Organic/inorganic composite hollow microspheres, and preparation method and application thereof

An inorganic composite, hollow technology, applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of poor temperature resistance and pressure resistance, and achieve improved temperature and pressure resistance, uniform particle size, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

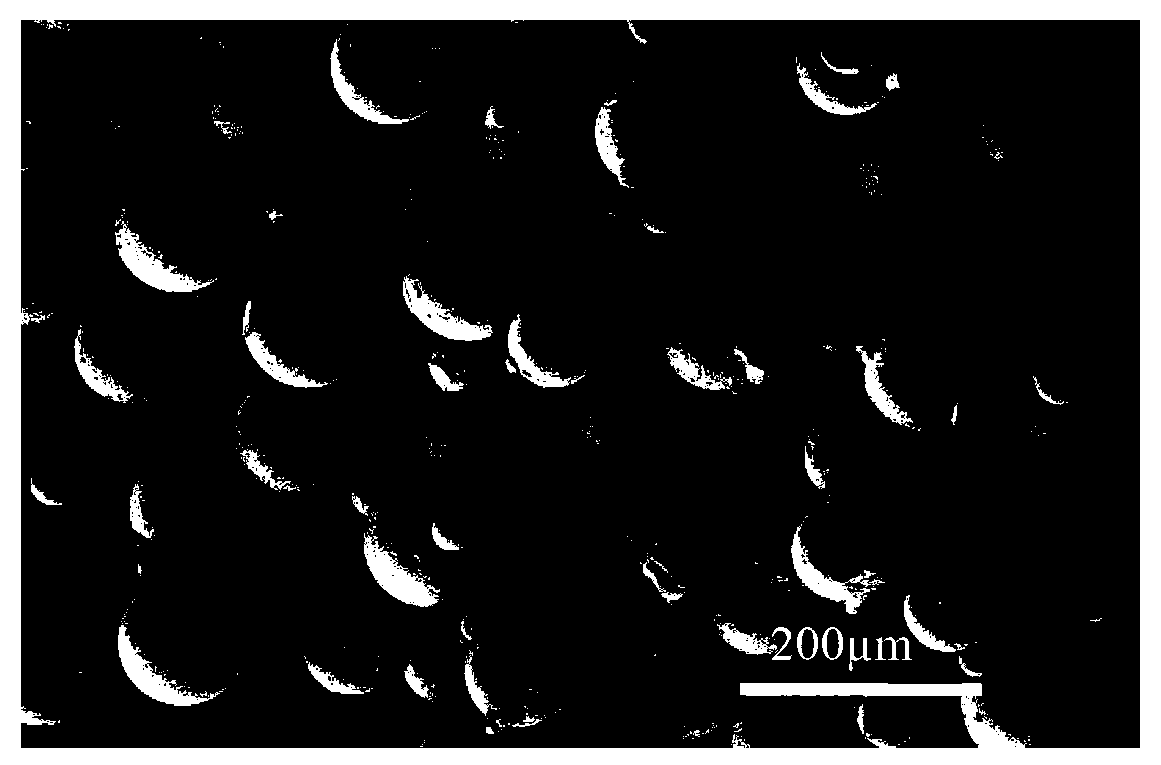

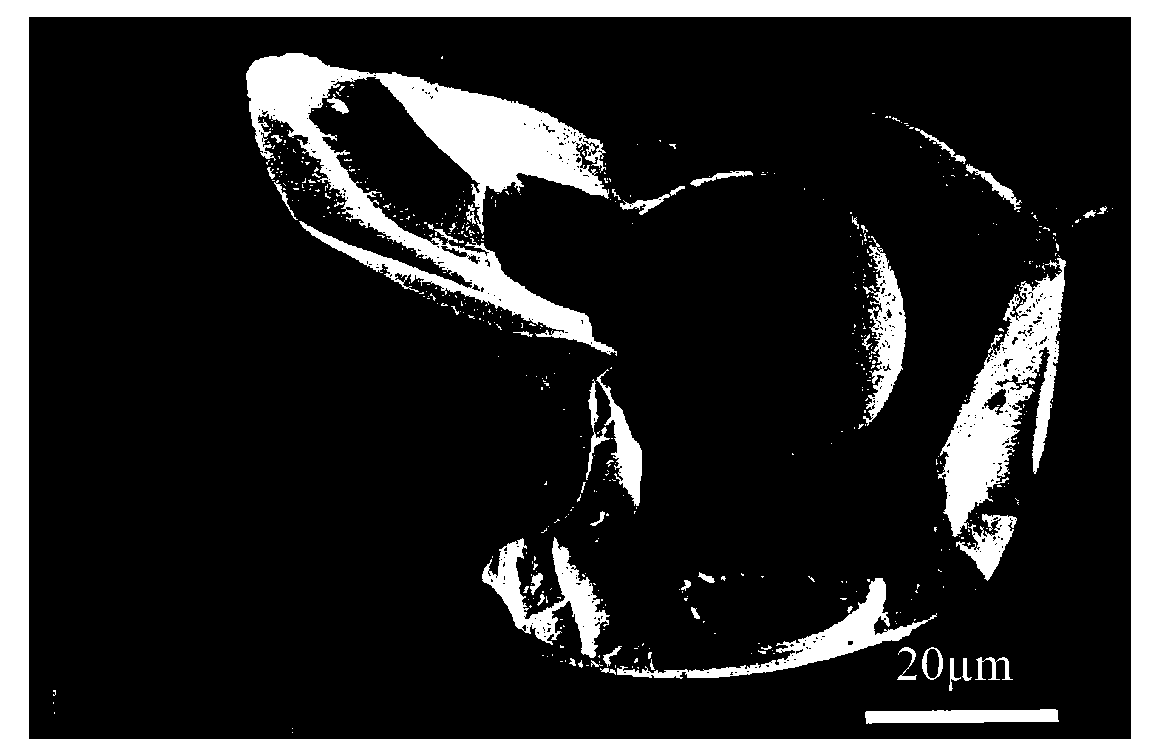

Image

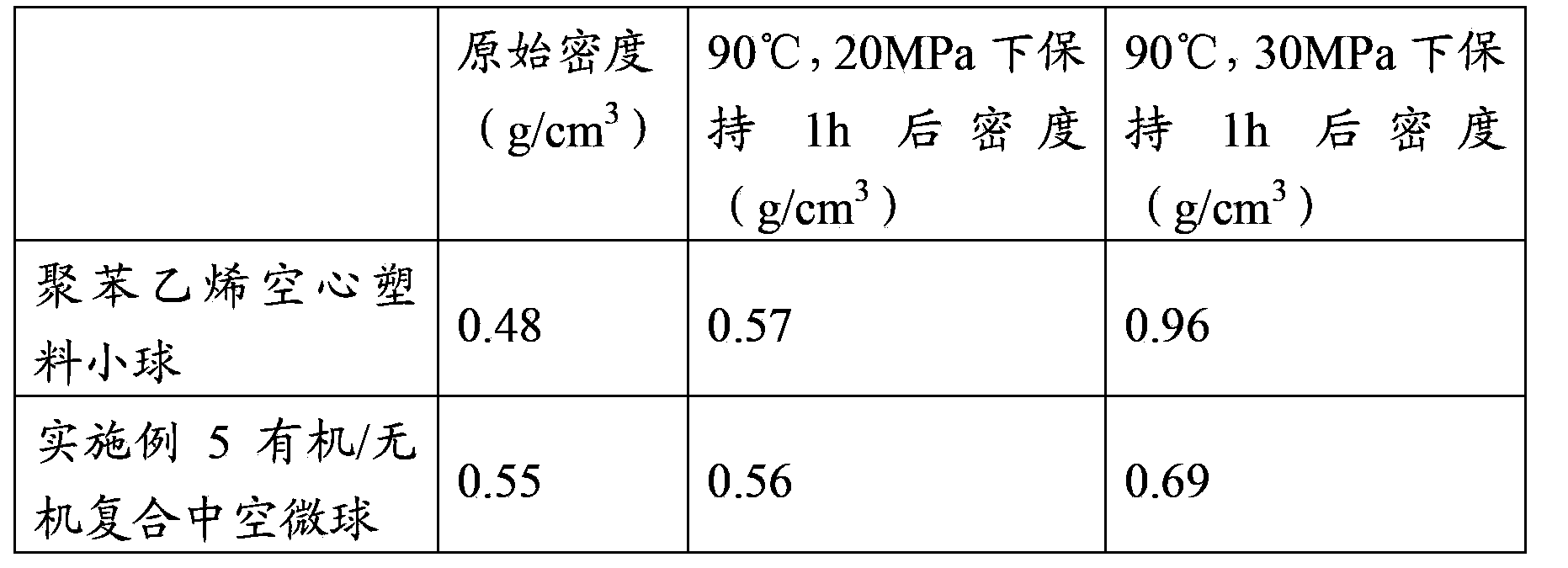

Examples

Embodiment 1

[0036] Wash the computer packaging with polystyrene foam and dry it for later use;

[0037] 1) Preparation of oil phase O: Weigh 7.38g of the above-mentioned clean polystyrene foam, add 24.6g of styrene monomer and 0.738g of benzoyl peroxide, add 0.615 of ethylene glycol dimethacrylate, and 603.198 of Span g, hydrophobic nano-silica 0.0032g, mixed uniformly to obtain an oil phase; wherein polystyrene weight is 30% of styrene monomer weight, initiator is 3.0% of styrene monomer weight; crosslinking agent weight is benzene 2.5% of the weight of ethylene monomer, the weight of emulsifier is 10% of the sum of polystyrene weight and styrene monomer weight, hydrophobic nano-silica is 0.01% of the sum of polystyrene and styrene mass, the total O phase The mass is 36.534g;

