Gas breaker

A gas circuit breaker and gas technology, applied in the direction of high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of reducing gas diversion, poor arc suppression performance, danger, etc., and achieve the goal of reducing fluid resistance and improving arc suppression performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

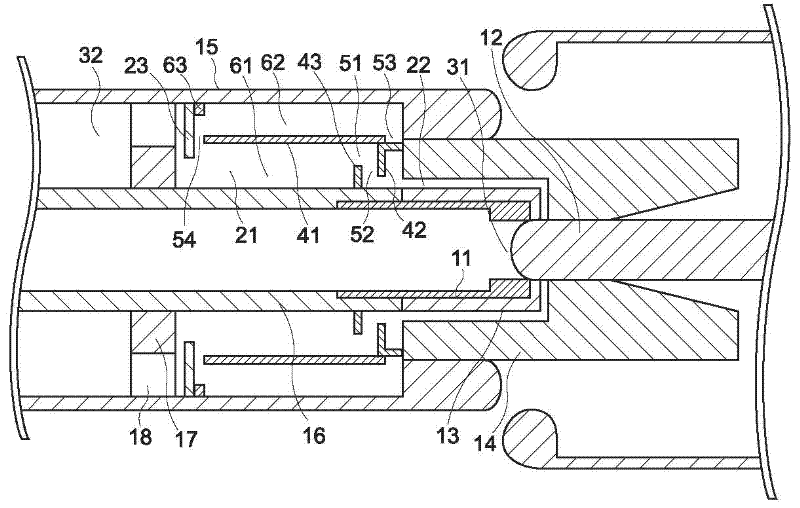

[0034] In the circuit breaker of the gas circuit breaker of the embodiment of the present invention, such as figure 1 As shown, the thermal blast chamber 21 and the variable-volume mechanical blast chamber 32 are provided in series via the partition wall 17 forming the communicating portion 18 of the opening. Inside the heat injection chamber 21 , a cylindrical partition member 41 is provided which divides the inside in the radial direction and divides it into an inner peripheral side space 61 and an outer peripheral side space 62 .

[0035] In addition, the communication part 18 constituting the opening part formed in the partition wall 17 is figure 1 In the example shown, it is installed on the side of the cylinder 15, but it may be installed at a position that does not hinder the inflow of arc-extinguishing gas that flows from the side of the mechanical injection chamber 32 as will be described later.

[0036] This partition member 41 includes, for example, the following...

Embodiment 2)

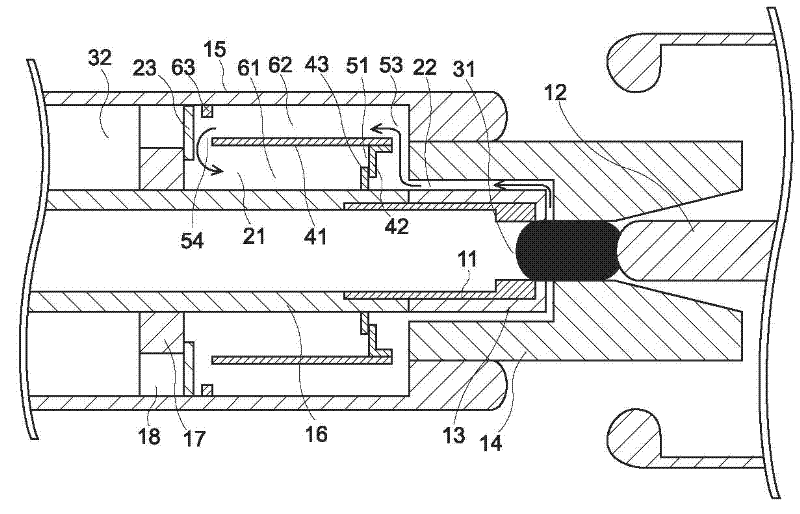

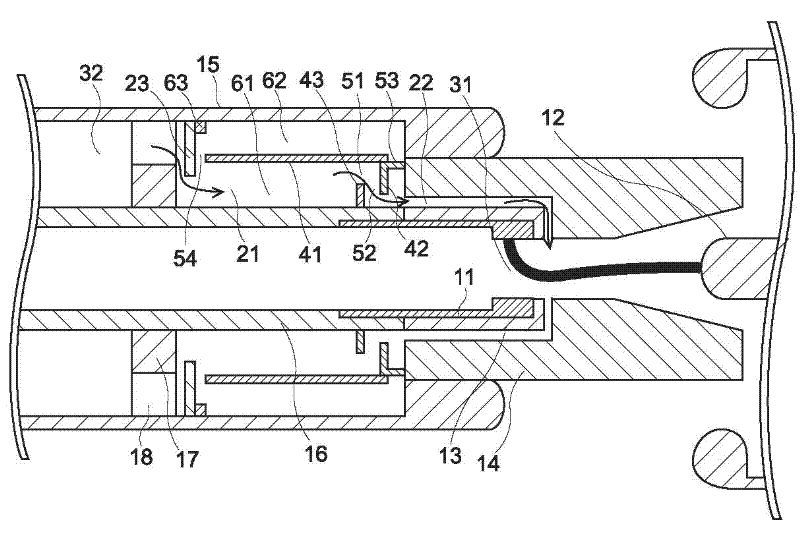

[0068] Figure 6 Another embodiment of the gas circuit breaker of the present invention is shown. In this embodiment, with respect to the above-mentioned embodiment 1, when the movable valve 23 is in an open state, the end face of the movable valve 23 and the partition member 41 on the side of the mechanical jet chamber 21 is in close contact, thus, the outer peripheral side space of the heat jet chamber 21 62 is disconnected from the inner peripheral space 61 .

[0069] When the medium and small currents are cut off, the rising degree of the pressure of the heat jet chamber 21 is less large when the large current is cut off, so the pressures of the mechanical jet chamber 32 and the heat jet chamber 21 are balanced. Accordingly, the movable valve 23 does not close the communicating portion 18 .

[0070] Near the zero point of the current, the mechanical jet chamber 32 is compressed by the breaking action. As a result, the pressure in the mechanical jet chamber 32 rises, and...

Embodiment 3)

[0074] Figure 7 Another example of the gas interrupter of the present invention is shown. In this embodiment, a polymer material 71 such as tetrafluoroethylene resin having an ablation effect is provided in the outer peripheral space 62 in the heat injection chamber 21 partitioned by the partition member 41 as compared to the above-mentioned embodiment 1.

[0075] If formed in this way, the high-temperature arc-extinguishing gas flowing from the arc space 31 into the thermal arc chamber 21 can directly contact the polymer material, effectively increasing the pressure, and obtaining higher breaking performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com