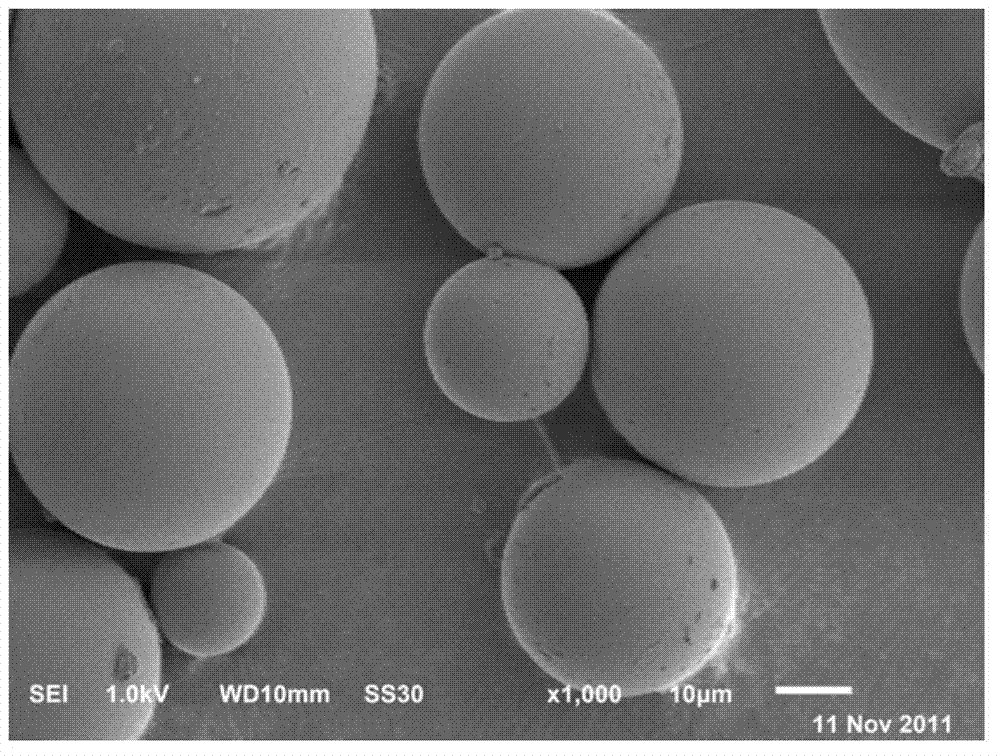

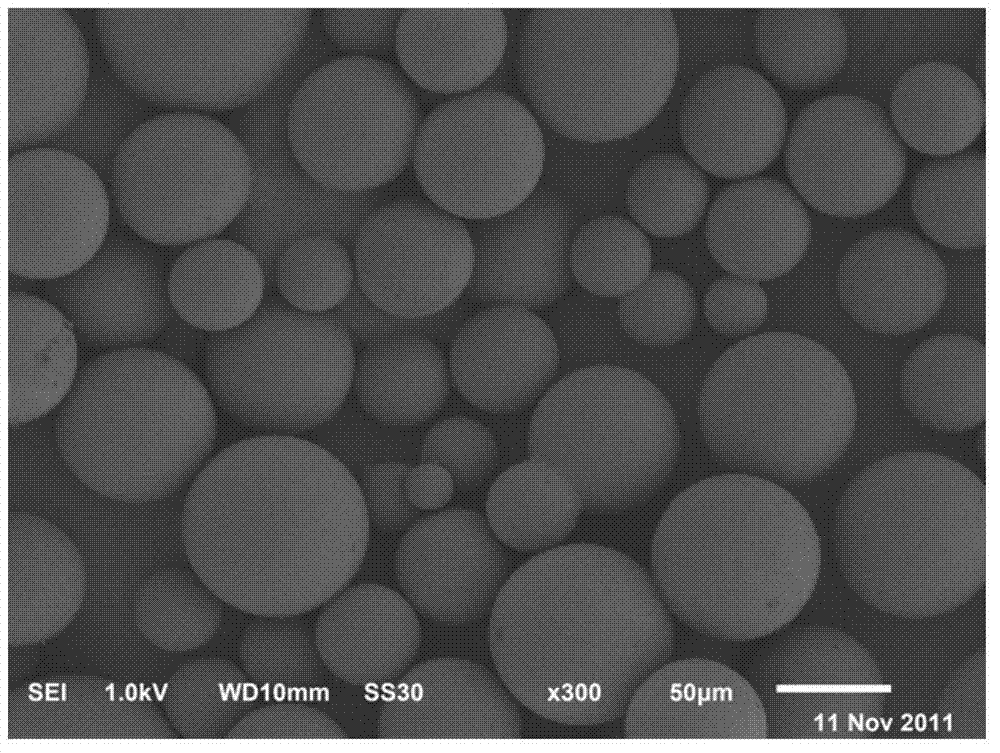

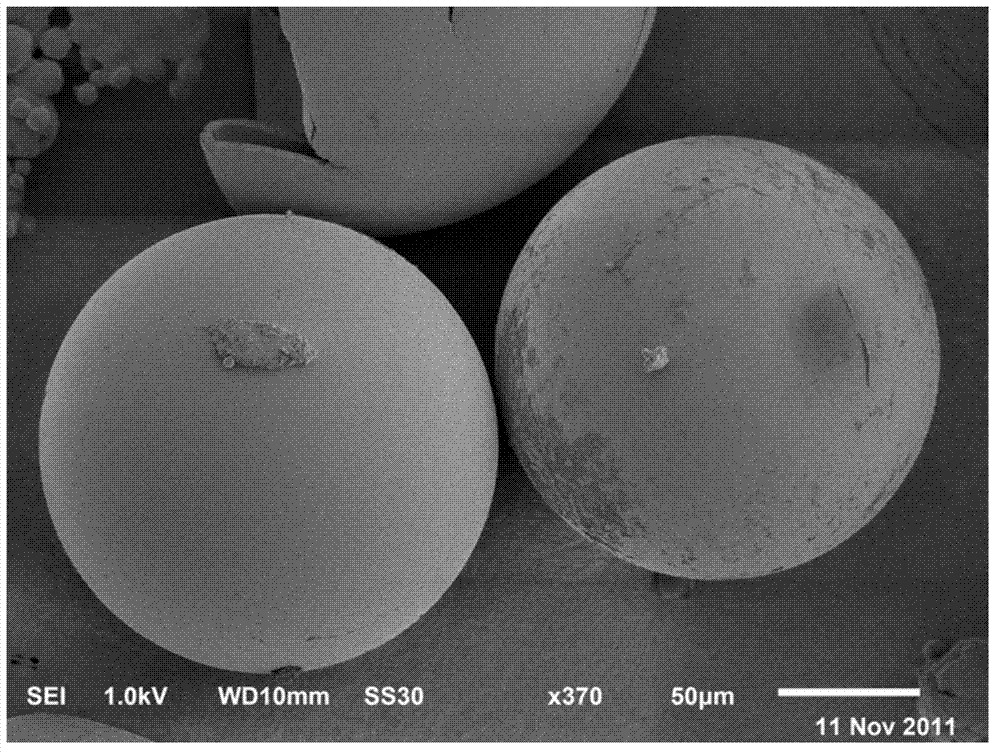

Preparation method for plastic hollow globule, and prepared product and application thereof

A hollow ball and plastic technology, applied in the field of plastic processing, can solve problems such as deformation, low glass transition temperature of polystyrene, loss of hollow structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Collect waste plastics whose main component is polycarbonate, clean them and dry them for later use.

[0066] (1) Configure the oil phase: Weigh 3.75g of the above polycarbonate and add it to 93g of chloroform, and stir evenly after the polycarbonate is completely dissolved as the oil phase (O); the oil phase solute accounts for 4% of the weight of the organic solvent , the weight percentage of polycarbonate plastic in the oil phase solute is 100%;

[0067] (2) Configure the first water phase: take 8ml of distilled water, add 0.16g of sodium dodecylsulfonate, completely dissolve and stir evenly, and use it as the first water phase (W1); the weight of the emulsifier accounts for 2% of the weight of the water;

[0068] (3) Configure the second water phase: Take 400ml of distilled water, add 0.48g of gelatin, 0.4g of sodium dodecylbenzenesulfonate, completely dissolve and stir evenly as the second water phase (W2); the weight of the dispersant accounts for the weight of th...

Embodiment 2

[0074] Collect waste plastics whose main component is polycarbonate, clean them and dry them for later use.

