Patents

Literature

114results about How to "Improve circularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

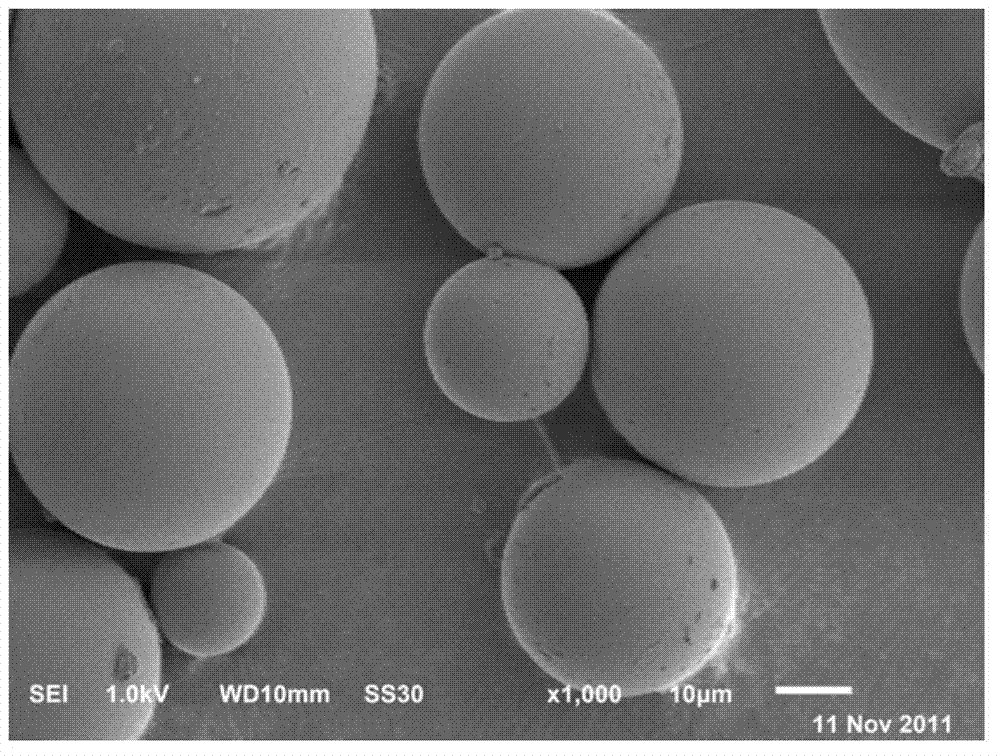

Organic/inorganic composite hollow microspheres, and preparation method and application thereof

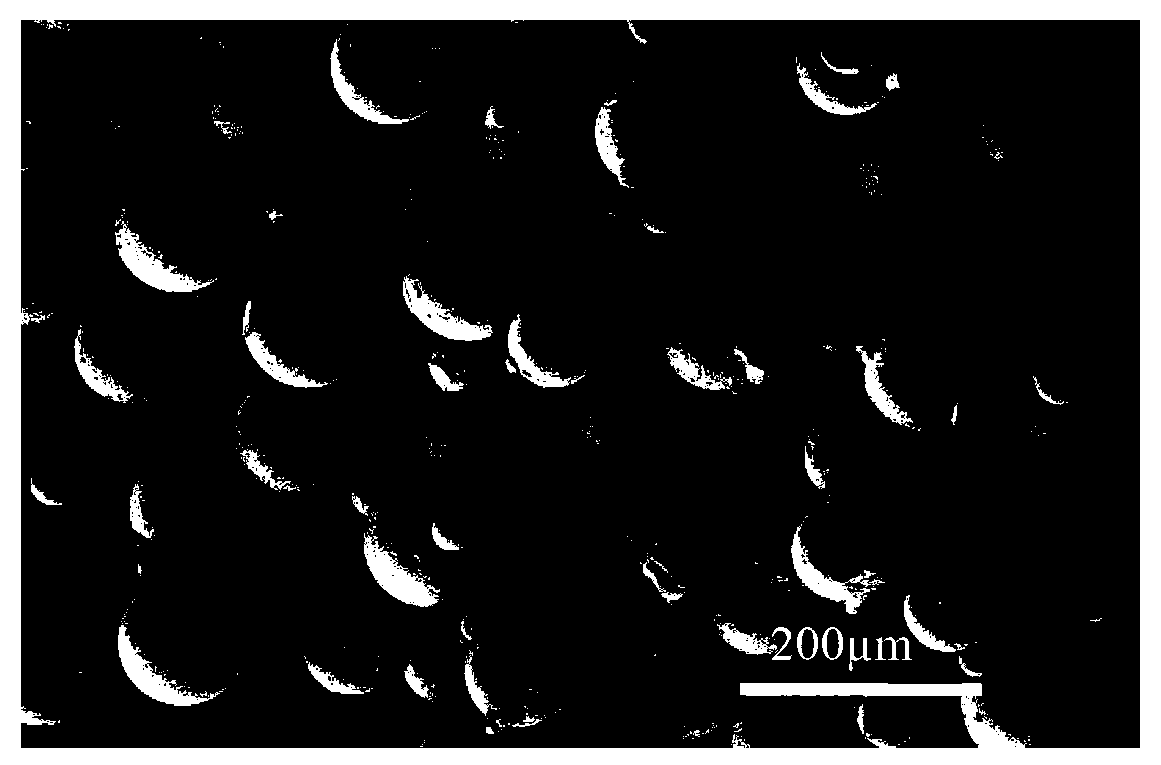

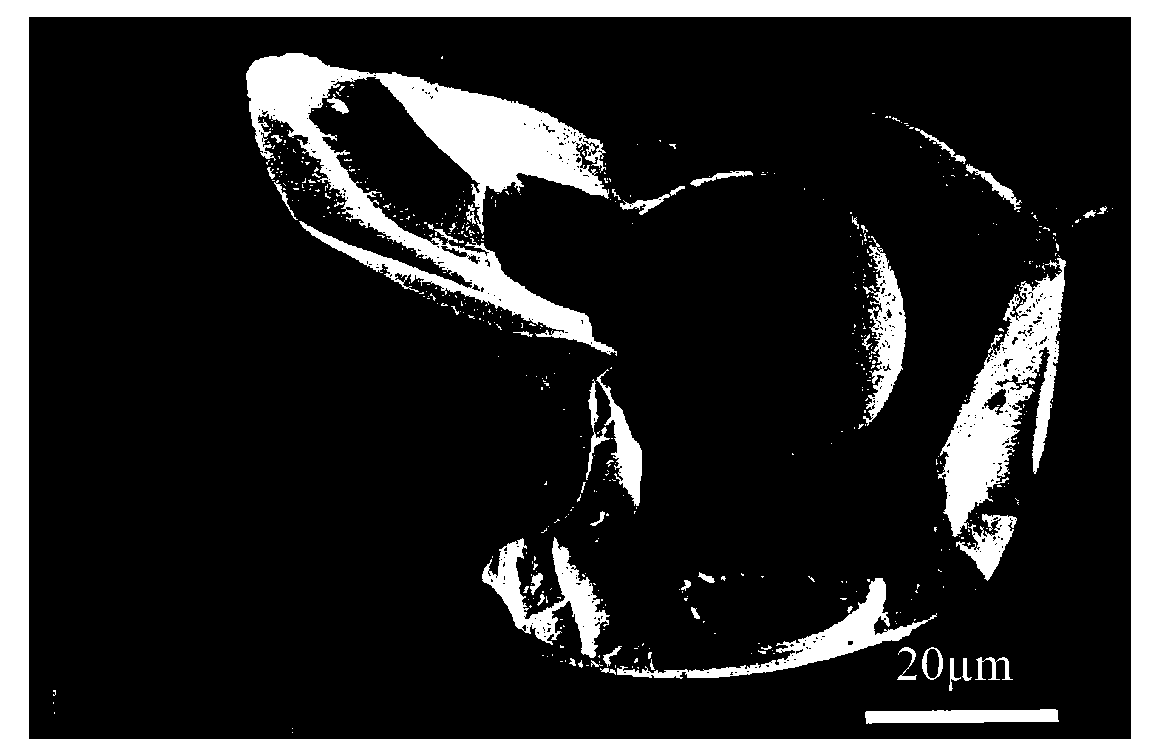

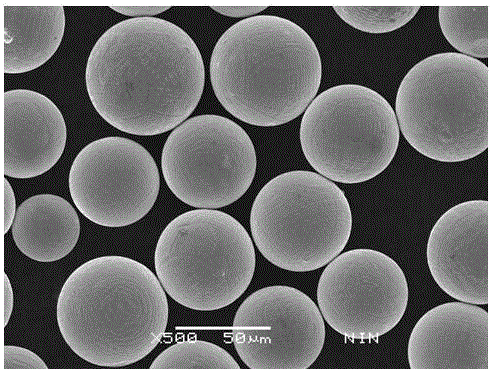

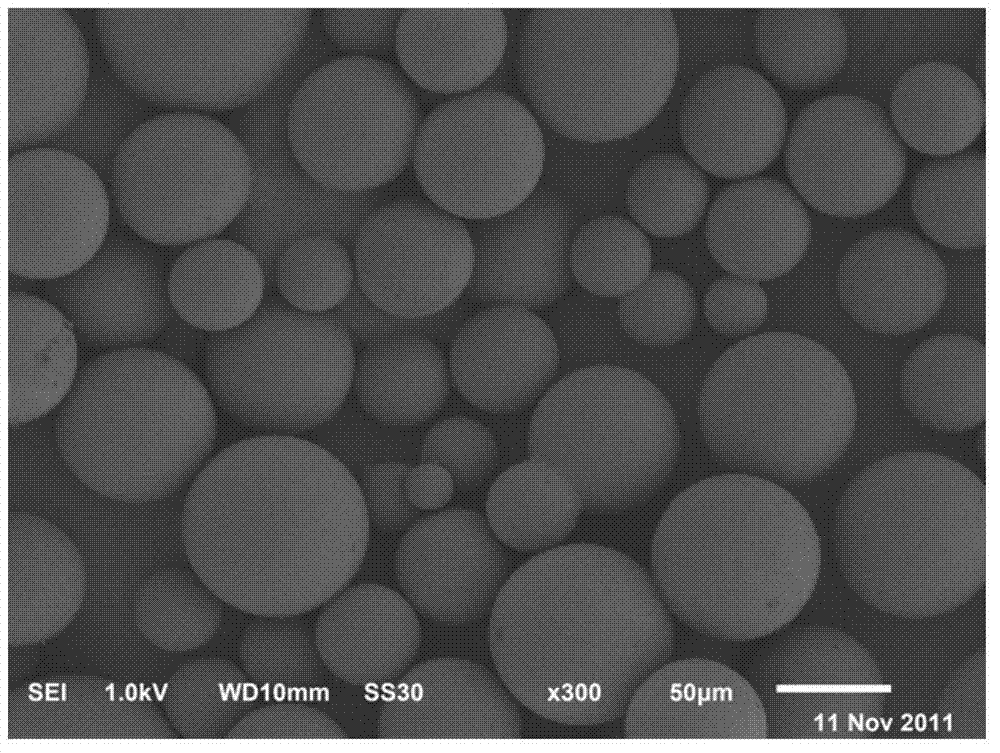

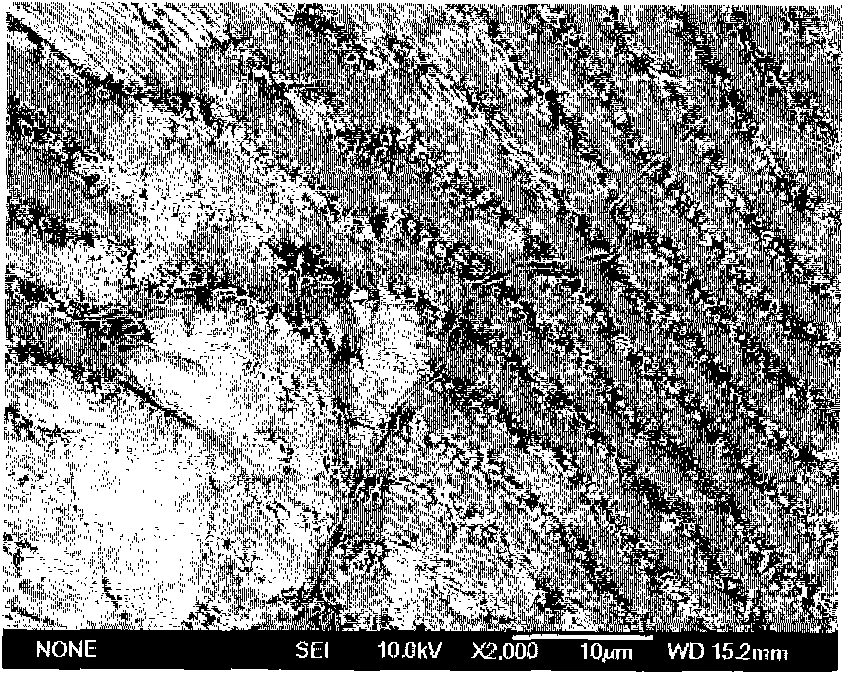

ActiveCN103387717AUniform particle sizeSmall particle sizeDrilling compositionMicroballoon preparationPolymer scienceMicrosphere

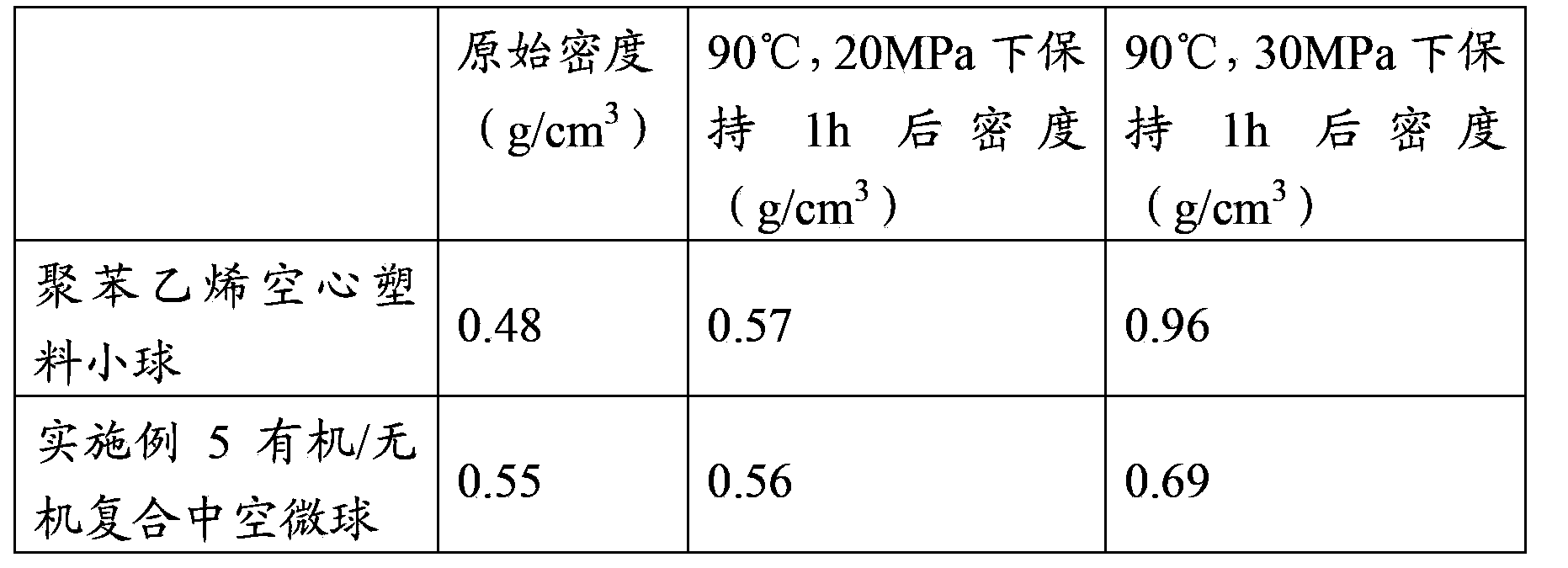

The invention relates to organic / inorganic composite hollow microspheres, and a preparation method and an application thereof. According to the invention, a part of hydrophobically modified inorganic nano-grade material is added into styrene monomer or styrene monomer dissolved with polystyrene; the mixture is uniform, and is adopted as an oil phase; the viscosity of the oil phase is controlled through controlling the concentration of polystyrene and the addition amount of the nano-grade material; and temperature resistance and pressure resistance of the hollow microspheres are improved through adding an inorganic nano-grade material. In a W1 / O / W2 triple emulsion, initiation and polymerization of the styrene monomer, precipitation hardening of polystyrene and the inorganic nano-grade material, and the like are realized, such that the organic / inorganic composite hollow microspheres with the hollow structure are formed.

