Preparation method of polyaniline

A technology of polyaniline and aniline, which is applied in the field of polyaniline preparation, can solve the problems of poor solubility of polyaniline, achieve high solubility, low molecular weight, and ensure regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention discloses a preparation method of polyaniline, comprising the following steps:

[0029] mixing aniline with an organic solvent to obtain a first mixed solution;

[0030] Mixing an oxidizing agent with an aqueous mineral acid solution to obtain a second mixed solution, the oxidizing agent being potassium ferricyanide;

[0031] The first mixed solution is mixed with the second mixed solution to obtain polyaniline after reaction.

[0032] According to the present invention, in the process of preparing polyaniline, the aniline monomer is first mixed with an organic solvent, that is, the aniline monomer is dissolved in the organic solvent to obtain a first mixed solution. The concentration of the aniline monomer in the first mixed solution is preferably 1-6 mol / L, more preferably 1.2-3.5 mol / L, and most preferably 1.5-3 mol / L. The concentration of the aniline monomer in the first mixed solution has a certain influence on the molecula...

Embodiment 1

[0045] Step 1: Dissolving 1 mol of aniline monomer in toluene to obtain a first mixed solution, the concentration of aniline monomer in the first mixed solution is 1 mol / L;

[0046] Step 2: Dissolving 1.2mol potassium ferricyanide in 1mol / L hydrochloric acid to obtain a second mixed solution;

[0047] Step 3: Mix the first mixed solution and the second mixed solution, and place it statically at -5°C for 12 hours;

[0048] Step 4: soak the reaction product obtained in step 3 with 150ml of 0.5mol / L ammonia water for 24h, then wash with water, methanol and deionized water until the filtrate is colorless;

[0049] Step 5: The product obtained in Step 4 was vacuum-dried for 24 hours at a vacuum degree of 0.6 MPa and a drying temperature of 40° C. to obtain polyaniline.