[0038] 2) Preparation of phase W1: take 7.0 g of distilled water, add 0.035 g of sodium dodecylbenzenesulfonate, dissolve evenly and use it as phase W1, the weight of emulsifier is 0.5% of the weight of distilled...

Embodiment 2

[0044] Wash the computer packaging with polystyrene foam and dry it for later use;

[0045] 1) Preparation of oil phase (O phase): Weigh 31.5g of styrene monomer, 0.0063g of benzoyl peroxide, 800.65g of Span, and 3.15g of hydrophobic nano-titanium dioxide, and mix them evenly to obtain an oil phase; polystyrene is 0% of the weight of styrene, the initiator is 0.02% of the weight of styrene monomer, the weight of crosslinking agent is 0% of the weight of styrene monomer, the weight of Span 80 is 2% of the weight of styrene monomer, inorganic nanomaterials It is 10% of the weight of styrene monomer, and the total mass of the oil phase is 35.31g;

[0046] 3) Preparation of W1 phase: Take 19.0 g of distilled water, add 1.52 g of sodium dodecyl sulfonate, dissolve evenly and use it as W1 phase, the weight of emulsifier is 8% of the weight of distilled water, and the total mass of W1 phase is 20.52 g;

[0047] 4) Prepare W2 phase: add 0.168g gelatin, 0.11g sodium dodecylbenzenesulf...

Embodiment 3

[0052] Wash the computer packaging with polystyrene foam and dry it for later use;

[0053] 1) Prepare the oil phase (O phase): weigh 4g of the above-mentioned clean polystyrene foam, add styrene monomer 100 and benzoyl peroxide 0.5g, add ethylene glycol dimethacrylate 3g, Span 605.2g, hydrophobic nano-calcium carbonate 0.104g, make oil phase after mixing; Wherein polystyrene weight 4% of styrene monomer weight, initiator is 0.5% of styrene monomer weight; Cross-linking agent weight is benzene 3% of the weight of ethylene monomer, emulsifier weight is 5% of the sum of polystyrene weight and styrene monomer weight, hydrophobic inorganic nanomaterial weight is 0.1% of the sum of polystyrene weight and styrene monomer weight , the sum of the mass of O phase is 112.804g;

[0054] 2) Preparation of W1 phase: Take 43g of distilled water, add 1.15g of sodium lauryl sulfate, 1.0g of OP-10, dissolve evenly and use it as W1 phase, the weight of emulsifier is 5% of the weight of distill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com