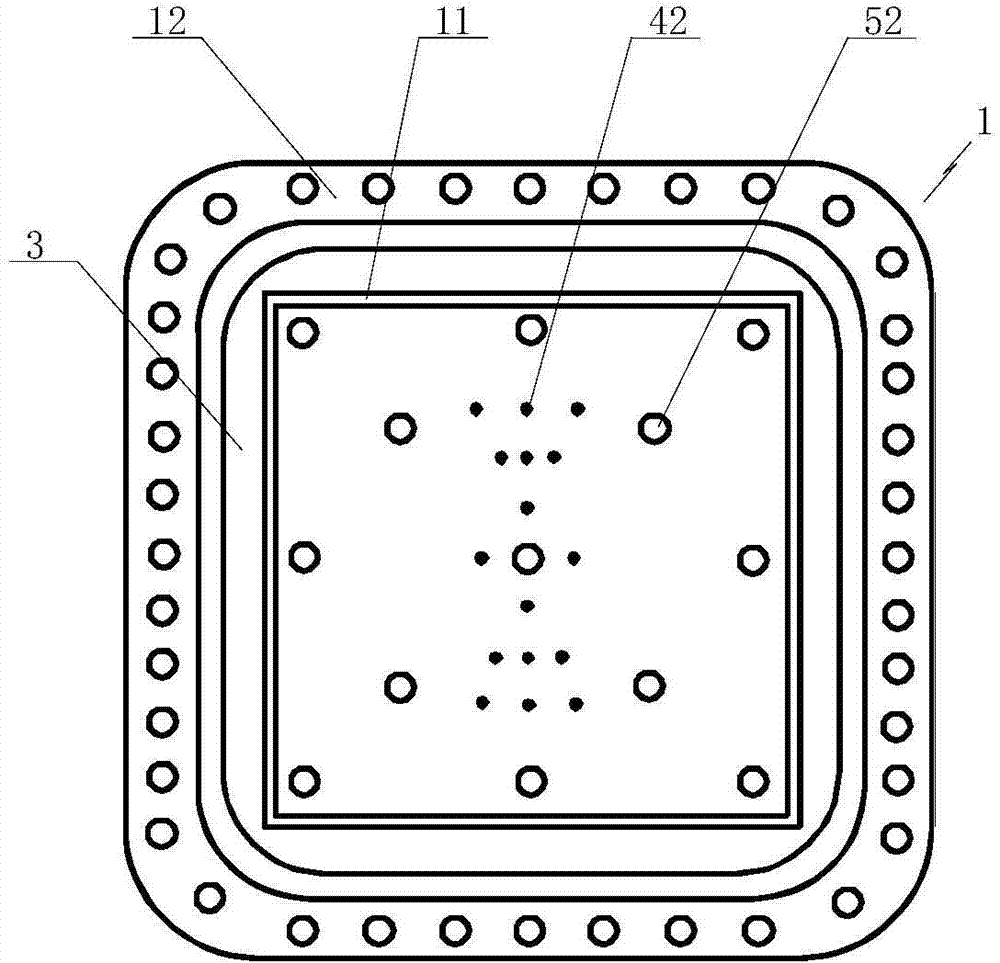

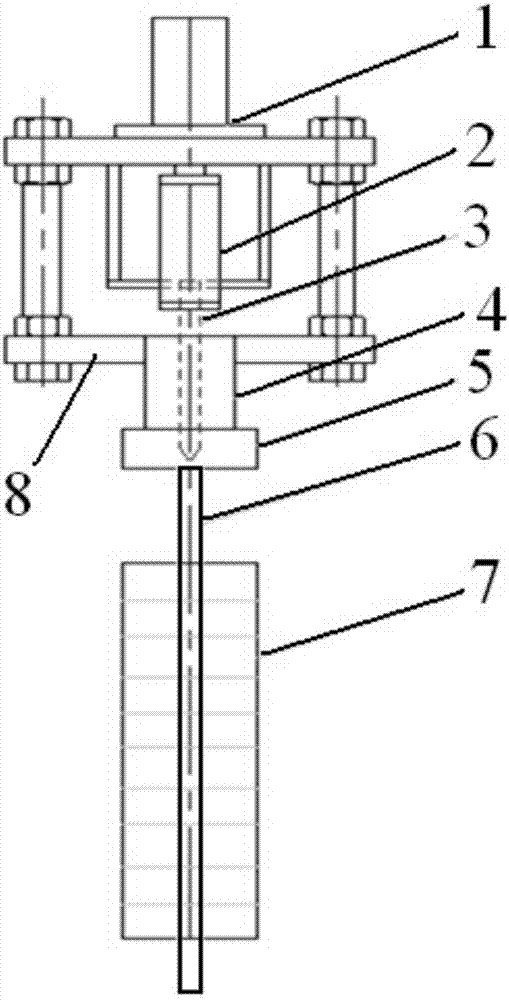

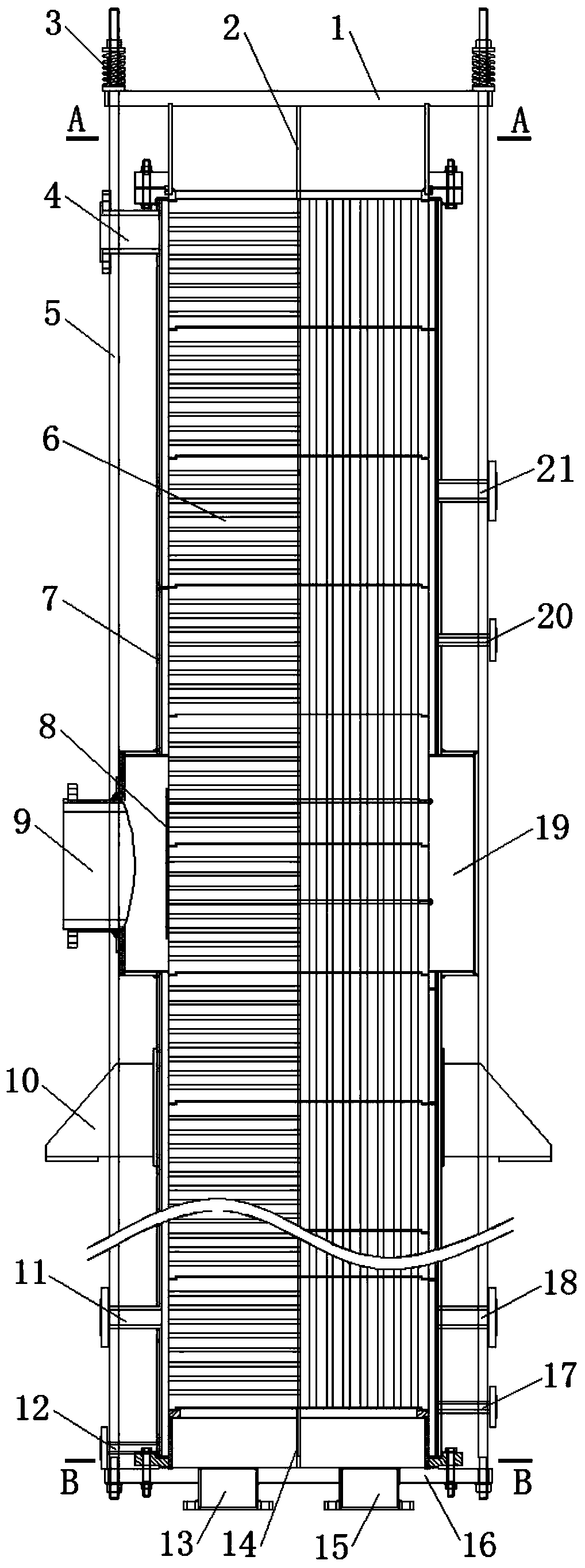

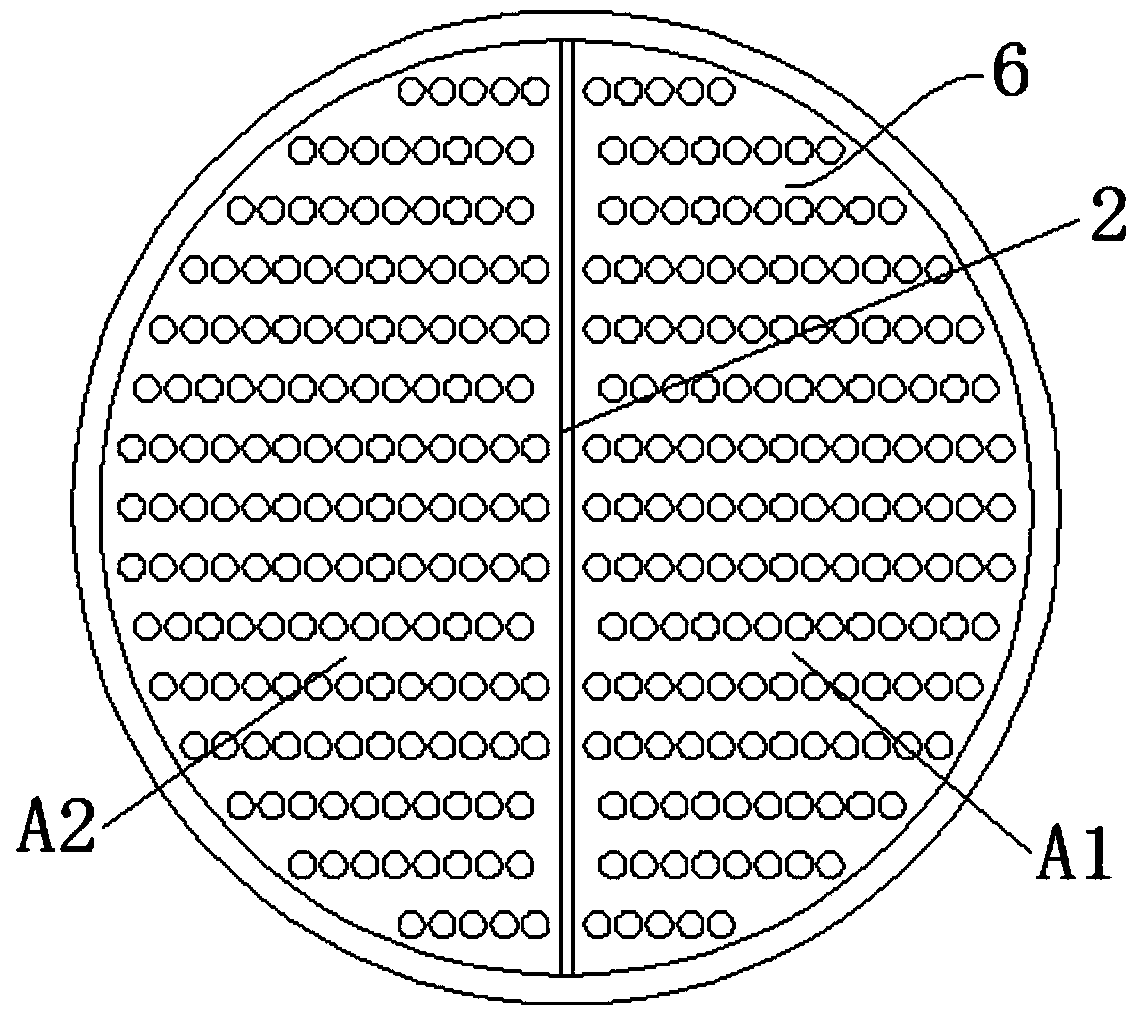

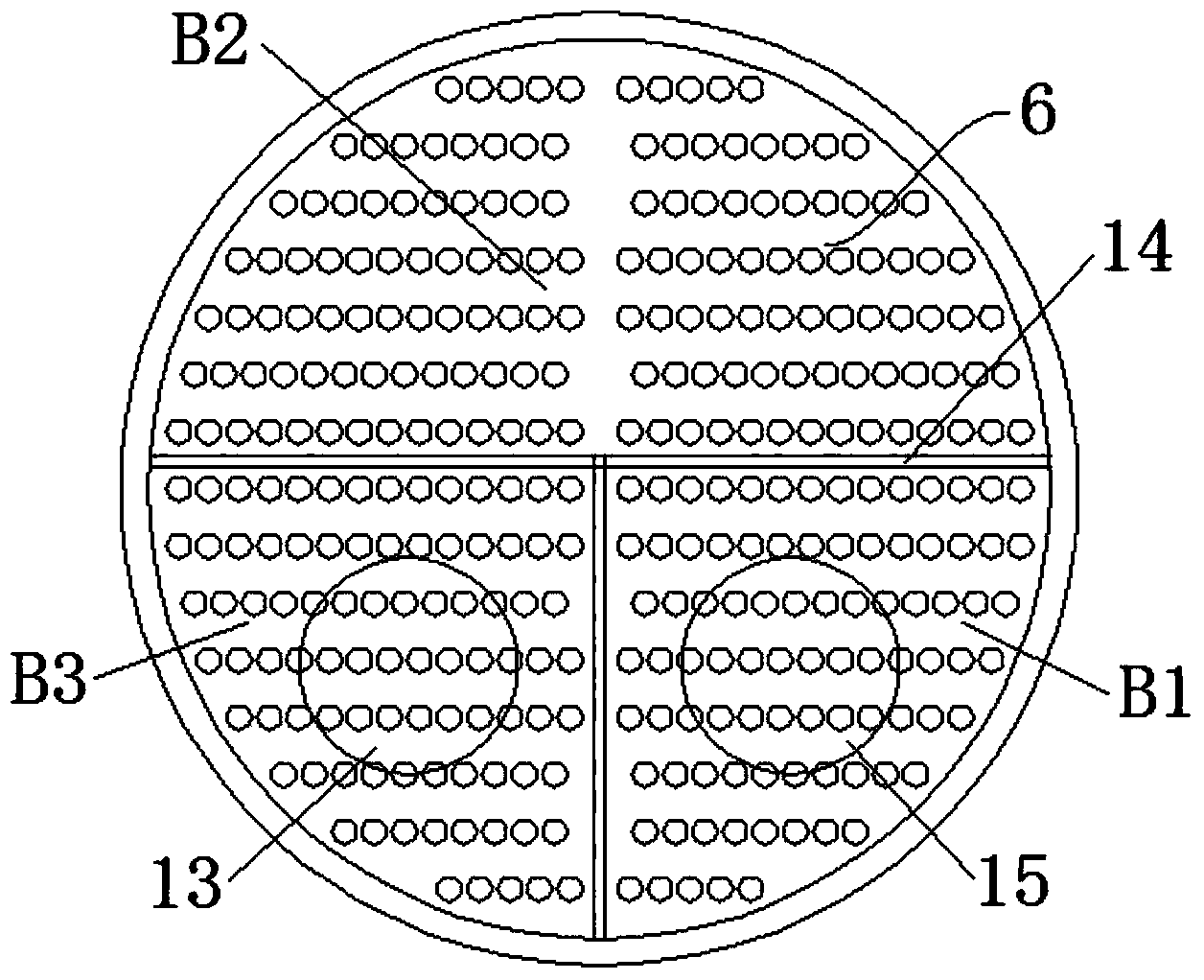

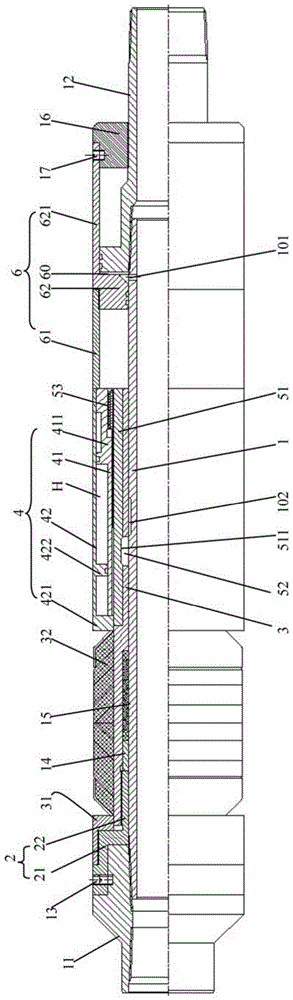

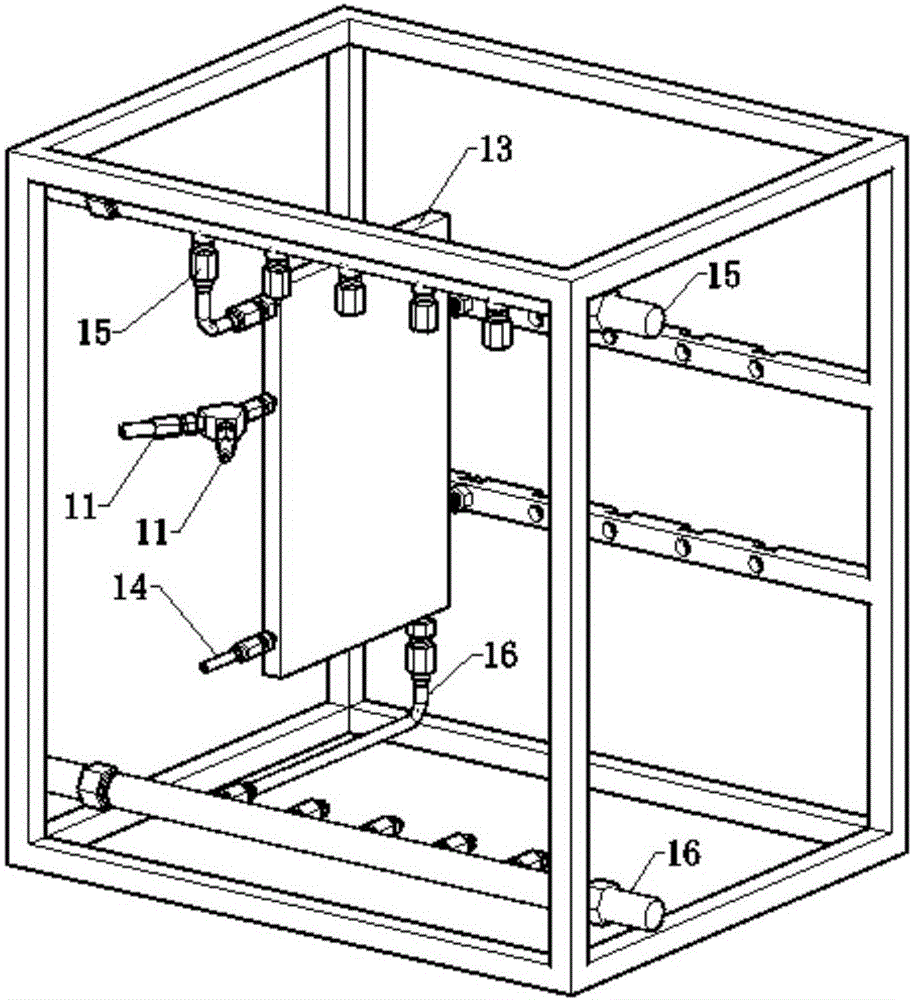

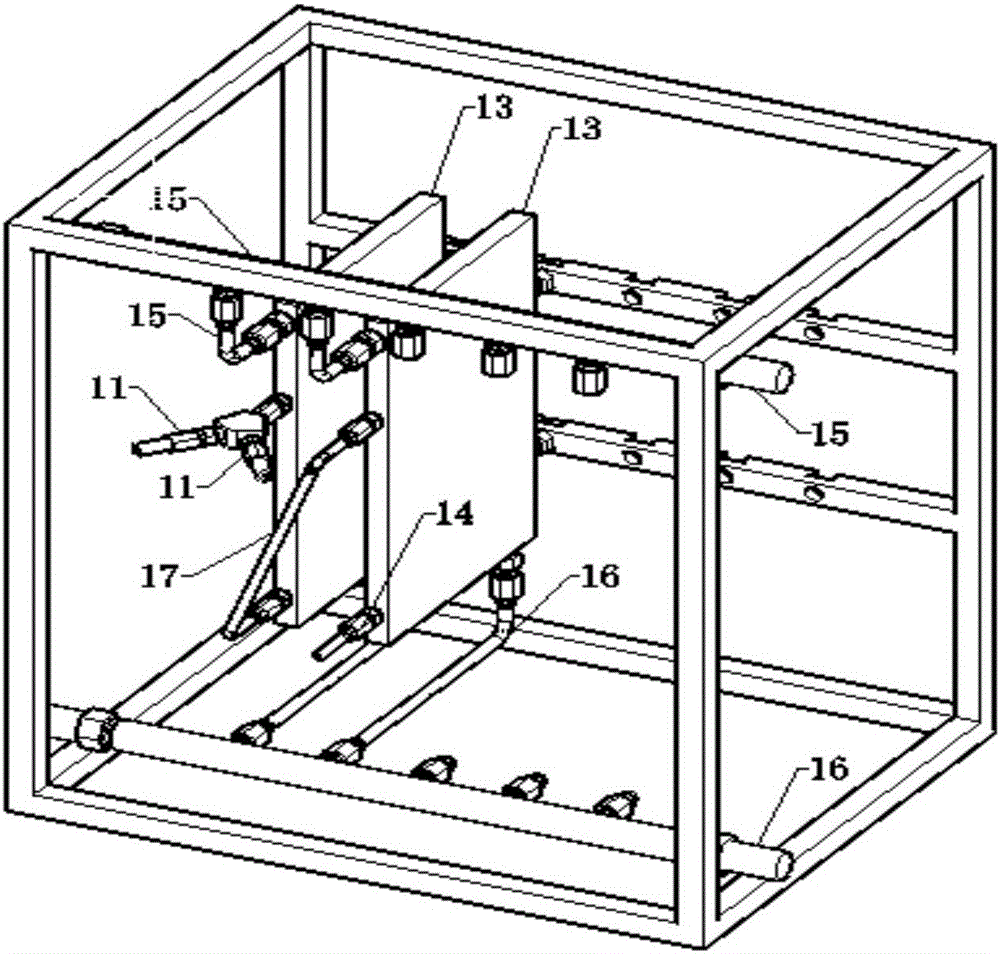

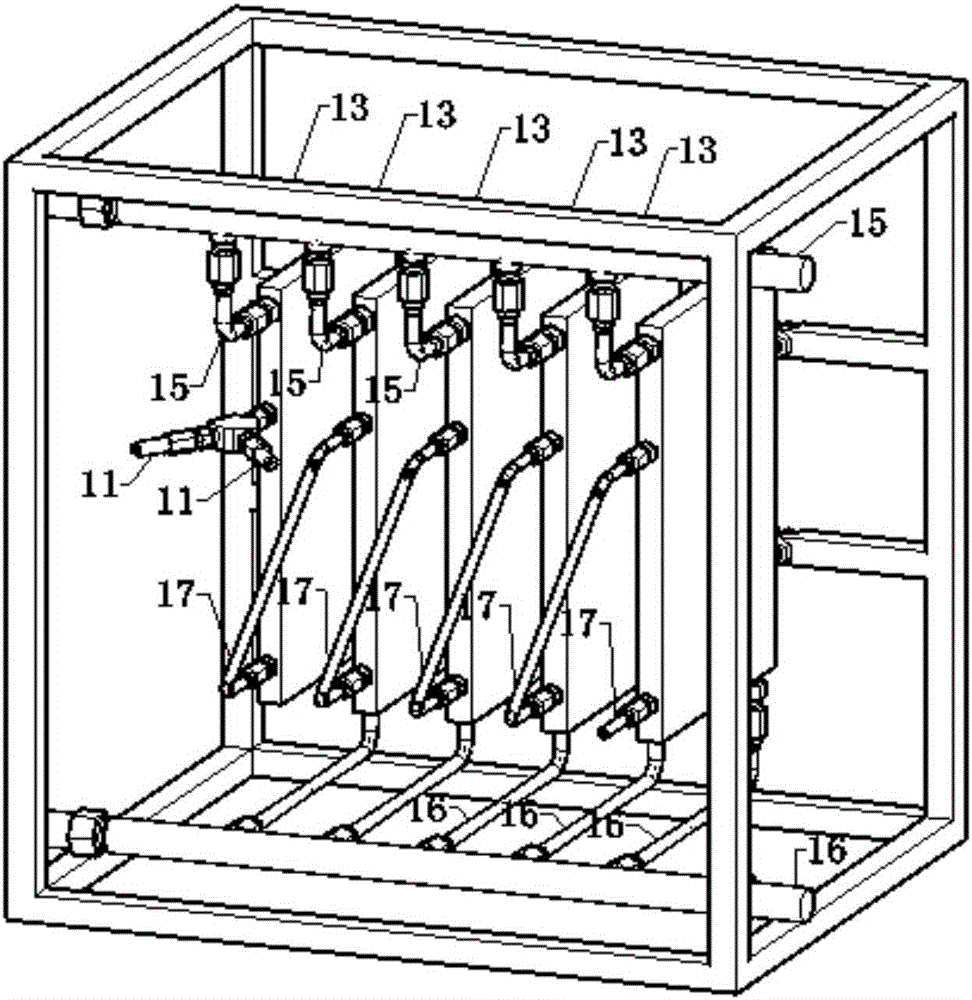

Multifunctional three-dimensional physical simulation experimental apparatus for thermal recovery by steam injection

ActiveCN104500013AImprove temperature and pressure resistanceAchieve storageFluid removalTemperature controlReservoir type

The invention relates to a multifunctional three-dimensional physical simulation experimental apparatus for thermal recovery by steam injection. The apparatus comprises a three-dimensional model body, a temperature control box, an injection and recovery device, an energy storage and buffer device and a data collector; the three-dimensional model body comprises an inner chamber and an outer chamber connected in a sleeving manner; an annulus is provided between the inner chamber and the outer chamber; the annulus is used as part of energy buffering so as to better accumulate and release energy during steam huff and puff; a perforation combination of the three-dimensional model body allows simulation of different well types, reservoir types and injection fluid combinations; the three-dimensional model body is moved into the temperature control box, simulation study on development manners and development mechanisms under different reservoir temperatures is achieved by changing the interior temperature of the temperature control