Vertical-type pump self-circulation thin oil lubrication bearing body

A technology of thin oil lubrication and vertical pumps, which is applied in the direction of non-variable pumps, pumps, pump components, etc. It can solve the problems of affecting the capacity of vertical pumps, poor cooling and lubrication effect of bearings, and easy failure of bearings, etc., and achieves structural Simplicity, reduced bearing temperature, and high operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

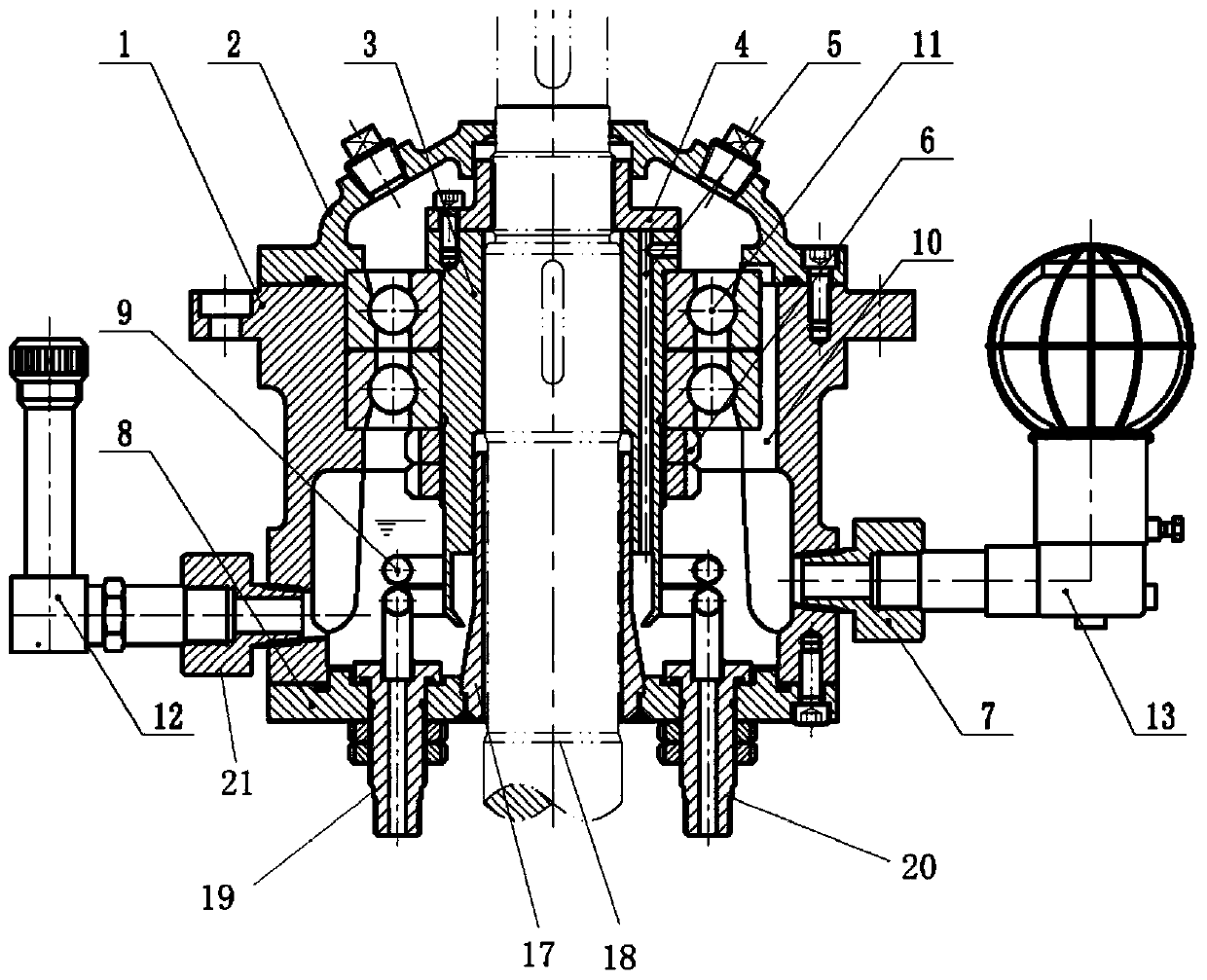

