Complementary circulating digging method for floated pebble stratum large section tunnel

A technology of large cross-section and boulders, applied in the field of complementary circulation excavation, can solve the problems of easy collapse of drilling bolts, slow construction speed, and easy falling of blocks from the vault, so as to achieve continuity and circulation, improve Construction progress, avoid the effect of falling and hurting people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

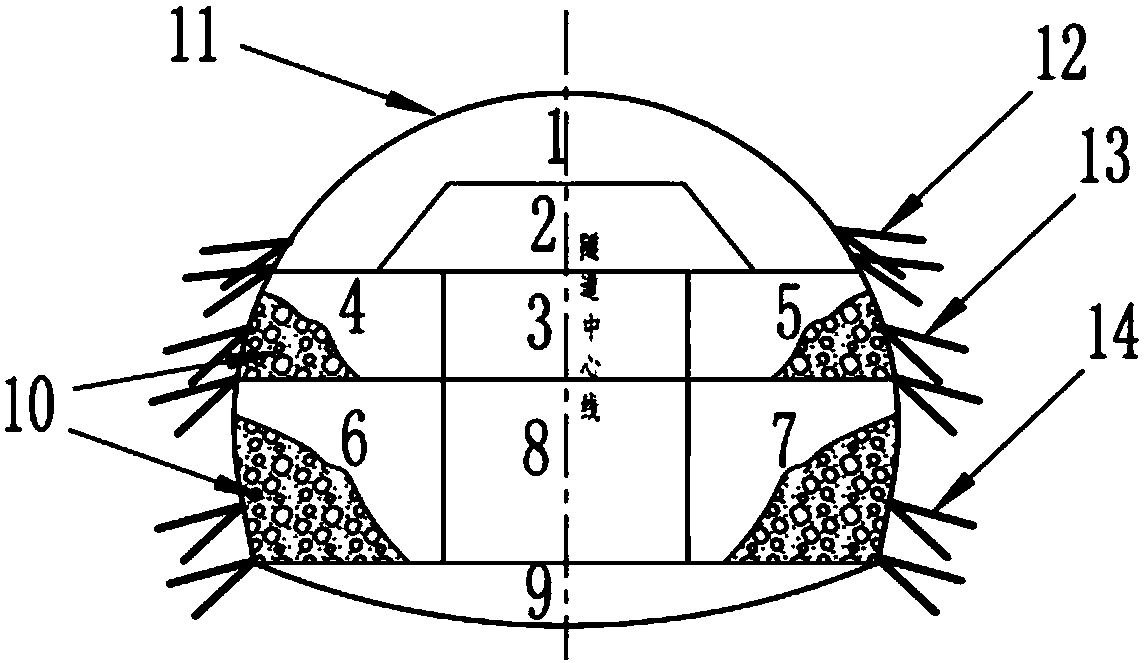

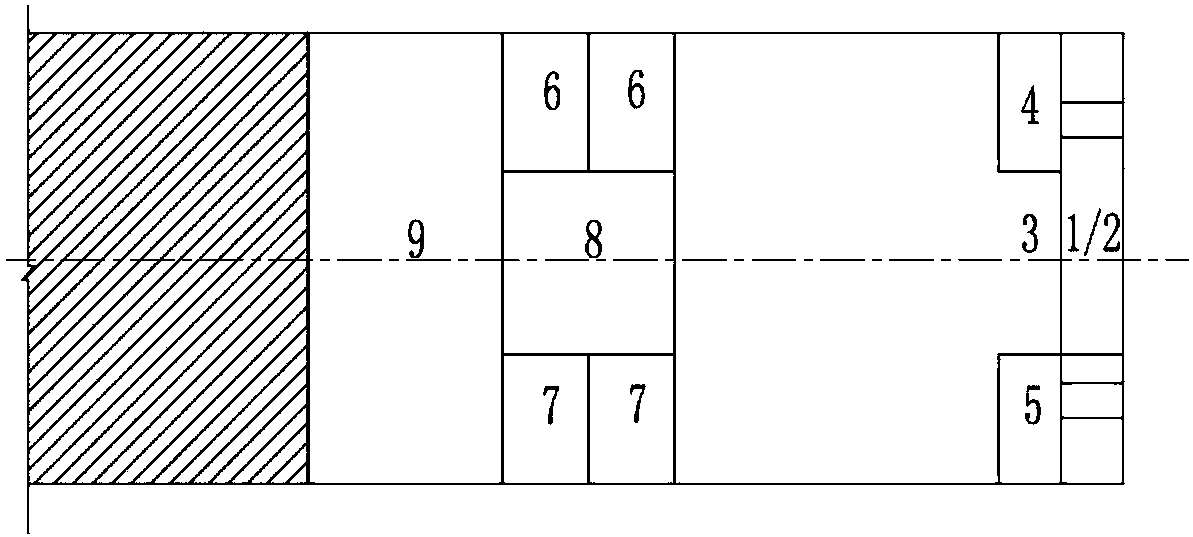

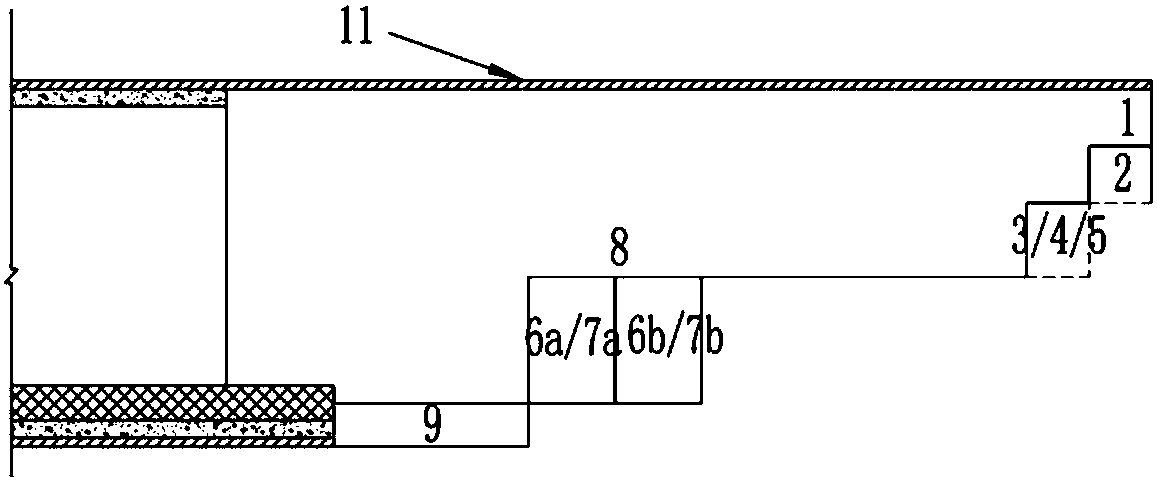

[0044] Such as Figure 1 to Figure 4 As shown, a kind of complementary circular excavation method suitable for large-section tunnels in boulder formations provided by the present invention includes the following contents:

[0045] The excavation is divided into upper and lower steps as a whole. The upper step includes the excavation part 1 of the arc-shaped pilot pit on the upper part of the upper step, the core soil reserved in the upper part of the upper step 2, the middle excavation part 3 in the lower part of the upper step, and the left side of the lower part of the upper step. The excavation part 4 and the excavation part 5 on the right side of the lower part of the upper step have a total of five parts of the excavation surface, and the lower part includes the excavation part 6 on the left side of the lower step, the right side excavation part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com