[0075] (1) Configure the oil phase: weigh 6g of the above-mentioned polycarbonate and add it to 93g of dichloromethane. After the polycarbonate is completely dissolved, add 0.3g of plasticizer dibutyl phthalate, stir evenly as the oil phase (O ); where the oil-phase solute accounts for 6.5% of the weight of the organic solvent, the weight percentage of polycarbonate plastic in the oil-phase solute is 100%, and the amount of plasticizer is 5% of the weight of polycarbonate;

[0076] (2) Configure the first water phase: take 55ml of distilled water, add 4.4g of sodium dodecylbenzenesulfonate, completely dissolve and stir evenly as the first water phase (W1); the weight of the emulsifier accounts for 8% of the weight of the water;

[0077] (3) Configure the second water phase: take 640ml of distilled water, add 12.8g of xanthan gum and 0.48g of sodium lauryl sulfate, comp...

Embodiment 3

[0083] Collect waste plastics whose main component is polycarbonate, clean them and dry them for later use.

[0084] (1) Prepare the oil phase: weigh 15g of the above-mentioned polycarbonate and add it to 93g of benzene. After the polycarbonate is completely dissolved, add 1.5g of plasticizer dioctyl terephthalate and stir evenly as the oil phase (O); Wherein the oil phase solute accounts for 16% of the organic solvent weight, the polycarbonate plastic weight percentage content in the oil phase solute is 100%, and the plasticizer consumption is 10% of the polycarbonate weight;

[0085](2) Configure the first water phase: take 32ml of distilled water, add 0.96g of sorbitan oleate, completely dissolve and stir evenly, and use it as the first water phase (W1); the weight of the emulsifier accounts for 3% of the weight of the water;

[0086] (3) Configure the second water phase: take 1350ml of distilled water, add 74g of carboxymethyl cellulose, completely dissolve and stir evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com