box; the apparatus is suitable for the physical simulation of the heat injection development of heavy oil reservoirs with bottom water; experimental conditions are provided for the study on different injection fluids, well pattern types and development modes.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

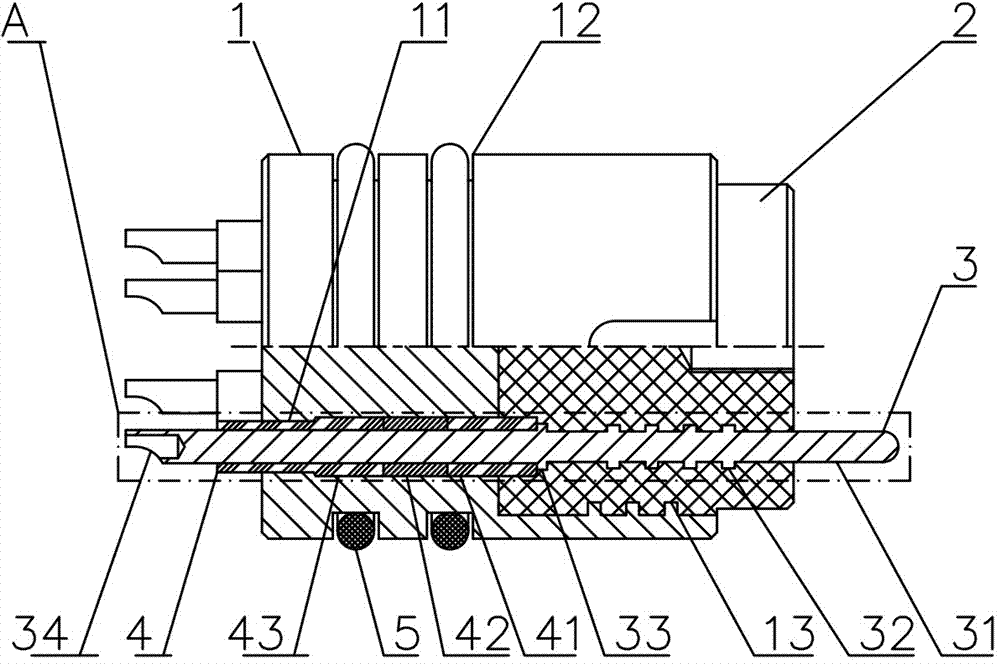

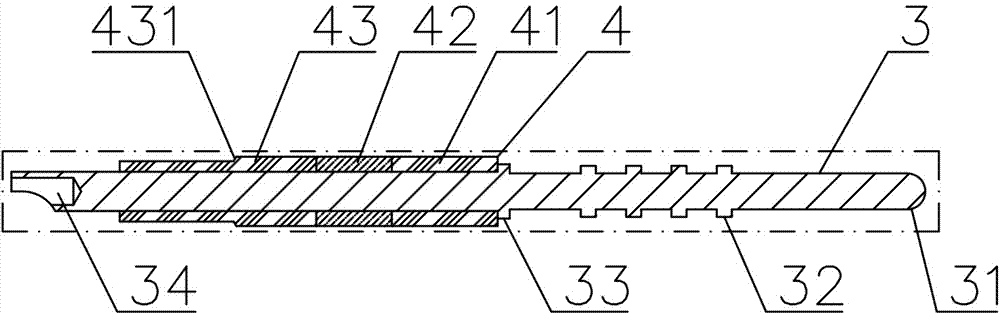

Electric connector with temperature-resistant voltage-bearing structure

InactiveCN104852205ASimple structureImprove sealingSecuring/insulating coupling contact membersCouplings bases/casesElectricityElectrical conductor

The invention discloses an electric connector with a temperature-resistant voltage-bearing structure, and the electric connector comprises a metal housing, a plastic housing, a conductor contact piece, an insulator, and a sealing ring. The metal housing is provided with a stepped hole, and the plastic housing is disposed in the metal housing and formed through injection molding of engineering plastics. The conductor contact piece and the insulator are disposed in the stepped hole of the metal housing and in the plastic housing. According to the invention, the conductor contact piece is disposed in the metal housing, the plastic housing and the insulator, and enables a working environment to be completely isolated at a state of electric signal conduction. Moreover, the electric connector can achieve unidirectional voltage bearing, is simple in structure, is reliable in sealing, is good in temperature-resistant voltage-bearing performances, and is long in service life.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