Owner:CHINA PETROLEUM & CHEM CORP +1

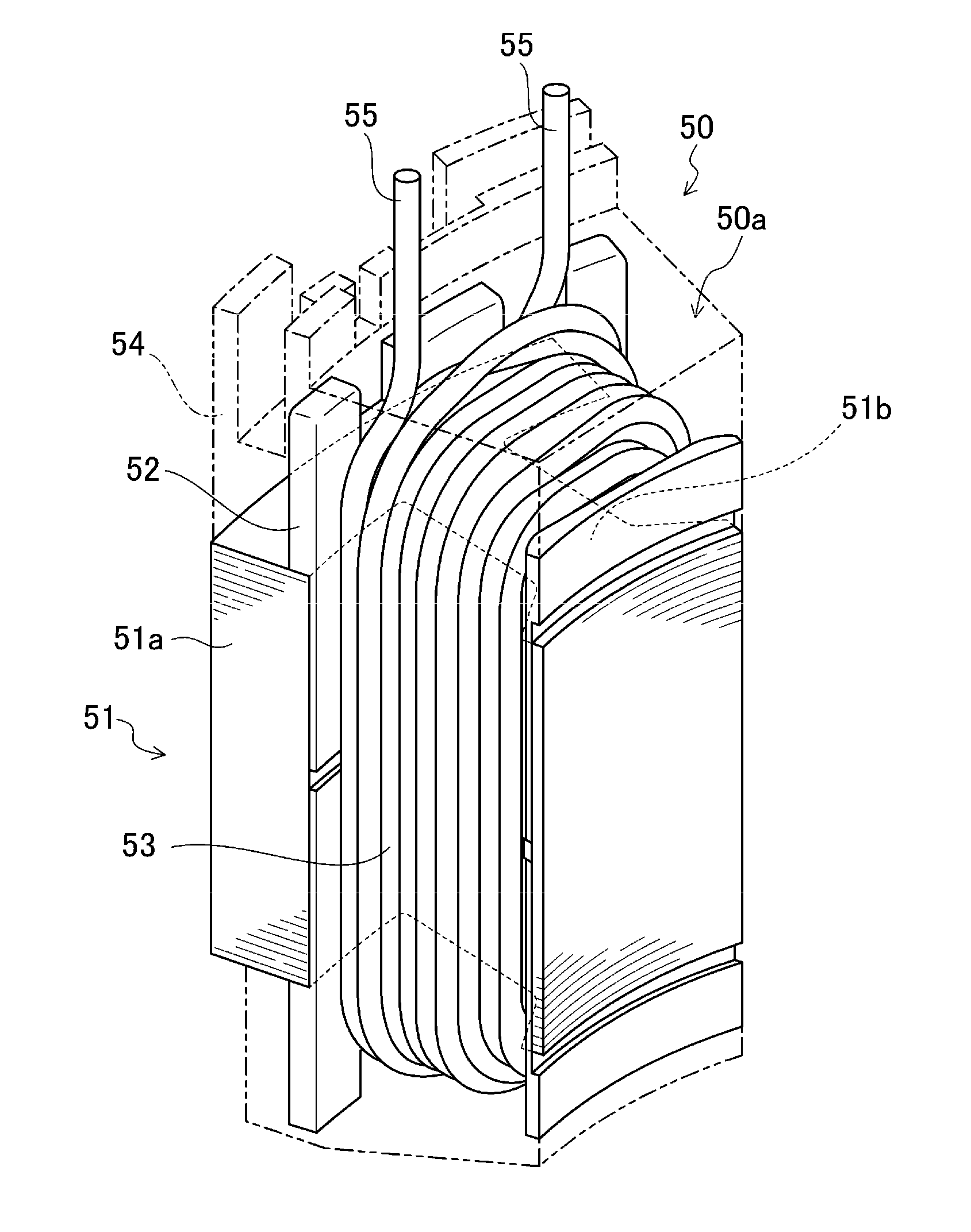

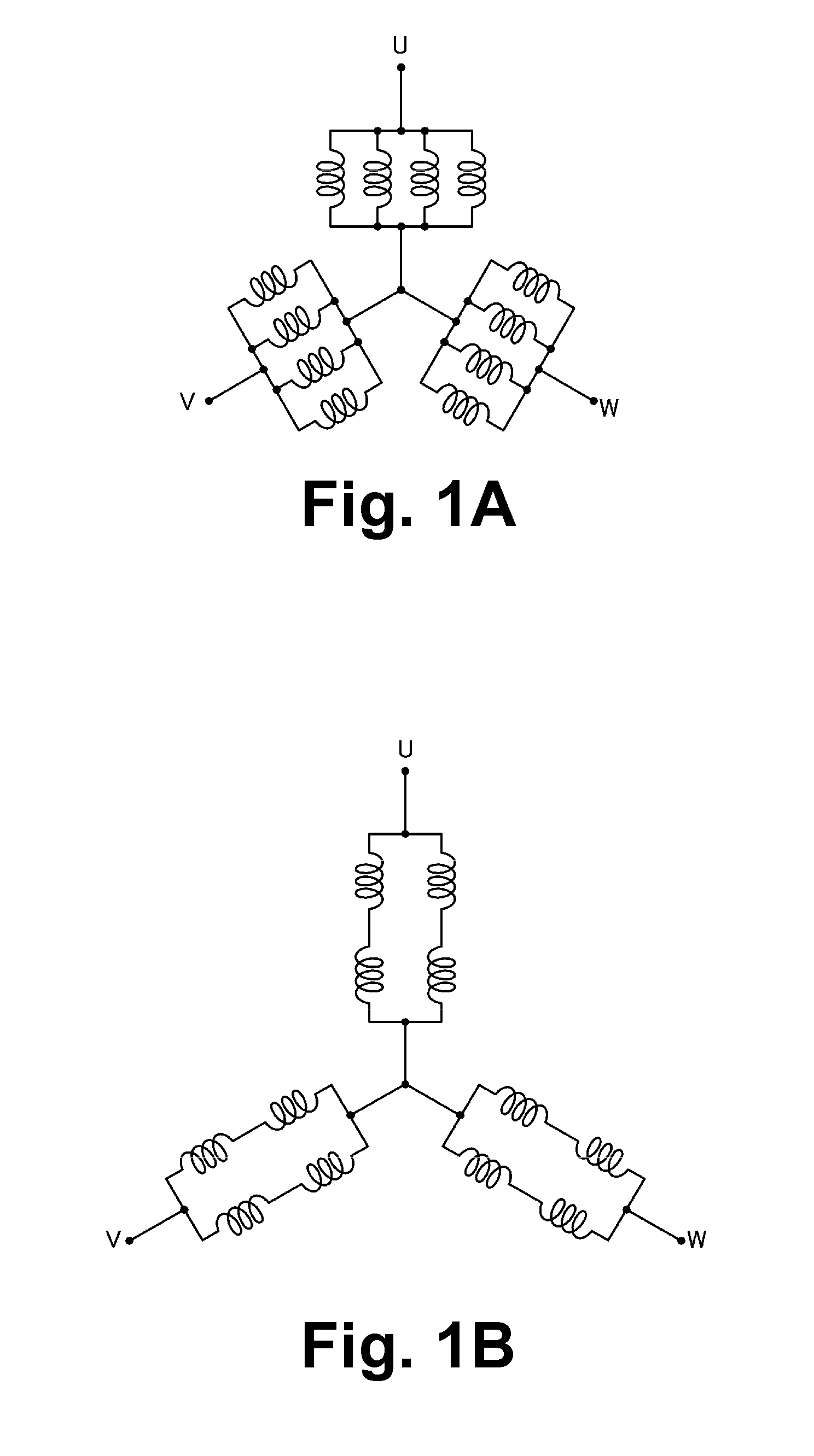

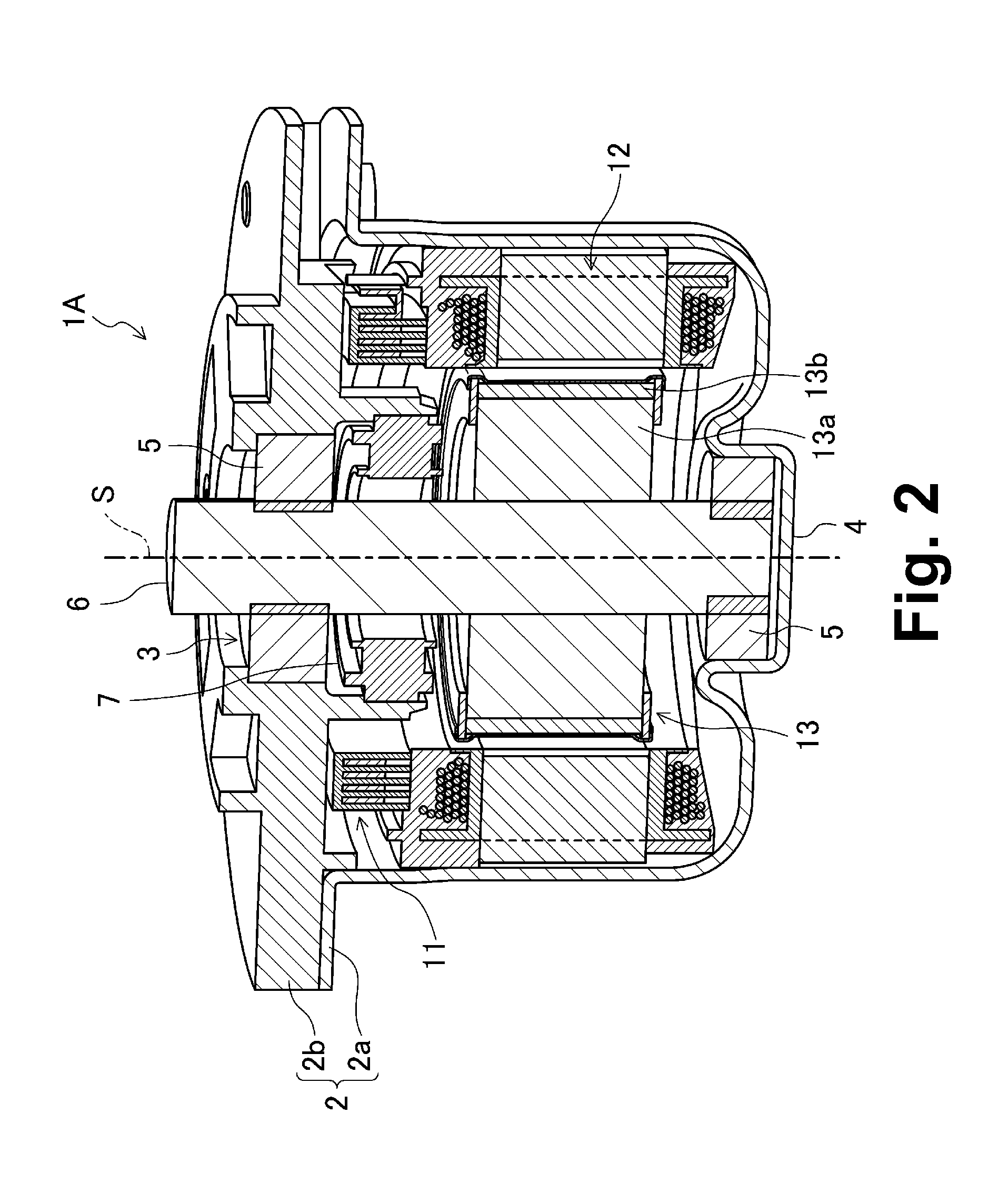

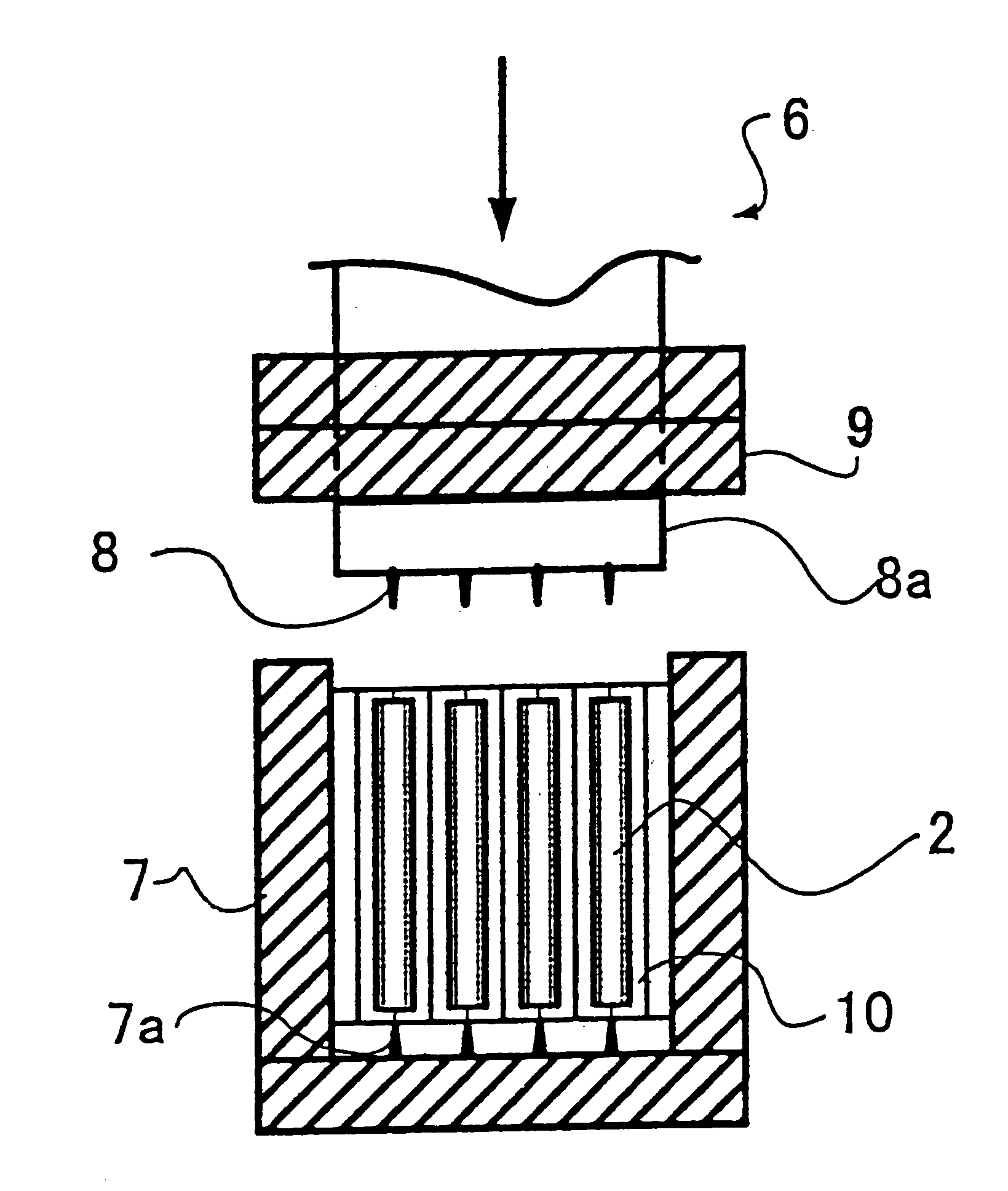

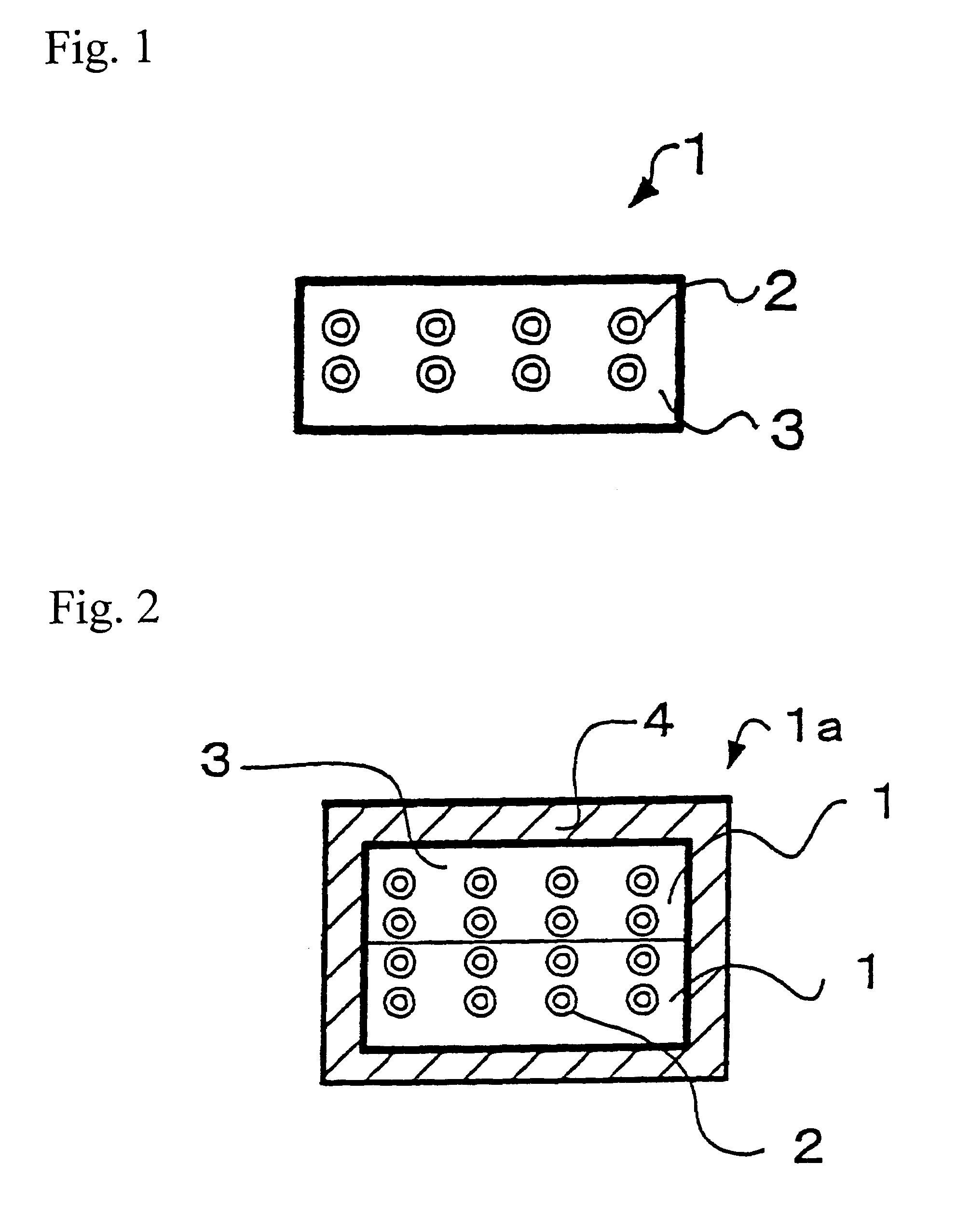

Stator segment and motor

ActiveUS20120293024A1Improve circularityProvide accuratelyWindings insulation shape/form/constructionManufacturing dynamo-electric machinesEngineeringStructural engineering

A stator segment arranged to define a portion of an annular stator includes a core segment including a core back portion arranged to extend in a circumferential direction of the stator, and a tooth portion arranged to extend from the core back portion in a radial direction of the stator; a coil wound around the tooth portion and including a pair of coil wire terminals; an insulating layer arranged between the coil and the tooth portion; and a resin layer arranged to seal the entire coil except for the pair of coil wire terminals. Circumferential end walls of the resin layer are arranged circumferentially inward of circumferential end walls of the core back portion.

Owner:NIDEC CORP

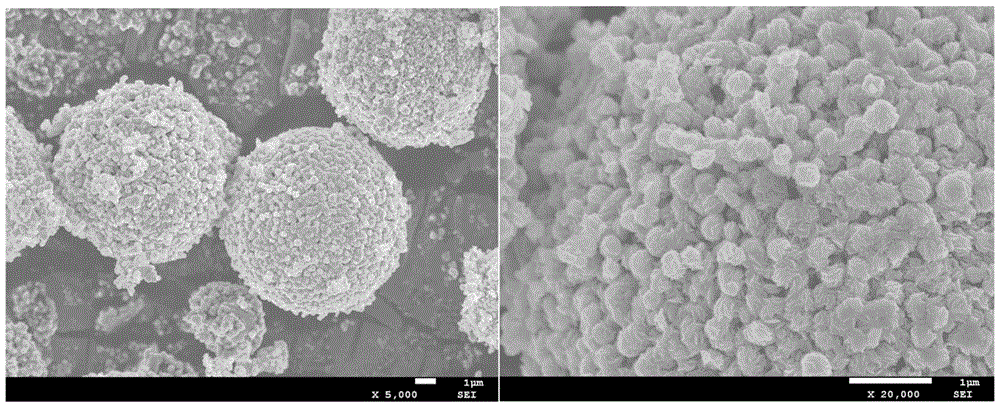

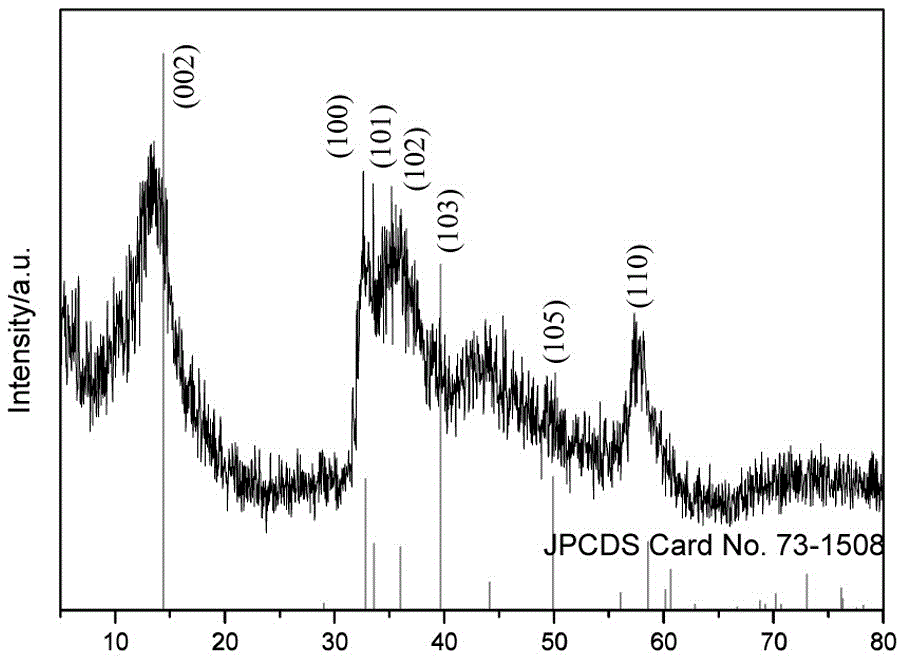

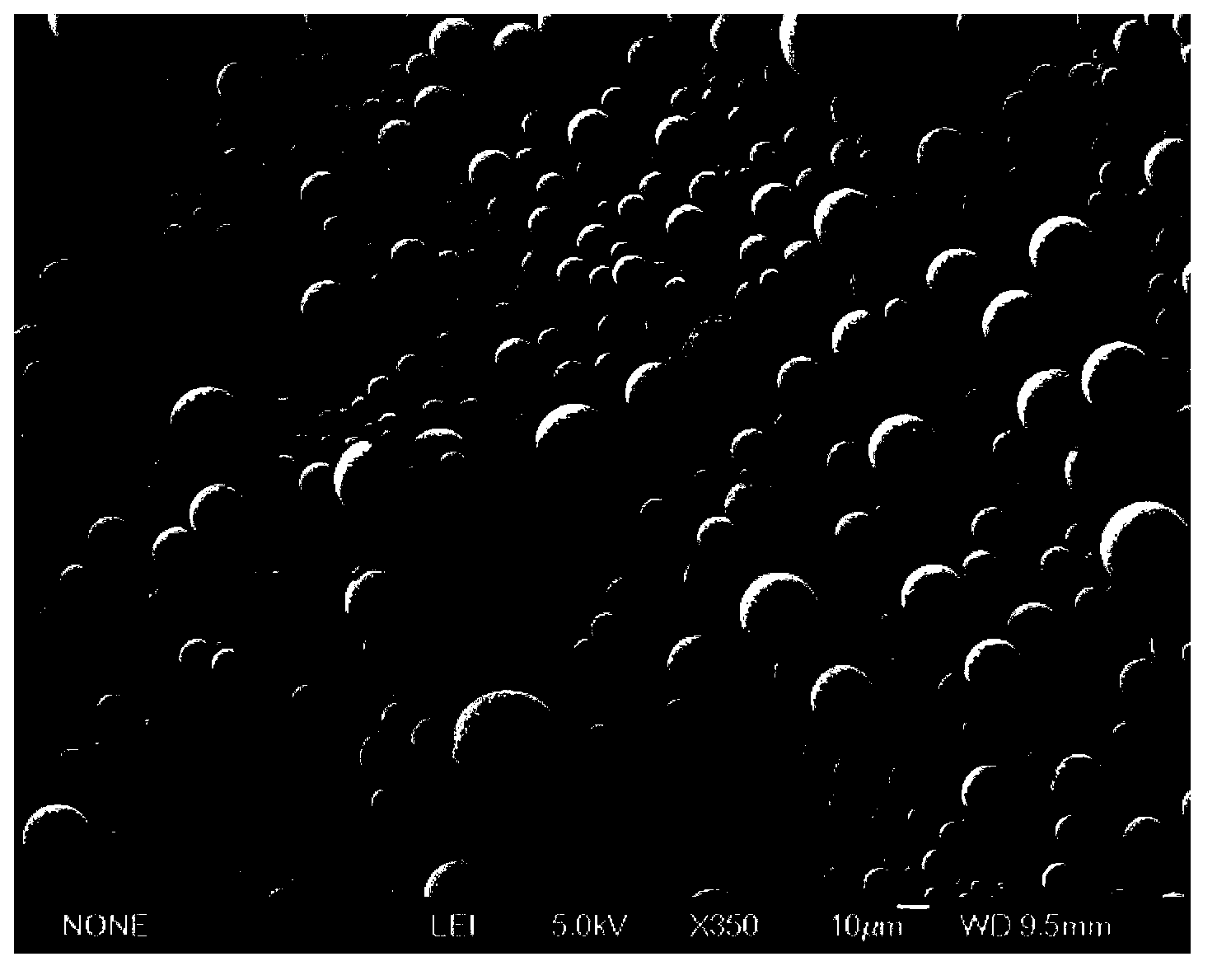

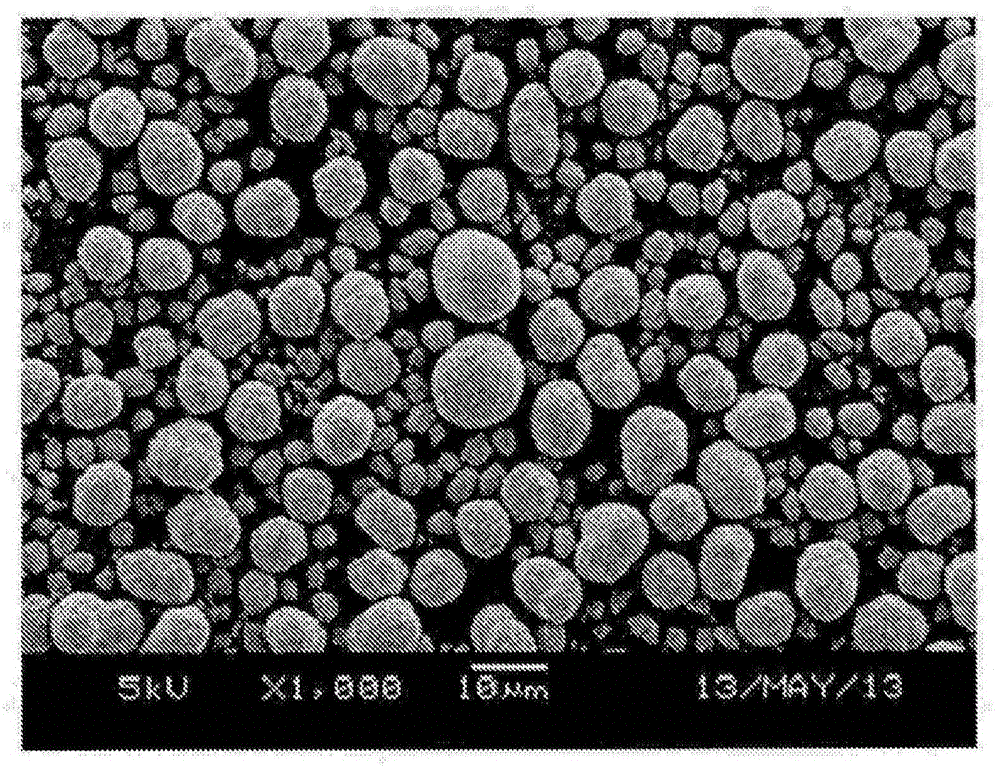

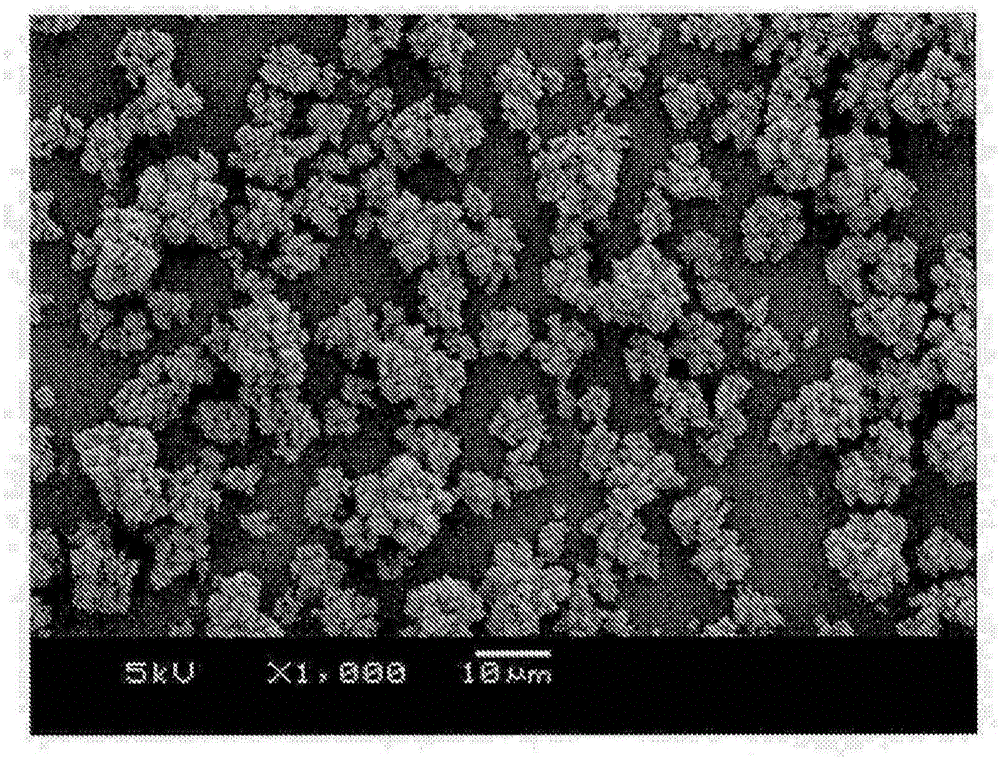

High-performance micro-nano multilevel-structure MoS2 material and preparation method and application thereof

ActiveCN105600824AGood dispersionUniform particle sizeElectrolysis componentsOther chemical processesMaterials preparationMicrometer

The invention relates to the technical field of nano material preparation and energy environmental protection, in particular to high-performance micro-nano multilevel-structure MoS2 material and a preparation method thereof. The preparation method is characterized in that nonionic surfactant polyglycol is introduced to allow MoS2 super-thin nano sheets generated by reaction to self-assemble into nano-sphere units, the nano-sphere units further assemble to form microspheres with a micro-nano multilevel structure, the microspheres are 2-10 micrometers in diameter, the nano-spheres are 50-200 nanometers in diameter, the nano sheets are 100-300 nanometers in length, 100-300 nanometers in width and 2-50 nanometers in thickness, the nano-sphere units interweave to form the microspheres, and the specific surface area of the microspheres is 10-100m<2> / g. The MoS2 material can bring the advantages of high activity and high efficiency of nano units into play. The preparation method completed in one step under a hydrothermal condition is simple in process, low in energy consumption and cost, short in preparation cycle, environmental friendly, beneficial to engineering large-scale preparation and application, and the like.

