10 kV live-line work lap joint arc extinguishing device

A technology for live work and arc suppression, applied in the parts of the connection device, coupling device, conductive connection, etc., can solve the problems of slow moving contact, unfavorable safe operation, slow lap speed, etc., to improve the current flow Ability and safety, arc suppression effect and effect with good safety and low probability of arcing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions and technical effects of the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings of the present invention.

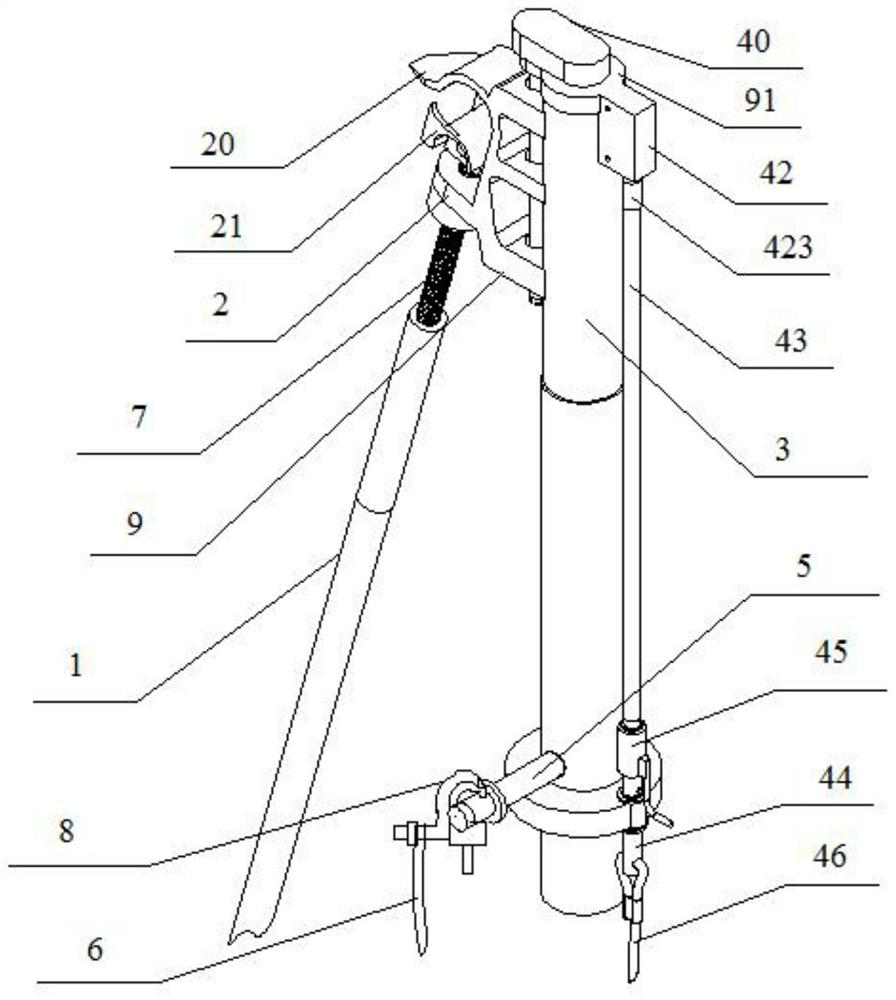

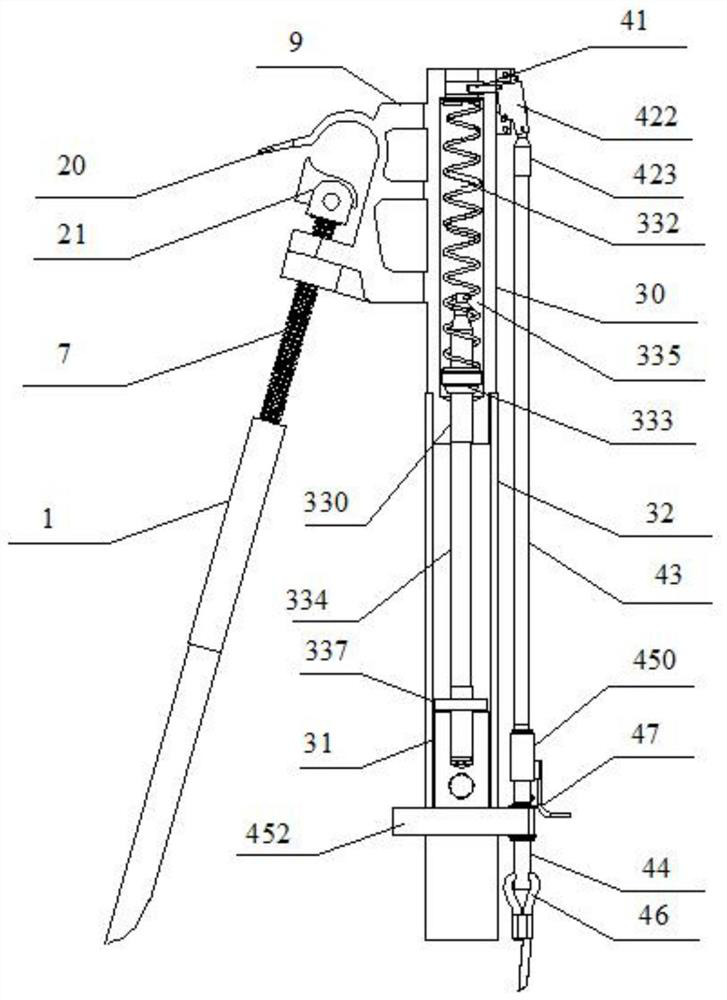

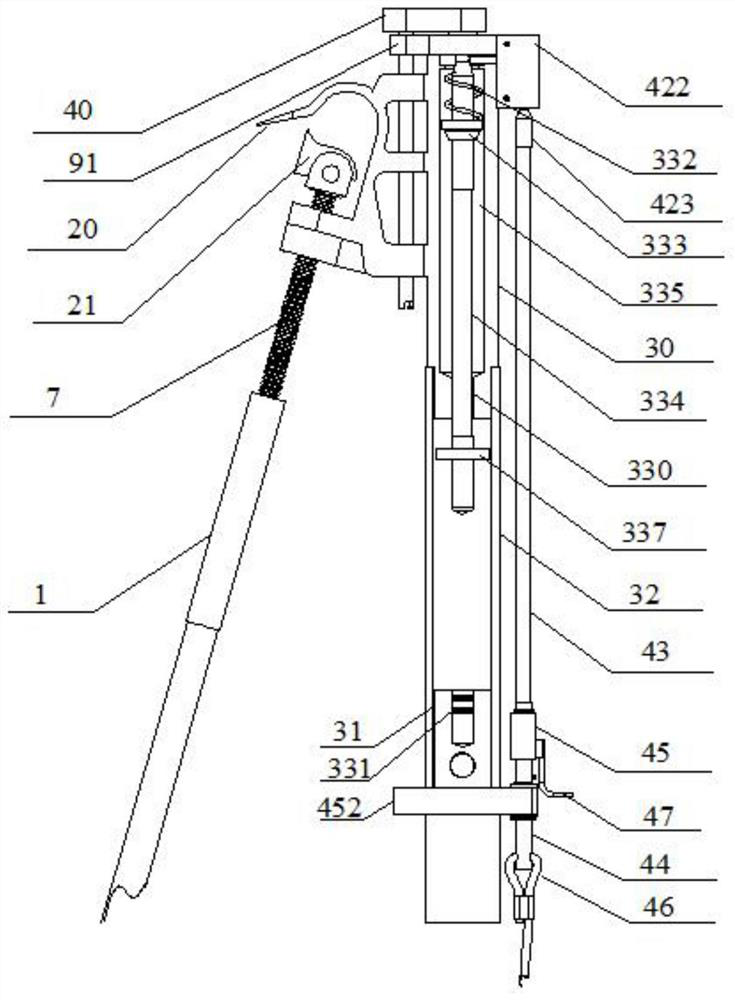

[0030] Please see figure 1 , 2 , 3, 4, 5 and 8, a 10kV live work lap splice arc suppressing device, including: an insulating operating rod 1, a wire clamp 2, an arc suppressing mechanism 3, a splitting mechanism, a wiring guide post 5 and a drain wire 6; The top of the insulating operating rod 1 is connected to the wire clamp 2 through the screw 7; the back of the wire clamp 2 is fixedly connected to one side of the arc suppression mechanism 3 through the connector 9; the connector 9 is made of conductive material; The side outside the mechanism 3 opposite to the wire clamp 2; the wiring guide post 5 is in fixed electrical communication with the bottom of the arc suppression mechanism 3; one end of the drain wire 6 is connected to the wiring guide post 5 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com