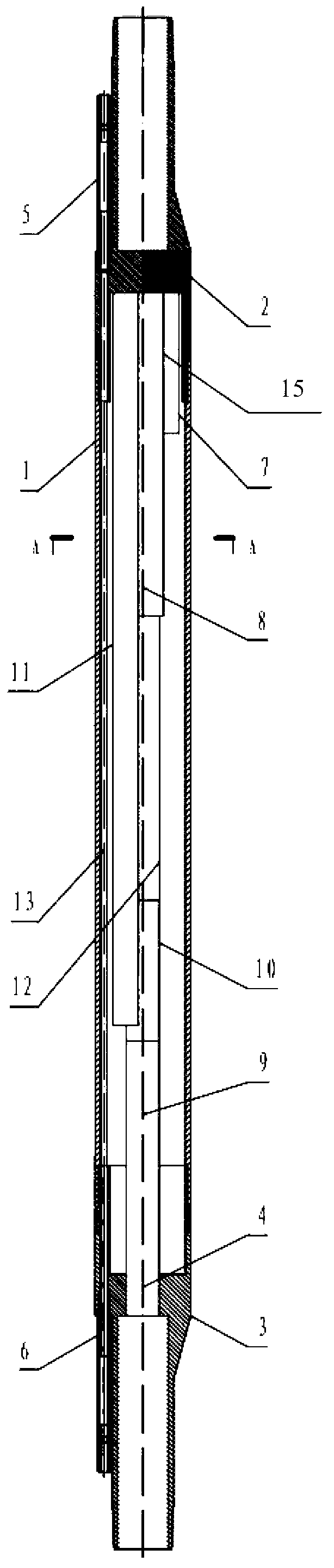

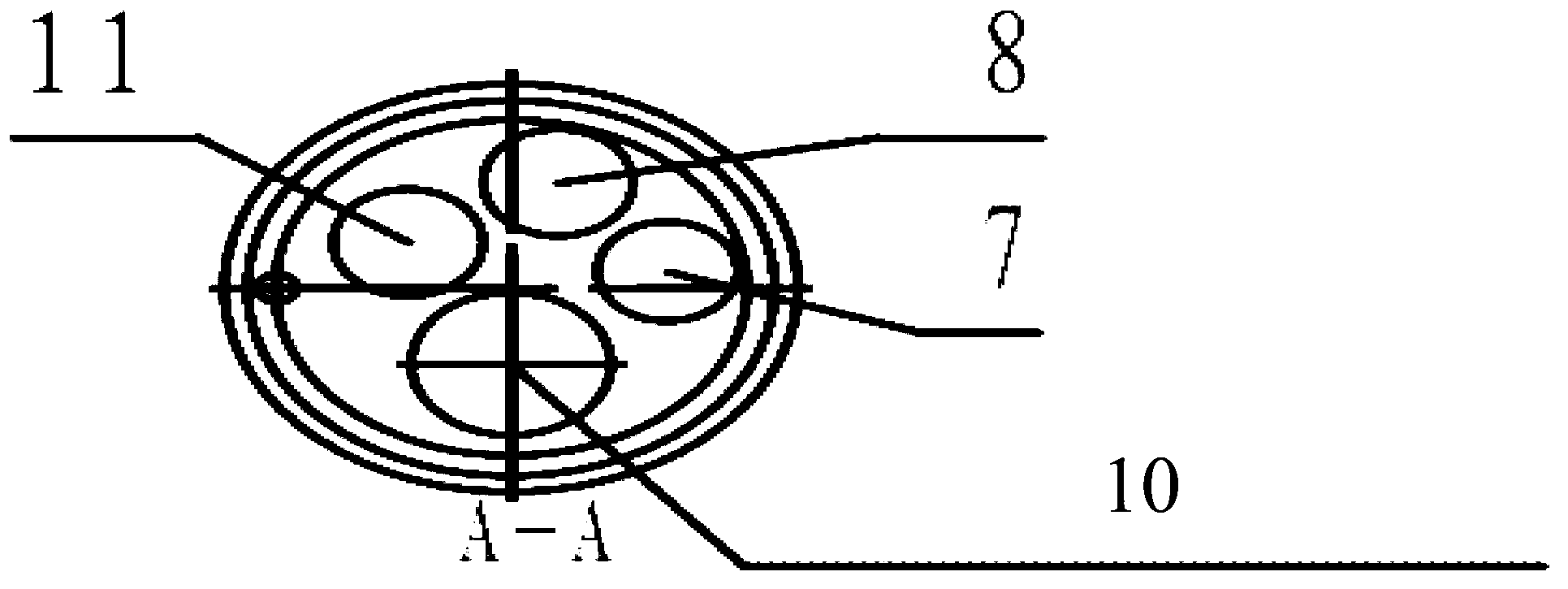

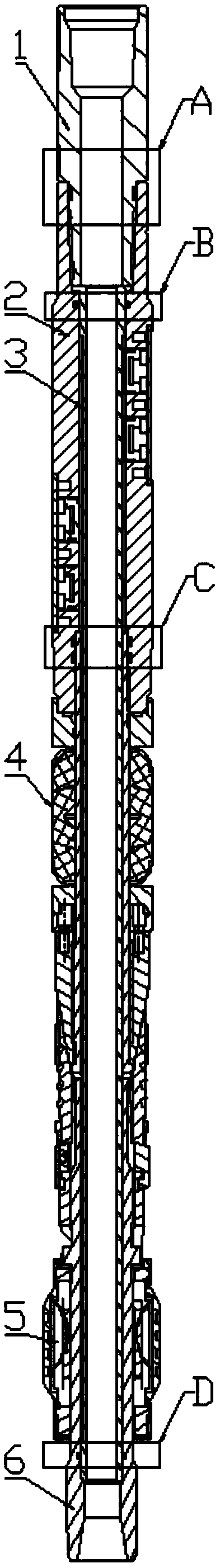

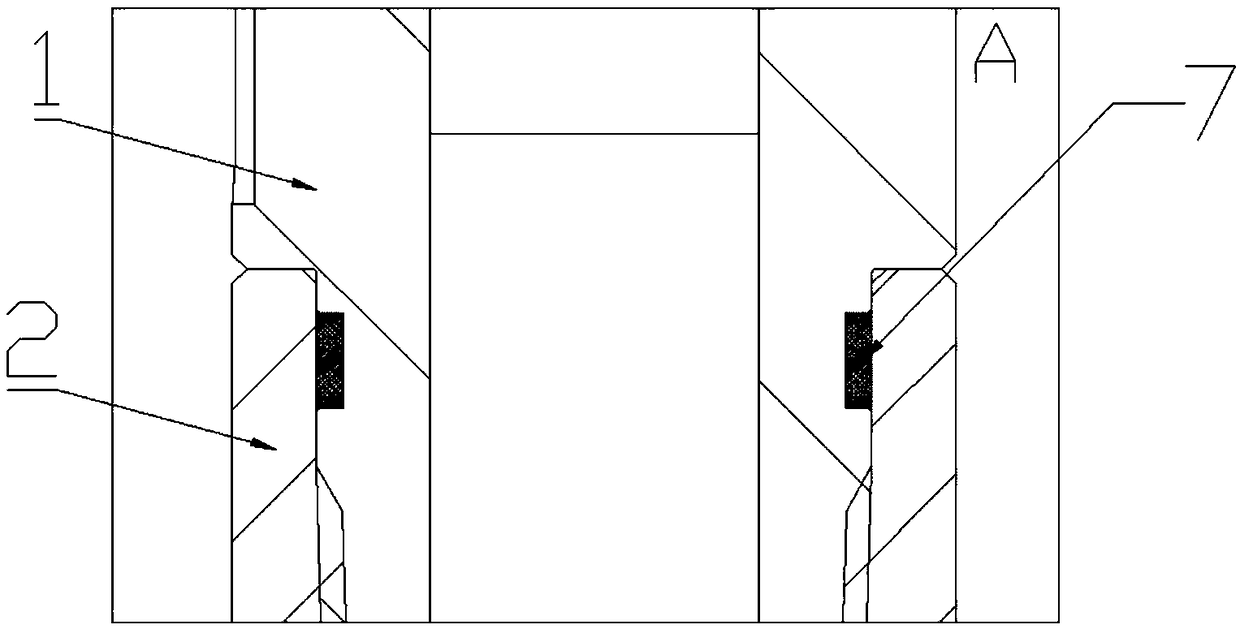

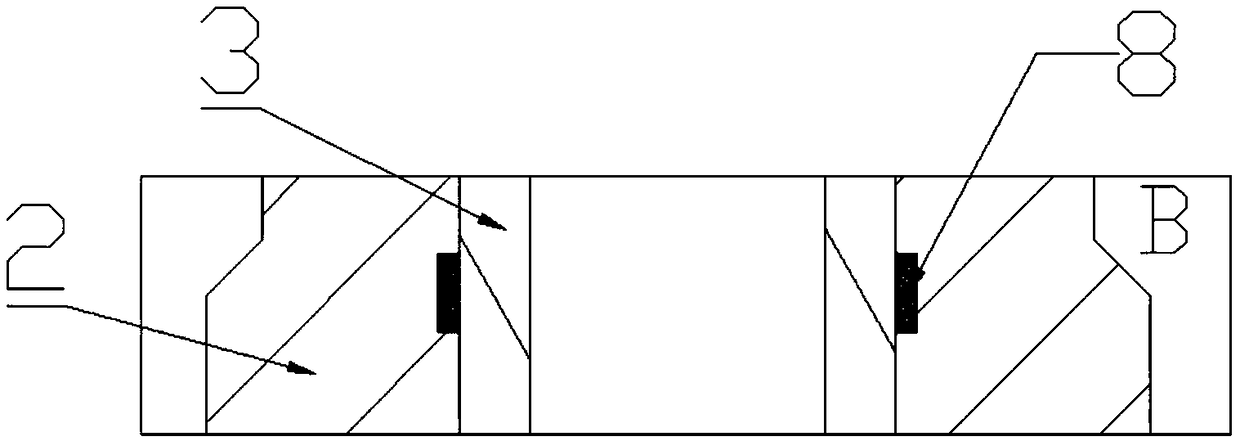

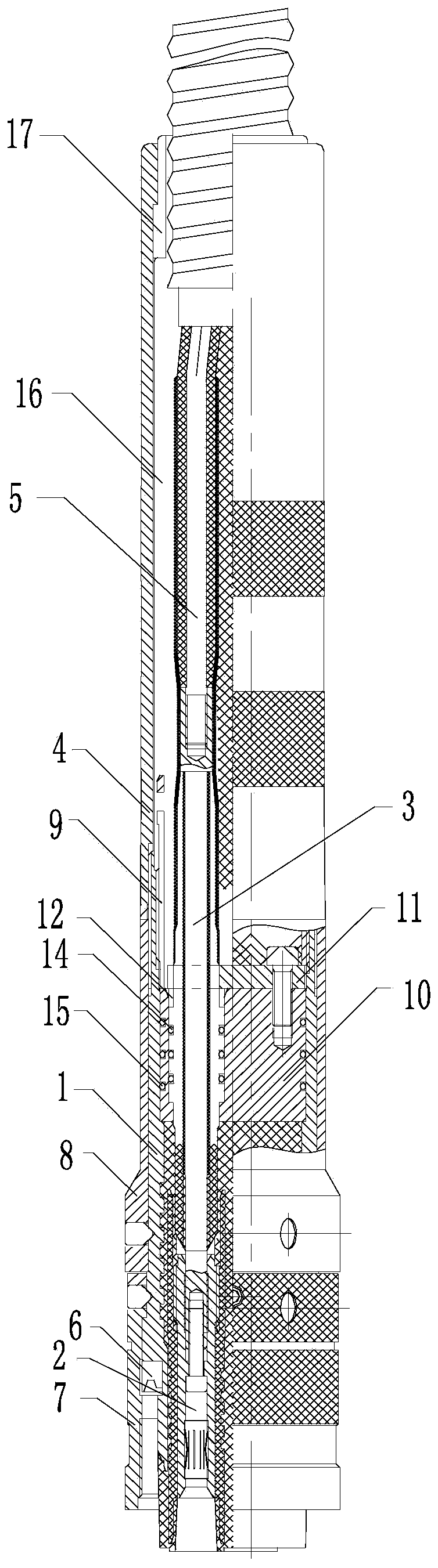

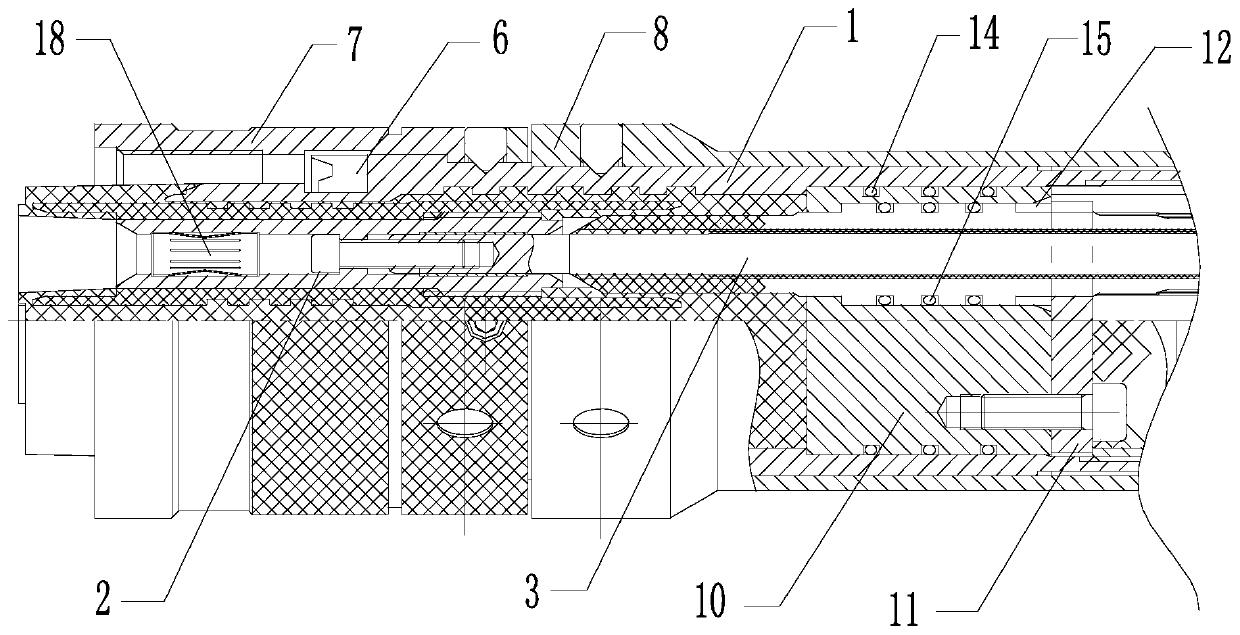

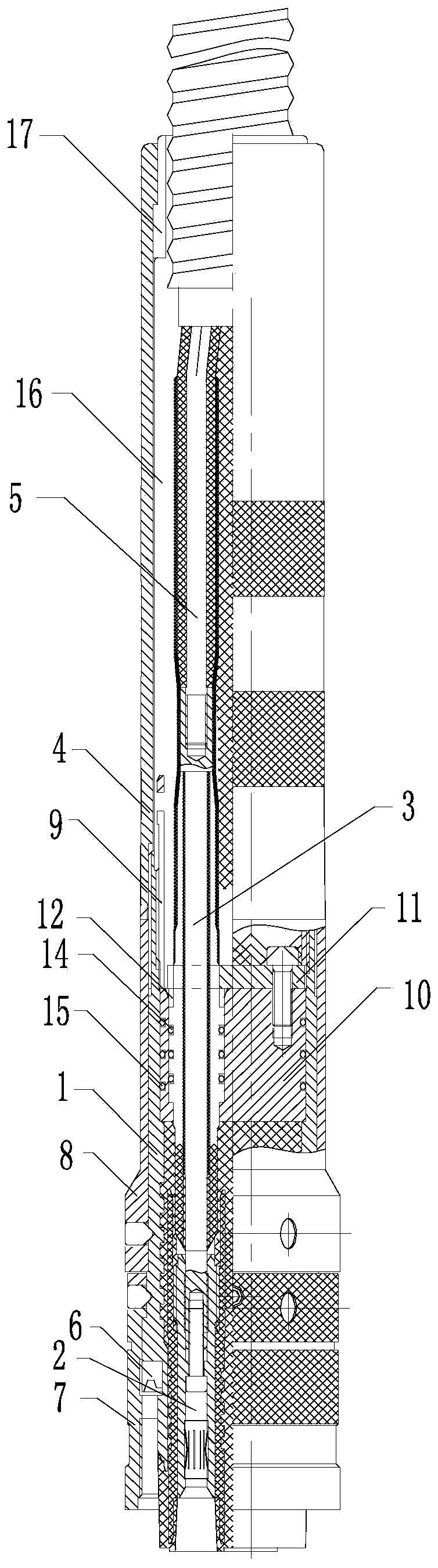

Control device for underground layered flow rate of water injection well

ActiveCN103075136AReal-time monitoring of downhole parameters of water injection wellsWith remote control functionFluid removalElectricityControl signal

The invention discloses a control device for the underground layered flow rate of a water injection well. The lower end of a tubular controller main body is provided with an executing mechanism, a flow passing passage and a cable are penetrated inside the tubular controller main body, the tubular controller main body is connected with a flow rate meter and a test control unit, the executing mechanism is connected with an electric adjustable water nozzle, a liquid inlet connected with the electric adjustable water nozzle is arranged in the flow passing passage, a liquid outlet connected with the electric adjustable water nozzle is arranged on the tubular controller main body, the flow rate meter and the executing mechanism are respectively and electrically connected with the test control unit, the flow rate meter obtains the layered water quantity in real time and transmits the results to the test control unit, when the layered water quantity is not in the preset water quantity range, the test control unit sends control signals to the executing mechanism, and the executing mechanism receives the control signals and regulates the water inlet quantity or the water outlet quantity of the electric adjustable water nozzle. The real-time monitoring on the underground parameters of the water injection well is realized, in addition, the injection quantity is regulated through the executing mechanism, the control device realizes the checking and sealing on a packer through the installation of a checking and sealing pressure meter, and the remote operation and control function is realized.

Owner:CNOOC ENERGY TECH & SERVICES

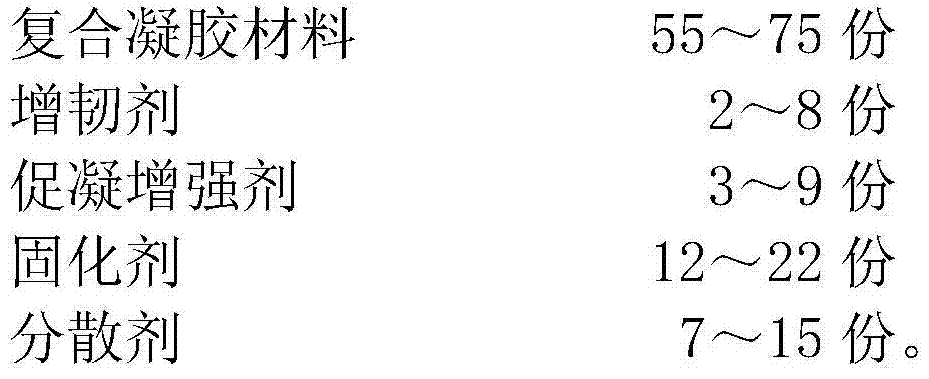

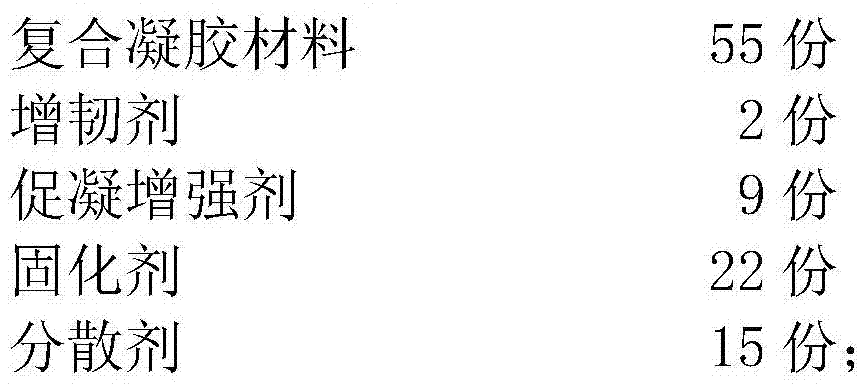

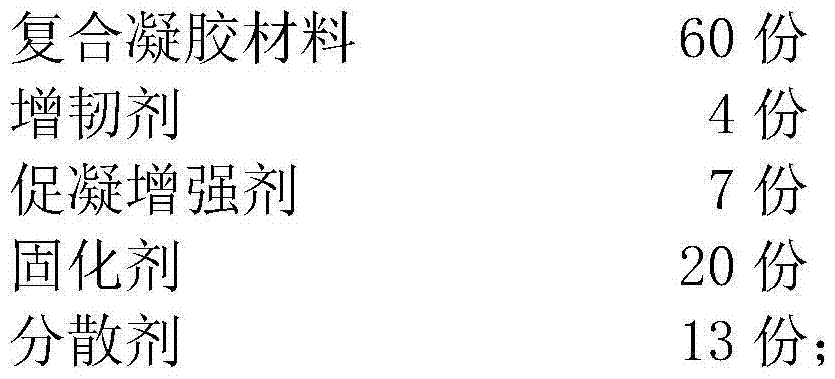

Compound plugging agent

ActiveCN104987017AWide temperature rangeImprove temperature and pressure resistanceMaterials scienceRaw material

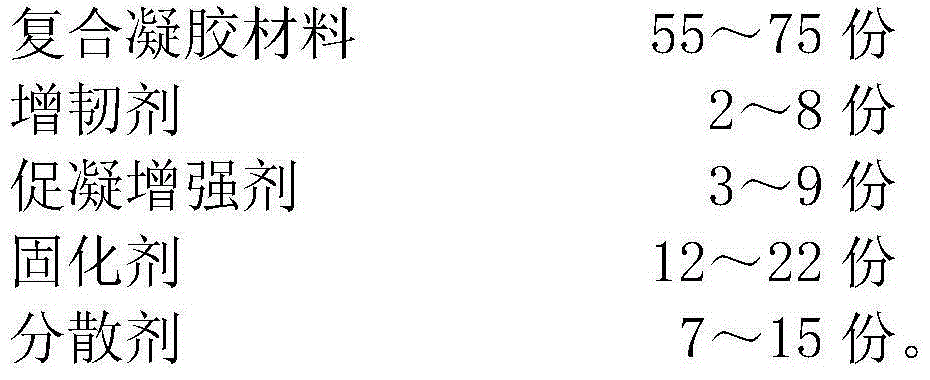

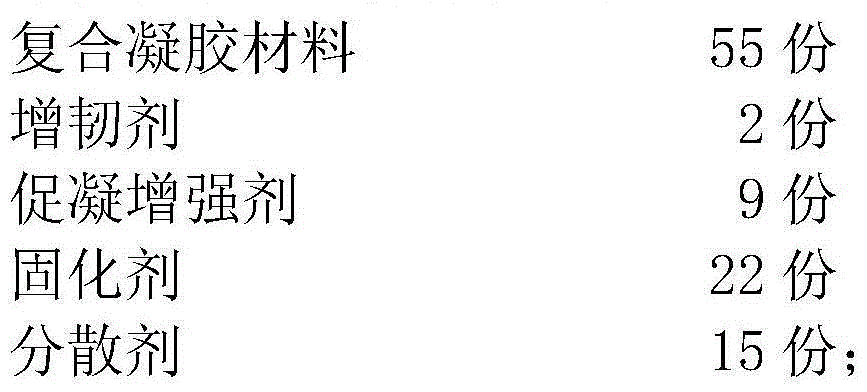

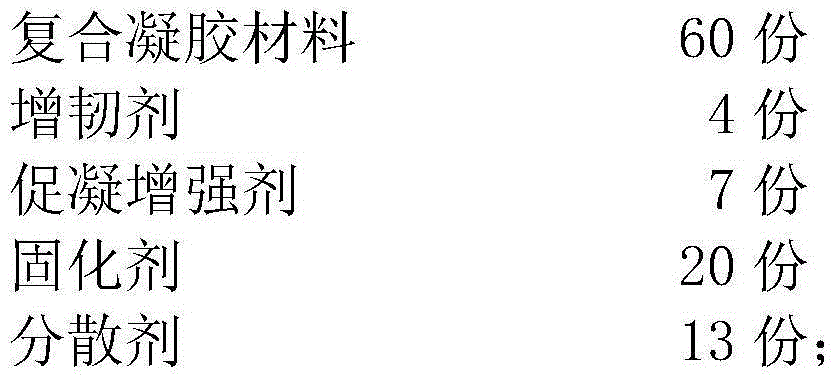

The invention relates to the technical field of building materials, in particular to a compound plugging agent, which is prepared from the following raw materials in parts by weight: 55 to 75 parts of composite gel material, 2 to 8 parts of flexibilizer, 3 to 9 parts of coagulating enhancer, 12 to 22 parts of curing agent and 7 to 5 parts of dispersant. The compound plugging agent provided by the invention has rigidness and flexibility, has the effects of transforming and filling, simultaneously, has the effects of bridging and transforming and filling, the use amount of plugging materials is greatly reduced and the cost is lowered.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Automatic production method of polytetrafluoroethylene (PTFE) dispersion resin

InactiveCN103213270AGood temperature and pressure resistanceImprove uniformityManufacturing technologyAutomatic control

The invention relates to fluorine plastic manufacturing techniques and discloses an automatic production method of polytetrafluoroethylene (PTFE) dispersion resin. The automatic production method of the PTFE dispersion resin comprises the steps of PTFE raw material mixing, preforming, extrusion forming, speed and location tracking of extrudate, signal feedback for controlling an extruder, sintering forming, quenching treatment, position measurement and feedback control of rolling parts, forming and rolling. According to the invention, the PTFE dispersion resin producing technology is improved through introducing an automatic control system, so that the method for continuously, uniformly and stably producing the PTFE dispersion resin is provided.

