Preparation method of organic/inorganic composite globules

An inorganic composite and organic technology, which is applied in the field of preparation of organic/inorganic composite pellets, can solve the problems of inapplicability, unusable formation with high temperature, brittleness and easy breakage of glass pellets, etc., and achieves good roundness of products. , uniform particle size, and the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

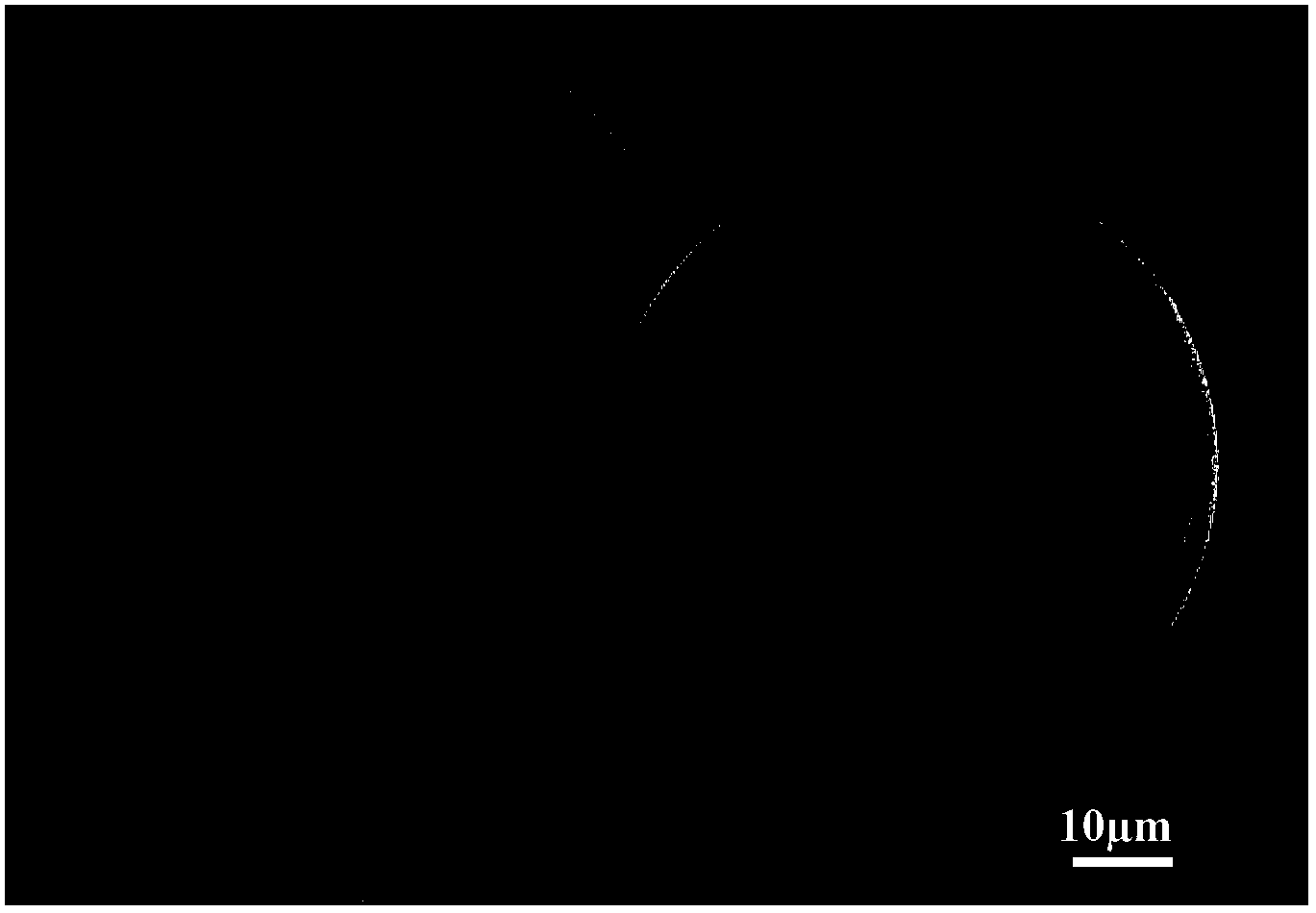

Image

Examples

Embodiment 1

[0032] Wash the computer packaging with polystyrene foam and dry it for later use;

[0033] (1) Prepare the oil phase: weigh 4.725g of the above-mentioned clean polystyrene foam, add 31.5g of styrene monomer, add 3.623g of hydrophobic nano-titanium dioxide after the dissolution is complete, ultrasonically disperse for 240min, and then add benzoyl peroxide 0.0063 G, Span 80 0.65g, mix homogeneously to obtain oil phase; polystyrene is 15% of styrene weight, hydrophobic titanium dioxide is 10% of polystyrene and styrene weight and, initiator is styrene monomer weight 0.02%, the weight of crosslinking agent is 0% of the weight of styrene monomer, and the weight of emulsifier is 2% of the sum of the weight of polystyrene and styrene monomer;

[0034] (2) Configure the dispersed water phase: add 0.48g of gelatin, 0.35g of sodium dodecylbenzenesulfonate and 0.05g of sorbitan oleate into 400ml of distilled water, and stir evenly to obtain the water phase; the weight of the dispersant ...

Embodiment 2

[0038] Wash the computer packaging with polystyrene foam and dry it for later use;

[0039](1) Prepare the oil phase: weigh 7.38g of the above-mentioned clean polystyrene foam, add 24.6g of styrene monomer, add 1.6g of hydrophobic nano-silica after the dissolution is complete, ultrasonically disperse for 60min, and then add 0.738g of peroxide Benzoyl, add 0.615g divinylbenzene, 3.198g Span-60, make the oil phase after mixing evenly; Wherein polystyrene weight accounts for 30% of styrene monomer weight, hydrophobic nano silicon dioxide weight is poly 5% of the sum of styrene and styrene weight, initiator is 3.0% of styrene monomer weight; crosslinking agent weight is 2.5% of styrene monomer weight, emulsifier weight is polystyrene weight and styrene monomer weight 10% of the sum of body weight;

[0040] (2) Configure the dispersed water phase: add 8g of polyvinyl alcohol to 100ml of distilled water and stir evenly; the weight of the dispersant is 8% of the weight of the water,...

Embodiment 3

[0044] Wash the computer packaging with polystyrene foam and dry it for later use;

[0045] (1) Prepare the oil phase: weigh 4g of the above-mentioned clean polystyrene foam, add 100% of styrene monomer, add 0.104g of hydrophobic nano-calcium carbonate after dissolution, ultrasonically disperse for 15min, add 0.5g of azobisisobutyronitrile , add ethylene glycol dimethacrylate 4g, Span 60 5.2g, and mix uniformly to obtain an oil phase; wherein the weight of polystyrene accounts for 4% of the weight of styrene monomer, and the weight of hydrophobic nano-calcium carbonate polystyrene and 0.01% of the weight of styrene monomer, the initiator is 0.5% of the weight of styrene monomer; the weight of crosslinking agent is 4% of the weight of styrene monomer, and the weight of emulsifier is the sum of the weight of polystyrene and styrene monomer 5% of

[0046] (2) Configure the dispersed water phase: add 6.6g of polyvinyl alcohol to 220ml of distilled water, then add 2.2g of sodium l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com