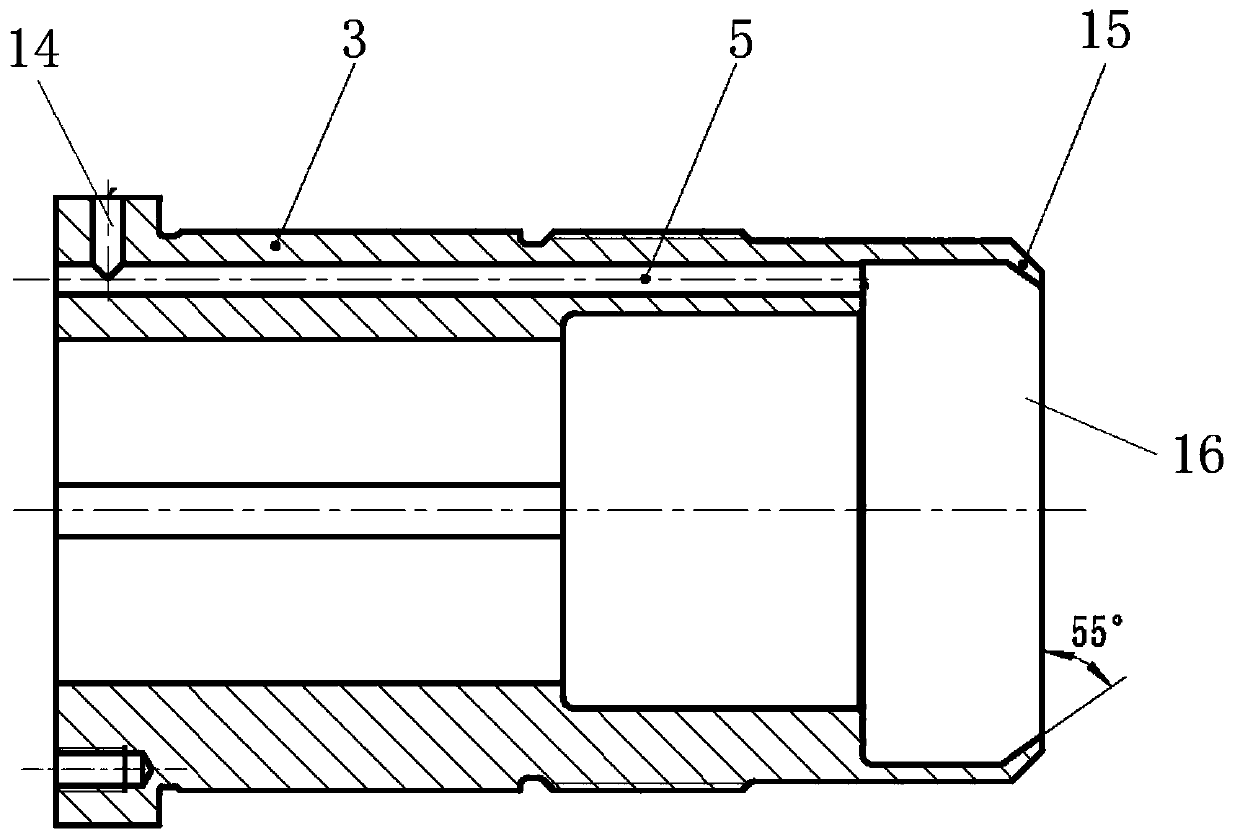

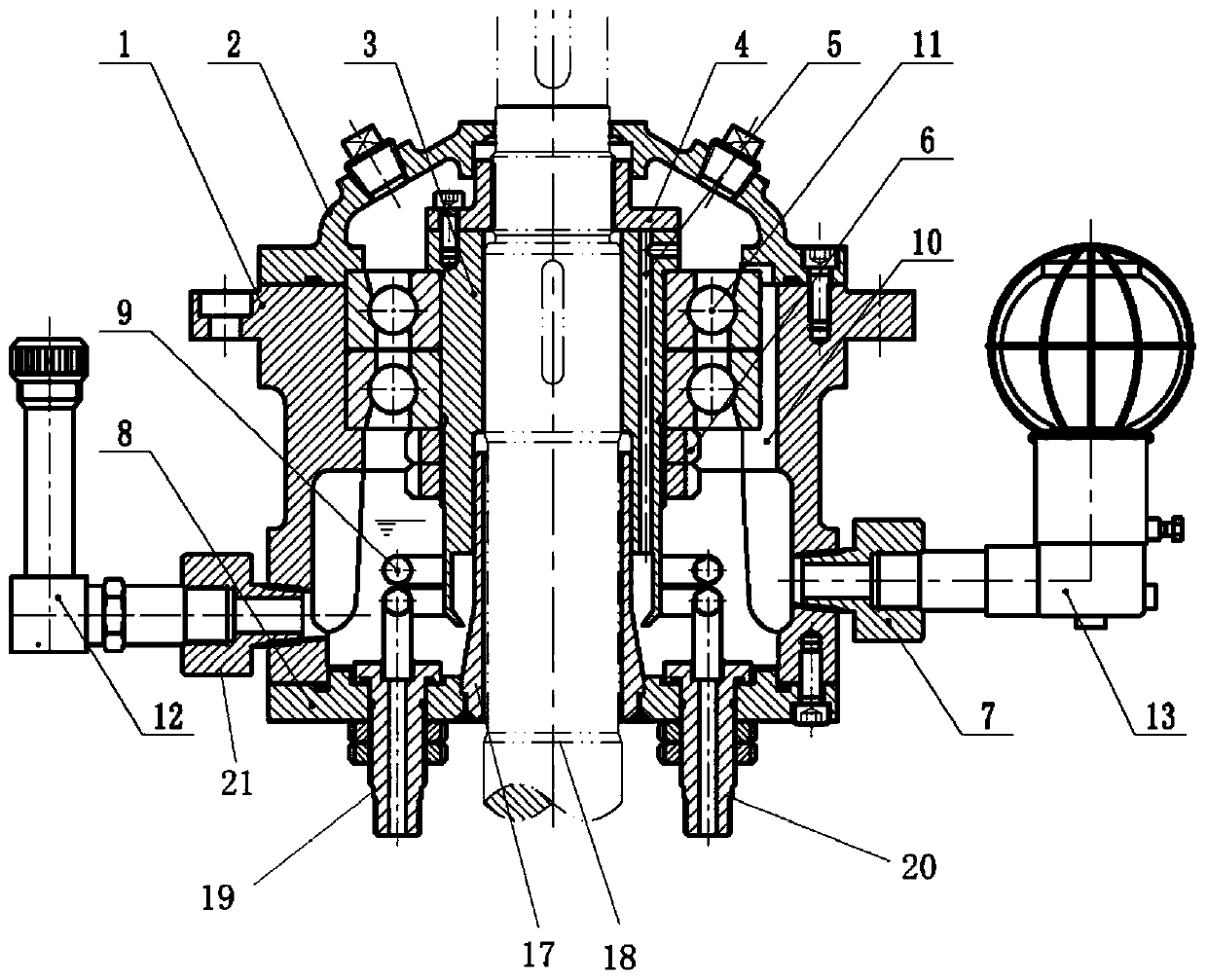

[0033] This embodiment provides a specific structure of a vertical pump self-circulating thin oil lubricating bearing body, such as figure 1 As shown, it includes a casing 1, an upper pressure cover 2, a lower pressure cover 8, a bearing 11 and a bearing sleeve 3 (the bearing 11 used in this embodiment is a double row angular contact ball bearing); the upper part of the casing 1 is installed on the Gland 2, lower gland 8 is installed on the lower part of the casing; the outer ring of the double row angular contact ball bearing is matched with the inner wall of the casing 1, and the inner ring of the double row angular contact ball bearing passes through the bearing sleeve 3 and the rotating shaft of the vertical pump 18 Fixed connection (in this embodiment, the bearing sleeve 3 and the rotating shaft 18 of the vertical pump are fixed by key connection);

[0034] The outer ring of the double row angular contact ball bearing is axially positioned through the upper gland 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com