Owner:天津市天塑科技集团有限公司技术中心

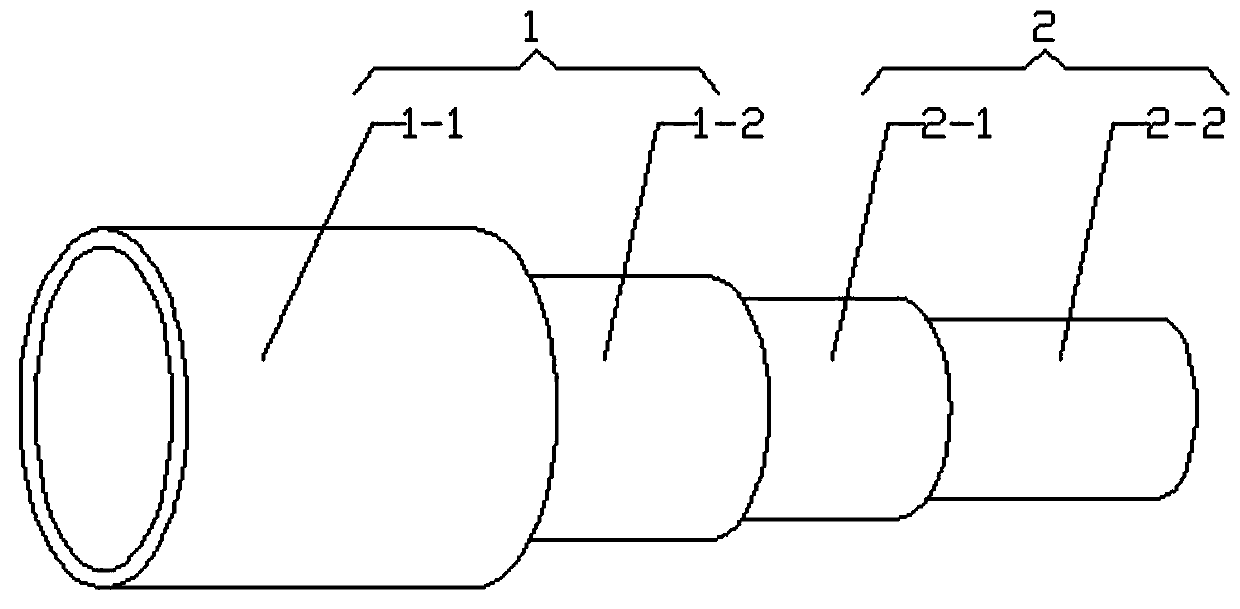

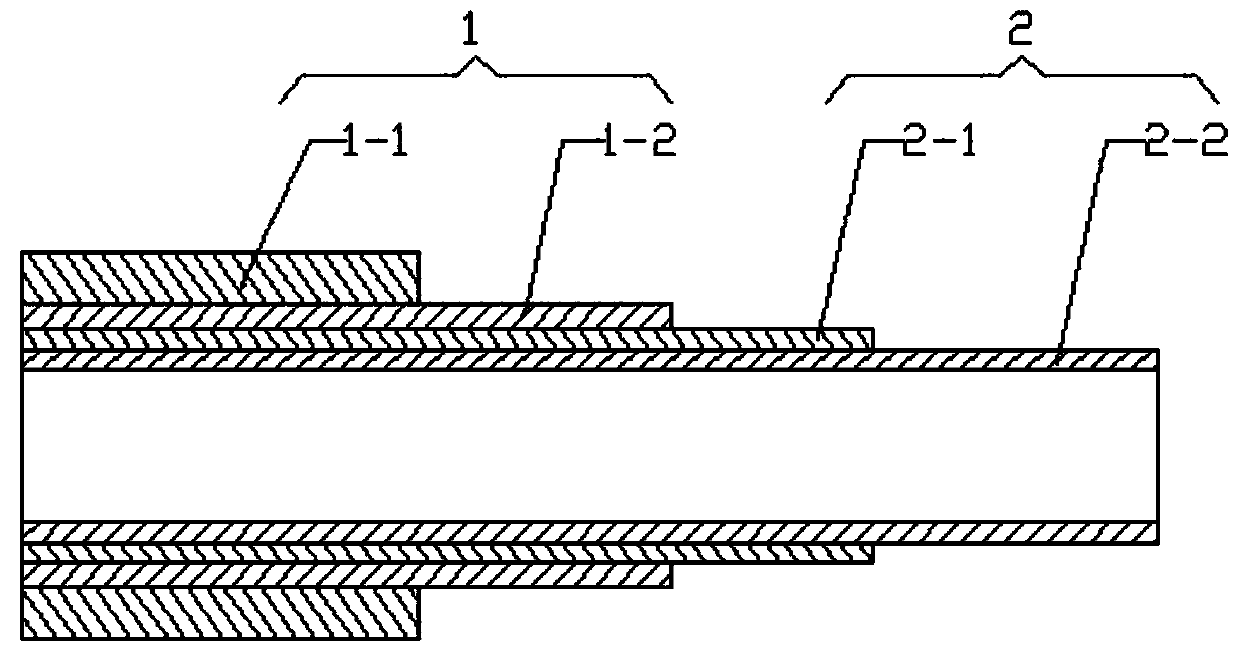

Preparation method of ultralong thin-walled pressure- and heat-resistant polytetrafluoroethylene dispersion resin heat exchange tube

InactiveCN102825792AGood temperature and pressure resistanceImprove uniformityTubular articlesManufacturing technologyPolymer chemistry

The invention relates to fluoroplastic manufacturing technology, in particular to an ultralong thin-walled pressure and heat-resistant polytetrafluoroethylene (PTFE) dispersion resin heat exchange tube. The ultralong thin-walled pressure and heat-resistant polytetrafluoroethylene (PTFE) dispersion resin heat exchange tube is prepared from polytetrafluoroethylene (PTFE) dispersion resin by means of material mixing, aging and infiltrating, pre-press forming, extruding forming, drying to remove oil, high temperature sintering, quenching treatment and finished product reeling. According to the invention, the material formula and the production technology of the ultralong thin-walled pressure and heat-resistant polytetrafluoroethylene (PTFE) dispersion resin heat exchange tube are improved, so that a continuous, uniform and stable method for producing the ultralong thin-walled pressure and heat-resistant polytetrafluoroethylene (PTFE) dispersion resin heat exchange tube is provided.

Owner:天津市天塑科技集团有限公司技术中心

Extrusion preparation method and extrusion equipment for extra-large-orifice PTFE pipe fitting paste

The invention discloses an extrusion preparation method for extra-large-orifice PTFE pipe fitting paste. The extrusion preparation method comprises the following steps of: mixing raw materials; pre-forming the raw materials; extruding and forming the raw materials; tracing extrusion speed and a position of an extruded pipe fitting, controlling an extruder through a feedback signal; sintering and forming; performing position measuring and feedback control on the position of a sintered extra-large-orifice PTFE pipe fitting product; and enabling polytetrafluoroethylene dispersion resin tube to form a product. The invention further discloses extrusion equipment for extra-large-orifice PTFE pipe fitting paste. The extrusion equipment comprises an extrusion drive part, a pushing-pressing assembly, a mandrel assembly, a raw material barrel, an extrusion mould and a thermal forming assembly which are sequentially connected coaxially, wherein the extrusion drive part is mounted on the tail part of the rack; one end of the pushing-pressing assembly is connected with the extrusion drive part; the other end of the pushing-pressing assembly is connected with one end of the mandrel assembly; the raw material barrel is mounted on the front part of the rack; the extrusion mould is mounted at an outlet end of the raw material barrel; the mandrel assembly passes through the center of the raw material barrel and the center of the extrusion mould; and the thermal forming assembly is supported in front of the rack and is concentric with the raw material barrel.

Owner:JIANGNAN FLUOROPLASTIC

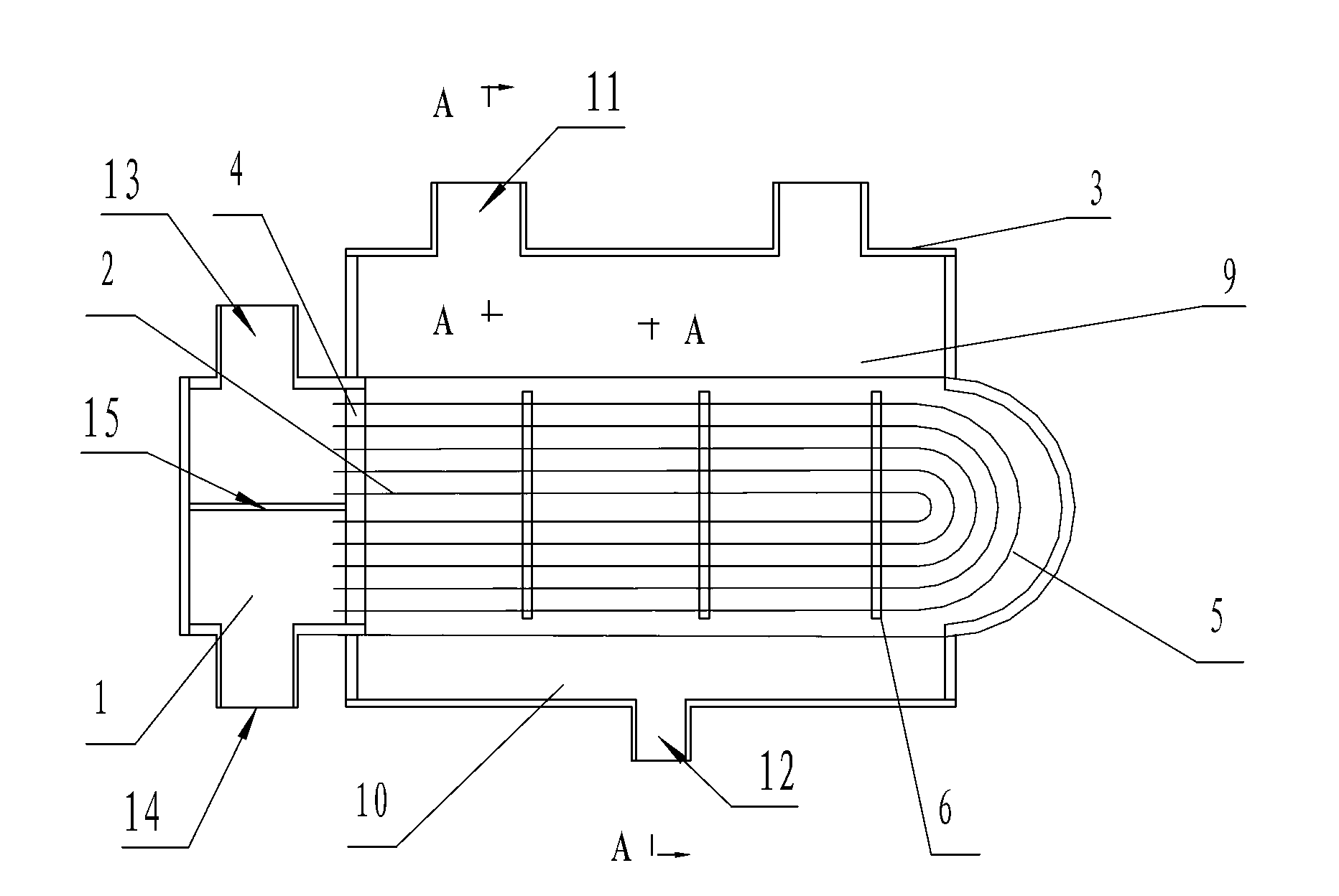

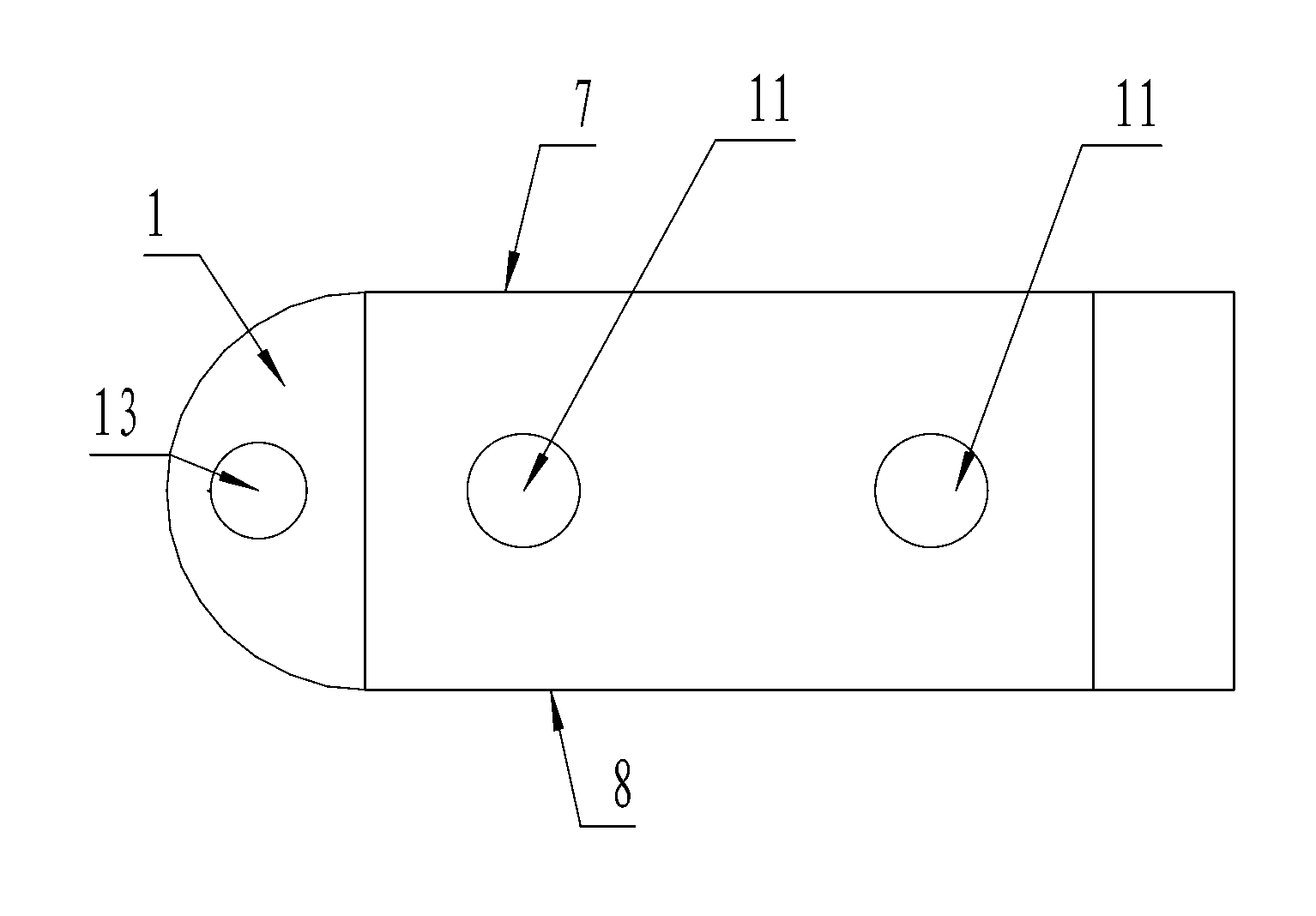

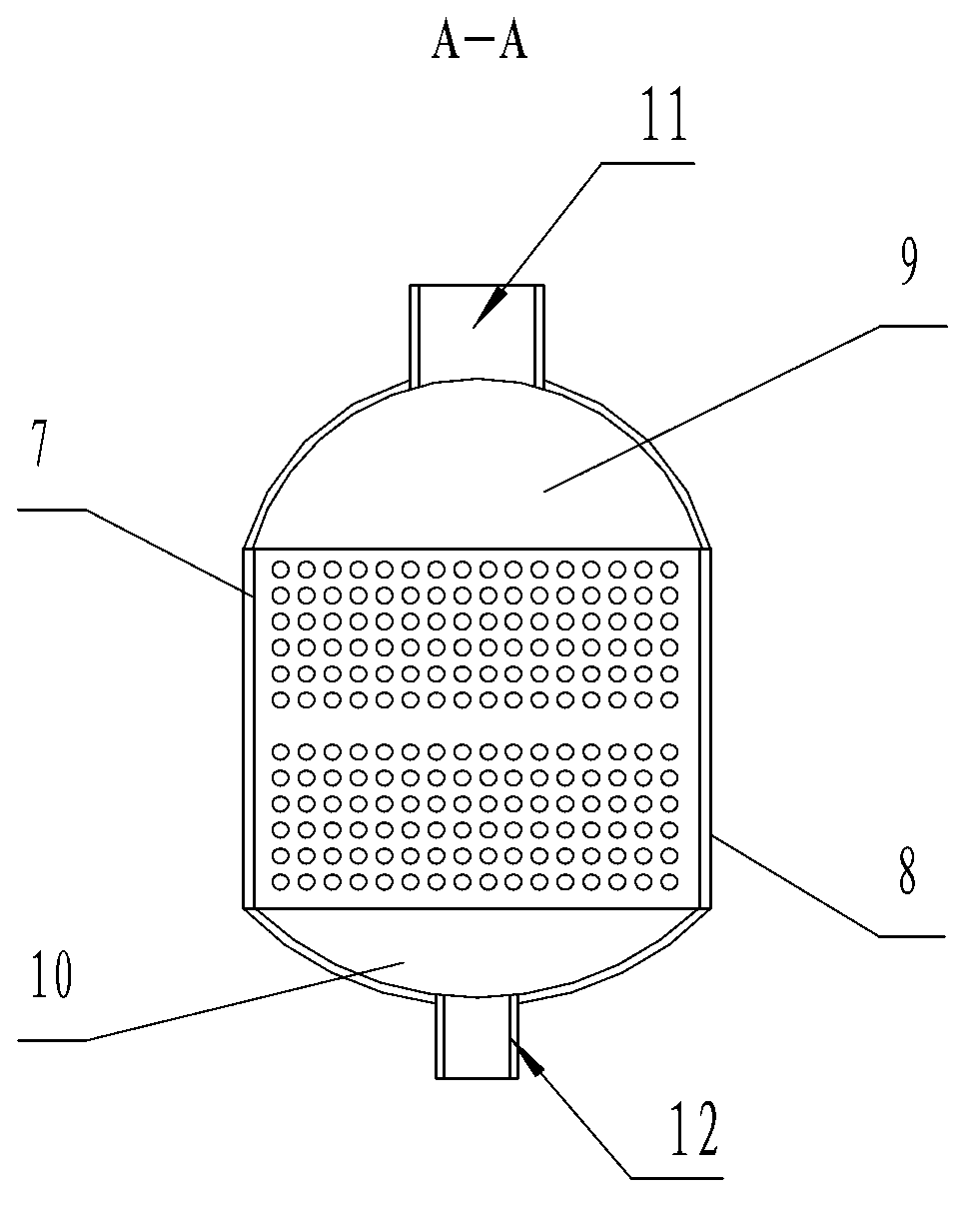

Rectangular fully welded U-shaped tube type heating network heater

InactiveCN103307911AAvoid direct impactReduce consumptionStationary tubular conduit assembliesEngineeringTubes types

