Phenolic resin hollow bead, and preparation method and application thereof

A phenolic resin and water-soluble phenolic resin technology, which is applied in the field of plastic processing, can solve the problems such as the difficulty of effectively and accurately controlling the thickness and phase composition of the hollow spherical shell, the difficulty in controlling the particle size of the sphere, and the lack of industrialized products, and achieves low cost, roundness and so on. Good shape and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Add 200g of water-soluble phenolic resin and 250g of water into the container, and start mechanical stirring to completely dissolve and disperse the water-soluble phenolic resin to obtain a uniformly dispersed slurry. The liquid phase viscosity of the slurry is 7.9mPa·s. The weight ratio with water is 1:1.25;

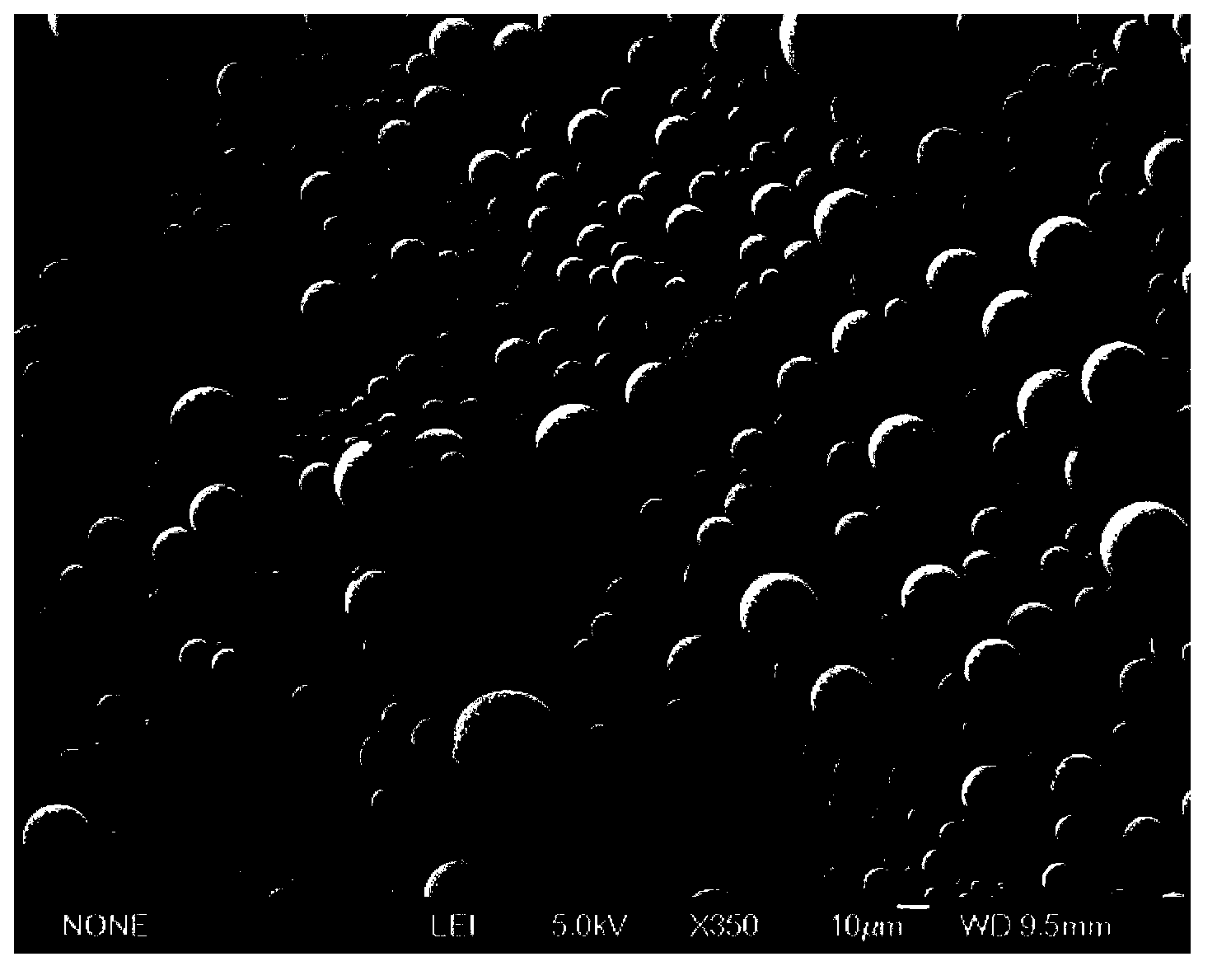

[0036] (2) Start the spray dryer, set the inlet temperature parameter to 250°C, the outlet temperature parameter to 160°C, and the frequency of the main frequency to 50Hz, so that the temperature field of the equipment is constant and uniform, and the airflow is stable; the rate of the volume pump is adjusted to 10ml / min , the slurry in step (1) is evenly sprayed under the working chamber, and the phenolic resin slurry is dried instantly to form hollow pellets, and the hollow pellets are driven by the wind-inducing device to collect samples in the cyclone, cloth bag and tower bottom respectively; the obtained phenolic resin The particle size of resin hollow s...

Embodiment 2

[0038](1) Add 200g of water-soluble phenolic resin, 10g of ammonium bicarbonate, 10g of ammonia water and 2000g of water into the container, and start mechanical stirring to completely dissolve and disperse the water-soluble phenolic resin to obtain a uniformly dispersed slurry; the liquid phase viscosity of the slurry is 2.7 mPa·s, the weight ratio of water-soluble phenolic resin to water is 1:10, and the blowing agent is 10% of the weight of water-soluble phenolic resin;

[0039] (2) Start the spray dryer, set the inlet temperature parameter to 270°C, the outlet temperature parameter to 170°C, and the frequency of the main frequency to 50Hz, so that the temperature field of the equipment is constant and uniform, and the air flow is stable; the rate of the volume pump is adjusted to 30ml / min , the slurry in step (1) is evenly sprayed under the working chamber, and the phenolic resin slurry is dried instantly to form hollow pellets, and the hollow pellets are driven by the wind...

Embodiment 3

[0041] (1) Add 100g of water-soluble phenolic resin, 5g of sodium bicarbonate and 2000g of water into the container, and start mechanical stirring to completely dissolve and disperse the water-soluble phenolic resin to obtain a uniformly dispersed slurry. The liquid phase viscosity of the slurry is 3.1mPa·s , water-soluble phenolic resin and water weight ratio is 1:20; Blowing agent is 5% of water-soluble phenolic resin weight;

[0042] (2) Start the spray dryer, set the inlet temperature parameter to 290°C, the outlet temperature parameter to 175°C, and the frequency of the main frequency to 50Hz, so that the temperature field of the equipment is constant and uniform, and the airflow is stable; the rate of the volume pump is adjusted to 60ml / min , the slurry in step (1) is evenly sprayed under the working chamber, and the phenolic resin slurry is dried instantly to form hollow pellets, and the hollow pellets are driven by the wind-inducing device to collect samples in the cycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com