Arc-extinguishing plate, manufacturing method of arc-extinguishing plate, and switch

A manufacturing method and technology of arc extinguishing boards, which are applied to electric switches, high-voltage air circuit breakers, high-voltage/high-current switches, etc., can solve the problems of arc extinguishing performance of arc extinguishing boards, damage to circuit breakers, etc., and achieve arc extinguishing Effects of performance improvement and breaking performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

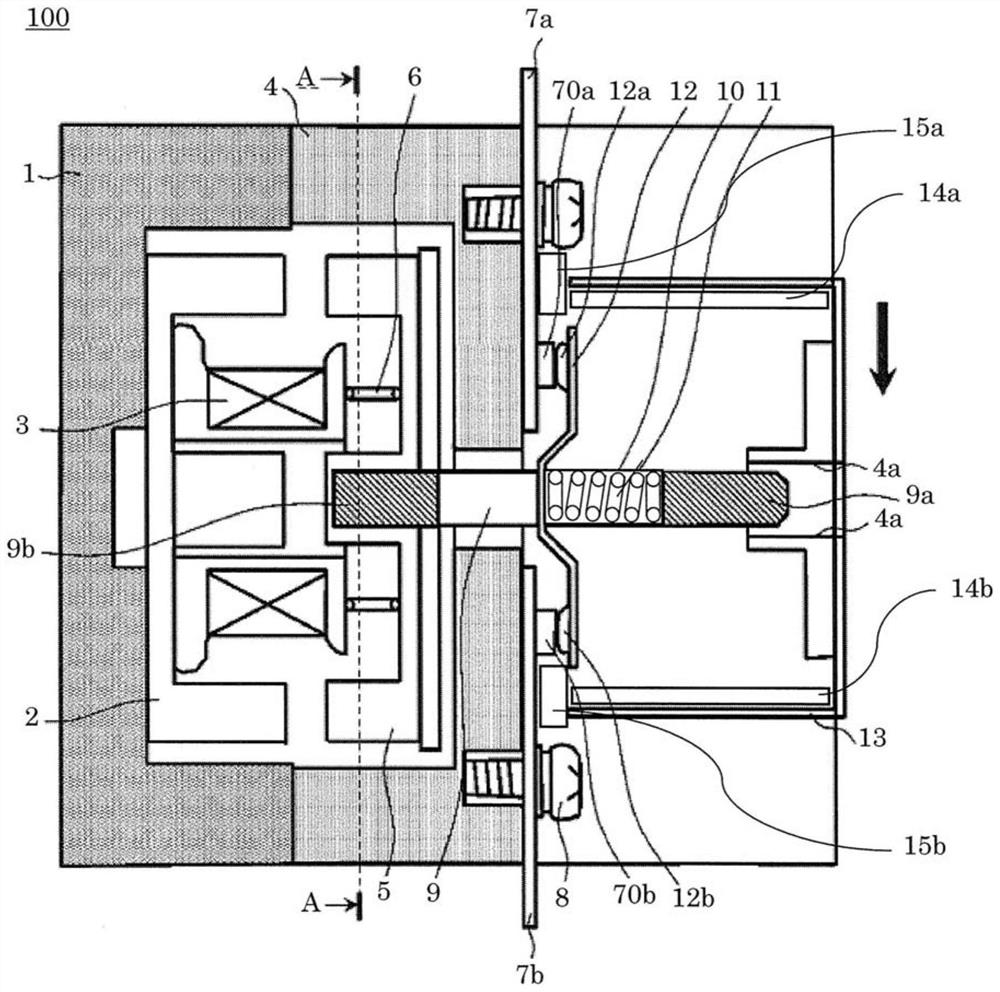

[0026] figure 1 It is a cross-sectional view of the electromagnetic switch in Embodiment 1 of the present invention when viewed from the lateral direction.

[0027] use figure 1 Each configuration of the electromagnetic switch 100 according to the first embodiment will be described. The mount 1 is formed of an insulator. The fixed iron core 2 is fixed to the mount 1, and is formed by laminating silicon steel sheets in an E shape. The operation coils 3 are respectively arranged in the concave portions of the mountain-shaped fixed iron core 2 .