Owner:CHINA THREE GORGES UNIV

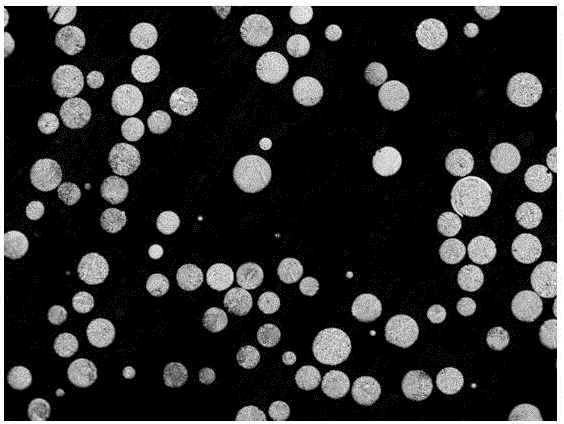

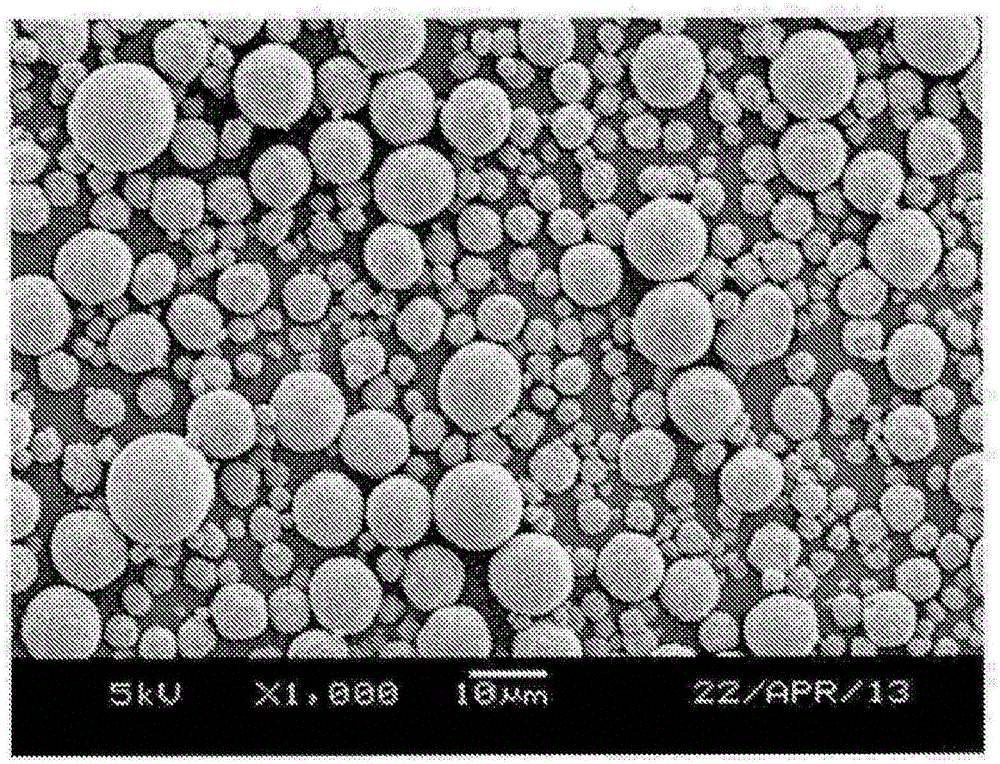

Phenolic resin hollow bead, and preparation method and application thereof

The invention provides a phenolic resin hollow bead and a preparation method and application thereof, relating to the field of plastics. The interior of the phenolic resin hollow bead is of a hollow structure, and the particle size of the bead is in a range of 5 to 100 mu m. The preparation method for the bead comprises the following steps: adding a water-soluble phenolic resin into water, carrying out stirring so as to form uniform slurry and selectively adding a foaming agent into the slurry; and subjecting the slurry to spray drying so as to allow the water-soluble phenolic resin to be cured and carrying out granulation so as to obtain the phenolic resin hollow bead. The phenolic resin hollow bead prepared in the invention has a small particle size and controllable particle size distribution and can be well applied in fields like petroleum drilling fluid; the preparation method for the bead is simple, takes a short period of time for preparation of the bead and can be easily industrialized.

Owner:CHINA PETROLEUM & CHEM CORP +2

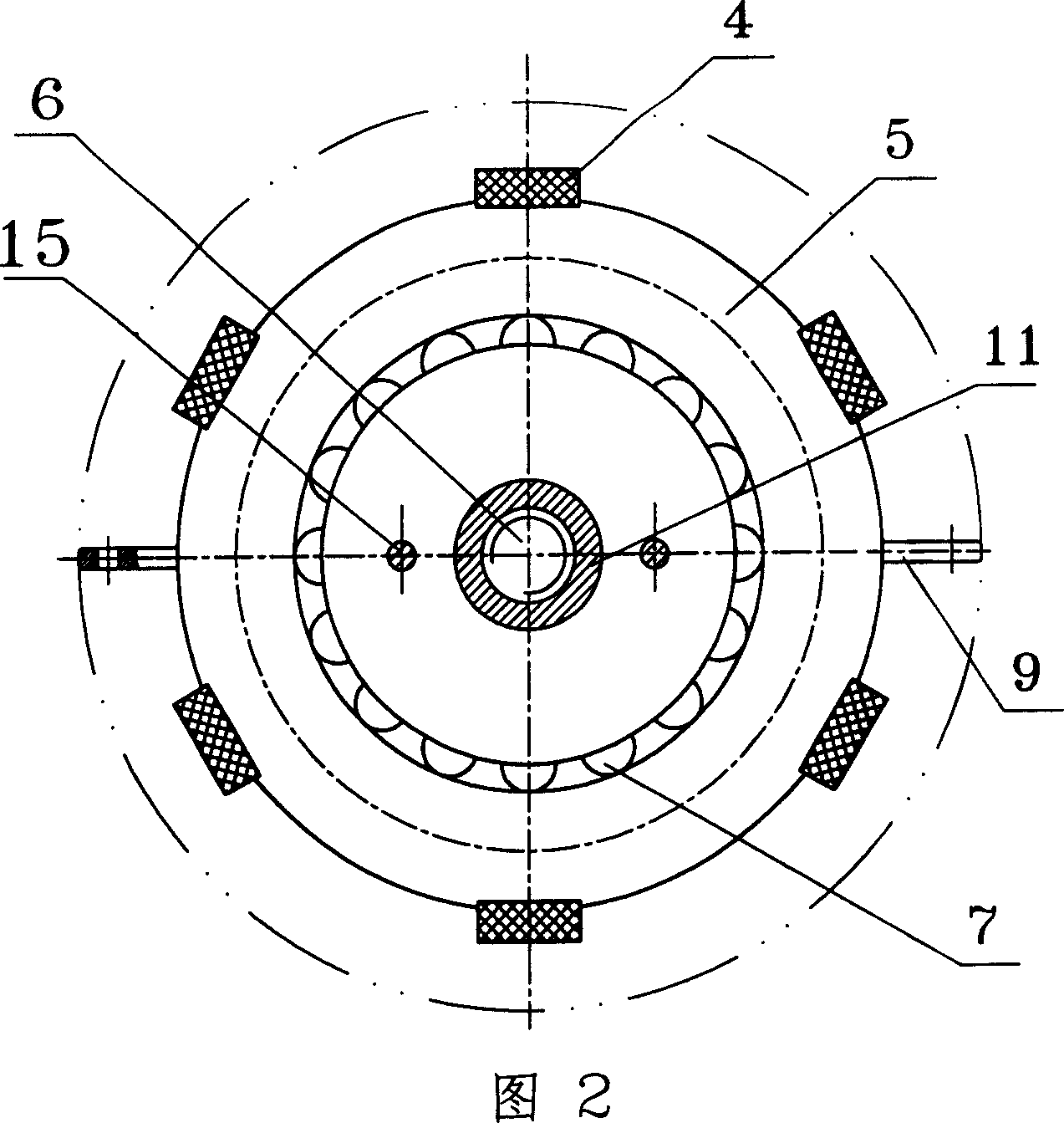

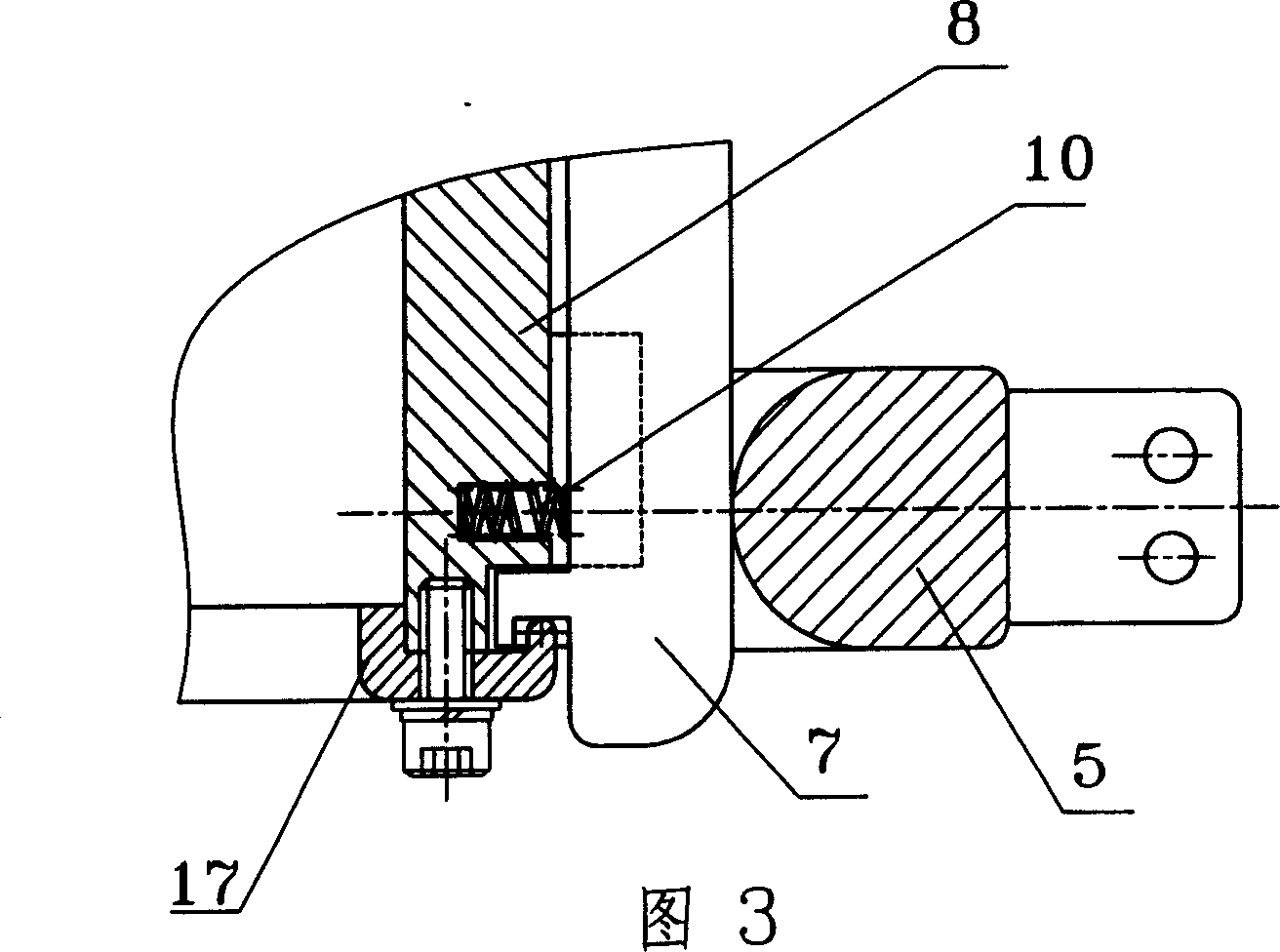

Preparation method of organic/inorganic composite globules

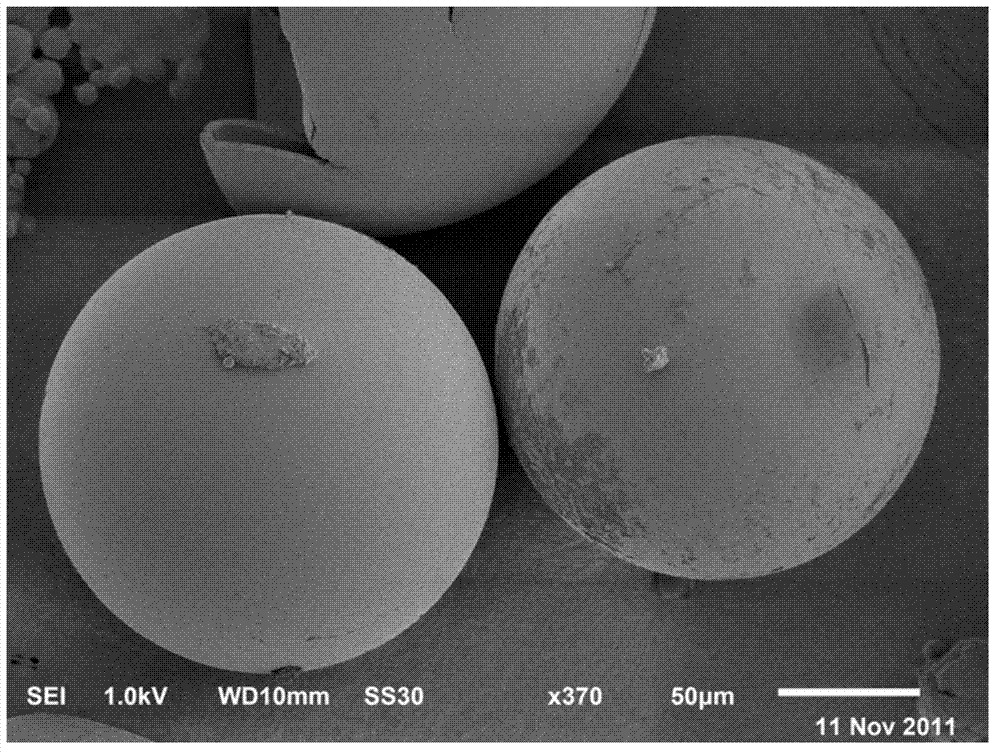

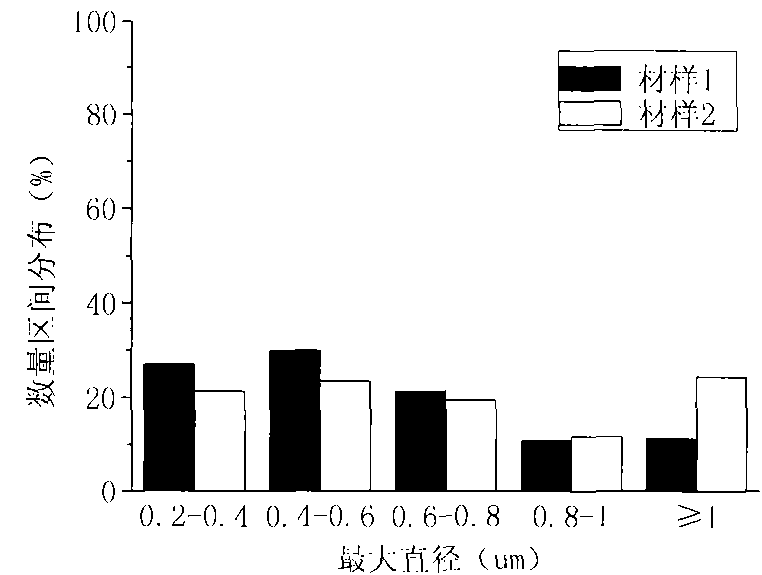

ActiveCN103509143AUniform particle sizeImprove circularityDrilling compositionPolystyreneMicroparticle

The invention provides a preparation method of organic / inorganic composite globules. The preparation method comprises the following steps: dissolving polystyrene into polymerization monomer styrene, uniformly dispersing hydrophobic nanometer inorganic particles into the solution, and meanwhile, adding an initiator and a crosslinking agent, uniformly dissolving the components and uniformly dispersing the components in the aqueous solution, heating up to polymerize the monomers, performing suction filtering on the obtained solid phase, and drying to obtain the organic / inorganic composite globules. The temperature resistance of the composite globules prepared by the method is higher than that of pure plastic globules, the particle diameters are uniform, the surfaces are smooth, and the composite globules can be used as solid lubricants for drilling fluids.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hollow polystyrene plastic spheres, and preparation method and application thereof

ActiveCN103387691AUniform particle sizeProduct circularity is goodDrilling compositionSolid phasesPetroleum

The invention provides a preparation method for hollow polystyrene plastic spheres, and spheres prepared by the method, and an application of the spheres, and relates to the plastic field. The preparation method for the hollow polystyrene plastic spheres comprises the steps of dissolving an oil-phase solute in an organic solvent, adding a foaming agent, mixing uniformly to obtain an oil phase, wherein the oil-phase solute is polystyrene or a mixture of polystyrene and styrene monomers; dissolving a dispersing agent or the dispersing agent and an emulsifying agent in water to obtain a water phase; mixing the oil phase and the water phase uniformly, so as to make the oil phase dispersed uniformly in the water phase to obtain an emulsion; heating to evaporate the organic solvent while curing and foaming the oil-phase droplets; then separating a solid phase from the emulsion; and drying to obtain the hollow polystyrene plastic spheres. The hollow polystyrene plastic spheres have an internal hollow-core structure, are small in particles and controllable in particle size distribution, and can be well applied in the fields of petroleum drilling fluids, cosmetics, coatings, etc. The preparation method is simple in process and short in preparation time and can be easily industrialized.

