Capillary for optical fibre, hoop for optical connector and capillary with optical fibre

一种毛细管、光纤的技术,应用在光学、光学元件、光波导的耦合等方向,能够解决不能调心作业、成本高、价格高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present inventors used, as an example of the capillary for optical fiber of the present invention, for example, a capillary for optical fiber made of crystallized glass having the composition given in Table 1.

[0053] Table 1

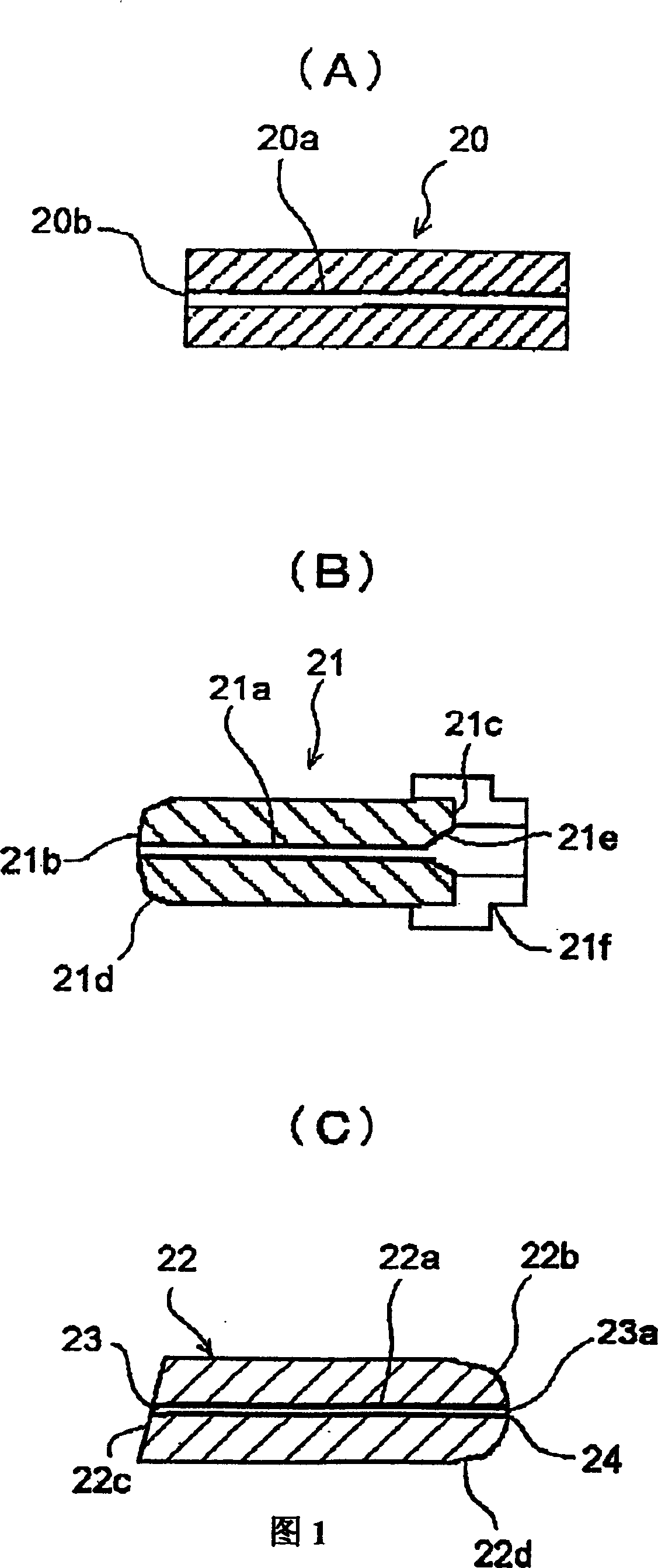

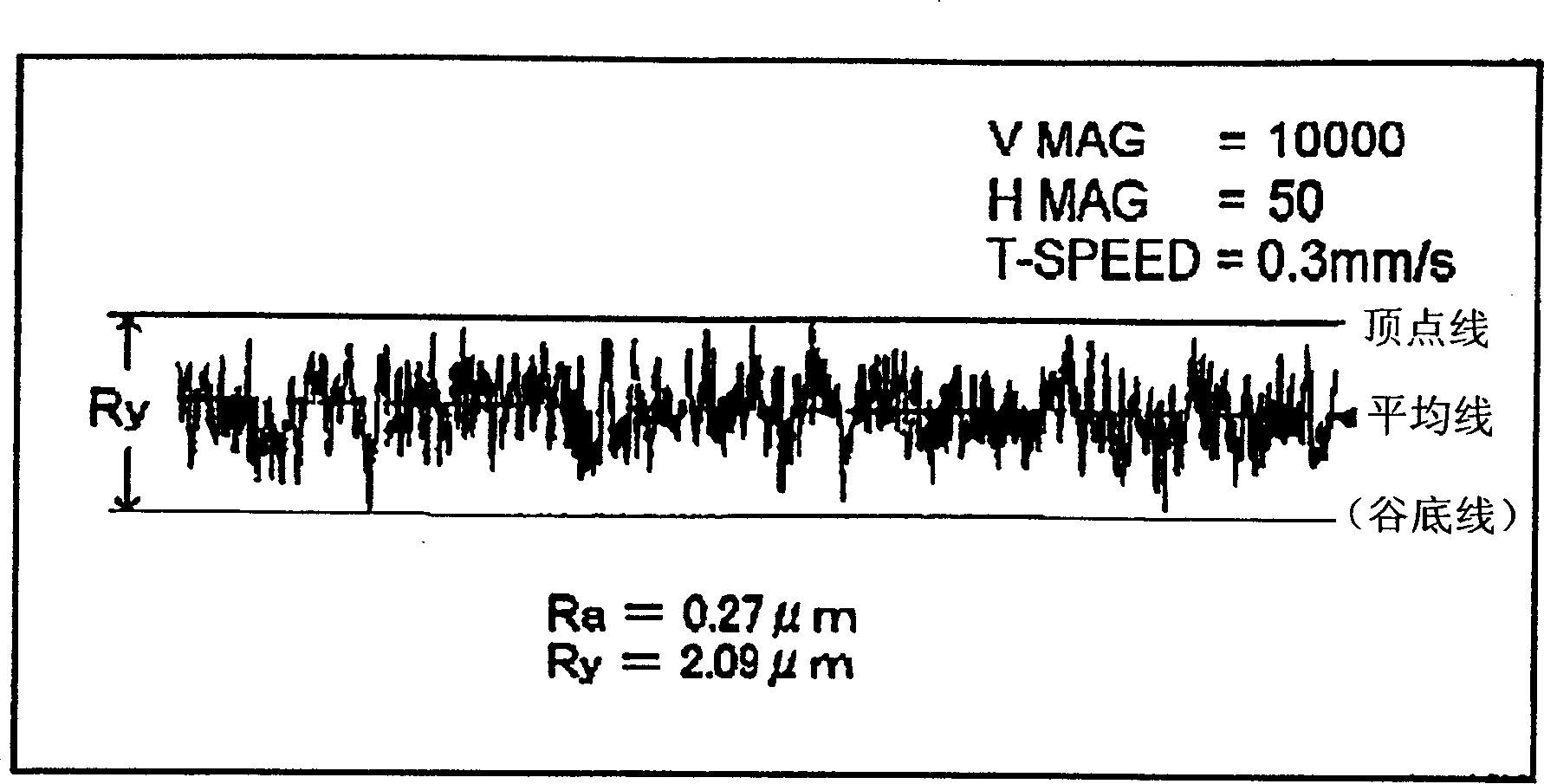

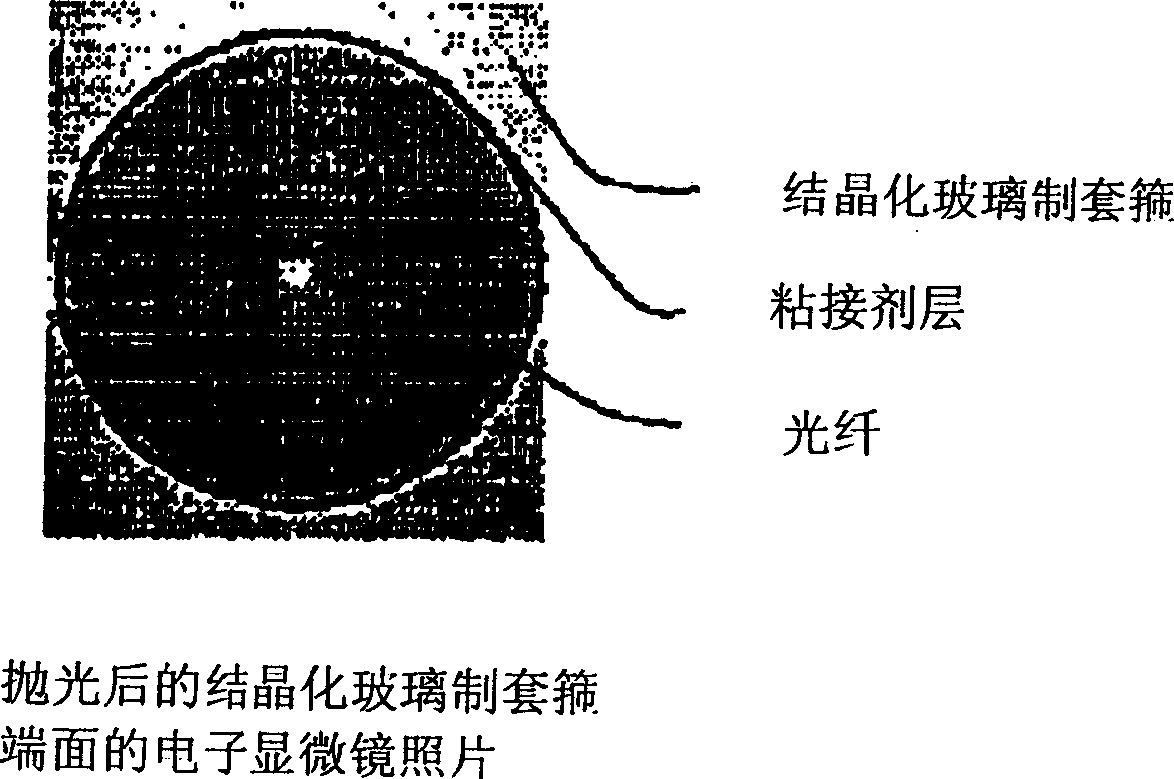

[0054] As shown in FIG. 1(A), a capillary 20 for an optical fiber made of crystallized glass is produced, wherein the Ra value of the surface roughness of the inner hole 20a is, for example, about 0.3 μm, Ry is about 2.0 μm, and the average The difference between the line and the apex line is about 1.0 μm, and the inner diameter of the inner hole 20 a is about 1.0 μm (0.95 to 1.05 μm) larger than that of the optical fiber.

[0055] Using the capillary 20 for an optical fiber, a ferrule 21 for an optical connector as shown in FIG. 1(B) is produced. That is, the manufactured ferrule 21 can be connected to other optical connector plugs according to the specified connection loss, for example, its outer diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com