Dustproof paper shredding device

A paper shredding and dust-proof technology, which is applied in the direction of grain processing, etc., can solve the problems of frequent failures of shredding devices and the entry of sundries, and achieve the effect of reducing the probability of failure and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

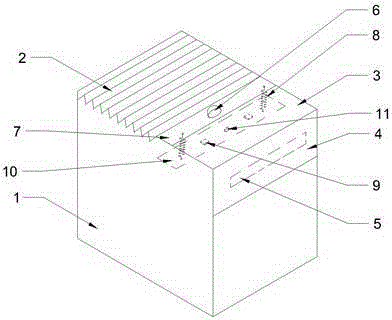

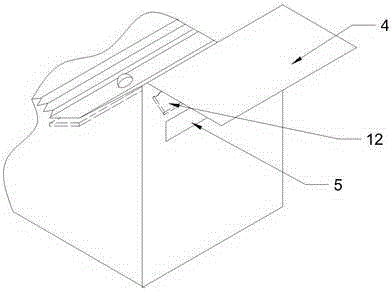

[0015] The reference signs in the drawings of the description include: body 1, organ folding cover body 2, swing plate 3, baffle plate 4, paper inlet 5, button 6, pressing plate 7, compression spring 8, magnetic piece 9, fixing plate 10 , touch switch 11, suction port 12 of negative pressure pump.

[0016] The embodiment is basically as attached figure 1 , figure 2 Shown: a dust-proof paper shredding device, including a machine body 1 and a machine cover connected to the machine body 1, and a paper inlet 5 is opened on the right side wall of the machine body 1. The machine cover is made of iron material. The machine cover includes an organ folding cover body 2 and a control cover body. The control cover body is formed by connecting the swing plate 3 and the baffle plate 4 end to end, and the angle between the swing plate 3 and the baffle plate 4 is At 90°, the organ f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com