Owner:CHINA PETROLEUM & CHEM CORP +1

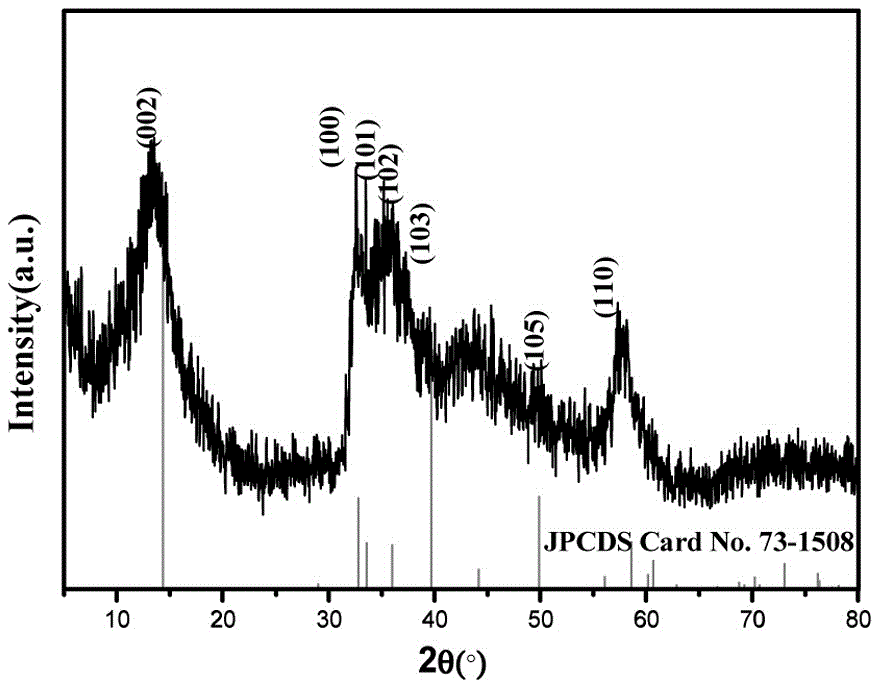

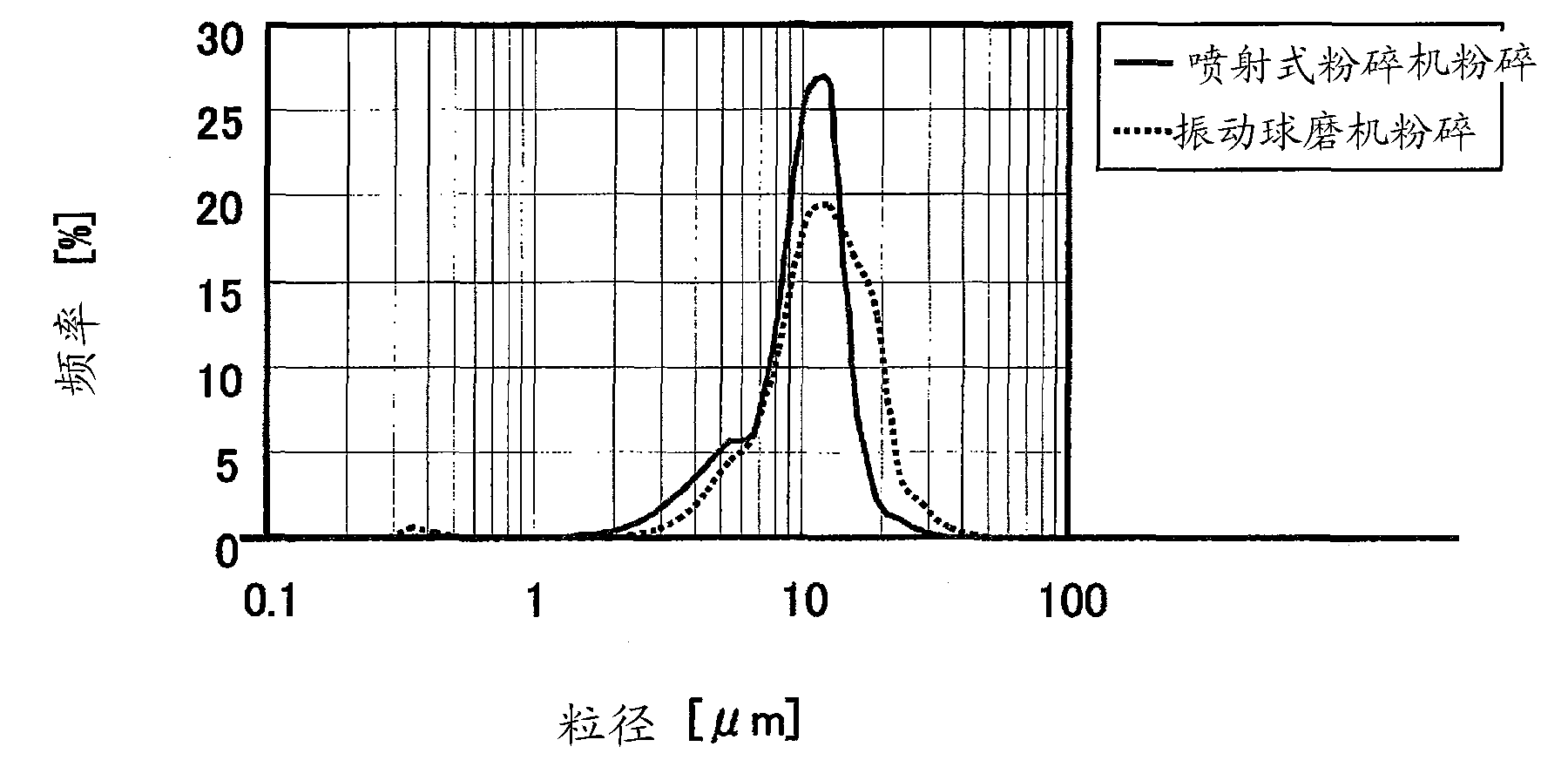

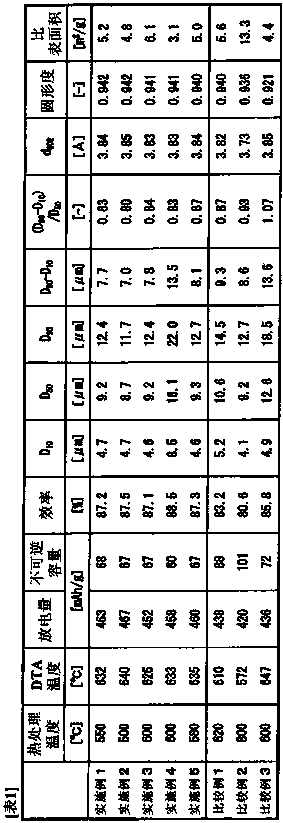

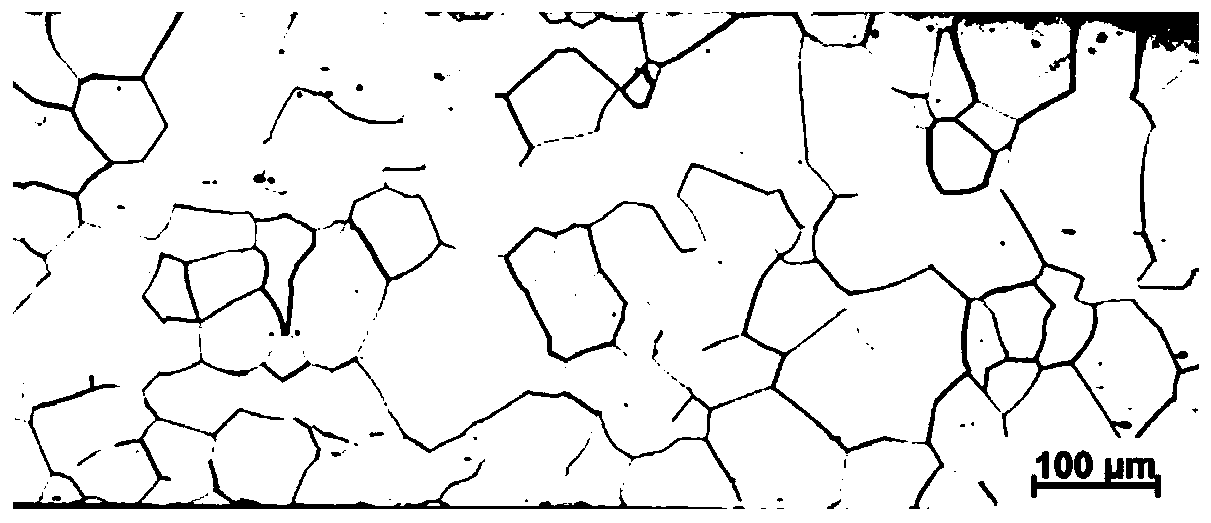

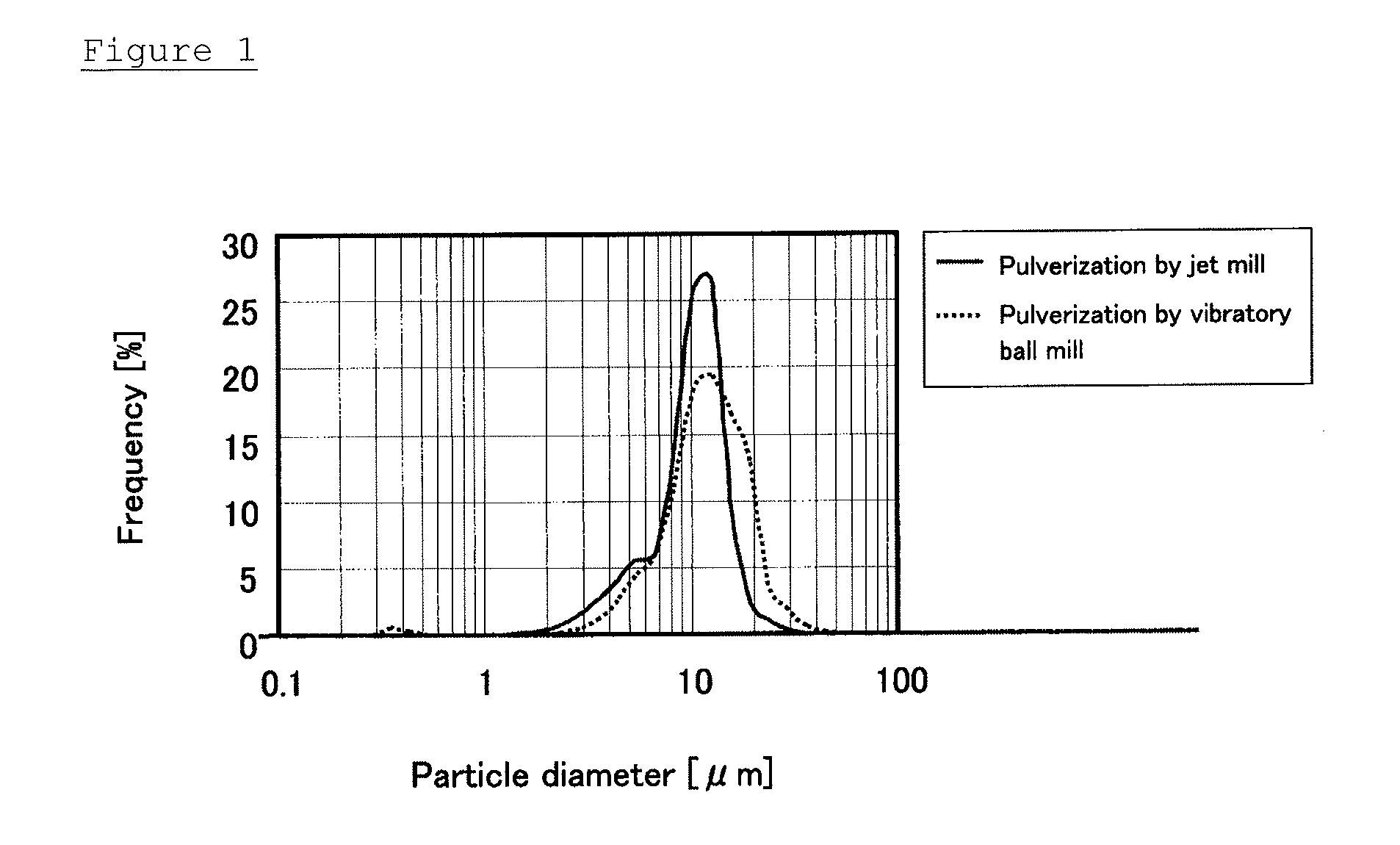

Carbonaceous material for non-aqueous electrolyte secondary battery negative electrode

InactiveCN103415948AImprove charge and discharge efficiencyReduce thicknessCell electrodesCarbon preparation/purificationAir atmosphereMicrometer

The purpose of the present invention is to provide a carbonaceous material for a non-aqueous electrolyte secondary battery negative electrode, which has large charge-discharge capacity, high charge-discharge efficiency and excellent charge-discharge cycle properties. The purpose is achieved by a carbonaceous material for a non-aqueous electrolyte secondary battery negative electrode, characterized in that the average interlayer spacing on face (002) is 0.365-0.40 nm as measured by an X-ray diffraction method, no exothermic peak appears in a temperature region of 620 DEG C or lower as measured by a differential thermal analysis under an air atmosphere, the BET specific surface area is 1-7 m2 / g, the average particle diameter (D50) is 5-25 micrometer, and the (D90-D10) / D50 ratio is 1.05 or less.

Owner:KUREHA KAGAKU KOGYO KK

Non-oriented electrical steel for ultrahigh-effect constant-frequency compressor and preparation method of non-oriented electrical steel

InactiveCN110241359AHigh dimensional accuracyReduce iron consumptionChemical compositionConstant frequency

The invention discloses non-oriented electrical steel for an ultrahigh-effect constant-frequency compressor and a preparation method of the non-oriented electrical steel. The non-oriented electrical steel for the ultrahigh-effect constant-frequency compressor comprises the following chemical components of, in percentage by weight, 1.0%-1.90% of Si, 0.20%-0.9% of Als, 0.10%-0.60% of Mn, 0.01%-0.02% of P, less than or equal to 0.01% of C, less than or equal to 0.02% of S, less than or equal to 0.02% of N, less than or equal to 0.01% of Ti, less than or equal to 100 ppm of C+S+N+Ti, and the balance Fe and inevitable impurity elements. According to the reasonable component design, the technological technologies such as hot rolling, normalizing, cold rolling, continuous annealing and the like are matched to optimize, so that the non-oriented electrical steel for the ultrahigh-effect constant-frequency compressor is obtained, which the thickness of 0.5mm, P1.0 / 50 is less than or equal to 3.20W / kg, B5000 is greater than or equal to 1.72T, the yield strength Rp0.2 is less than or equal to 350 MPa, and the transverse longitudinal strength difference delta Rp0.2 is less than or equal to 10 MPa.

Owner:MAANSHAN IRON & STEEL CO LTD

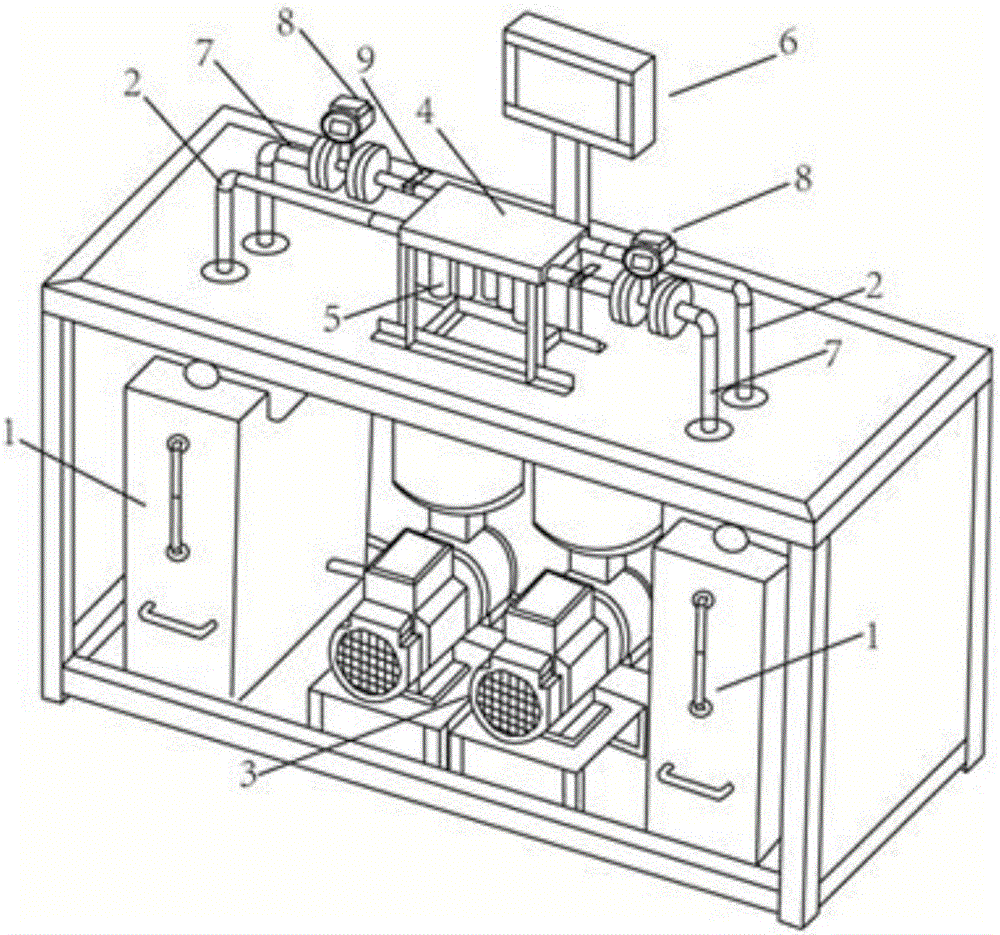

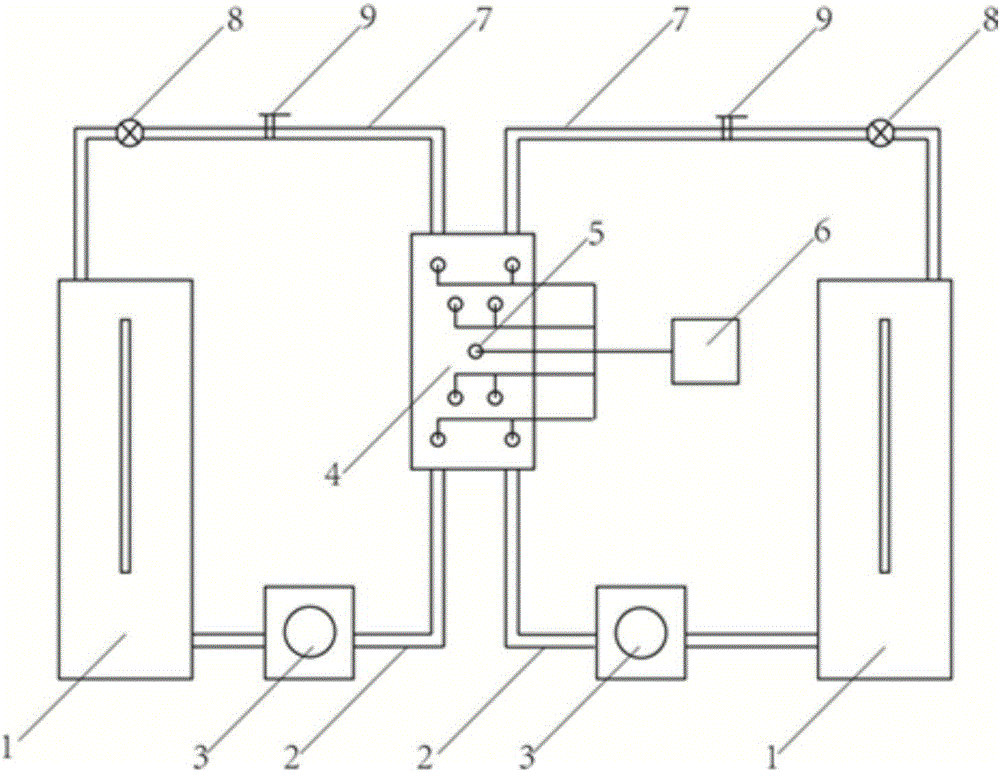

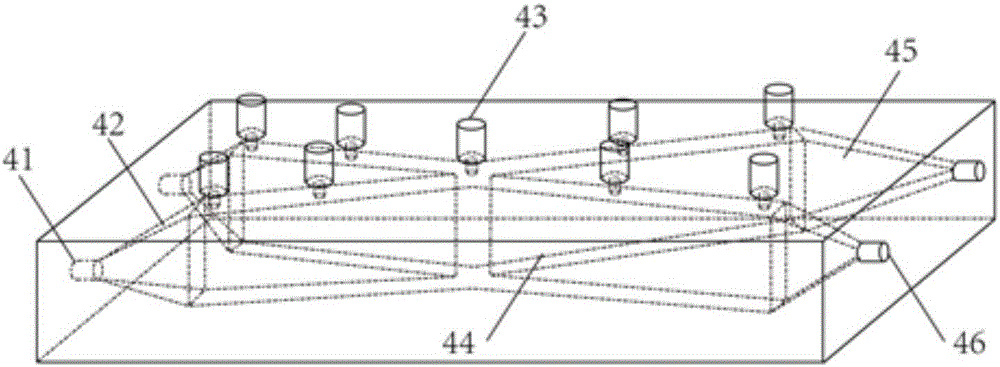

Rough cross crack seepage testing device and method

ActiveCN106290107ARoughness is easy to controlAdjustable crack crossing anglePermeability/surface area analysisStructure of the EarthEngineering

The invention discloses a rough cross crack seepage testing device and method. The rough cross crack seepage testing device comprises a cross crack model, the interior of the cross crack model is of a crossed crack structure, dewatering areas and water gathering areas are arranged on the two sides of the crack structure, the dewatering areas are communicated with water inlets respectively, the water gathering areas are communicated with water outlets respectively, and the water inlets and the water outlets located on the same side of the cross crack model are connected with the same water tank and form a circulation loop; by means of the two circulation loops, crack seepage of one-way entering and multi-way exiting, multi-way entering and one-way exiting and multi-way entering and multi-way exiting is achieved; besides, pressure measuring holes communicated with the crack structure are further formed in the crack structure, and water pressure sensors for measuring fluid pressure are arranged in the pressure measuring holes.

Owner:SHANDONG UNIV

Carbonaceous material for non-aqueous electrolyte secondary battery negative electrode

InactiveUS20140080004A1High discharge capacity to charge capacityEasy dischargeCarbon preparation/purificationNon-aqueous electrolyte accumulator electrodesAir atmosphereMetallurgy

The object of the present invention is to provide a carbonaceous material for a negative electrode of non-aqueous electrolyte secondary batteries having a great charge-discharge capacity, high charge-discharge efficiency, and an excellent charge-discharge cycle characteristic.The object can be solved by a carbonaceous material for a negative electrode of non-aqueous electrolyte secondary batteries, characterized in that an average (002) interlayer spacing d002 determined by X-ray diffractometry is 0.365 to 0.400 nm, a specific surface area determined by a BET method is 1 to 7 m2 / g, an average diameter is 5 to 25 μm, a value of (D90−D10) / D50 is 1.05 or less, and an exothermic peak does not emerge at a temperature range of 620° C. or less in differential thermal analysis measured in an air atmosphere.

Owner:KUREHA KAGAKU KOGYO KK

Preparing method for superfine high-grade spherical GH4133 alloy powder

The invention discloses a preparing method for superfine high-grade spherical GH4133 alloy powder. The method includes the steps that firstly, burdening is conducted according to components of a GH4133 alloy, and a GH4133 alloy bar is formed through smelting; secondly, the GH4133 alloy bar is subjected to finish machining to form an electrode bar; thirdly, the electrode bar is loaded into a reaction chamber, vacuum pumping is conducted on the reaction chamber, and the reaction chamber is inflated with inert gas according to a certain proportion; and fourthly, a plasma torque comprises a tungsten cathode and a copper anode, the electrode bar does not serve as the electrode, the end portion of the electrode bar is heated so that the end portion can be evenly melted; atomized liquid drops are thrown out from the end portion of the electrode bar so that the liquid drops can be rapidly cooled in the inert gas environment to form spherical particles and fall into a collector; and fifthly, the prepared GH4133 alloy powder is screened and subjected to electrostatic impurity removing in the inert gas protection environment. The GH4133 alloy powder prepared through the method has the beneficial effects of being superfine, high in purity capable of achieving a high-grade spherical shape and free of hollow powder and satellite powder.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