The invention discloses a rectangular fully welded U-shaped tube type heating network heater, which belongs to heat transfer equipment, particularly to steam-water heat transfer equipment using U-shaped heat transfer tubes. The rectangular fully welded U-shaped tube type heating network heater comprises a heat transfer tube bundle formed by the U-shaped heat transfer tubes and mounted in a casing, and a tube box provided with a secondary heat medium inlet and a secondary heat medium outlet and mounted at one end of the casing, wherein the heat transfer tube bundle is formed by a rectangular tube plate, the U-shaped heat transfer tubes and rectangular support plates; the U-shaped heat transfer tubes sequentially penetrate at least two rectangular support plates and the rectangular tube plate and are in welding connection and expanded joint with the two types of plates; a semi-circular steam ingoing collection box with a steam inlet is welded above parallel side plates A and B of the casing, and a semi-circular water outgoing collection box with an outgoing water outlet is welded below the side plates A and B; the semicircular cylinder-shaped tube box with the secondary heat medium inlet and the secondary heat medium outlet is welded to the end of the casing, at which the rectangular tube plate is welded. Compared with the conventional U-shaped tube type heat transfer equipment, the fully welded structure is more reliable in sealing, stronger in temperature resistance and pressure resistance, and simpler in structure.

Owner:SHANDONG BEICHEN MECHANICAL & ELECTRICAL EQUIP

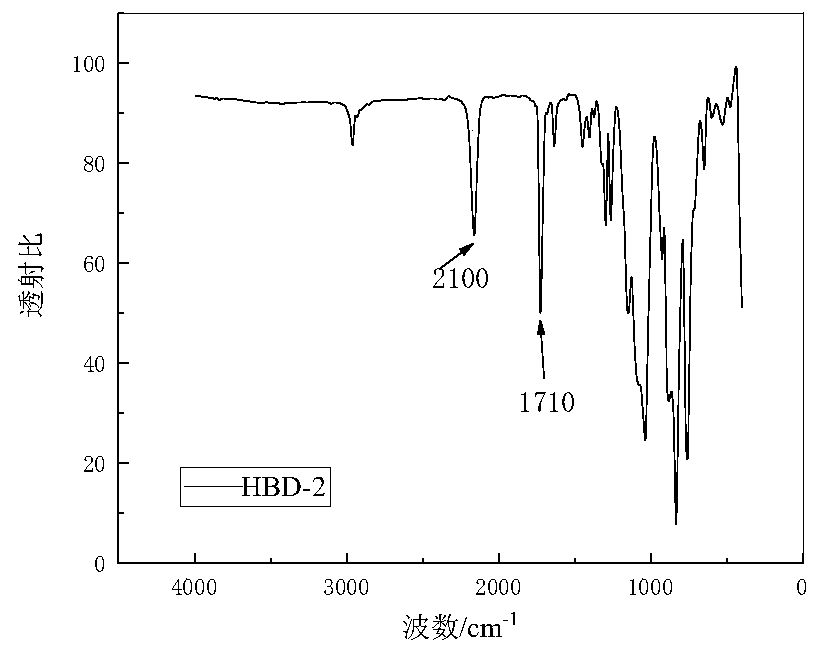

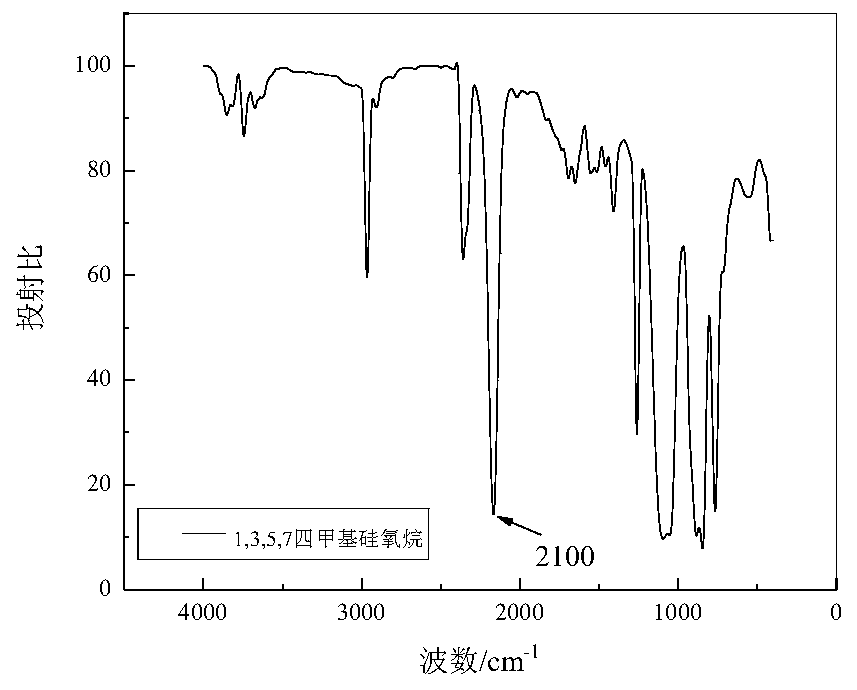

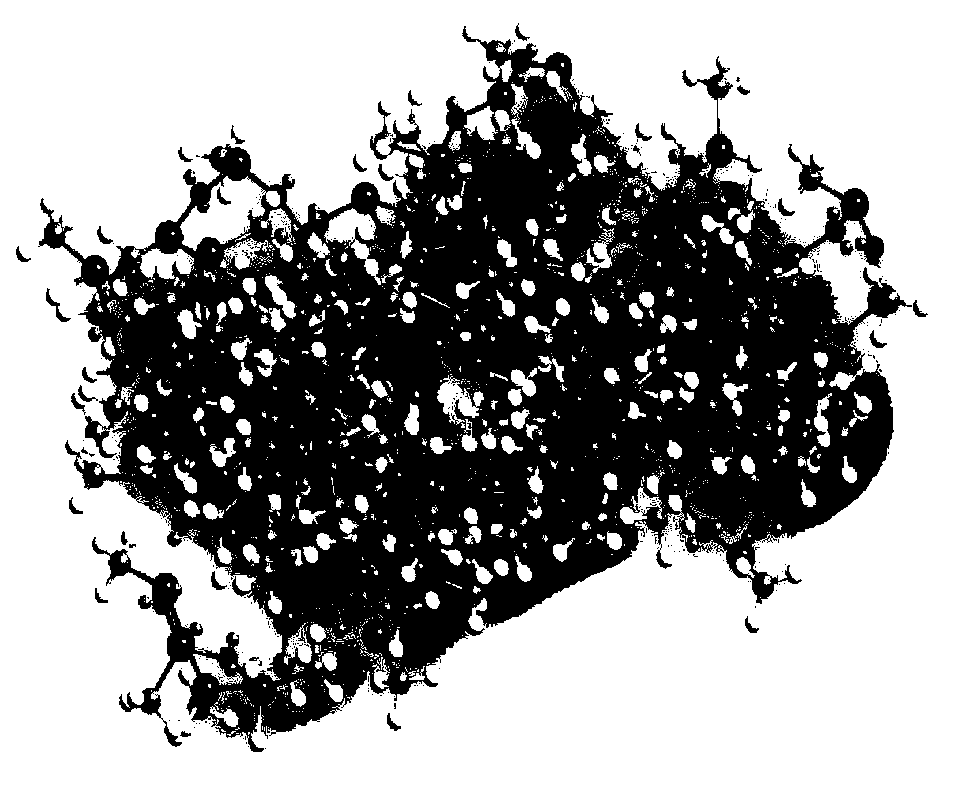

Preparation method of hyperbranched hydrosiloxane supercritical carbon dioxide thickener

ActiveCN110862543AGood viscosity increasing effectReduce dosageDrilling compositionBulk chemical productionPtru catalystTriethyleneglycol dimethacrylate

The invention relates to a preparation method of a hyperbranched hydrosiloxane supercritical carbon dioxide thickener. The method includes: in the presence of a catalyst, carrying out silicon-hydrogenreaction on triethylene glycol dimethacrylate and 1, 3, 5, 7-tetramethylcyclotetrasiloxane to generate a polymer. The hyperbranched hydrosiloxane polymer supercritical carbon dioxide thickener disclosed by the invention has good temperature resistance and pressure resistance, and can realize thickening performance under different temperature and pressure conditions, has good compatibility with various cosolvents, is non-toxic and safe to use, has small damage to the stratum, is small in dosage, and has good thickening effect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Round block hole type multi-path graphite heat exchanger

InactiveCN103837019AImprove heat transfer efficiencyReduce flow rateHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerGraphite

The invention discloses a round block hole type multi-path graphite heat exchanger and belongs to the technical field of heat exchangers. The round block hole type multi-path graphite heat exchanger comprises a shell, a graphite block arranged in the shell, a steam inlet formed in the middle of the shell, a condensed fluid outlet, a water outlet, a water inlet, an upper partition plate and a lower partition plate, wherein the condensed liquid outlet, the water outlet, the water inlet, the upper partition board and the lower partition board are arranged at the lower portion of the shell. The gap between the shell and the graphite block forms the shell pass of the graphite heat exchanger, and the steam inlet and the condensed outlet are communicated with the shell pass respectively. The upper partition is arranged at the upper end of the shell, and the tube pass of the upper end of the graphite heat exchanger is divided into a plurality of upper partition zones. The lower partition board is arranged at the lower end of the shell, and the tube pass of the lower end of the graphite heat exchanger is divided into a plurality of lower partition zones. The lower partition zones and the upper partition zones are connected in series to from a multi-path channel which is bent vertically. The initial end of the multi-path channel is a water inlet, and the tail end of the multi-path channel is a water outlet. The heat exchange efficiency and the durability of the graphite heat exchanger are improved, the service life of the graphite heat exchanger is prolonged, and the technical blank of the block hole type multi-path graphite heat exchanger is filled up.

Owner:常州泰特环境设备工程有限公司

Method for producing temp.-resistance, pressure-resistance oxide membrane aluminium wire and aluminium foil

The invention relates to a manufacturing method for heat-proof pressure-proof aluminum wire aluminum foil. The technology process is that: taking softening and cleaning process to the bare aluminum wire aluminum foil or aluminum band, taking continuously anode oxidation by 100-1000HZ 38V AC voltage at 2.6 + / -0.3m / min in electrolytic tank electrolyte; putting into the solution made up of water, vitriol and oxalic acid to form 0.02-0.04mm A1203 oxide film, washing and drying. The invention has thick aluminum film, good heat proof pressure proof ability, low cost, high efficiency, good safety, and has great application prospect.

Owner:毛根善

Layered steam driving packer with combination effect

ActiveCN105178906AImprove sealingGood construction success rateFluid removalSealing/packingUpper jointEngineering

The invention provides a layered steam driving packer with a combination effect. The layered steam driving packer with the combination effect comprises a central tube, an outer central tube and an expanding portion, wherein an upper joint and a lower joint are correspondingly connected to two ends of the central tube through outer threads; a pressure transferring hole is formed in a side wall of the central tube; the outer central tube sleeves the central tube; the upper end of the outer central tube can be connected with the outer side surface of the upper joint in a separating mode; an adjusting ring and a sealing rubber barrel sleeve the outer side of the outer central tube; the expanding portion comprises an expanding inner barrel; the expanding inner barrel sleeves the outer central tube; an expanding jacket sleeves the expanding inner barrel; a sealing cavity is formed between the expanding inner barrel and the expanding jacket and is filled with expanding liquid; the upper end of the expanding jacket is in contact with the lower end of a sealing rubber barrel; and a locking and retaining mechanism is arranged between the expanding inner barrel and the outer central tube. During liquid injection, a pushing portion which can push the expanding portion to move upwards sleeves the central tube, is adjacent to the lower side of the expanding portion, and is hermetically connected with the outer side surface of the lower joint, a sealing ring cavity is formed between the pushing portion and the outer side surface of the lower joint and is connected with the pressure transferring hole, and liquid can be injected into the sealing ring cavity.

Owner:PETROCHINA CO LTD

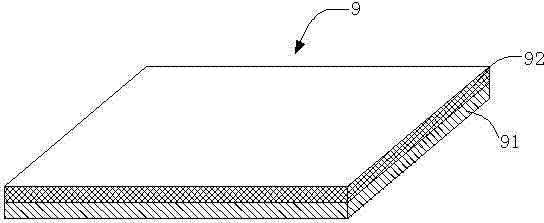

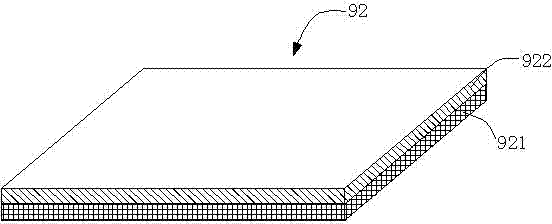

Filtering element capable of resisting high temperature and high pressure and manufacturing method of filtering element

ActiveCN102512879AReduce consumptionImprove temperature and pressure resistanceFiltration separationPolyethylene terephthalateEngineering

The invention relates to a filtering element capable of resisting high temperature and high pressure and a manufacturing method of the filtering element, in particular to a purifying filtering element applied to a high-precision electronic electroplating industry and other high-precision industries relating to high temperature and high pressure. The filtering element capable of resisting high temperature and high pressure consists of the following raw material components in parts by weight: 100 parts of polypropylene, 5-15 parts of polyethylene terephthalate, and 1-5 parts of maleic anhydride grafted polypropylene. The filtering element capable of resisting high temperature and high pressure, disclosed by the invention, has the advantages of good filtering efficiency, large filtering flux, stable quality and long service life.

Owner:HANGZHOU DEEFINE FILTRATION TECH

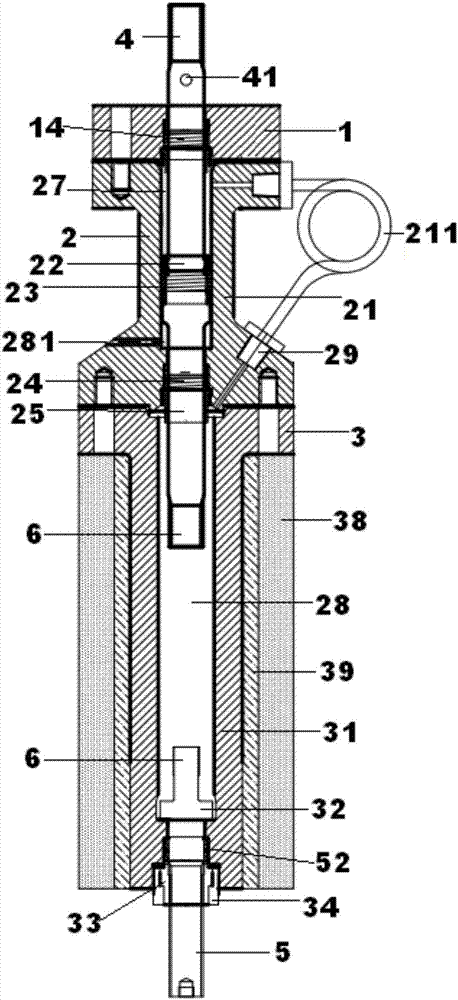

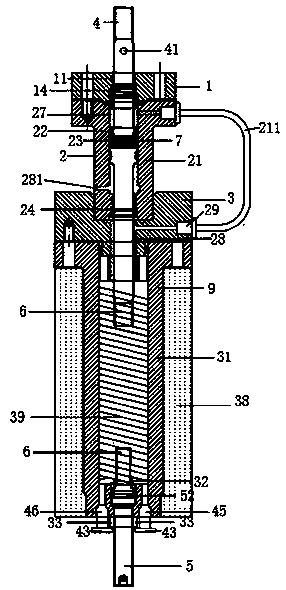

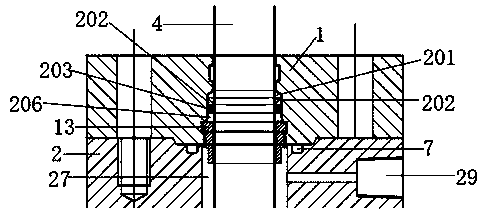

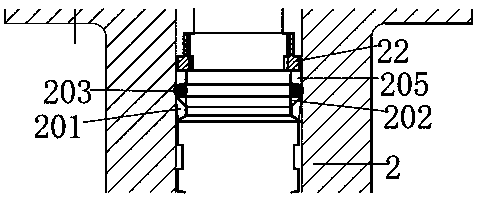

Portable high-temperature and high-pressure mechanical test device

ActiveCN107192619AReduce volumeReduce experiment costMaterial strength using tensile/compressive forcesHigh pressureMechanical engineering

The invention discloses a portable high-temperature and high-pressure mechanical test device. The portable high-temperature and high-pressure mechanical test device comprises a cover, an upper kettle body connected with the cover, a lower kettle body connected with the upper kettle body, an upper tension bar and a lower tension bar. The upper end of the upper tension bar is connected with a tension machine, the upper tension bar stretches into the cover, the upper kettle body and the lower kettle body, the upper portion of the lower tension bar stretches into the lower kettle body, and the opposite ends of the upper tension bar and the lower tension bar are provided with chucks. The upper kettle body comprises an upper cavity, an upper annular support piece, a first dynamic seal structure, a second dynamic seal structure and a lower annular support piece, wherein the upper cavity is provided with a first vertical through hole, the upper annular support piece and the first dynamic seal structure are arranged between the middle of the upper tension bar and the first vertical through hole in sequence from top to bottom, and the second dynamic seal structure and the lower annular support piece are arranged between the upper tension bar and the lower portion of the first vertical through hole in sequence from top to bottom. The portable high-temperature and high-pressure mechanical test device has the advantages of being convenient to disassemble and assemble, good in temperature-resistant and pressure-resistant effect and high in safety.