[0028] The frame body 4 is fixed to the mounting seat 1 and is molded from the same insulating material as the mounting seat 1 . Moreover, the housing|casing 4 has the housing|casing head slide part 4a which opposes the head slide part a of the crossbar 9 mentioned later. The movable iron core 5 is formed by laminating silicon steel sheets in the same E shape as the fixed iron core 2 . In addition, the movable iron core 5 and the ...

Embodiment approach 2

[0065] Next, the manufacturing method of the arc extinguishing plate in Embodiment 2 of this invention is demonstrated.

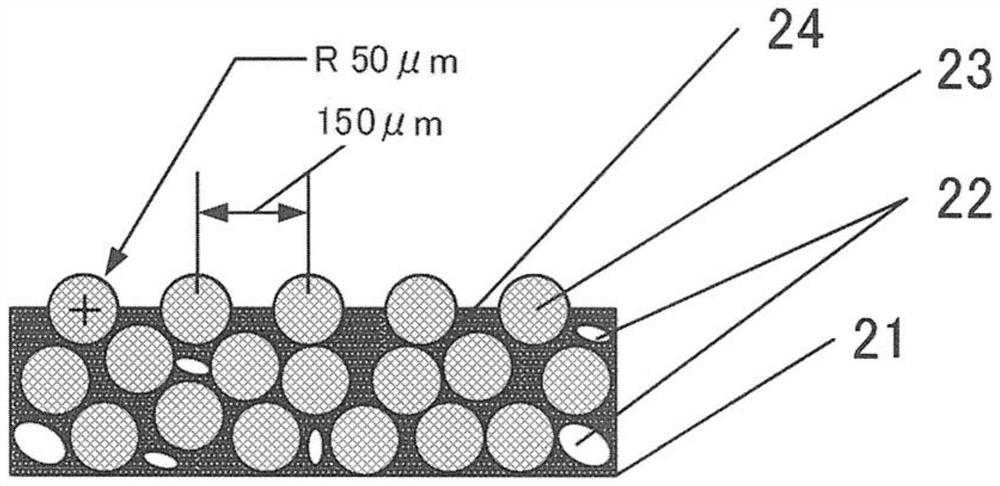

[0066] As the overall weight composition ratio, a silica sand material containing 80% or more by weight of silica as the main component and 60% as the main component, and magnesia and alumina as sintering aids at 20% were mixed and stirred. Forming Auxiliary PVA (resin: polyvinyl alcohol) was diluted with pure water into a solution of 10% by volume, and mixed and stirred in a mortar.

[0067] Here, as the silica sand material, a material having a particle size distribution of 50 to 150 μm and a center particle diameter of about 100 μm is used, and magnesia and alumina use a material with a center particle diameter of about 1 μm.

[0068] Next, a desired amount of the mixed and stirred material is weighed on a mold coated with oleic acid as a mold release material, and processed into a plate shape by pressing. Here, 10 g of the mixed material was weighed fo...

Embodiment approach 3

[0082] Next, the manufacturing method of the arc extinguishing plate in Embodiment 3 of this invention is demonstrated.

[0083] As the overall weight composition ratio, a silica sand material containing 80% or more of silicon oxide by weight (here, a material with a weight ratio of 95% of silicon oxide) as the main component, 60% of magnesium oxide as a sintering aid And alumina was mixed and stirred at 20% by adding PVA (resin: polyvinyl alcohol) diluted with pure water as a molding aid to a solution of 10% by volume, and mixed and stirred in a mortar.

[0084] Here, three types of silica sand materials are used, namely, a particle size distribution of 50 to 150 μm and a center particle diameter of about 100 μm, a particle size distribution of 75 to 450 μm and a center particle diameter of about 200 μm, a particle size distribution of 200 to 1200 μm and a center particle diameter of 500μm or so. In addition, the manufacture of an arc extinguishing plate was attempted using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com