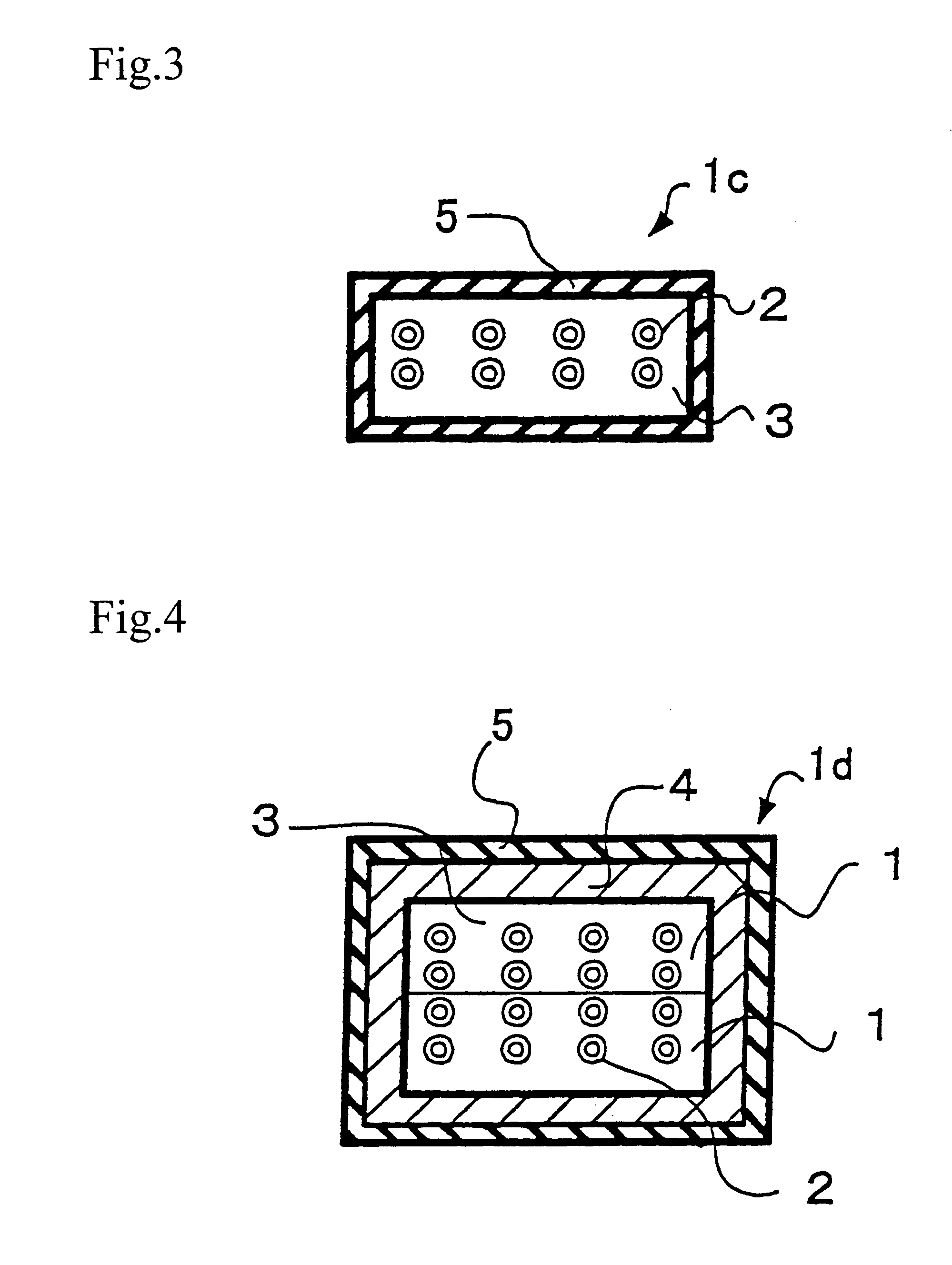

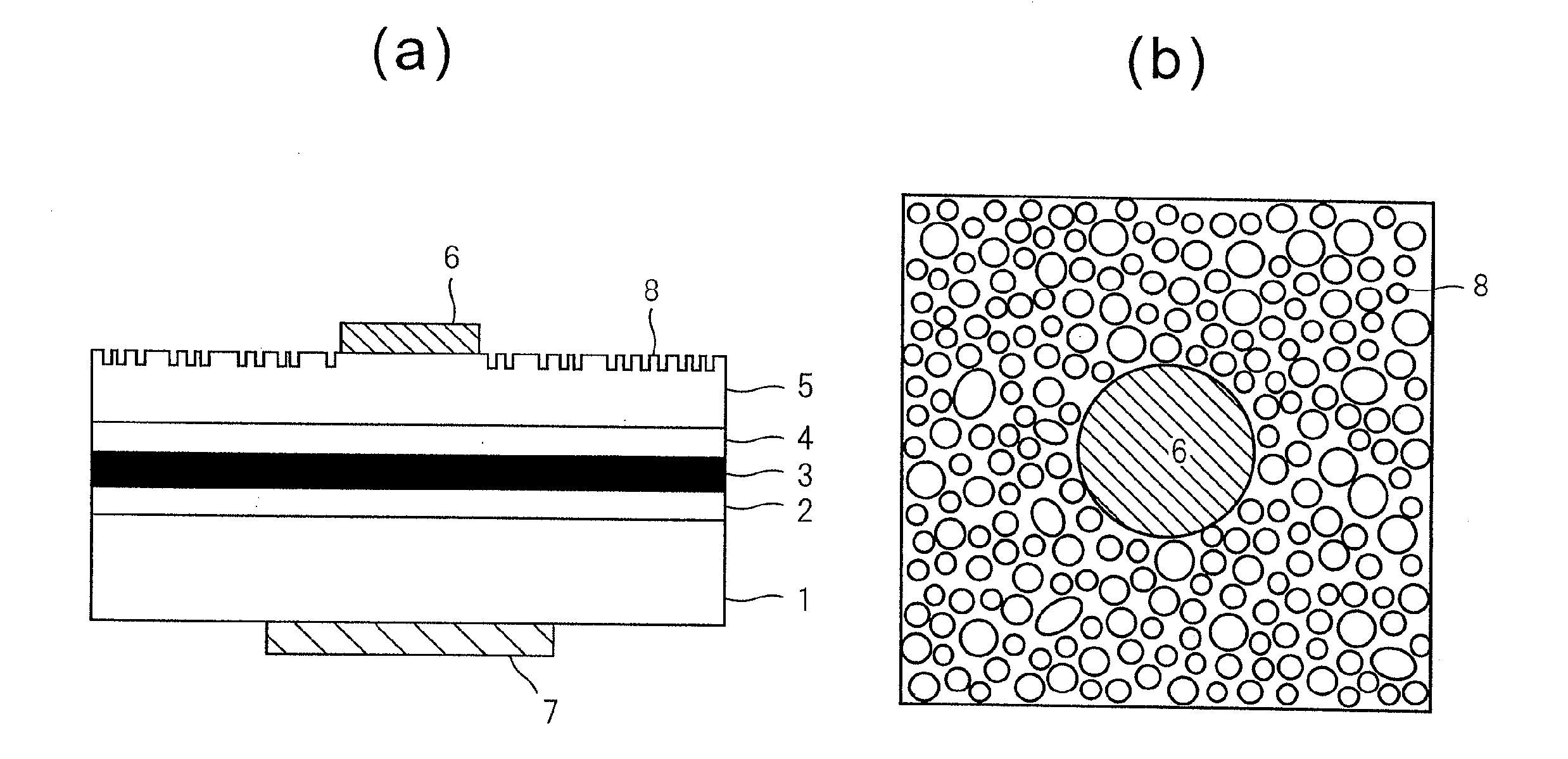

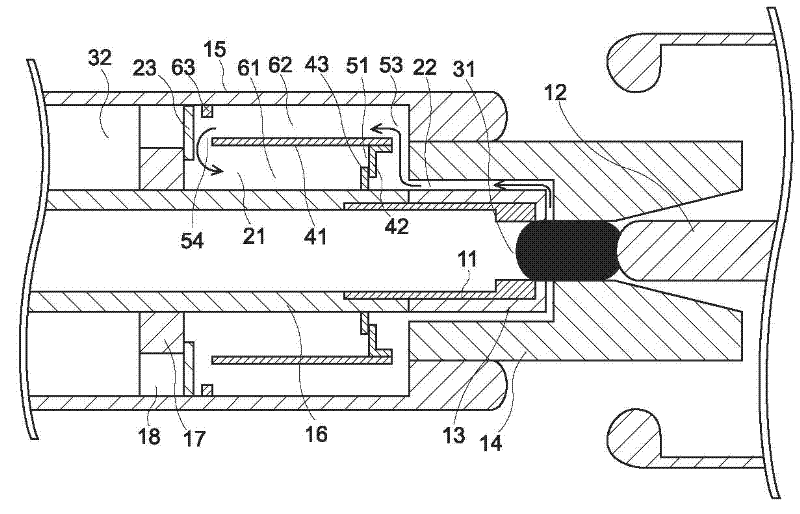

Connector component for multi-core optical fiber, ferrule, and method for manufacturing the same

InactiveUS7083332B2Improve wettabilityAvoid formingCoupling light guidesElectroforming processesThermal sprayingEngineering

The objective is to offer a connector component for multi-core optical fiber, or an assembly of ferrules, having high precision ferrules in concentricity, circularity, axial linearity, and spacing distance, as well as to offer a method of manufacturing the same at a reduced cost. The connector (or ferrules) is featured by its manufacturing method including thermal-spraying or electroforming is applied, using a resin or a metal, to a plurality of cylinder-shaped ferrules, under the condition that projections which are positioned opposite each other of a positioning member are fitted and nipped to both ends of insertion holes of the cylinder-shaped ferrules so that each ferrule is properly positioned and the central axes are parallel to each other at specified positions so that the plurality of cylinder-shaped ferrules are coated.

Owner:MUKOUDA TAKAHIKO

Novel method used for recycling urban industrial sludge

InactiveCN106277692AMain modes of widening processingLow priceSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningCombustionExpanded clay aggregate

The invention discloses a novel method used for recycling urban industrial sludge. The novel method comprises following steps: water content of urban industrial sludge obtained via sewage treatment plant mechanical dewatering is reduced to 50 to 65% using a drying device, wherein an independent heat source or gas waste heat is adopted by the drying device as a heat source; the dewatered sludge, an auxiliary material, and a certain amount of an additive are mixed at a certain ratio, wherein the above materials are delivered into corresponding feed hoppers, and automatic induction weighing machines arranged under the feed hoppers are used for realizing material automatic compounding measuring; an obtained mixture is delivered into a blender for stirring, is conveyed using a conveying belt, and is made into material balls via twisting; the material balls are delivered into a rotary kiln with a certain gradient for calcination, wherein with rotating of the rotary kiln, the material balls roll to a kiln head, 2mm bran is sprayed into the rotary kiln for combustion, and the material balls are transformed into ceramsite via calcination in the kiln; and at last the obtained ceramsite is subjected to drying, natural cooling, sieving and grading, and finished product pre-delivery inspection. The novel method possesses following advantages: waste sludge is changed into valuable things, sludge treatment mode is widened, and sludge is cheap, so that enterprise cost is reduced.

Owner:NINGBO PINGHAI BUILDING MATERIALS

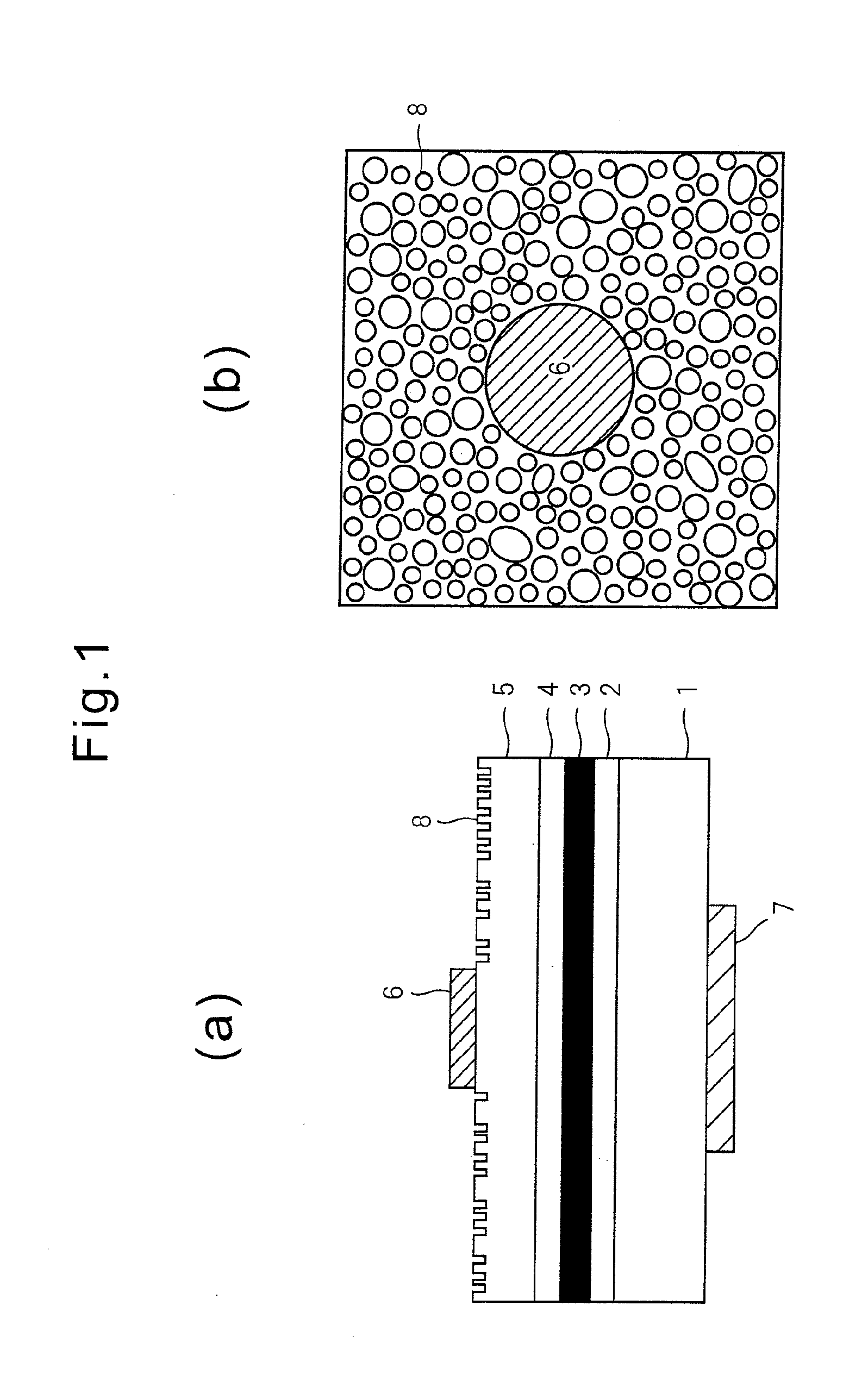

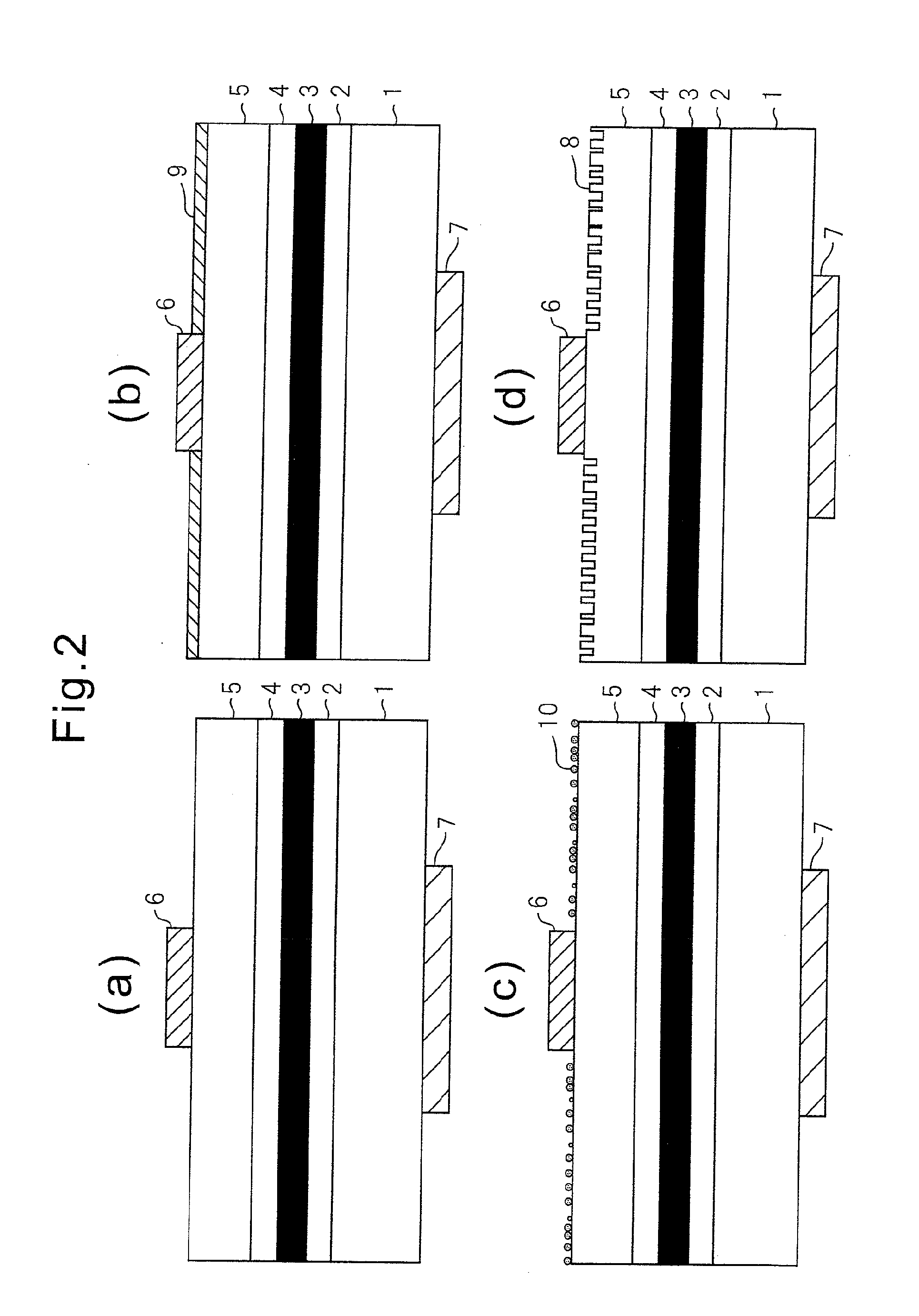

Resin composition for pattern formation, pattern formation method and process for producing light-emitting element

ActiveUS20120097640A1Increase brightnessPromote circulationDecorative surface effectsFilm/foil adhesivesEthylene HomopolymersLength wave

Disclosed are: a resin composition for pattern formation, which enables the stable formation of a pattern at a level of the wavelength of light; a method for forming a pattern having a sea-island structure using the composition; and a process for producing a light-emitting element that can achieve high luminous efficiency properties. The resin composition for pattern formation comprises: (a) a specific block copolymer containing an aromatic ring-containing polymer and a poly(meth)acrylate as block moieties; (b) a homopolymer of a specific aromatic ring-containing polymer; and (c) a homopolymer of a specific poly(meth)acrylate, wherein the ratio of the total amount of the aromatic ring-containing homopolymer (b) and the poly(meth)acrylate homopolymer (c) relative to the entire resin composition is 0% by weight to 90% by weight, and the total amount of an aromatic ring-containing polymer moiety contained in the block copolymer (a) as a block moiety and the aromatic ring-containing homopolymer (b) relative to the entire resin composition is 10% by weight to 60% by weight.