Owner:ZHEJIANG UNIV OF TECH

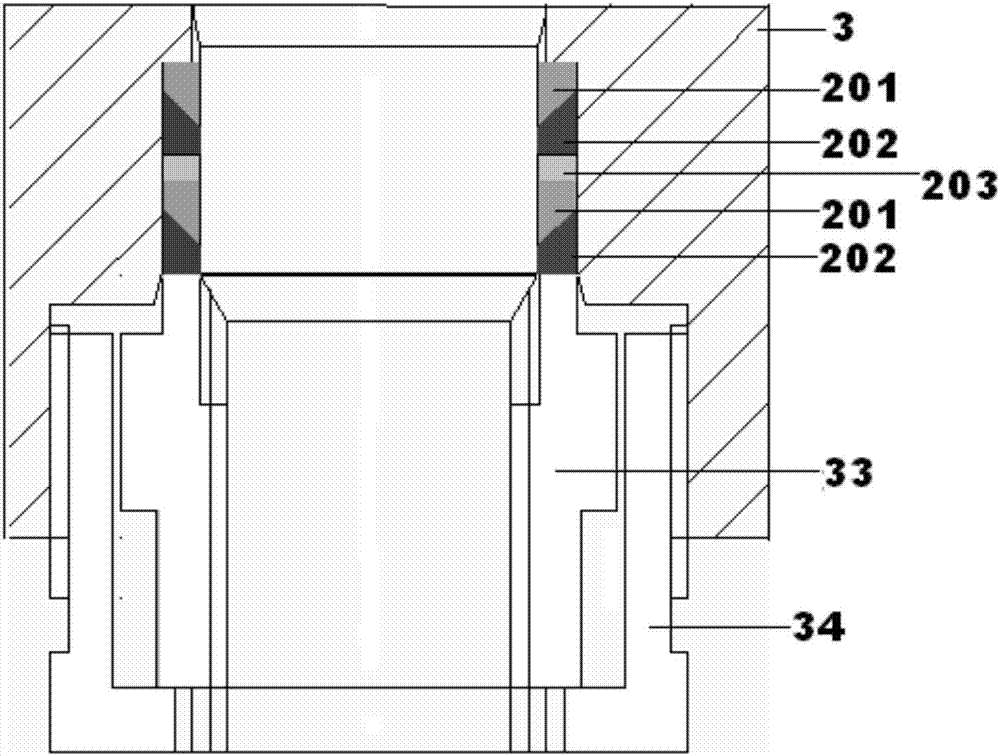

Small-sized packer capable of resisting high temperature and pressure

PendingCN109356547AImprove protectionAvoid rheologySealing/packingHigh pressureTemperature resistance

The invention relates to a small-sized packer capable of resisting the high temperature and pressure. The small-sized packer comprises a volume pipe and an outer central pipe which sleeves one end ofthe volume pipe;a plurality of first sealing assemblies which are mutually arranged in parallel are arranged between the volume pipe and the outer central pipe; each first sealing assembly comprises at least two sealing rings and blocking rings with the number being one more than the sealing rings; and the two sides of the sealing rings are clamped with the blocking rings correspondingly. The blocking rings made of materials with better high temperature resistance and rheological resistance effects are arranged on the two sides of the sealing rings, the sealing rings and the blocking rings canbe mutually matched with each other, good protection action can be provided for the sealing rings, the facts that the rheological phenomenon of the sealing rings due to softening under the tested high temperature and high pressure conditions, and the rheological sealing rings flow out from gaps between assemblies are avoided, thus sealing performance of thesealing rings is better, occurrence of the conditions of weakening and failure of the setting effect is avoided, and thus high temperature and high pressure resistance performance of the packer is ensured; and meanwhile a bevel cutting structure of the blocking rings is utilized, and thus the problem of difficult assembly caused by selection of blocking rings is solved.

Owner:成都托克密封件有限责任公司

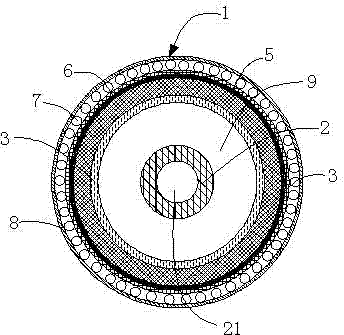

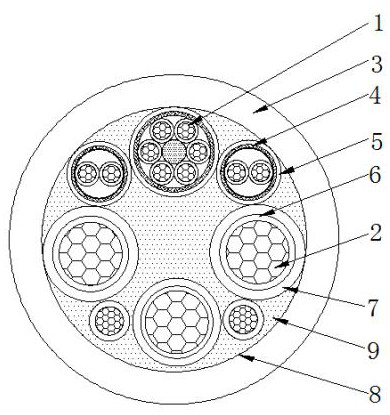

Submarine power cable with insulating composite layer

InactiveCN104240817AImprove insulation performanceImprove temperature and pressure resistancePower cables with screens/conductive layersSubmarine cablesEpoxyElectrical conductor

The invention provides a submarine power cable with an insulating composite layer. The submarine power cable sequentially comprises a cable conductor, a metal jacket, a reinforced layer, a polyethylene jacket, a copper strip lapped layer, an armor layer and an outer coating layer from an inner layer to an outer layer, and further comprises the insulating composite layer. A central oil passage is formed in the cable conductor, radial cross-section sides of the reinforced layer and the armor layer are in pup joint with each other, and the insulating composite layer is arranged between the cable conductor and the metal jacket and structurally comprises an insulating material layer and an insulating shielding layer. The submarine power cable has the advantages that the pressure-resistant insulating composite layer with an excellent electric insulating property is additionally arranged between the cable conductor and the metal jacket and is made of nanometer modified epoxy resin and other components such as methyl tetrahydrophthalic anhydride and Qishi toughening agents by means of compounding, and accordingly the temperature-resistant and pressure-resistant performance, the mechanical strength and the insulating property of the submarine power cable can be greatly improved under synergistic effects of the nanometer modified epoxy resin and the other components.

Owner:STATE GRID CORP OF CHINA +2

Metal small channel reactor

InactiveCN105817188AImprove corrosion resistanceImprove temperature and pressure resistanceChemical/physical/physico-chemical microreactorsLaboratory scaleVolumetric Mass Density

The invention discloses a novel metal small channel reactor, relating to the technical field of material mixing and reaction equipment. The novel metal small channel reactor comprises a feeding hole, modules, a discharging hole, a heat exchanger inlet pipe and a heat exchanger outlet pipe, wherein the modules are alternatively stacked between the inlet pipe and the outlet pipe, which are arranged in parallel relatively; and the modules are connected through module connection pipes. Each module of the small channel reactor is composed of a pipe pass and a shell pass; and materials pass through a metering pump and are pre-heated, mixed and reacted in a pipe pass region; and a refrigerant medium in a shell pass region is used for controlling the temperature in the small channel reactor through an external heat exchanger. The mini-type reactor modules have excellent mass transferring and heat transferring effects and can bear very high operation pressure, and the highest pressure can reach 10Mpa; the production efficiency, the reaction speed, the safety and the like are improved to the great extent; and the novel metal small channel reactor has the properties of high strength, small density, good mechanical properties and good toughness and corrosion resistance, engineering enlargement is convenient to realize, and a production process from a laboratory scale to industrial production is finished in one step.

Owner:CHANGZHOU UNIV

A compound plugging agent

ActiveCN104987017BWide temperature rangeImprove temperature and pressure resistanceLost circulationMaterials science

The invention relates to the technical field of building materials, in particular to a composite plugging agent, which is made of the following raw materials in parts by weight: 55-75 parts of composite gel material, 2-8 parts of toughening agent, and 3-9 parts of coagulation accelerator 12-22 parts of curing agent, 7-15 parts of dispersant. The composite plugging agent of the present invention has both rigidity and flexibility, can play the roles of deformation and filling, bridging and deformation filling at the same time, greatly reduces the amount of plugging materials and reduces the cost.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Low-temperature-resistant waterproof charging pile cable and production process

InactiveCN112201391AImprove waterproof performanceAvoid the danger of water ingressPlastic/resin/waxes insulatorsClimate change adaptationPolyesterNonwoven fabric

The invention discloses a low-temperature-resistant waterproof charging pile cable, which comprises a conductor formed by twisting a plurality of core wires, and further comprises an outer cover, wherein a braided layer is braided on the surfaces of the core wires, the surface of the braided layer is coated with a middle cover, the surface of the conductor is wound with a water-blocking tape, thesurface of the water-blocking tape is coated with an insulating sleeve, an aluminum-plastic composite tape is attached to the inner wall of the outer cover, a water-blocking material is filled in thealuminum-plastic composite tape and located between the outer surfaces of the insulating sleeve, and the water-blocking tape is prepared by using a polyester non-woven fabric as a base cloth and adding a water-absorbing polymer rubber and a plastic coating material. The invention relates to the technical field of charging pile cables. According to the low-temperature-resistant waterproof chargingpile cable and the production process, the cable body of the low-temperature-resistant waterproof charging pile cable is still soft even when the low-temperature-resistant waterproof charging pile cable is used at the temperature of minus 40 DEG C, so that the low-temperature-resistant waterproof charging pile cable adapts to severe cold environments in northeast China, North America and North European China, waterproofness of the charging cable is improved, and hidden danger of water entering the cable is avoided.

