Non-oriented electrical steel for ultrahigh-effect constant-frequency compressor and preparation method of non-oriented electrical steel

A technology of oriented electrical steel and compressor, which is applied in the field of non-oriented electrical steel and its preparation for ultra-high-efficiency fixed-frequency compressors, achieving the effect of good circularity and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

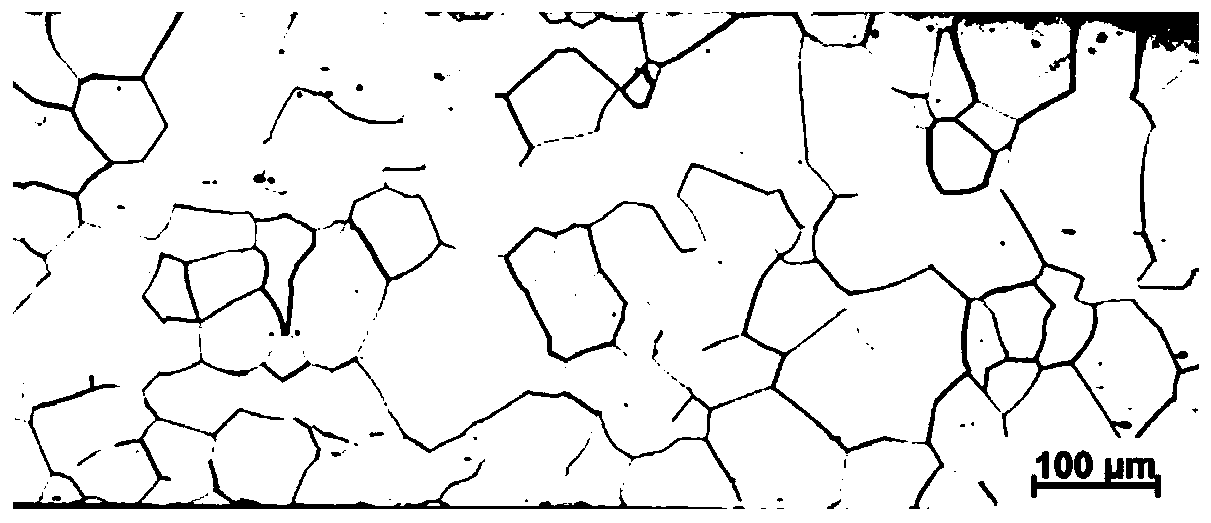

Image

Examples

Embodiment 1

[0044] A non-oriented electrical steel for an ultra-high-efficiency fixed-frequency compressor and a preparation method thereof, specifically comprising the following steps:

[0045] 1) The molten iron enters the converter for smelting after pretreatment, and the molten steel after smelting in the converter is refined and alloyed through the RH furnace, and the alloying elements such as Si, Al, Mn, P and other alloying elements are fine-tuned according to the composition design requirements;

[0046] 2) The molten steel refined in the RH furnace is continuously cast into a slab with a thickness of 230 mm, and electromagnetic stirring is used in the continuous casting process. The chemical composition weight percentages of the slab are Si: 1.57%; Als: 0.75%; Mn: 0.33%; P: 0.04%; C+S+N+Ti=76ppm, and the content of each element is ≤26ppm, and the rest are Fe and inevitable impurity elements;

[0047]3) The slab is heated up in a walking heating furnace to ensure that the discharg...

Embodiment 2

[0054] A non-oriented electrical steel for an ultra-high-efficiency fixed-frequency compressor and a preparation method thereof, specifically comprising the following steps:

[0055] 1) The molten iron enters the converter for smelting after pretreatment, and the molten steel after smelting in the converter is refined and alloyed through the RH furnace, and the alloying elements such as Si, Al, Mn, P and other alloying elements are fine-tuned according to the composition design requirements;

[0056] 2) The molten steel refined in the RH furnace is continuously cast into a slab with a thickness of 230 mm, and electromagnetic stirring is used in the continuous casting process. The chemical composition weight percentages of the slab are Si: 1.63%; Als: 0.68%; Mn: 0.35%; P: 0.03%; C+S+N+Ti=78ppm, and the content of each element is ≤25ppm, and the rest are Fe and inevitable impurity elements;

[0057] 3) The slab is heated up in a walking heating furnace to ensure the discharge te...

Embodiment 3

[0064] A non-oriented electrical steel for an ultra-high-efficiency fixed-frequency compressor and a preparation method thereof, specifically comprising the following steps:

[0065] 1) The molten iron enters the converter for smelting after pretreatment, and the molten steel after smelting in the converter is refined and alloyed through the RH furnace, and the alloying elements such as Si, Al, Mn, P and other alloying elements are fine-tuned according to the composition design requirements;

[0066] 2) The molten steel refined in the RH furnace is continuously cast into a slab with a thickness of 230 mm, and electromagnetic stirring is used in the continuous casting process. The chemical composition weight percentages of the slab are Si: 1.65%; Als: 0.72%; Mn: 0.41%; P: 0.03%; C+S+N+Ti=80ppm, and the content of each element is ≤25ppm, and the rest are Fe and inevitable impurity elements;

[0067] 3) The slab is heated up through a walking heating furnace to ensure that the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com