Owner:KK TOSHIBA +1

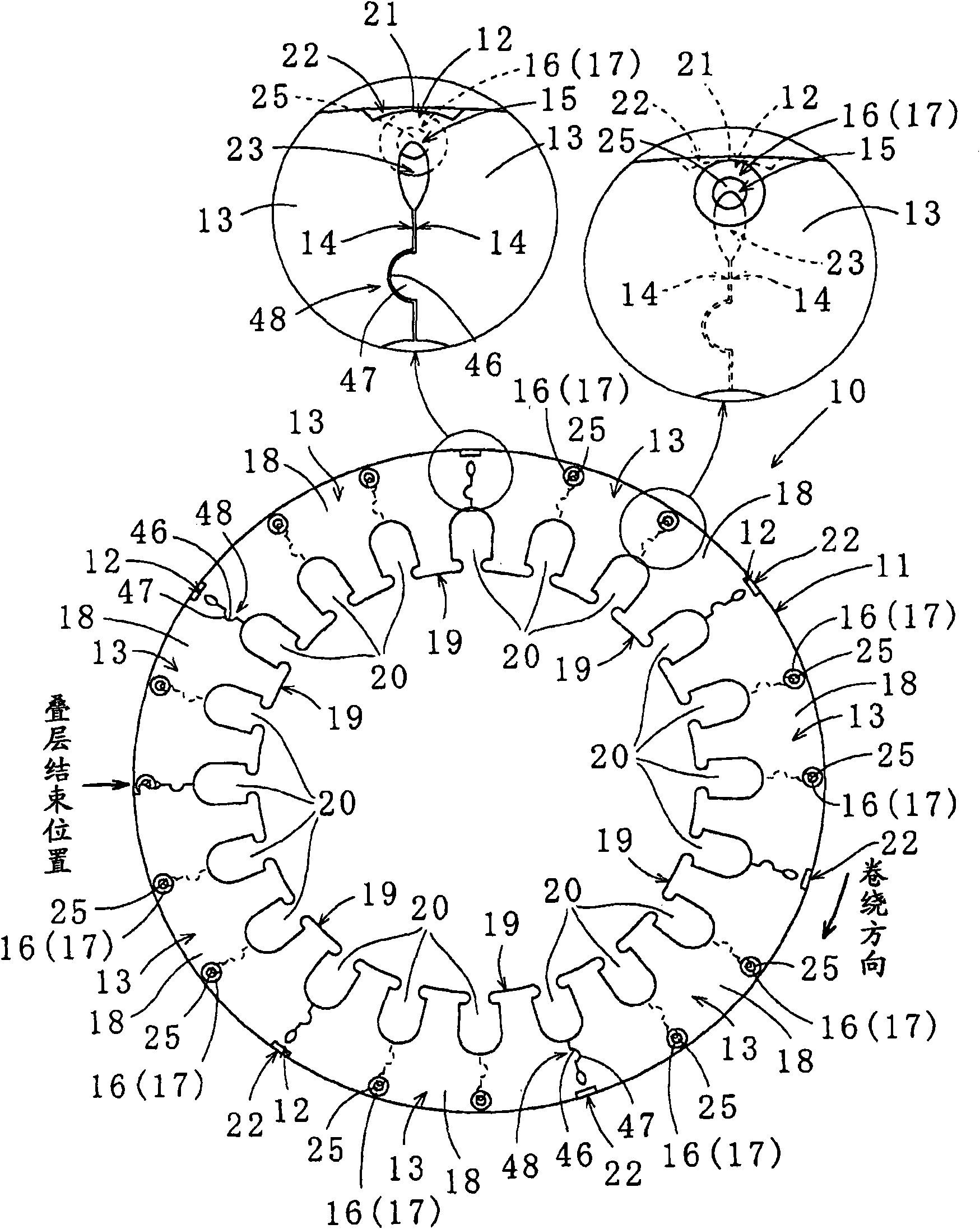

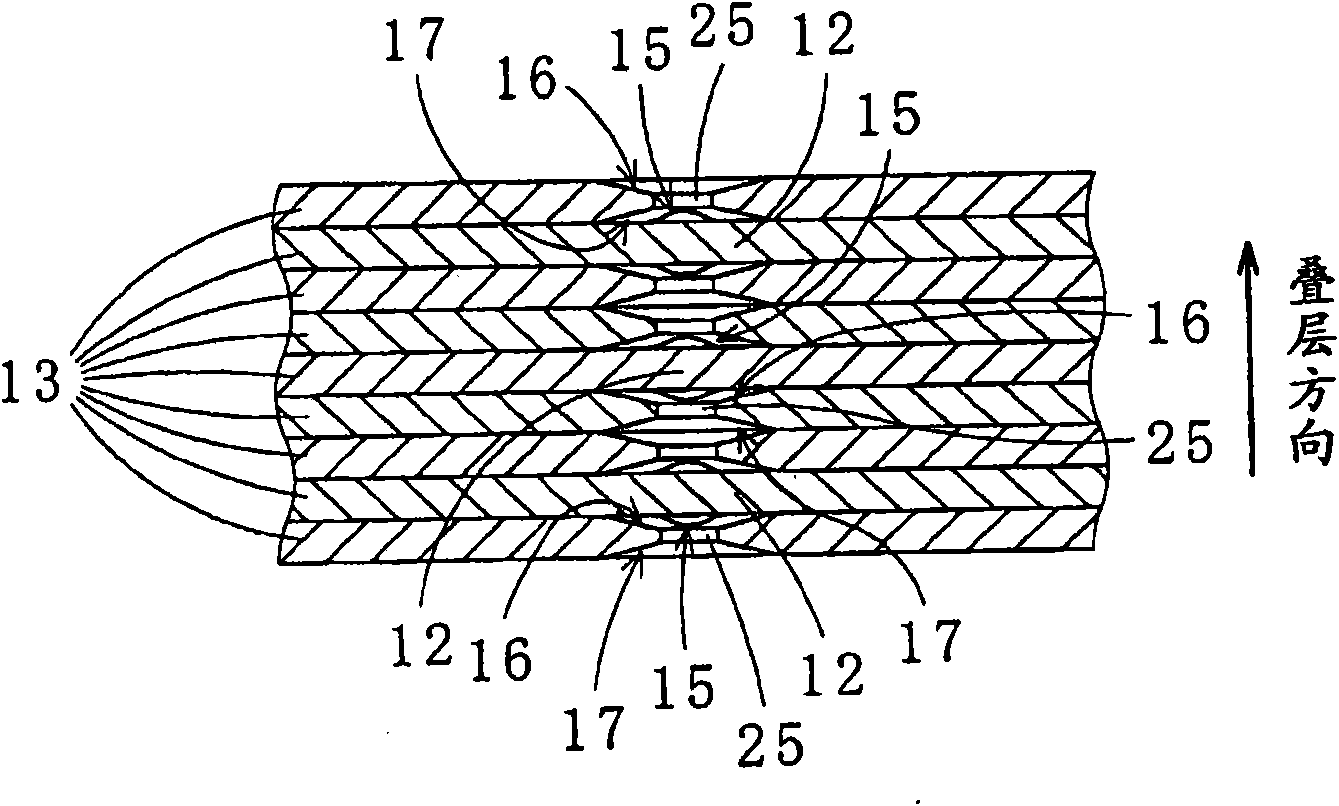

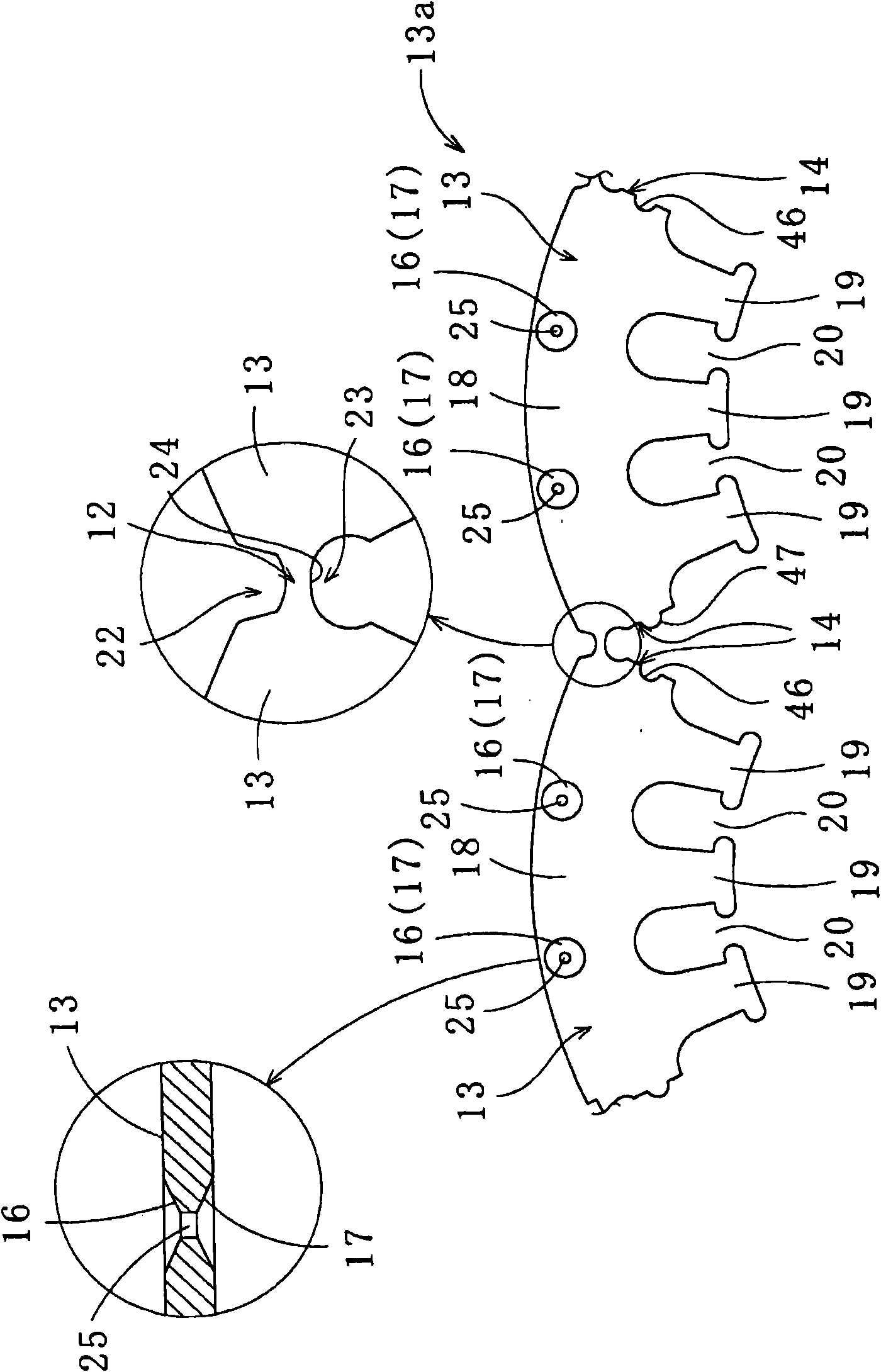

Laminated iron core, and its manufacturing method

InactiveCN101682219AReduce gapEasy quality managementMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringAdjacent segment

The invention provides a laminated core 10 including a plurality of segment core sheets 13 spirally wound and laminated in layers while connecting portions 12 connecting the adjacent segment core sheets 13 are bent, ends of the segment core sheets 13 are aligned with each other and the connecting portions 12 in the adjacent layers are circumferentially displaced relative to each other, the connecting portions 12 located in outer peripheral areas 11 of the segment core sheets 13, the laminated core 10 comprising: a concave cutout 22 formed on a radially outward side of the connecting portion 12, the concave cutout 22 accommodating a radially expanded part 21 within an outer circle of the laminated core 10, the radially expanded part 21 formed in the connecting portion 12 radially outward atthe bending of the connecting portion 12; an interior cutout 23 formed on a radially inward side of the connecting portion 12, the interior cutout 23 defining a bent position of the connecting portion 12; and depressed receptacles 16, 17 respectively formed on a top side and a bottom side of a radially outward area of the segment core sheet 13 except for the connecting portions 12, the depressedreceptacles 16, 17 each receiving a thickness-direction expanded part 15 formed in the connecting portion 12 in a thickness direction thereof at the bending of the connecting portion 12.

Owner:MITSUI HIGH TEC INC

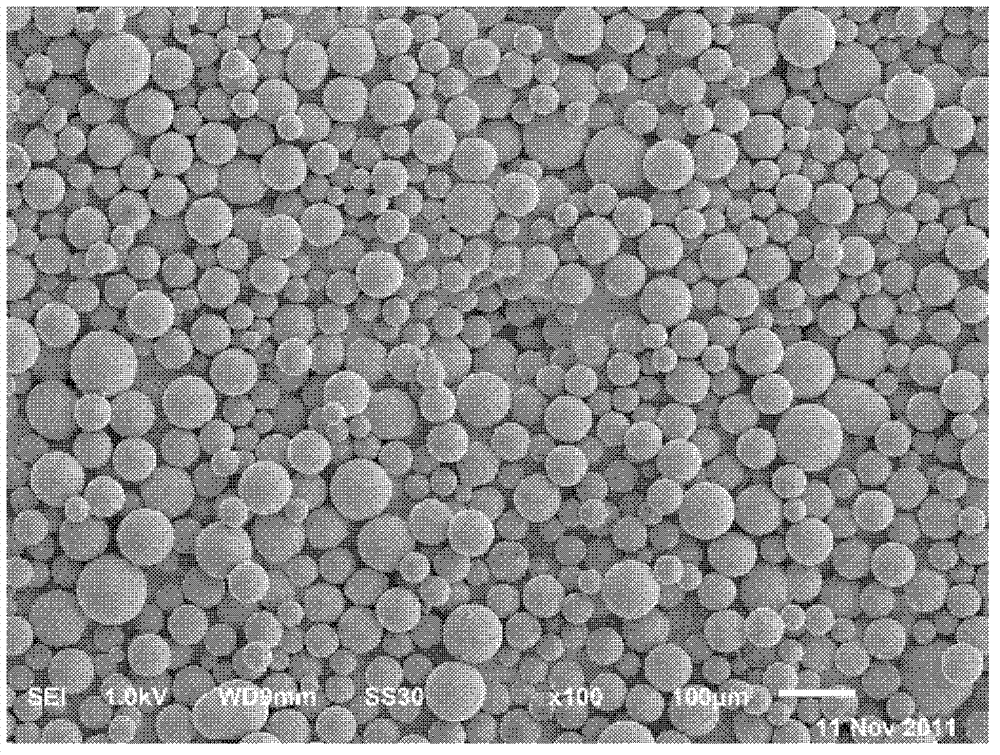

Preparation method for plastic hollow globule, and prepared product and application thereof

ActiveCN103585936AUniform particle sizeImprove circularityMicroballoon preparationMicrocapsule preparationSolid phasesPolycarbonate

The invention provides a preparation method for a plastic hollow globule and the prepared plastic hollow globule and application thereof. The preparation method comprises the following steps: dissolving an oil phase solute in an organic solvent to obtain an oil phase, wherein the oil phase solute is polycarbonate or a mixture of polystyrene and / or a styrene monomer and polycarbonate; adding an emulsifier into water to obtain a first water phase; adding a dispersant or a mixture of the dispersant and the emulsifier into water to obtain a second water phase; fully emulsifying the oil phase and the first water phase to prepare a first emulsion; adding the second water phase into the first emulsion for complete emulsification so as to obtain a second emulsion and heating the second emulsion to allow the organic solvent to evaporate and an oil phase liquid drop to be cured and foamed; and carrying out liquid-solid separation, separating out a solid phase and drying the solid phase to prepare the plastic hollow globule with a hollow structure inside and an average particle size of 1 to 300 mu. The plastic hollow globule has a small and controllable particle size and can be used in fields like oil drilling fluids, cosmetics and paints.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nickel-manganese composite hydroxide particles, method for producing same, positive electrode active material for nonaqueous electrolyte secondary batteries, method for producing positive electrode active material for nonaqueous electrolyte secondary batteries, and nonaqueous electrolyte secondary battery

ActiveCN105934409AImprove circularityImprove filling capacityElectrode thermal treatmentSecondary cellsElectrical batteryManganese

A staring material aqueous solution containing at least Ni and Mn, an aqueous solution containing an ammonium ion donor and an alkali solution are supplied into a reaction vessel, and are mixed so as to obtain an aqueous reaction solution and to have nickel-manganese composite hydroxide particles crystallized. In this connection, the oxygen concentration in the reaction vessel is controlled to be 3.0% by volume or less, the temperature of the aqueous reaction solution is controlled to be 35-60 DEG C, and the nickel ion concentration is controlled to be 1,000 mg / L or more. Consequently, there are obtained nickel-manganese composite hydroxide particles which are represented by general formula NixMnyMt(OH)2+alpha (wherein 0.05 < / = x < / = 0.95, 0.05 < / = y < / = 0.95, 0 < / = t < / = 0.20, x + y + t = 1, 0 < / = alpha < / = 0.5 and M represents one or more elements selected from among Co, Ti, V, Cr, Zr, Nb, Mo, Hf, Ta and W), and which are composed of secondary particles, each of said secondary particles being composed of a plurality of primary particles aggregated together. The average circularity of the secondary particles having particle diameters that are 70% or more of the average particle diameter is 0.82 or more, and the tap density of the nickel-manganese composite hydroxide particles is 2.20 g / cm3 or more.

Owner:SUMITOMO METAL MINING CO LTD

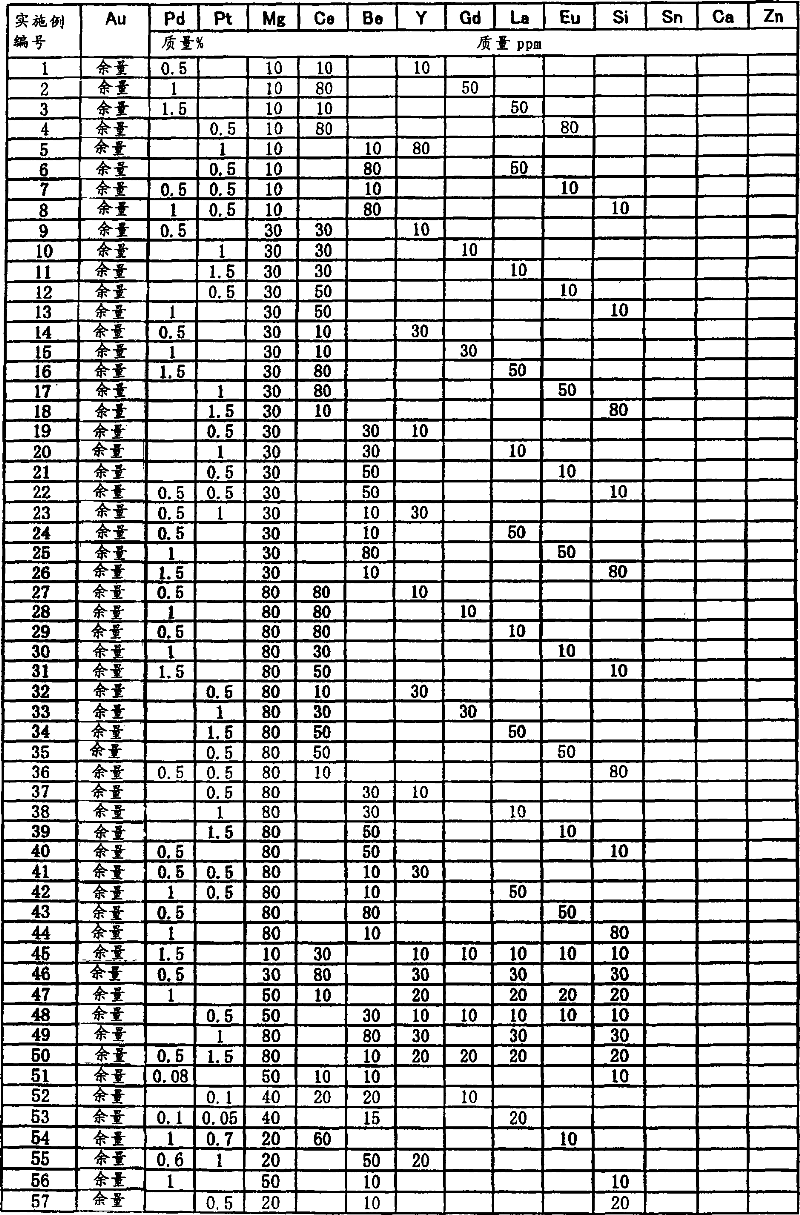

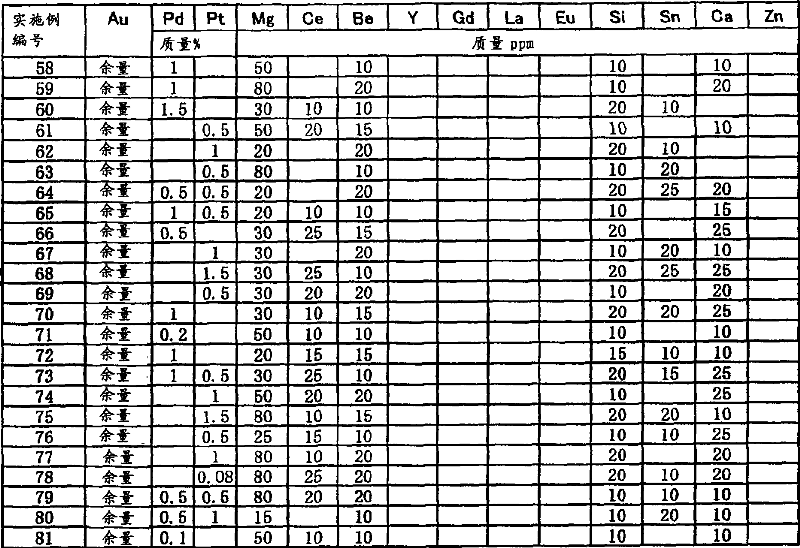

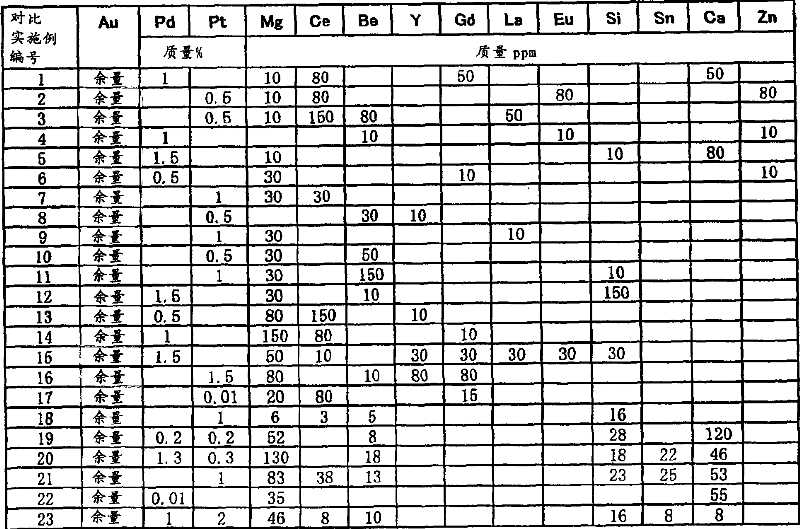

Au alloy bonding wire

ActiveCN101040372ADelays the effect of interdiffusionEasy to shapeSolid-state devicesSemiconductor/solid-state device manufacturingTrace elementAlloy

An Au alloy bonding wire which comprises an Au alloy matrix containing high purity Au and at least one of high purity Pd and Pt in a total amount of 0.05 to 2 mass %, and, incorporated in the matrix as a trace element, Mg in an amount of 10 to 100 mass ppm, Ce in an amount of 5 to 100 mass %, and at least one of Be, Y, Gd, La, Eu and Si in an amount of each element of 5 to 100 mass % and in a total amount of Be to Si of 5 to 100 mass ppm; an Au alloy bonding wire which comprises the above Au alloy matrix and, incorporated in the matrix as a trace element, Mg and Be and at least one of Y, La, Eu and Si; an Au alloy bonding wire which comprises the above Au alloy matrix and, incorporated in the matrix as a trace element, Mg in an amount of 10 to 100 mass ppm, Si in an amount of 5 to 30 mass ppm, Be in an amount of 5 to 30 mass ppm, and at least one of Ca, Ce and Sn in an amount of 5 to 30 mass ppm. The above bonding wire is a fine diameter Au alloy bonding wire which has a desired strength, exhibits good binding characteristics and good stability for a long period of time, and is improved in the circularity of a pressed ball and the sphericity of a molten ball.

Owner:TANAKA DENSHI KOGYO KK

Composite output increasing type grinding aid and preparation method thereof

The invention discloses a composite output increasing grinding aid, which is especially designed for assisting the grinding of common silicate cement, and belongs to the field of grinding assistance in cement production. The grinding aid is composed of the following raw materials: triethanolamine, triisopropanolamine, diethanolisopropanolamine, propylene glycol, glacial acetic acid, and water. The preparation method of the grinding aid comprises the following steps: washing a stirring boiler with water before the production, adding water into the stirring boiler, adding diethanolisopropanolamine, stirring until the diethanolisopropanolamine is totally dissolved; adding glacial acetic acid, stirring until the glacial acetic acid is totally dissolved; then orderly adding triethanolamine, propylene glycol, and triisopropanolamine; and finally stirring for 30 to 40 minutes so as to obtain the grinding aid. The grinding aid can improve the endurance and corrosion resistance of cement concrete products, which have the advantages of more stable volume, lower hydration heat, and better construction property. After the grinding aid is mixed into cement, the average particle size of the cement is prominently reduced, the content of fine particles is prominently increased, the particle shape is basically not changed, the roundness of the particles is increased, the repose angle is prominently reduced, and the fluidity is enhanced.