Owner:GUANGDONG OMG TRANSMITTING TECH CO

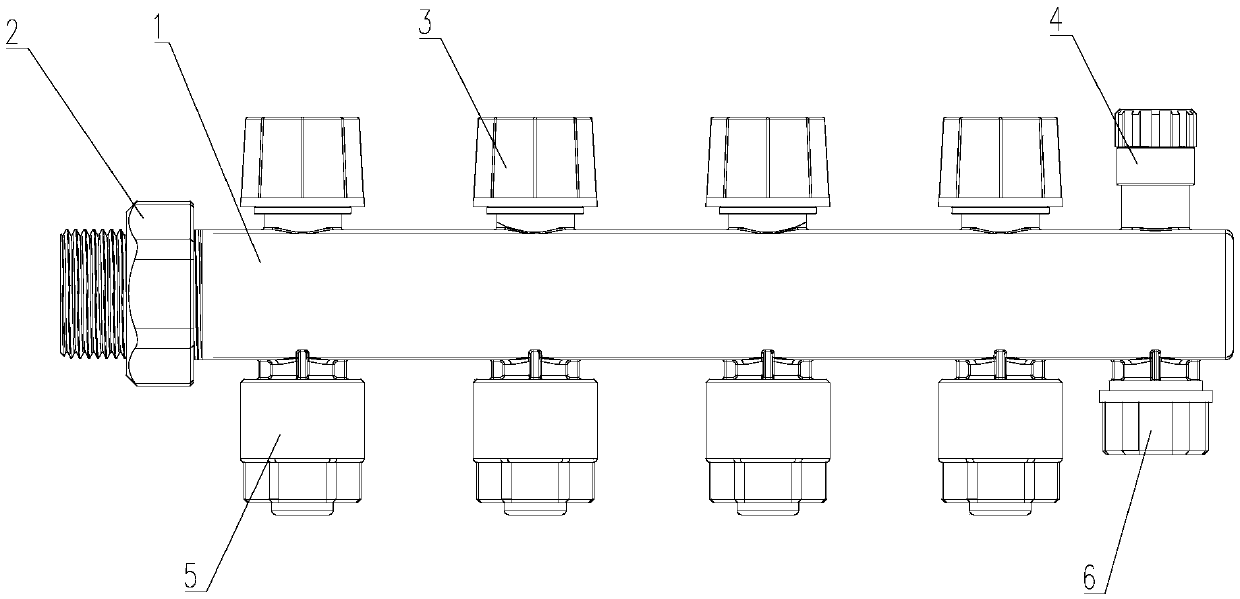

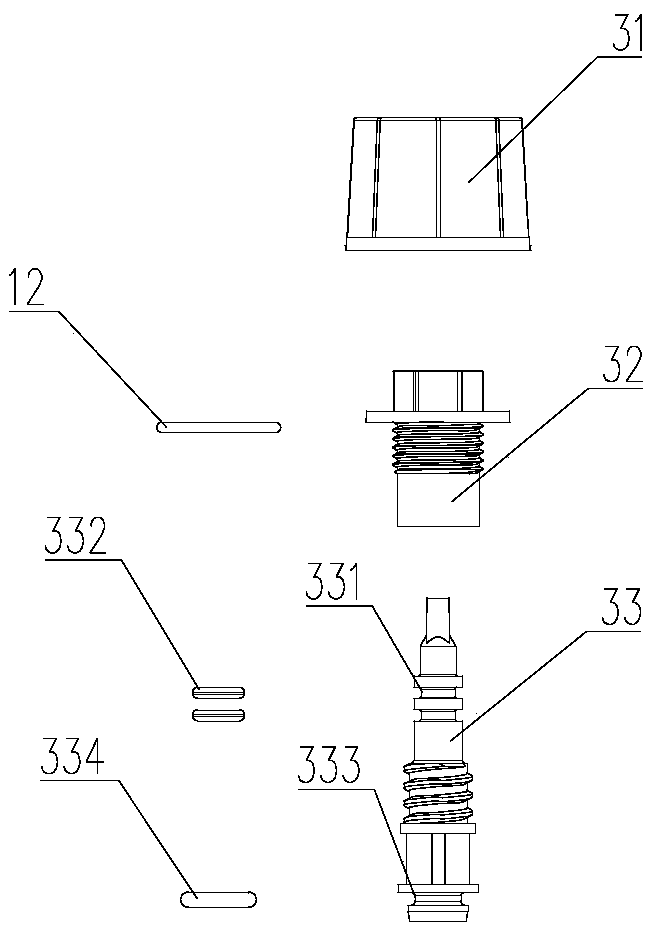

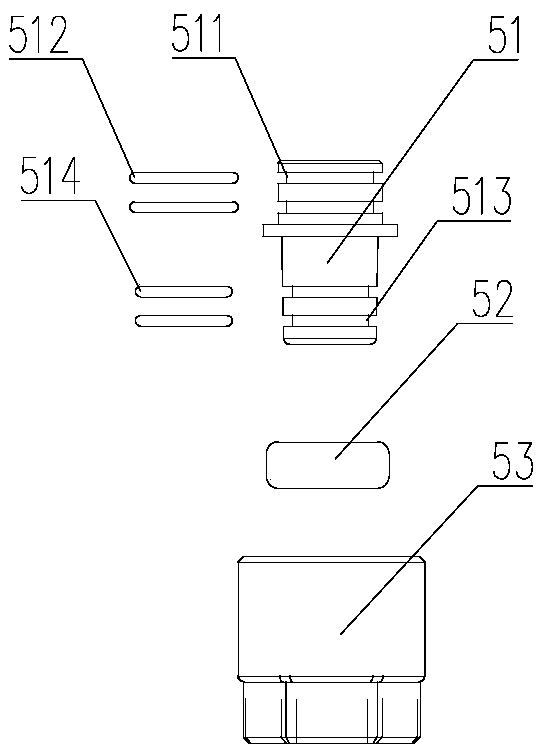

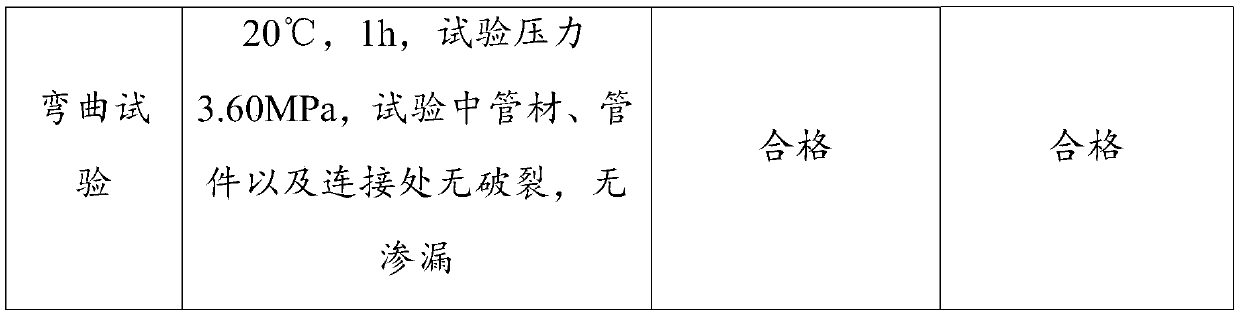

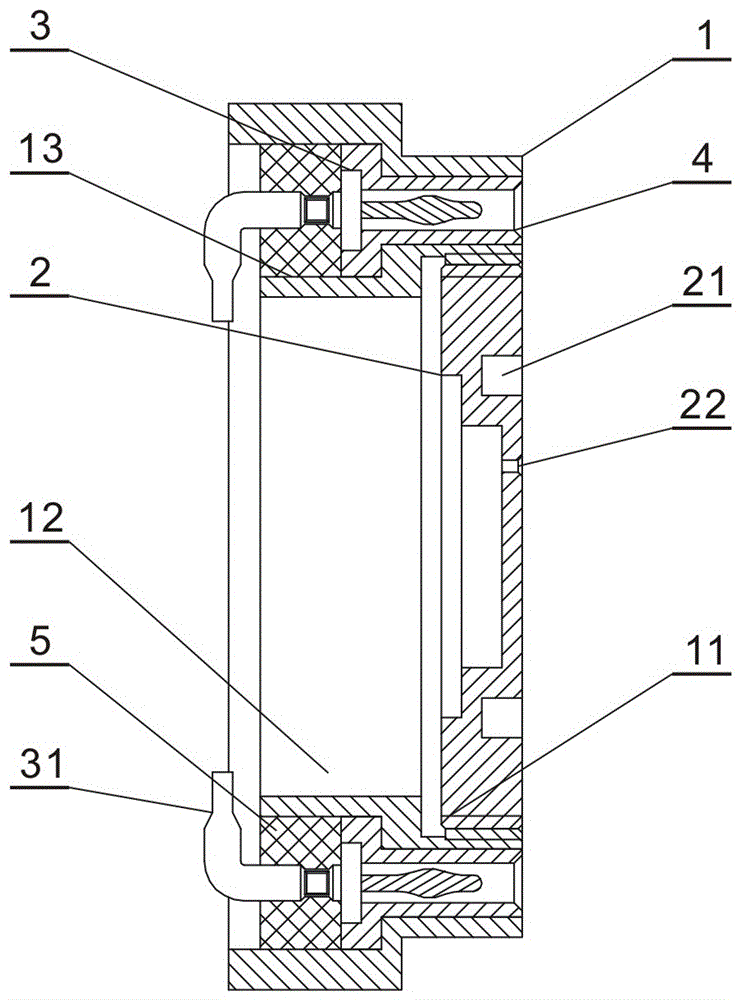

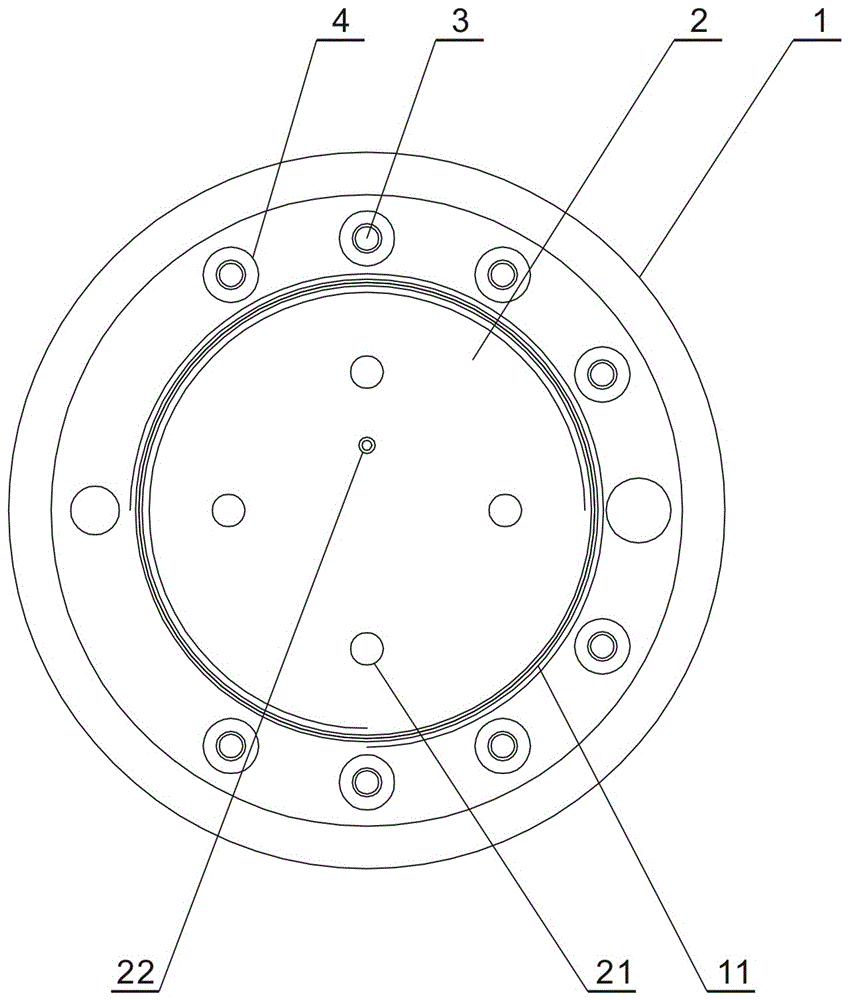

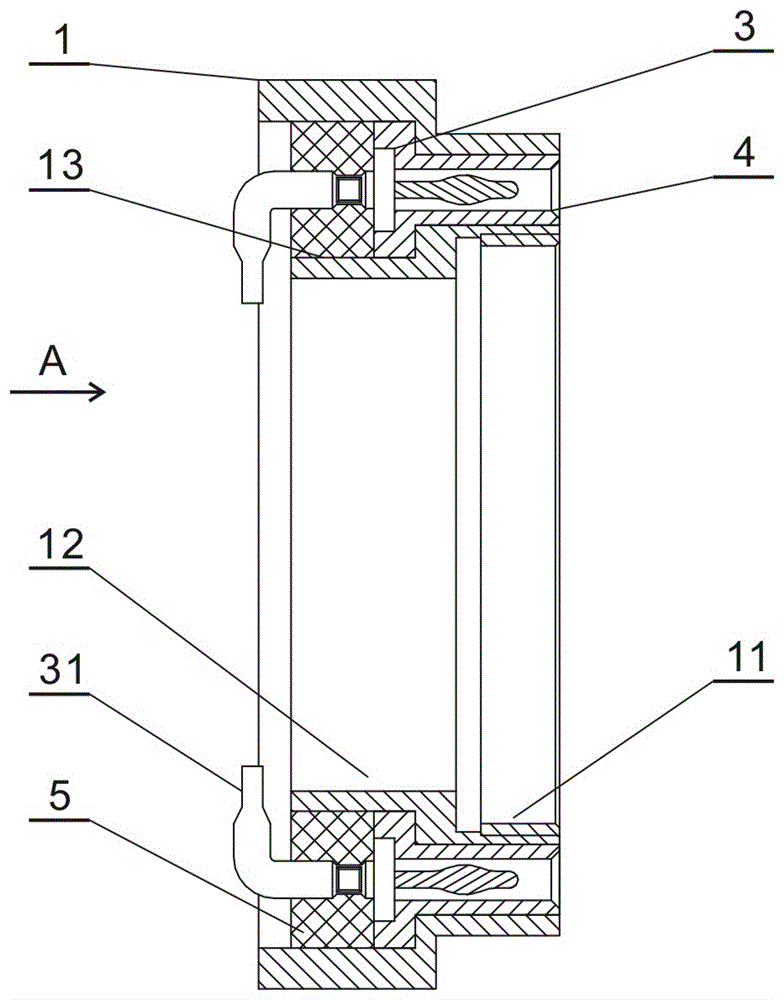

Transparent visible polysulfone water distribution manifold

ActiveCN105508790AWith transparentAnti-foulingLighting and heating apparatusBranching pipesExhaust valveWater leakage

The invention provides a transparent visible polysulfone water distribution manifold which solves the problems of heavy weight, high tendency to rusting, high tendency to water leakage and cracking, waste of resources and the like in the existing water separator. The transparent visible polysulfone water distribution manifold is provided with a water distribution manifold main body, a joint, an adjusting valve, an exhaust valve, a flexible insertion pipe head and a pipe cap, wherein the front end of the water distribution manifold main body is connected with the joint through threads, the upper end is connected with the adjusting valve and exhaust valve through internal threads, and the lower end is connected with the flexible insertion pipe head and pipe cap through external threads. The water distribution manifold is connected with the floor heating pipe in a flexible insertion connection mode; and the water distribution manifold is prepared from a special-type engineering plastic biphenyl polyethersulfone material. The transparent visible water distribution manifold can be widely used in the technical fields of pipeline water supply and heating.

Owner:WEIHAI JINHONG PIPE CO LTD

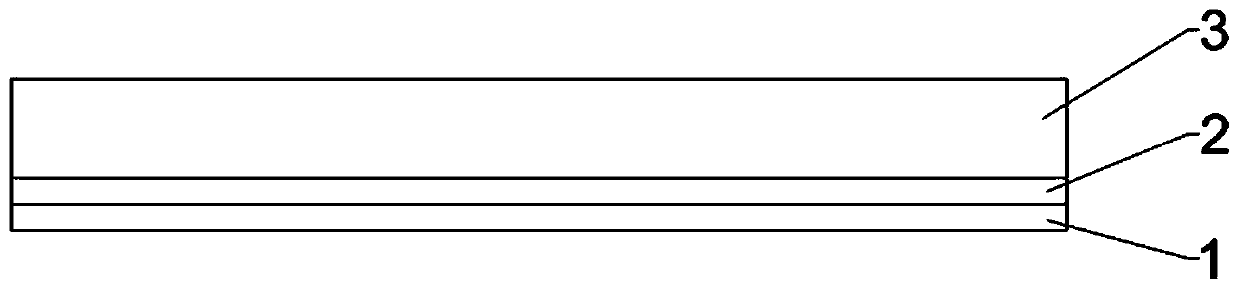

Heat-insulating integrated continuous fiber prepreg tape enhanced composite pipe and processing method

InactiveCN111425672AImprove its own pressure and temperature resistance and overall rigidityHigh strengthThermal insulationPipe protection by thermal insulationFiberFoaming agent

The invention discloses a heat-insulating integrated continuous fiber prepreg tape enhanced composite pipe and a processing method. The heat-insulating integrated continuous fiber prepreg tape enhanced composite pipe comprises a foaming heat-insulating pipe and a heat-resistant and pressure-resistant work pipe. The processing method comprises the following steps: placing mixing an inner layer of plastic and an AC foaming agent with plastic respectively, placing the mixtures into a plastic inner layer extruder and a foaming extruder, extruding and entering a plastic inner layer mold and a foaming mold, cooling and shaping, and packaging after fusing, identifying and cutting. The heat-insulating integrated continuous fiber prepreg tape enhanced composite pipe improves the overall rigidity, the pressure and temperature resistance, waterproof property and strength; and by the processing method of the heat-insulating integrated continuous fiber prepreg tape enhanced composite pipe, the fusion mildness is improved and processing cost is reduced.

Owner:上海英泰塑胶股份有限公司

Organic composite porous ceramic material and preparation method thereof

ActiveCN111620678AEasy to prepareLow costReversible hydrogen uptakeCeramicwarePore distributionAdhesive

The invention discloses an organic composite porous ceramic material and a preparation method thereof, and relates to the technical field of porous ceramic processing. The organic composite porous ceramic material disclosed by the invention is composed of silicon dioxide, diatomite, aluminum powder and modified cellulose. The preparation method comprises the following steps: uniformly mixing the components, grinding the mixture into mixed powder, adding a water-soluble adhesive and water into the mixed powder, uniformly mixing, carrying out freeze drying to obtain a porous ceramic precursor, and carrying out high-temperature sintering on the porous ceramic precursor. The organic composite porous ceramic material provided by the invention has very high porosity and uniform pore distribution, and the pore size and shape can be controlled. The organic composite porous ceramic material can also be used for storing hydrogen, has the characteristics of high hydrogen storage capacity, simplehydrogen absorption and desorption operation, high-temperature and high-pressure resistance and the like, is good in cycling stability and can be repeatedly used for multiple times, and the prepared product is high in strength and not easy to deform.

Owner:贵州群华九九特种陶瓷科技有限公司

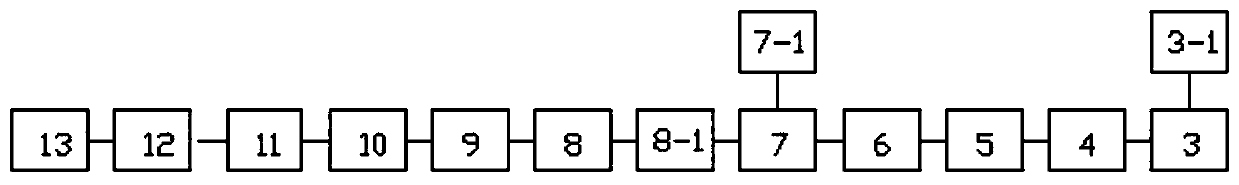

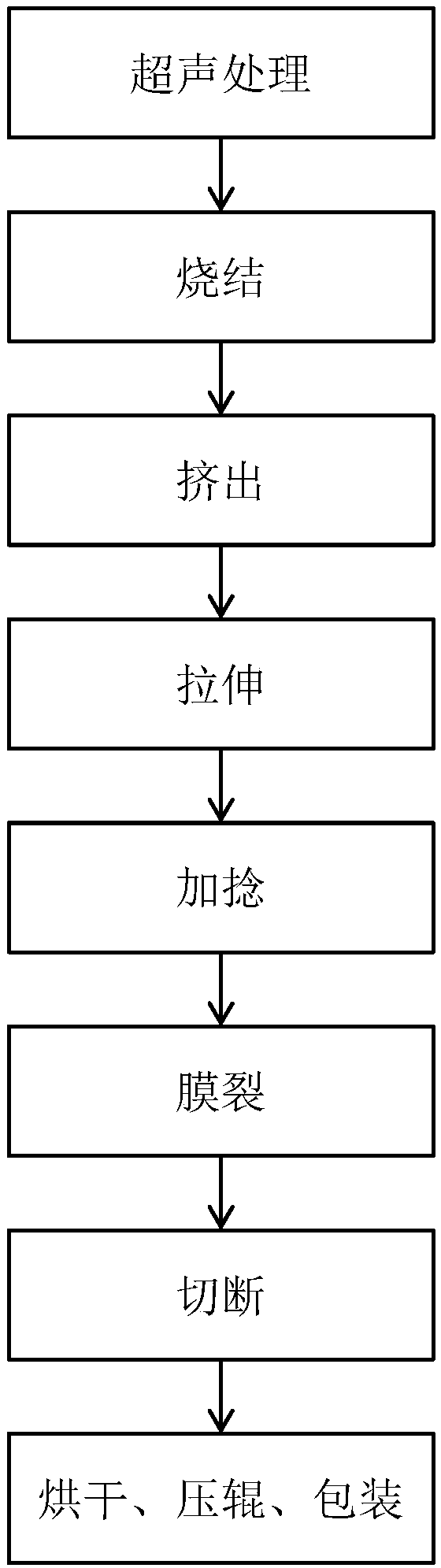

Preparation method of PTFE (Polytetrafluoroethylene) fluff fibers

InactiveCN108914232AReduce manufacturing costHigh temperature and pressure resistanceArtificial filament washing/dryingSevering to form staple fibresYarnLubrication

The invention discloses a preparation method of PTFE (Polytetrafluoroethylene) fluff fibers. The preparation method comprises the following steps: 1) carrying out ultrasonic treatment on a PTFE resinraw material; 2) adding the PTFE resin raw material subjected to the ultrasonic treatment into a mold; then putting the mold into a sintering furnace and sintering to prepare a blank; 3) adding the blank into an extruding machine and extruding to obtain a blank material; 4) adding the blank material into a stretching machine and stretching to obtain crude fiber yarns; 5) adding the crude fiber yarns into a twisting machine and twisting crude fiber yarn bundles to prepare a PTFE fiber film; 6) carrying out film tearing on the PTFE fiber film through a needle roller to prepare tow filaments; 7)after carrying out humidification treatment on the tow filaments through a conveying roller, conveying the tow filaments into a cutting-off machine and cutting the tow filaments into the fluff fibers;8) drying the fluff fibers and then molding through a pressure roller; then carrying out packaging treatment. The PTFE fluff fibers prepared by the preparation method can be used for replacing existing PTFE micro-powder and also has performance including lubrication and the like.

Owner:江苏金由新材料有限公司

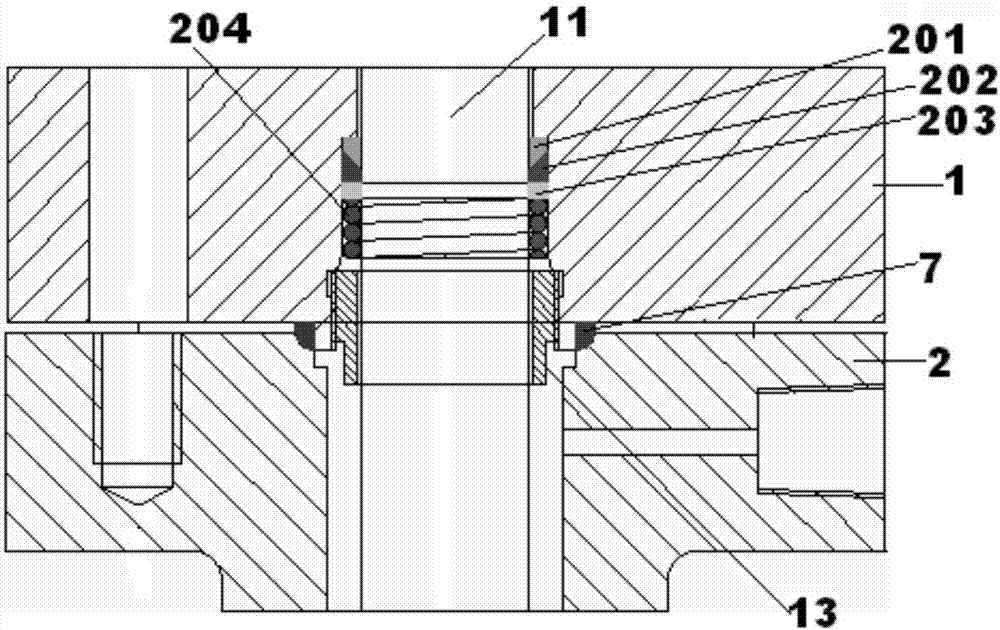

Temperature-controllable high-pressure environmental mechanical test box

PendingCN111060393AAvoid premature breakageFlexible and convenient disassemblyMaterial strength using tensile/compressive forcesTemperature controlTest chamber

The invention discloses a temperature-controllable high-pressure environmental mechanical test box which comprises a sealing cover, an upper kettle body connected with the sealing cover, a middle kettle body connected with the upper kettle body, a lower kettle body connected with the middle kettle body and provided with a temperature control solenoid, an upper stretching rod and a lower stretchingrod. The upper end of the upper stretching rod is connected with a stretcher, the upper stretching rod extends into the sealing cover, the upper kettle body, the middle kettle body and the lower kettle body, and the upper part of the lower stretching rod extends into the lower kettle body. Chucks are arranged at the opposite ends of the upper stretching rod and the lower stretching rod. The upperkettle body comprises an upper cavity provided with a first vertical through hole, an upper annular supporting piece, a first dynamic sealing structure, a second dynamic sealing structure and a lowerannular supporting piece, wherein the upper annular supporting piece and the first dynamic sealing structure are arranged between the middle part of the upper stretching rod and the first vertical through hole from top to bottom and the second dynamic sealing structure and the lower annular supporting piece are sequentially arranged between the lower part of the upper stretching rod and the lowerpart of the first vertical through hole from top to bottom. The test box has the characteristics of adjustable and controllable test temperature and high safety.