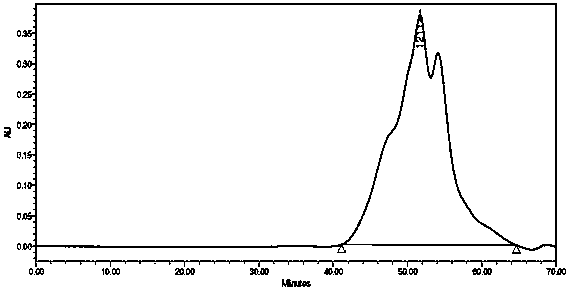

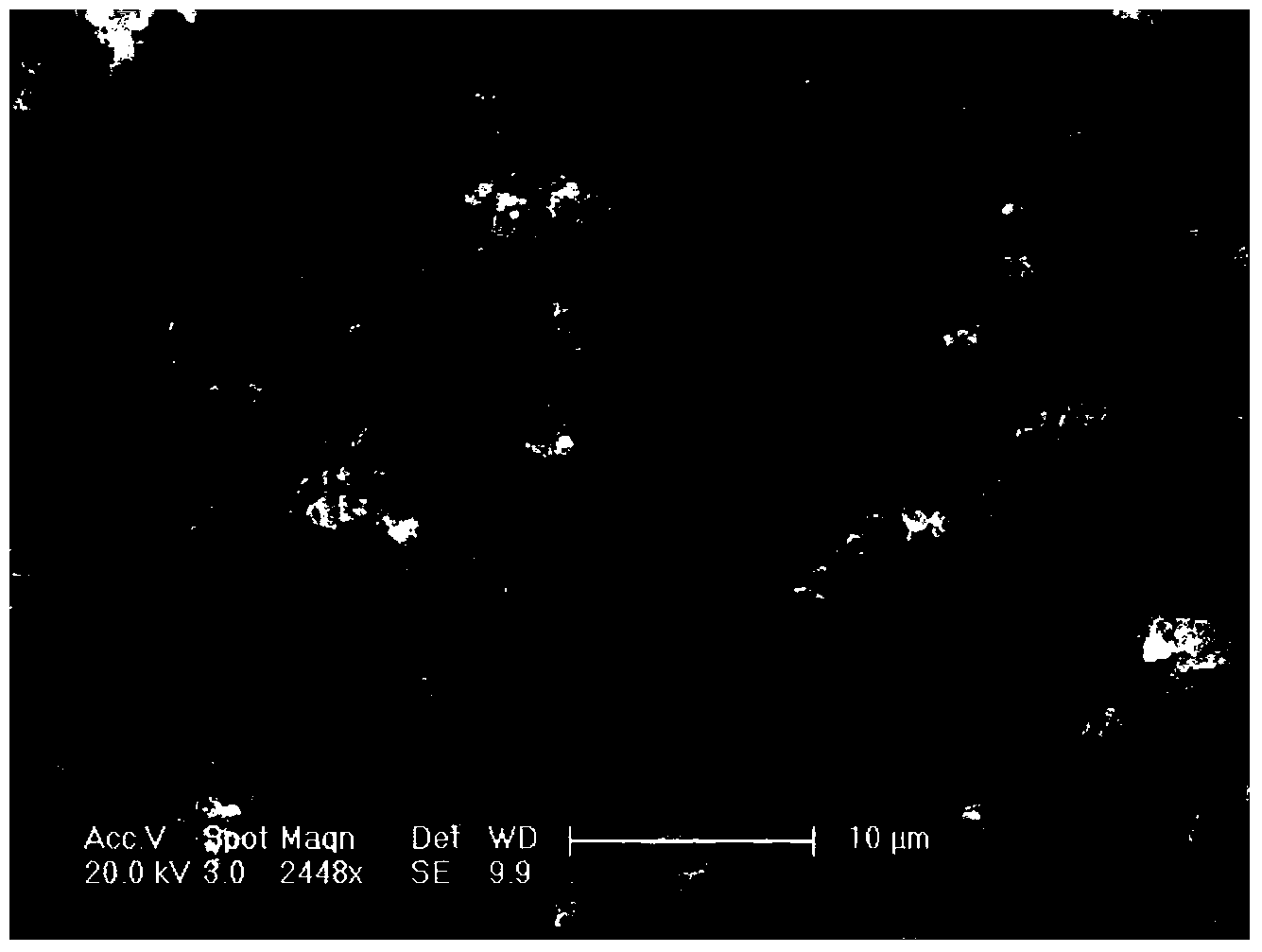

[0050] The polyaniline prepared in this example was tested, and the results showed that the polyaniline obtained in this example had a particle size of 0.8-1.2 μm, a number average molecular weight Mn of 3509 Dalt...

Embodiment 2

[0052] Step 1: Dissolving 1mol of aniline monomer in carbon tetrachloride to obtain a first mixed solution, the concentration of aniline monomer in the first mixed solution is 6mol / L;

[0053] Step 2: 20mol potassium ferricyanide is dissolved in the hydrochloric acid of 1mol / L, obtains the second mixed solution;

[0054] Step 3: Mix the first mixed solution and the second mixed solution, and place it statically at 25°C for 36 hours;

[0055] Step 4: soak the reaction product obtained in step 3 with 280ml of 1mol / L ammonia water for 2h, then wash with water, methanol and deionized water until the filtrate is colorless;

[0056] Step 5: The product obtained in Step 4 was vacuum-dried for 36 hours at a vacuum degree of 0.9 MPa and a drying temperature of 50° C. to obtain polyaniline.

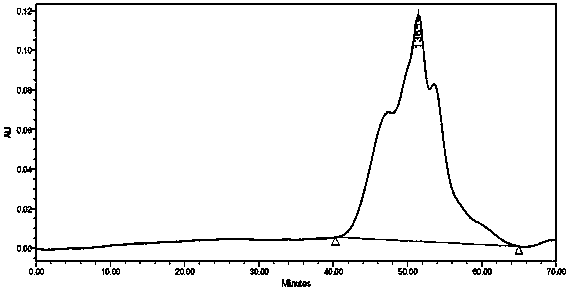

[0057] The polyaniline prepared in this example was tested, and the results showed that the polyaniline obtained in this example had a particle size of 0.52-0.87 μm, a number average molecular wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com