Owner:张恩源

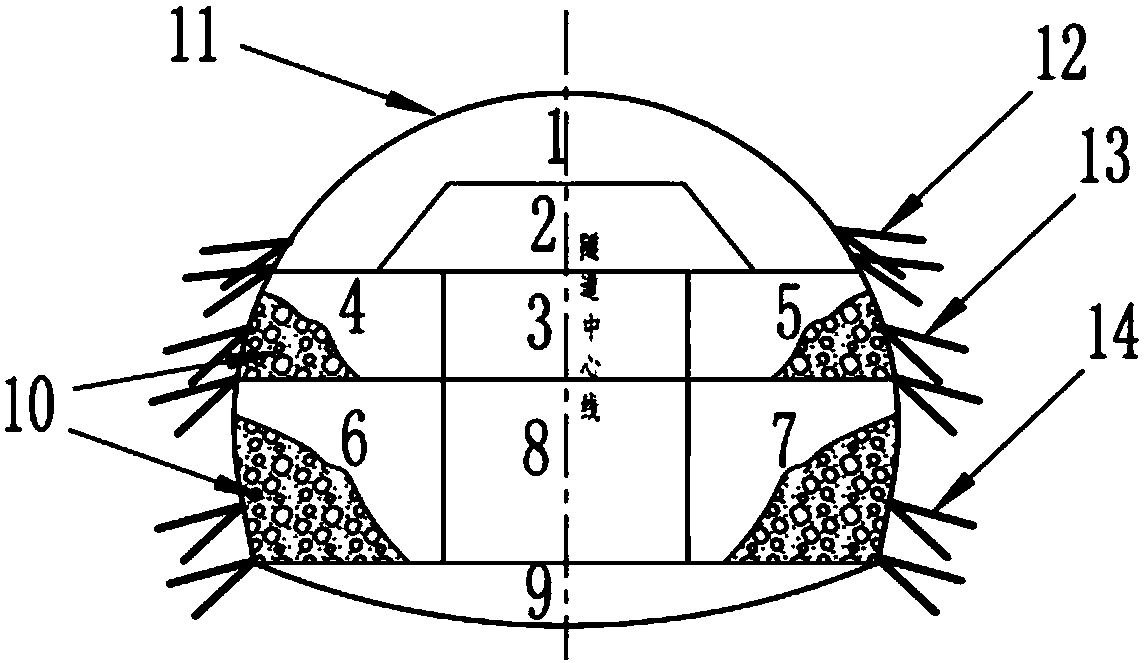

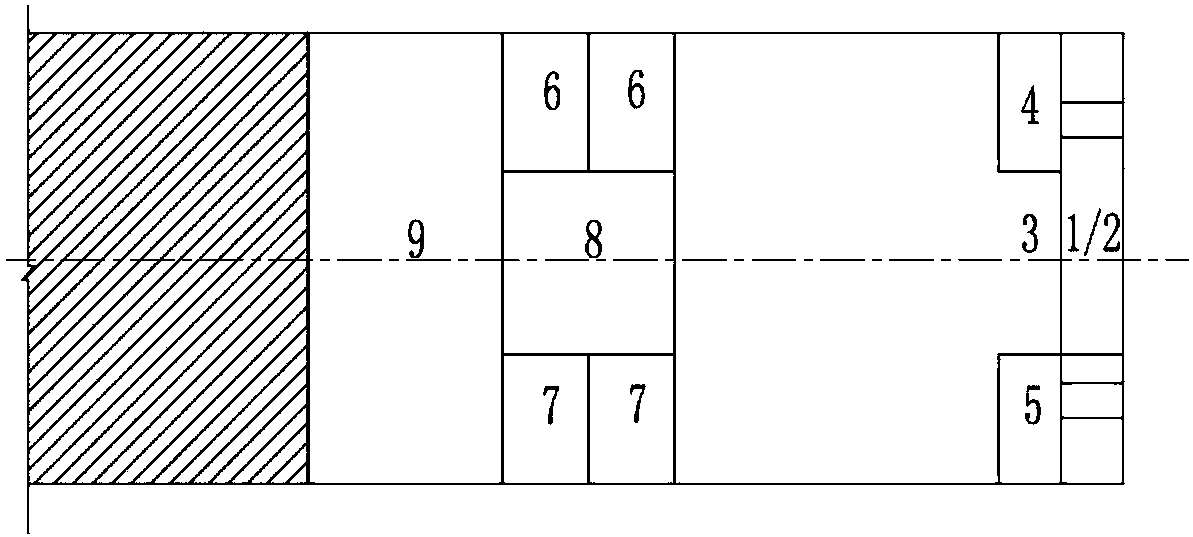

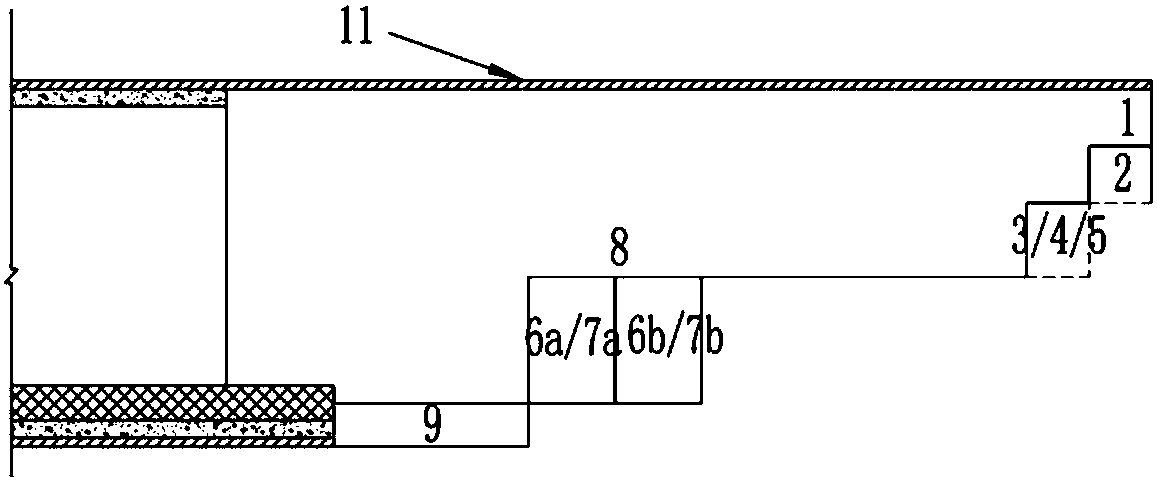

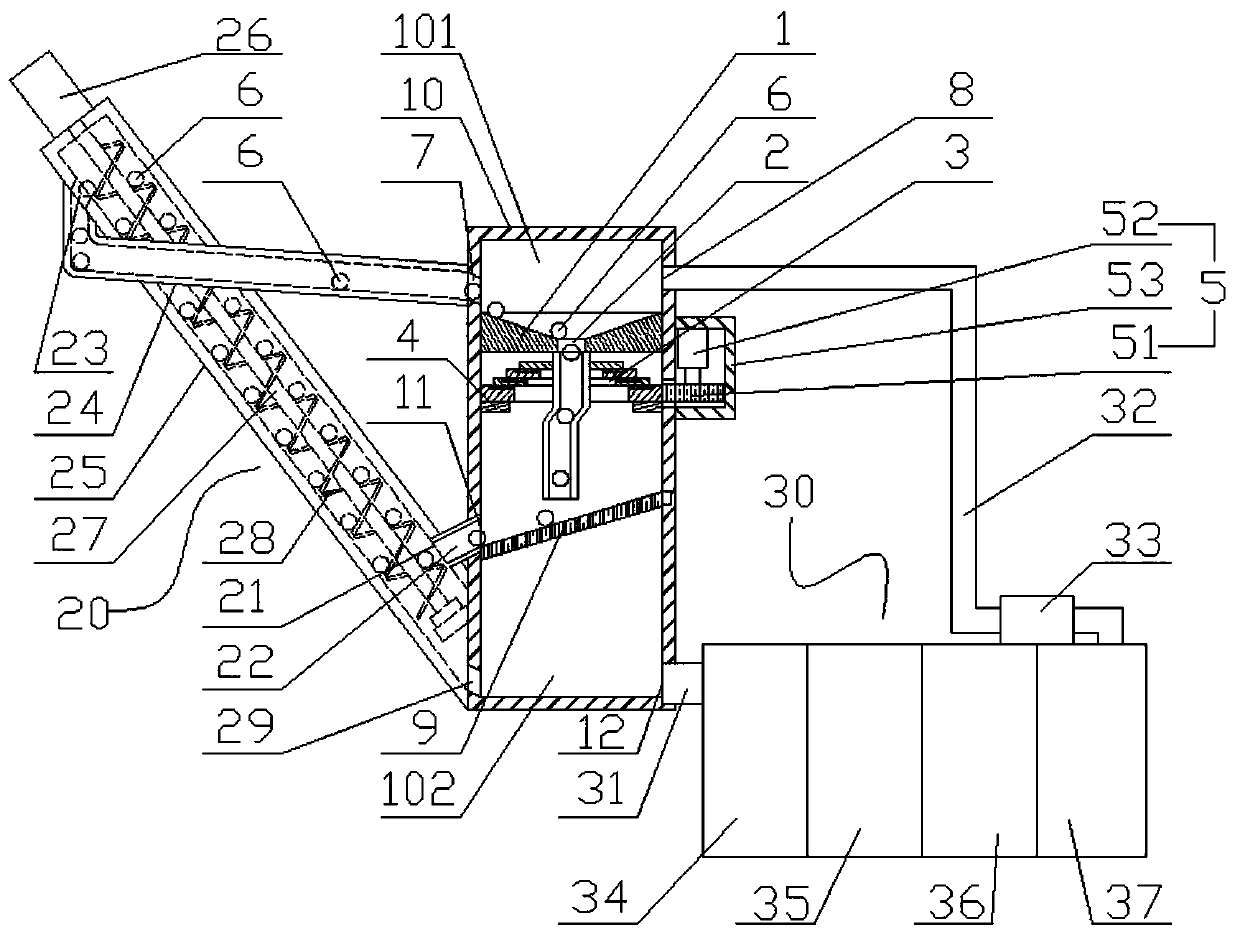

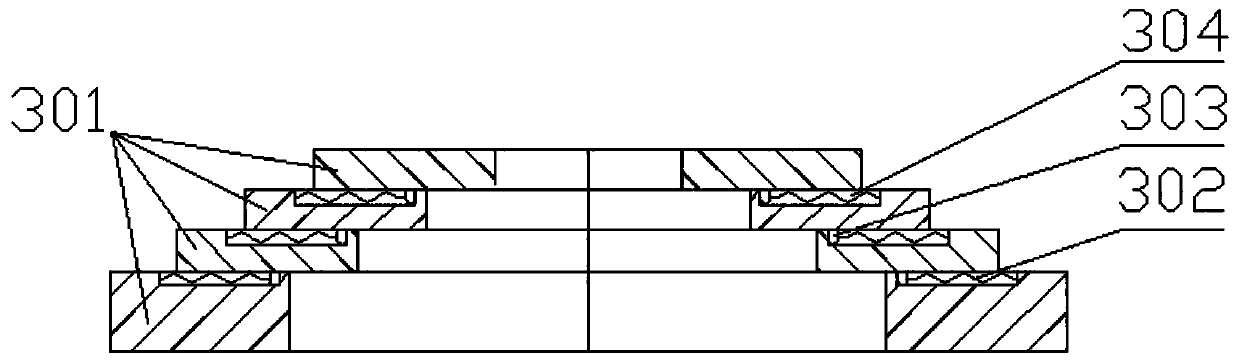

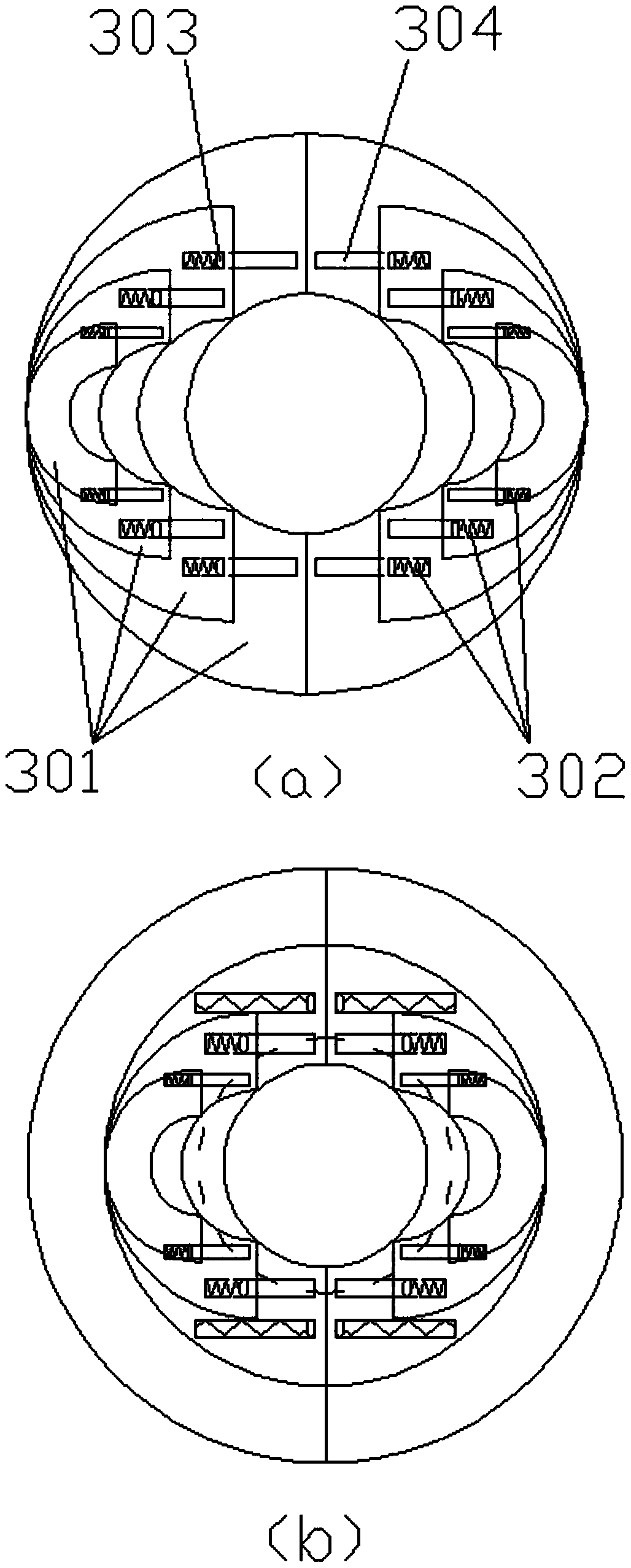

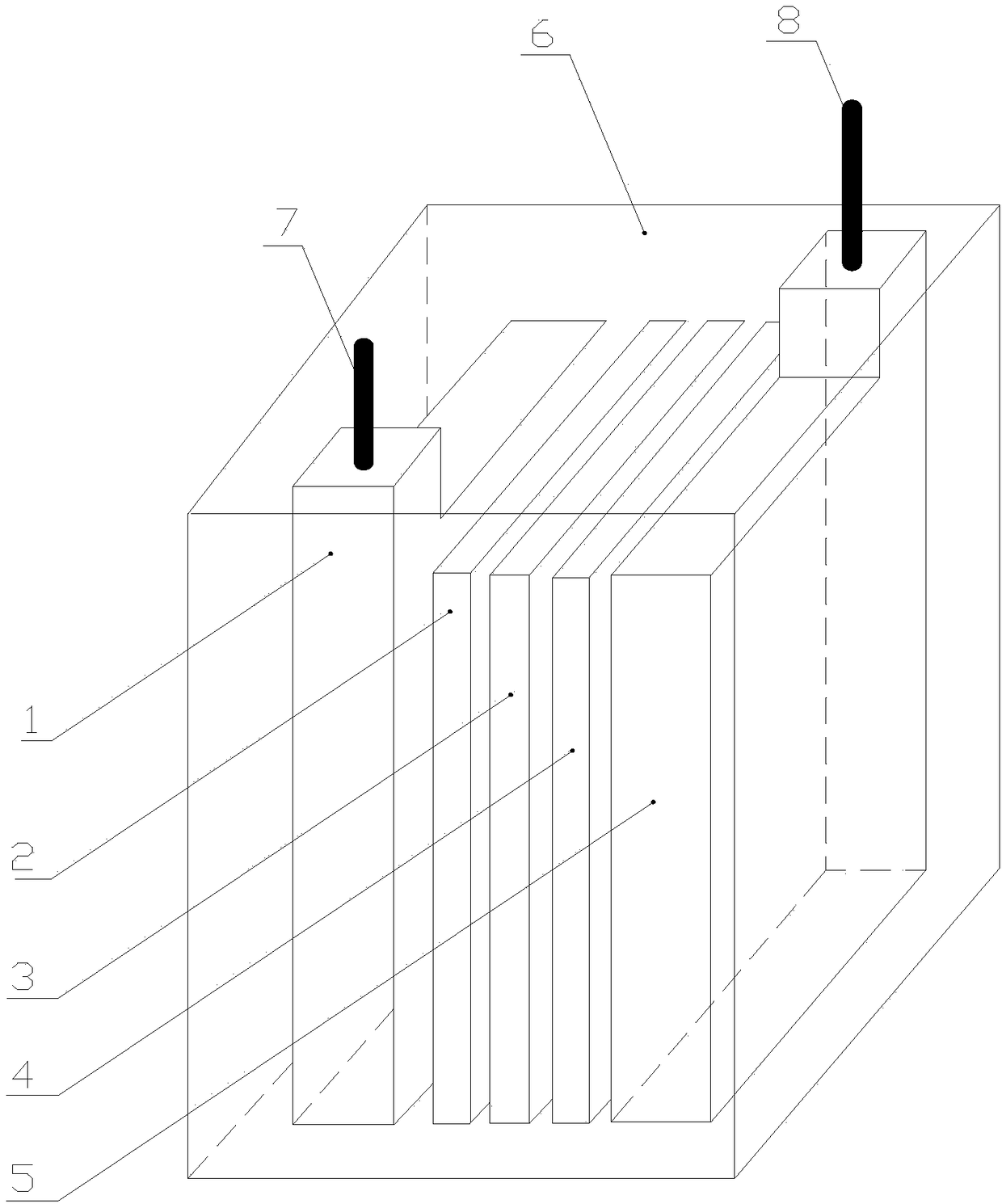

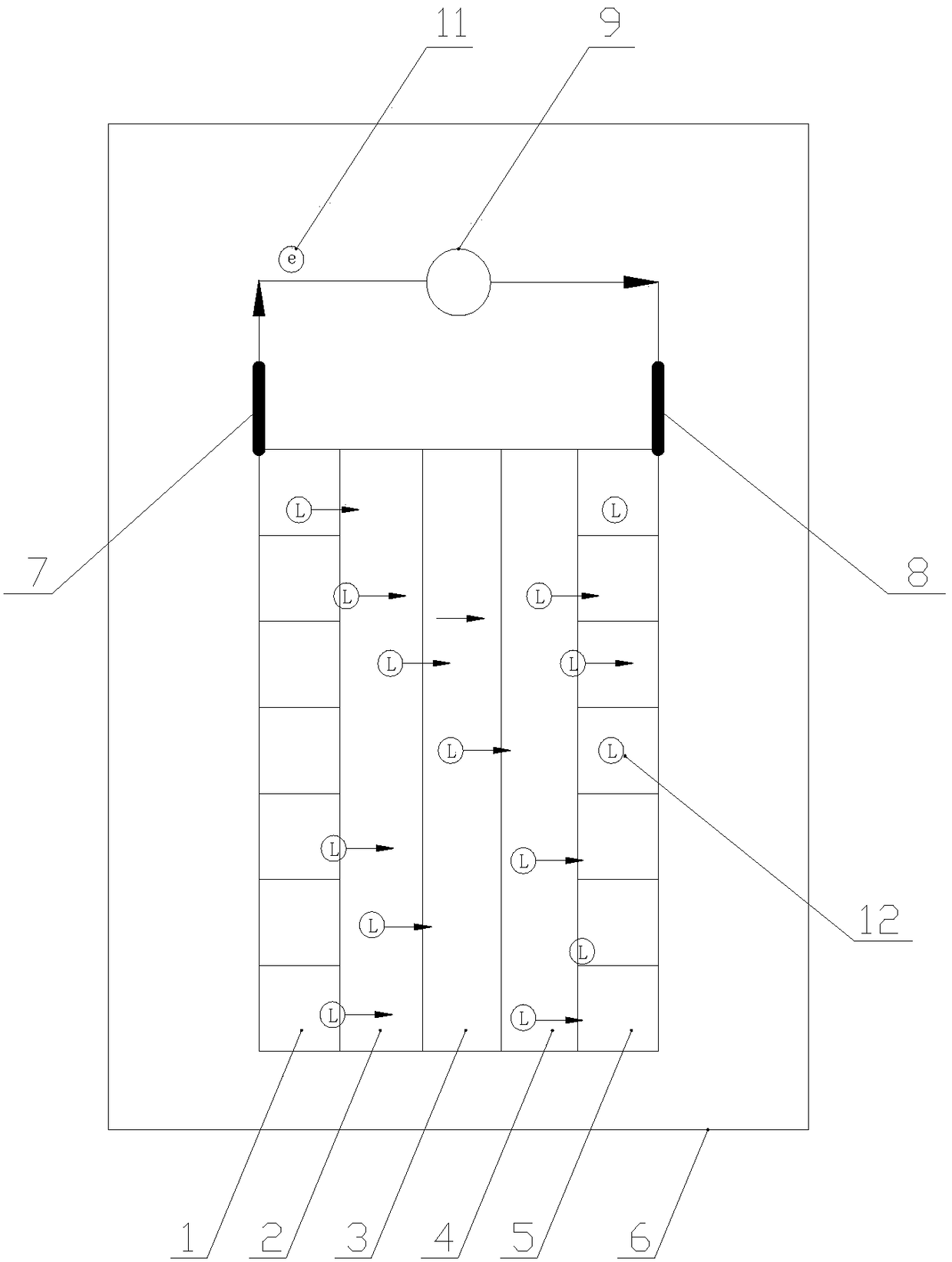

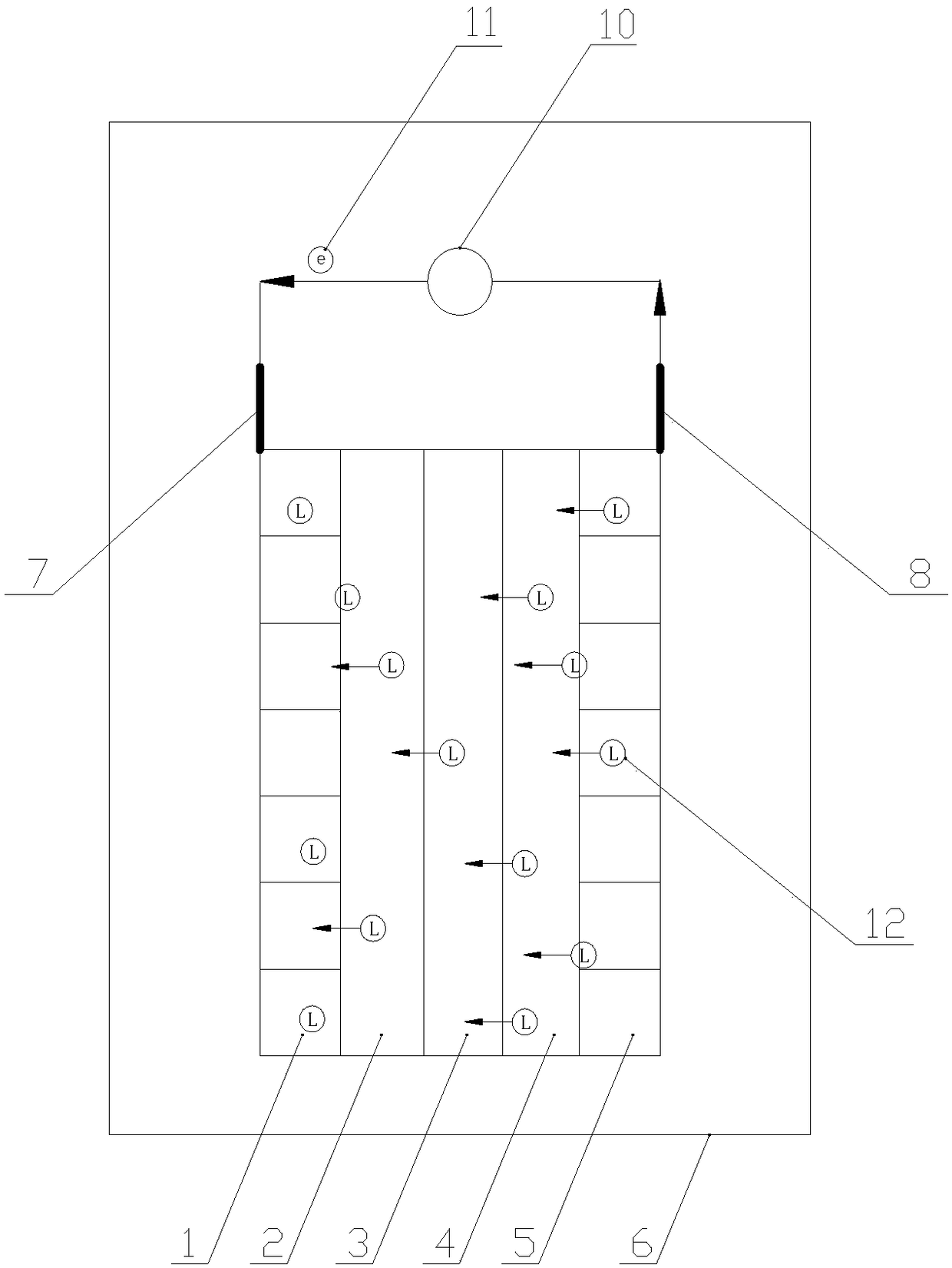

Complementary circulating digging method for floated pebble stratum large section tunnel

InactiveCN107829748AGuaranteed RegularitySolve the problem of over miningUnderground chambersTunnel liningSupporting systemDeformation monitoring

The invention discloses a complementary circulating digging method for a floated pebble stratum large section tunnel. The digging method includes: using dug dregs at different parts to complement eachother; alternatively and circularly backfilling and stabilizing arc feet; canceling advance supports and system anchoring rods in a support system so as to reduce surrounding rock disturbance; adopting small-bore dual-layer reinforcing meshes; reinforcing a supporting and restraint function of foot locking anchoring rods for steel frames by increasing the group number of the self-propelled foot locking anchoring rods and reduce the length of the self-propelled foot locking anchoring rods; and using a monitoring system including deformation monitoring and foot locking anchoring rod axial forcemonitoring to master a safe state of surrounding rocks and a structure in real time from deformation and stress dual views. The digging method can fully consider the features of a floated pebble stratum, can reinforce a horizontal restraint effect of the support system on the surrounding rocks, can effectively reduce surrounding rock disturbance, can improve the construction efficiency, can savethe project cost, can ensure the safety of the structure and the stability of the surrounding rock in an early tunnel construction process.