Owner:ZHEJIANG UNIV OF TECH

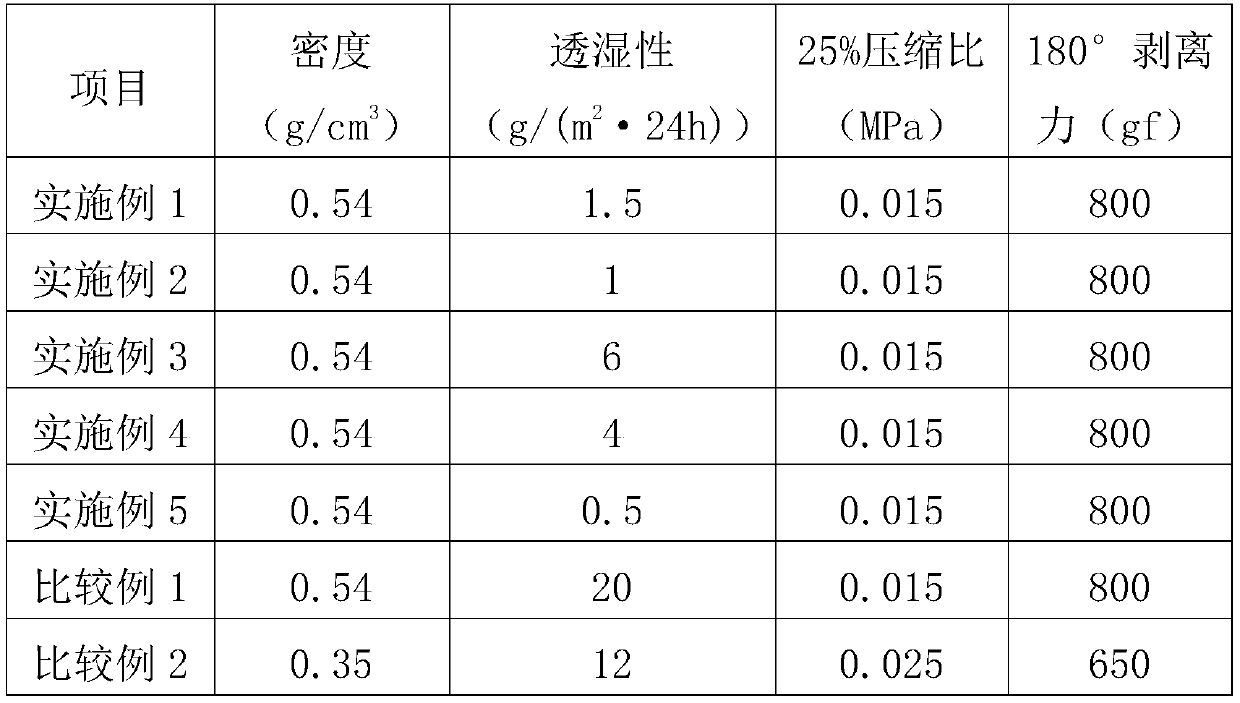

Water-blocking foam and its preparation method and application

ActiveCN108128007BLow moisture permeabilityImprove water resistanceFilm/foil adhesivesSynthetic resin layered productsPolymer scienceMoisture permeability

The invention relates to the technical field of foam, in particular to water blocking foam, and a preparation method and application thereof. The water blocking foam comprises a PET layer, a PVDC layer and a foam layer. The water blocking foam compounds the PET layer, the PVDC layer and the foam layer, thereby having a high barrier property, and further having excellent water resistance and bufferperformance, the moisture permeability can be smaller than 0.5g / (m<2>.24h), and a three-dimensional network structure of the foam layer and uniform and dense foam holes can effectively protect electronic equipment and prolong the service life.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

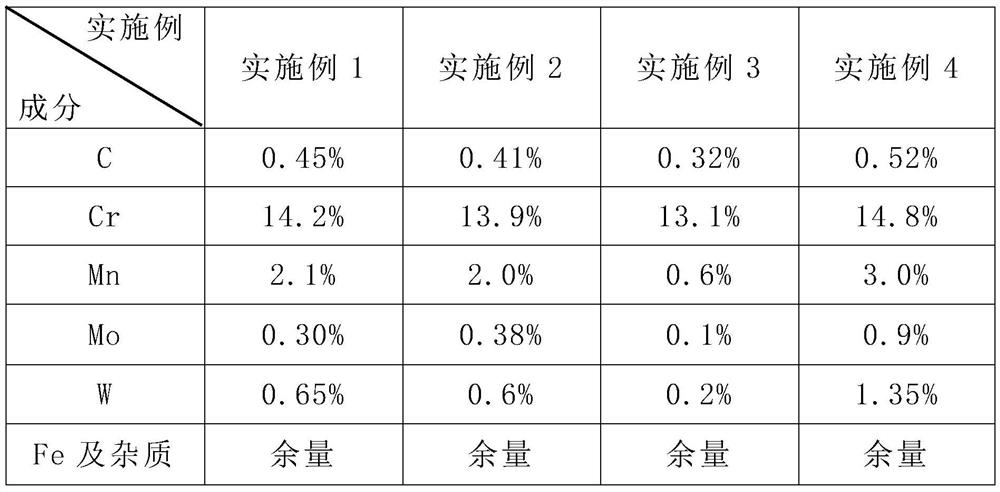

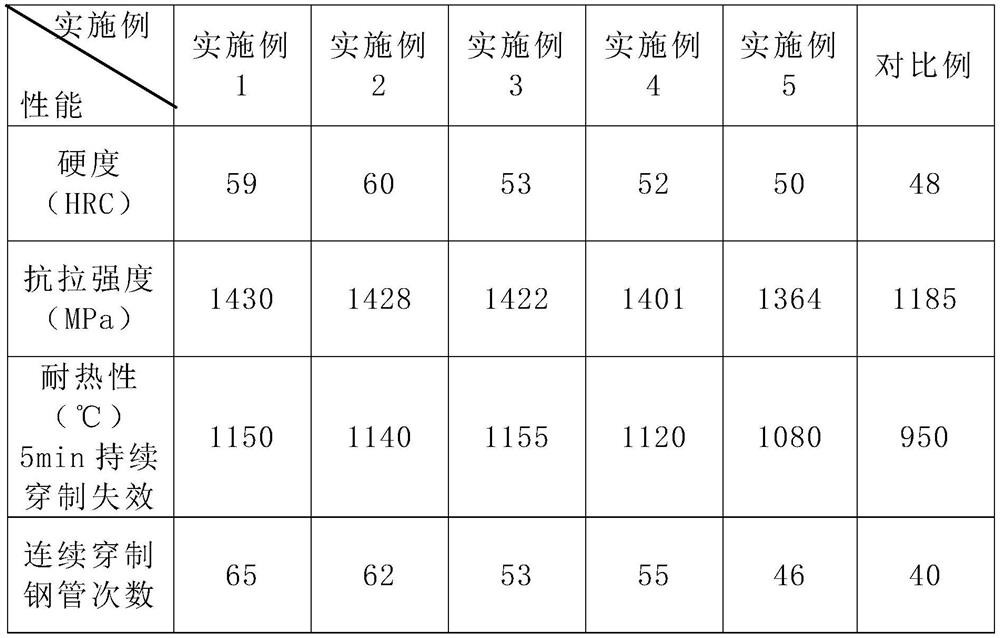

High temperature and high pressure resistant perforated plug and preparation method thereof

ActiveCN112375993BImprove temperature and pressure resistanceImprove work performanceNuclear energy generationVacuum evaporation coatingHeat resistanceMetallic materials

Owner:宁波文而昌新材料科技有限公司

Underground direct plug of conductive cylinder glue injection type

ActiveCN109713508AImprove temperature and pressure resistanceGuaranteed sealing reliabilityCouplings bases/casesEngineeringLip seal

The invention provides an underground direct plug of a conductive cylinder glue injection type. The plug comprises a direct plug housing, a conductive cylinder which is arranged in the front part of the direct plug housing and is provided with an insulating layer; an insulating contact pin with an insulating sleeve which is arranged in the middle of the direct plug housing. A direct plug tail housing which is adaptive to the direct plug housing is arranged at the tail part of the direct plug housing; a cable stripping head is arranged in the direct plug tail housing; the cable stripping head is connected with the insulating contact pin; a lip sealing ring is arranged at the front end of the direct plug housing; a direct plug connecting screw cap and a direct plug positioning sleeve are sequentially arranged outside the direct plug housing; a direct plug tail connecting ring is arranged at the connecting part of the direct plug housing and the direct plug tail housing; a direct plug sealing stop block is arranged at the position of the insulating contact pin in the direct plug housing. An insulating contact pin pressing plate is arranged at one side of the direct plug sealing stop block, and a pressing gasket is arranged between the insulating contact pin pressing plate and the direct plug sealing stop block; a glue injection layer is arranged between the direct plug tail housing and the cable stripping head, and a tail pressing ring is arranged between the glue injection layer and the tail housing.

Owner:重庆昌瑞电器制造有限公司

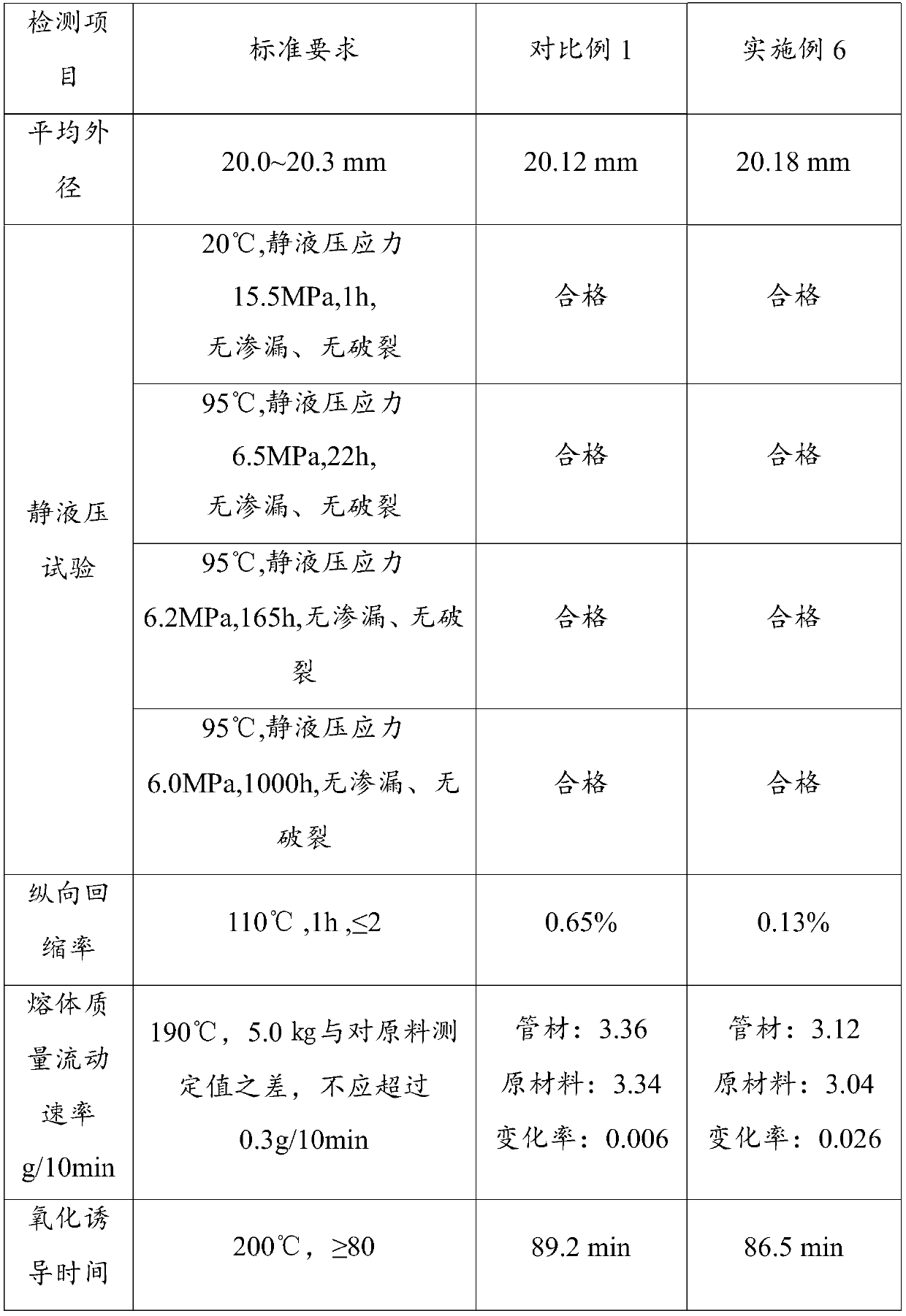

Oxygen barrier material for PB tube and preparation method thereof and oxygen barrier PB tube

ActiveCN111410798AGood flexibilityImprove temperature and pressure resistanceGeneral water supply conservationNano al2o3Oxygen barrier

The invention provides an oxygen barrier material for a PB tube and a preparation method thereof and the oxygen barrier PB tube. The preparation method of the oxygen barrier material comprises the following steps: (1) uniformly mixing nano-alumina and a surface modification solution according to a weight ratio of (85-95):(5-15) to obtain surface-modified nano-alumina, the surface modification solution comprising acetone and vinyl tri (2-methoxyethoxy) silane; and (2) mixing polybutylene, the surface-modified nano-alumina obtained in the step (1) and a lubricant, and performing extruding at 130-180 DEG C to obtain the oxygen barrier material for the PB tube, wherein the weight ratio of polybutylene to the surface-modified nano-alumina obtained in the step (1) is (50-35):(40-25). The oxygenbarrier material for the PB tube can be added into the PB tube, so that a compact oxygen barrier structure is microscopically formed in the PB tube, and oxygen permeation is effectively prevented; andthe PB tube disclosed by the invention has good mechanical property and oxygen barrier property.

Owner:RIFENG ENTERPRISE GRP CO LTD

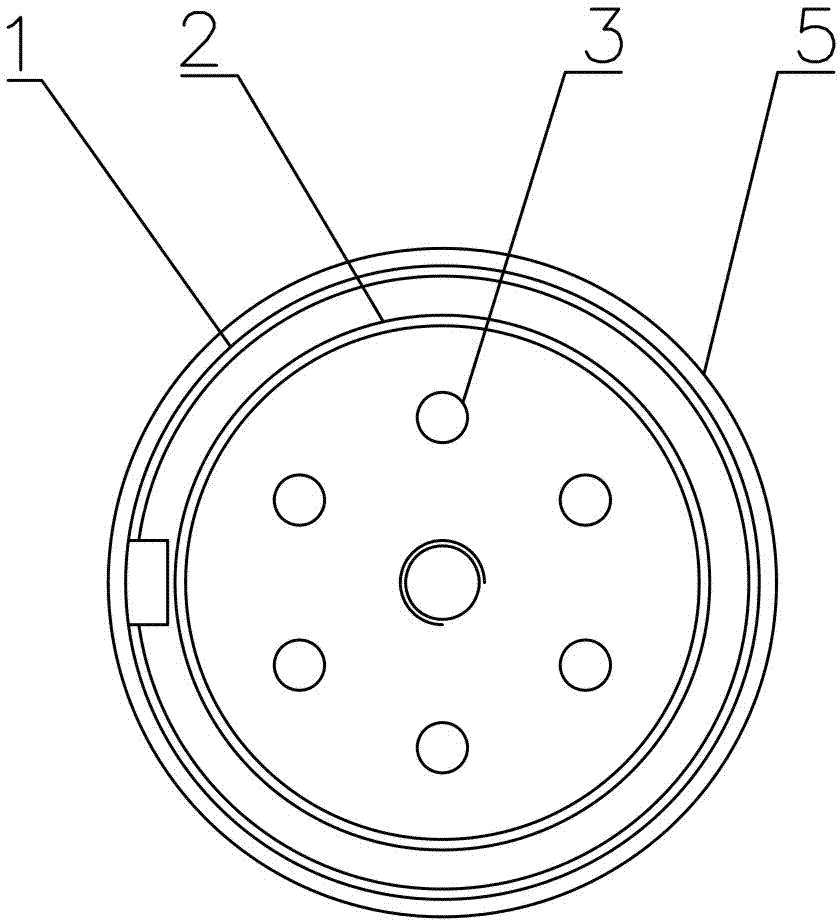

Round twist pin connector

ActiveCN106374268ACompact structureReduce volumeSecuring/insulating coupling contact membersCouplings bases/casesAdhesiveEngineering

The invention discloses a round twist pin connector, which comprises an upper cover, an end cover, a twist pin assembly, an insulating sheath and a potting adhesive, wherein the upper cover is provided with an end cover base, a microelectronic component base and a twist pin base; an inner thread is arranged in the end cover base; an outer thread, four blind holes and a vent hole are formed in the end cover; a flat-square bend is arranged at the tail part of a pin body of the twist pin assembly; the end cover is arranged in the end cover base of the upper cover and the outer thread is meshed with the inner thread; the insulating sheath is arranged in the twist pin base of the upper cover; the twist pin assembly is arranged in the insulating sheath; and the potting adhesive is potted between the tail part of the twist pin assembly and the insulating sheath. By the structure of arranging the microelectronic component base and the twist pin base in the upper cover, a microelectronic component is arranged in the upper cover and the twist pin assembly is directly bonded with the microelectronic component, so that the round twist pin connector has the advantages of being compact in structure, small in volume, stable and reliable in work and good in heat resistance and pressure resistance.

Owner:TAIZHOU HANGYU ELECTRICAL DEVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com