Owner:CHANGAN UNIV

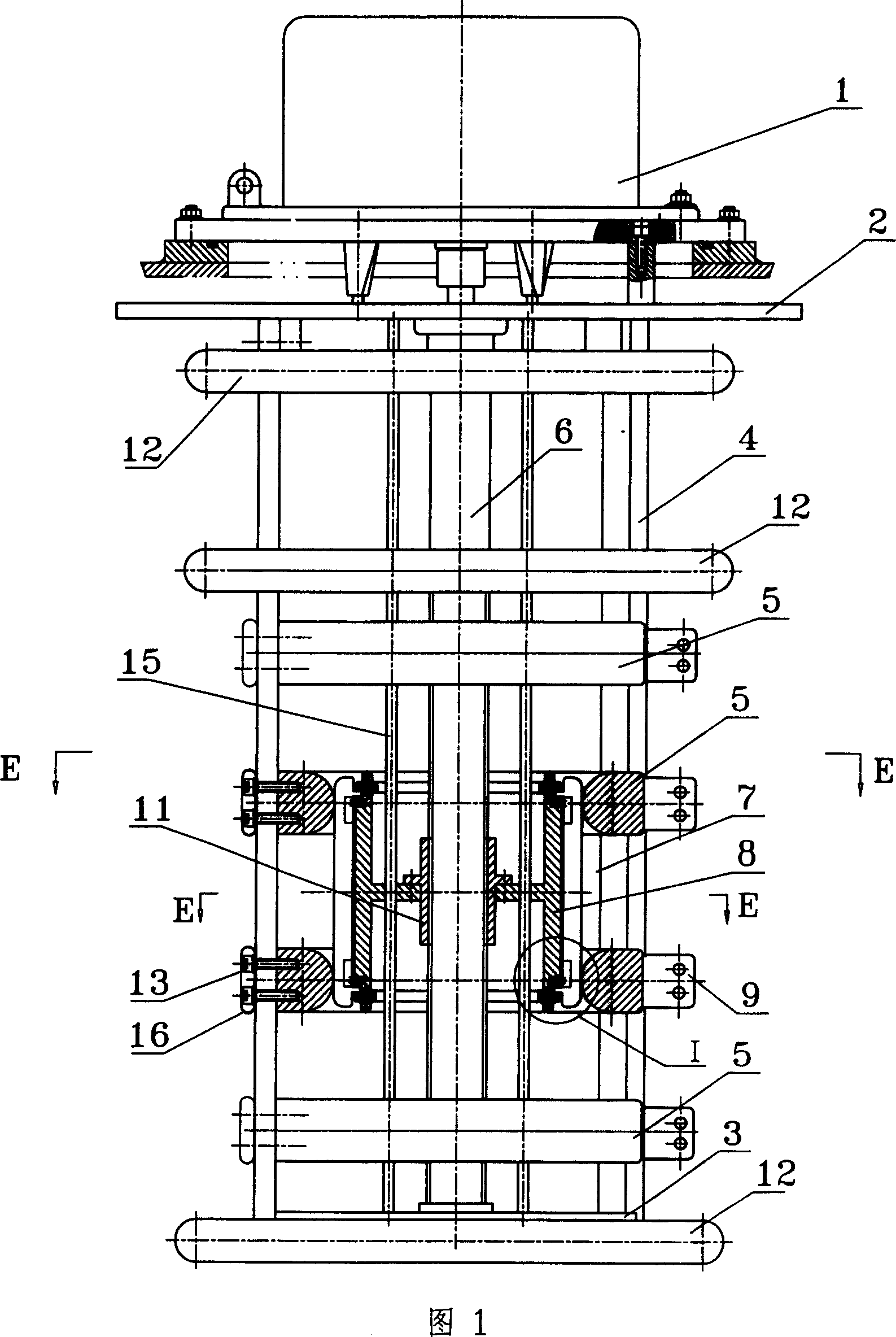

Non-field cage-shape tap changer for transformer

ActiveCN1933055AGood circularityImprove structural rigidityContact driving mechanismsVariable inductancesTap changerControl theory

A cage-style tap-changer without excitation for transformer relates to up and down brackets and there are insulating pole of edge connecting between them. There are interval ring static state relays on the axes of insulating pole and there are dynamic relays at the up and down brackets and inside of the ring static state relays. The dynamic relays connects with one up / down gearing, and there are dynamic relays connects with closed two static state relays in the outside of dynamic relays subassembly and the corresponding ring static state relays. The beneficial effect is 1. The dynamic and static state relays touch with stabilization and short moment when switch operation moves along the axes and high orientation precision. 2. Static state relays enhance the stiffness of cage-style with strong anti-short ability of switch for large current and single-phase switch with high and insulated level.

Owner:WUHAN TAIPU TRANSFORMER CHANGER

Plastic bead as well as preparation method and applications thereof

ActiveCN102775751AUniform particle sizeSmall dispersion coefficientDrilling compositionOrganic solventPolystyrene

The invention discloses a plastic bead as well as a preparation method and applications of the plastic bead. The plastic bead comprises the following components by weight percent: 0.1-100% of polycarbonate and the balance of polystyrene. The preparation method comprises the steps of dissolving an oil-phase solute into an organic solvent, mixing uniformly to obtain a mixture taken as an oil phase which is polycarbonate, or a mixture of polystyrene and / or styrene monomer and polycarbonate; dissolving a dispersing agent or the dispersing agent and an emulsifying agent into water to prepare a water phase; sufficiently mixing the oil phase and the water phase so as to uniformly disperse the oil phase in the water phase to prepare emulsion; rising the temperature so as to volatilize the organic solvent and simultaneously solidify drops of the oil phase; and then separating the emulsion to separate a solid phase, and drying to obtain the plastic bead. According to the plastic bead and the preparation method, the environmental conservation is good, the process is simple, the problem of white pollution can be solved, and the application is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

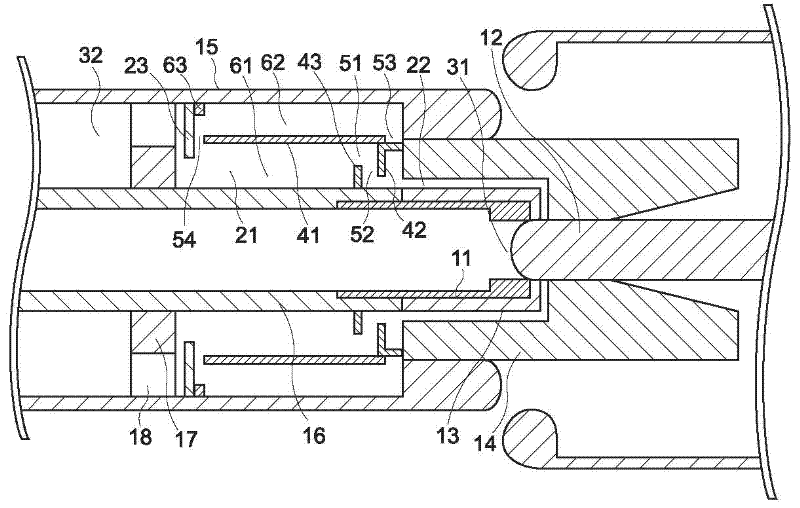

Gas breaker

ActiveCN102446655AImprove arc suppression performanceLow fluid resistanceHigh-tension/heavy-dress switchesAir-break switchesElectric arcEngineering

For forming a gas breaker which effectively realizes large electric current switching-off and medium / small electric current switching-off, a heat gas jetting chamber (21) and a mechanical gas jetting chamber (32) are equipped in series. In the heat gas jetting chamber (21), a spacing component (41) is equipped. The spacing component divides the inner part of the chamber along a radial direction for dividing to an inner periphery side space (61) and an outer periphery side space (62). A switching valve (42) which is used as a gas flow control mechanism is equipped between an arc space (31) and the heat gas jetting chamber (21). A movable valve (23) is equipped for opening and closing a communication part (18) of a spacing wall (17) between the heat gas jetting chamber (21) and the mechanical gas jetting chamber (32). When the large electric current is switched off, high-temperature and high-pressure de-arcing gas which comes from the arc space (31) is blown to the arc by means of the switching valve (42) from the outer periphery side space (62) of the spacing component (41) through the inner periphery side space (61). When the medium-small current is switched off, the de-arcing gas which comes from the mechanical gas jetting chamber (32) is only guided to the inner periphery side space (61) of the spacing component and is blown to the electric arc.

Owner:HITACHI LTD

Preparation method of high-sphericity-degree silicon carbide powder for ceramic membrane

The invention discloses a preparation method of high-sphericity-degree silicon carbide powder for a ceramic membrane. The preparation method comprises the following steps: (1) pre-treating silicon powder; (2) preparing a silicon powder precursor; (3) carbonizing the precursor; (4) calcining silicon carbide: putting amorphous carbon coated silicon powder particles prepared by step (3) into a high-temperature furnace; raising the temperature to be 800 DEG C under a vacuum condition according to a speed of 10 DEG C / min; raising the temperature to be 1300 DEG C to 1500 DEG C according to a speed of 5 DEG C / min and calcining; keeping the heat for 2h to 3h; naturally cooling to room temperature to obtain the silicon carbide powder. The high-sphericity-degree silicon carbide powder disclosed by the invention has the characteristics of narrow particle size distribution, controllability and high sphericity degree.

Owner:湖北迪洁膜科技有限责任公司

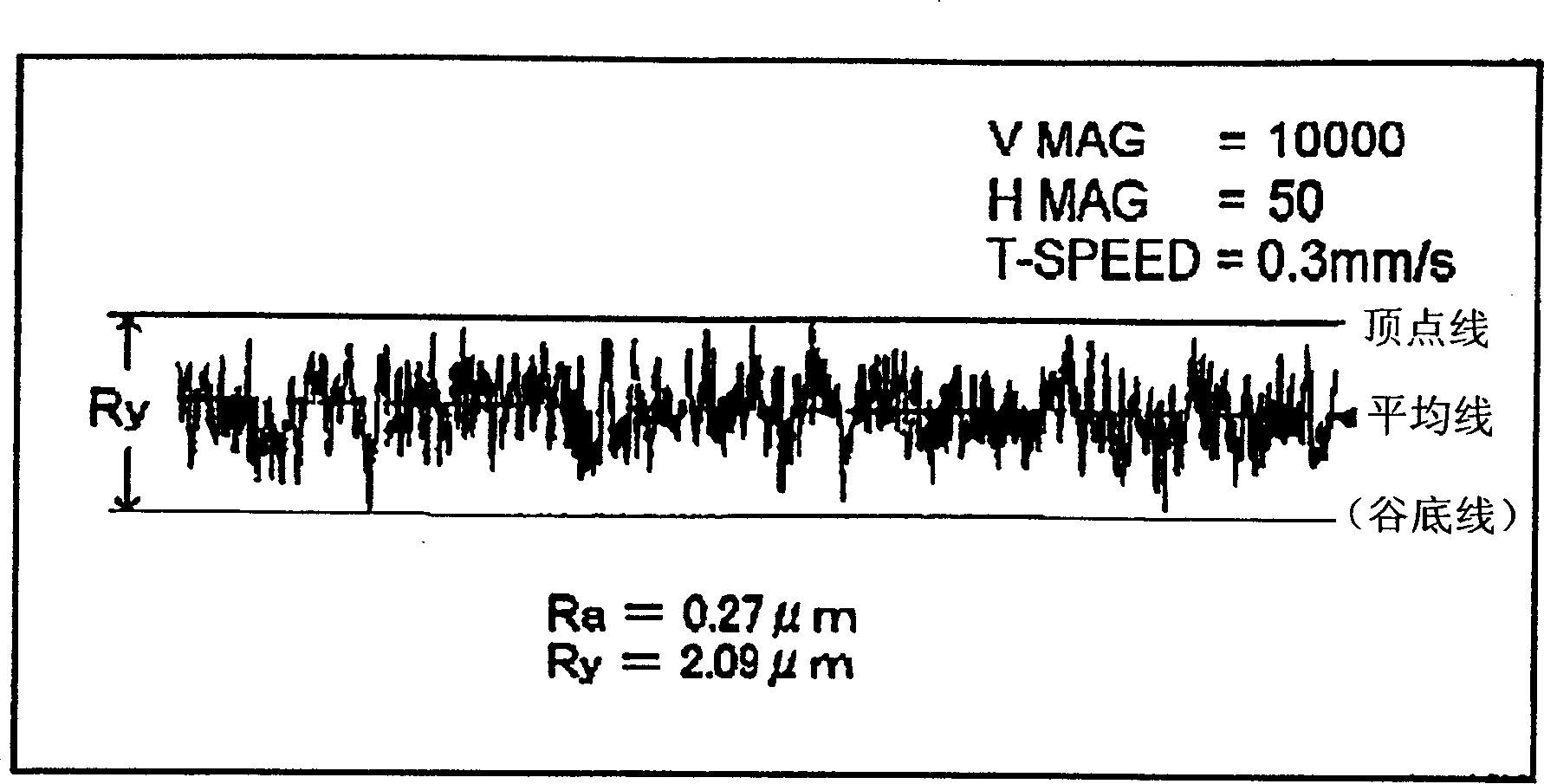

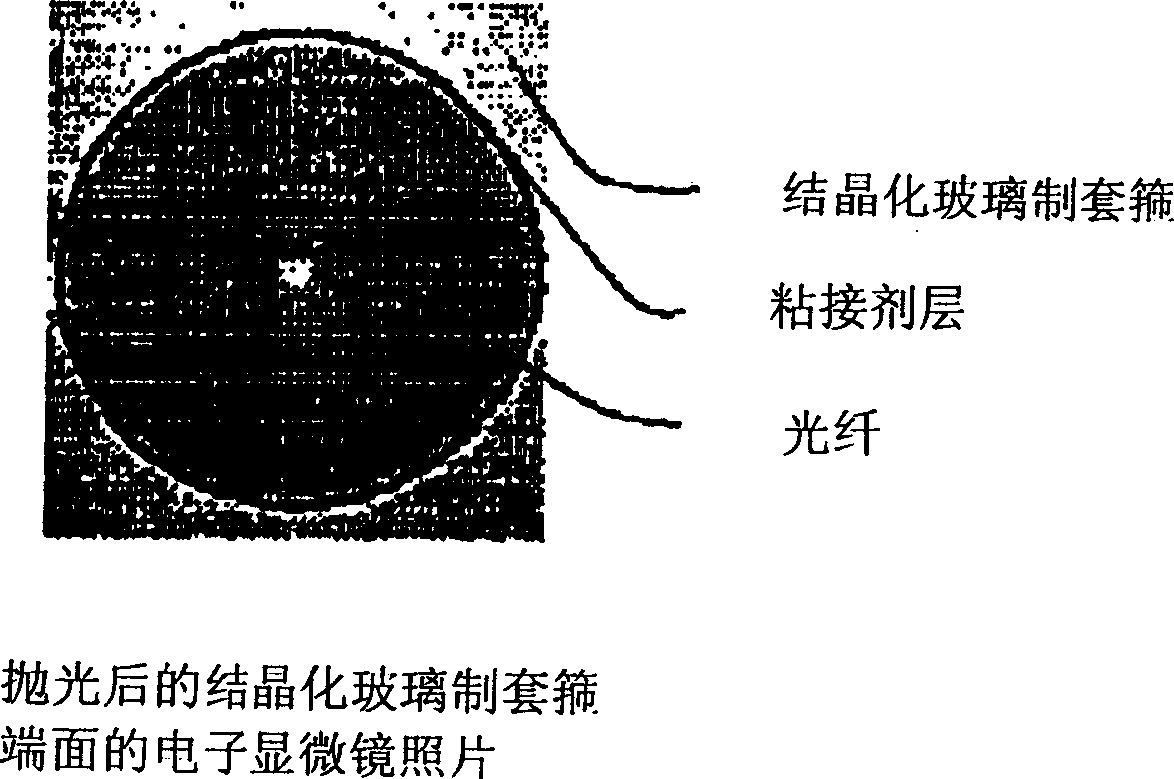

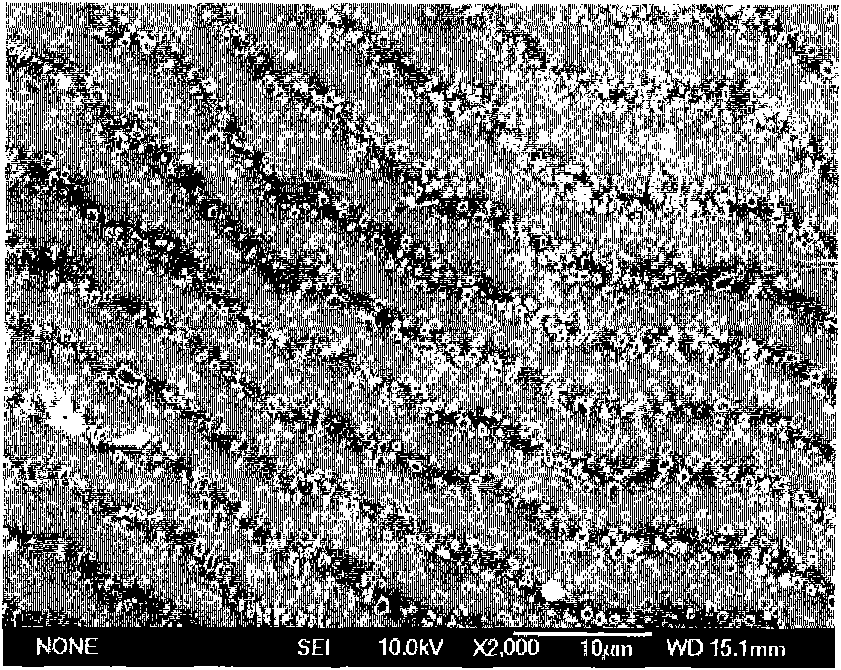

Capillary for optical fibre, hoop for optical connector and capillary with optical fibre

InactiveCN1420376AImprove circularityEasy to make effectivelyCoupling light guidesSurface roughnessEngineering

The present invention provides a capillary for optical fiber, a ferrule for optical connector, and an optical-fiber-fixed capillary. The capillary for optical fiber has an inner hole allowing an optical fiber to be inserted and retained therein Ra value of the surface roughness of the inner hole is 0.1 mum to 0.5 mum. The ferrule for optical connector is provided with a chamfered part on one end of the capillary for optical fiber for guiding it into a sleeve and a flared part on the other end of the capillary for optical fiber for guiding the optical fiber into the inner hole.

Owner:NIPPON ELECTRIC GLASS CO LTD

Graphite electrode production process

A graphite electrode production process is as follows: (1) taking a raw material, to be more specific, taking baked graphite scrap as the raw material; (2) crushing, to be more specific, using a crusher for crushing the baked graphite scrap; (3) purifying, to be more specific, mixing hydrofluoric acid, sulfuric acid and hydrochloric acid with crushed spheroidizing-formed graphite according to certain formula proportion for purifying; (4) drying, to be more specific, drying the purified spherical graphite; (5) screening, to be more specific, removing larger impurities in the dried spherical graphite; (6) fusing, to be more specific, fully mixing the dried spherical graphite and resin; (7) coating, to be more specific, coating the mixed spherical graphite and resin by reaction; (8) lightly crushing, to be more specific, using a light crusher for beating the sintered anode material into powder; and (9) packing, to be more specific, cooling the material, and packaging; the advantages of the graphite electrode production process are that the process method uses less dosage of sulfuric acid and hydrochloric acid, is less in pollution and high in production efficiency, and compared with the general process, the step is improved by 0.7h.

Owner:LIANYUNGANG JIANGLIDA MINERAL

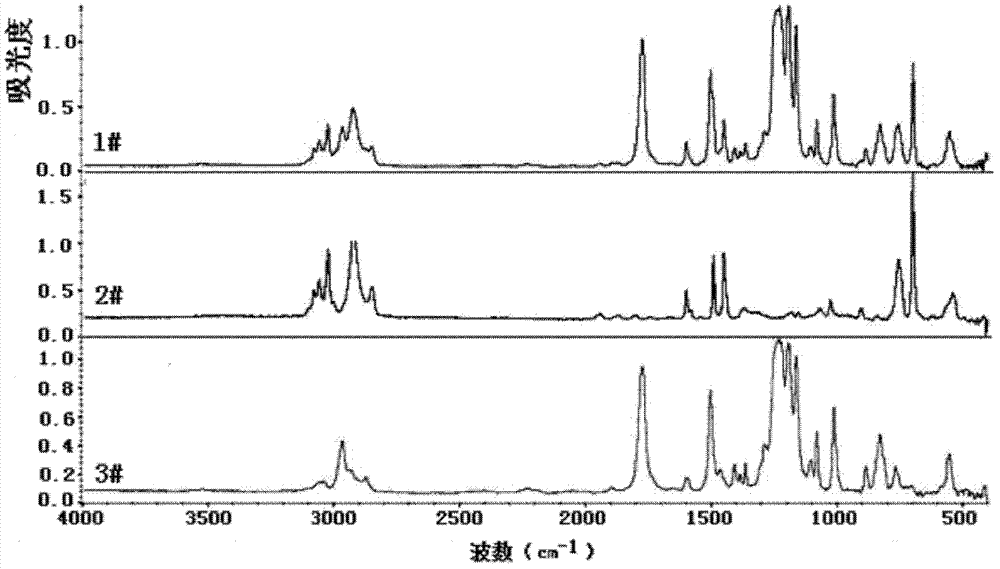

Preparation method and application of polystyrene plastic pellet

ActiveCN103387681AUniform particle sizeImprove circularityDrilling compositionAdhesion coefficientPolymer science

The invention relates to a preparation method and application of polystyrene plastic pellets. A self-dissolving method is employed to dissolve polystyrene in styrene monomers; then the mixture is added into an aqueous solution containing a dispersant and an emulsifier; and styrene monomer polymerization is initiated by controlling a certain temperature under dynamic dispersion conditions, so as to obtain the polystyrene plastic pellets. The prepared polystyrene plastic pellets can be added to a drilling fluid to reduce an adhesion coefficient of the drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for controlling form of carbide in bearing steel

The invention discloses a method for controlling the form of carbide in bearing steel. The method comprises the following steps: smelting the bearing steel in a ladle refining (LF) furnace, transferring into a vacuum degassing (VD) furnace, and smelting the changed refining slag components for 10-15 minutes under the process parameters of the temperature of 1520-1570 DEG C and the vacuum pressure of 30-100 Pa. The invention has the advantages of simple process and low cost, and has obvious effects on controlling the Mg content in the bearing steel, further controlling the form of the carbide in the bearing steel, improving the distribution of the carbide in the bearing steel and improving the circularity and length-diameter ratio of the carbide in the bearing steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Automobile pipe fitting cleaning device

ActiveCN109967461AImprove flowFlexible scrollingHollow article cleaningTreatment involving filtrationBristleWater source

The invention discloses an automobile pipe fitting cleaning device, and belongs to the technical field of automobile part cleaning. The automobile pipe fitting cleaning device comprises a cleaning tank, a material lifting mechanism and a water purification mechanism, wherein a multi-stage fixture is arranged on the upper part in the cleaning tank; a drive structure for driving the multi-stage fixture to rotate is arranged on one side of the multi-stage fixture; multiple cleaning ball bodies are built in the cleaning tank and comprise gravity balls and wrapping layers on the outer sides of thegravity balls; bristles are spread over the wrapping layers; a filter plate is arranged on the lower part in the cleaning tank; a port I is formed in one side of the filter plate; a feed inlet communicating with the port I is formed in the lower part of the material lifting mechanism; a discharge hole communicating with the upper end side of the cleaning tank is formed in the upper end of the material lifting mechanism; the input end of the water purification mechanism communicates with the bottom part of the cleaning tank; a water return pipe connected to the upper end side of the cleaning tank is arranged at the output end of the water purification mechanism; and a water pump is arranged on the water return pipe. The automobile pipe fitting cleaning device provided by the invention can be suitable for multiple types of automobile pipe fittings, is good in cleaning effect, can realize circulation of related materials and water bodies, and is beneficial to saving materials and water sources.

Owner:安徽科润管业有限公司

Novel graphene-based total-soil metal lithium battery and working method thereof

ActiveCN108321391ALower internal resistanceEasy transferPhosphatesElectrode carriers/collectorsElectrical batteryNew energy

The invention discloses a novel graphene-based total-soil metal lithium battery. The novel graphene-based total-soil metal lithium battery comprises a positive electrode, a negative electrode, solid electrolyte, a diaphragm and a battery shell. In the battery, a positive current collector adopts a LiFePO4-graphene based compound; a negative current collector adopts metal lithium; the diaphragm adopts polypropylene; the solid electrolyte adopts a V2S5-graphene based composite material; the middle of the positive electrode and the solid electrolyte is coated with one layer of the diaphragm; themiddle of the negative electrode and the solid electrolyte is coated with one layer of the diaphragm; the diaphragms are arranged in parallel and are accommodated in the battery shell; the battery isformed by stacking the positive electrode, the negative electrode, the diaphragms and the solid electrolyte in an inserting bag mode; and convex parts on substrates of the positive electrode and the negative electrode are connected with leads to form conductive lugs. The graphene total-soil metal lithium battery reduces the internal resistance of the battery, has excellent electronic conductivity,lithium ion conversation rate and metal lithium rechargeability, improves electrode solid / solid interface contact stability, has high energy density and high safety, and is suitable for a power battery of a new energy automobile.

Owner:ANHUI ANKAI AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com