Plastic bead as well as preparation method and applications thereof

A technology of plastic pellets and plastics, applied in the field of petroleum exploration, can solve the problems of harsh in-situ intercalation conditions, difficult industrialization, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

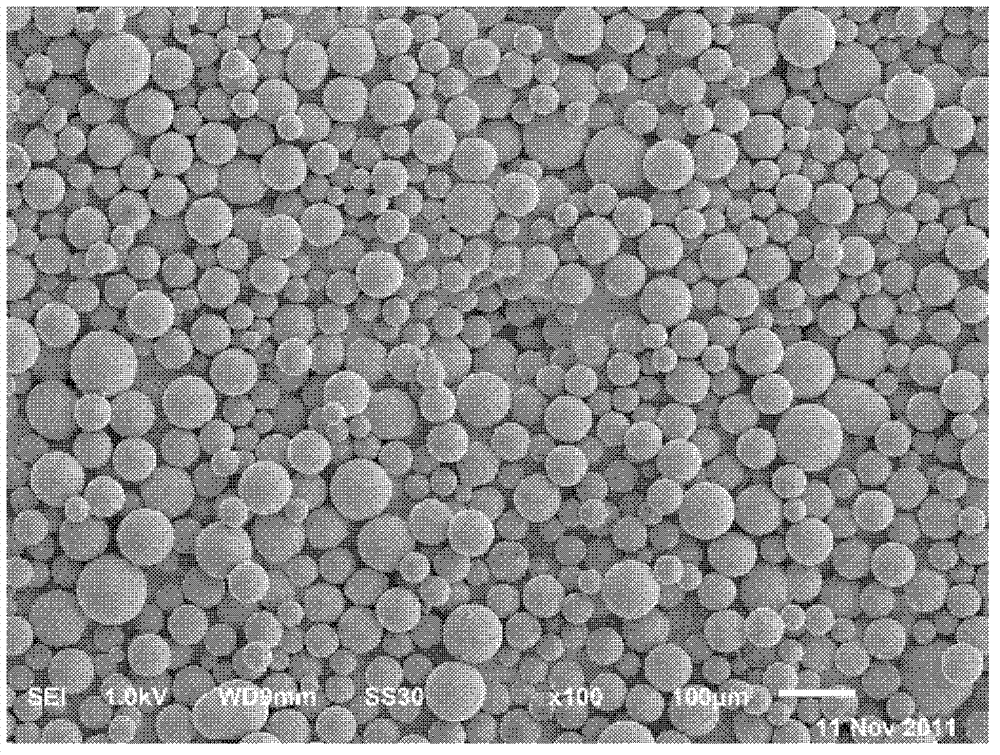

Image

Examples

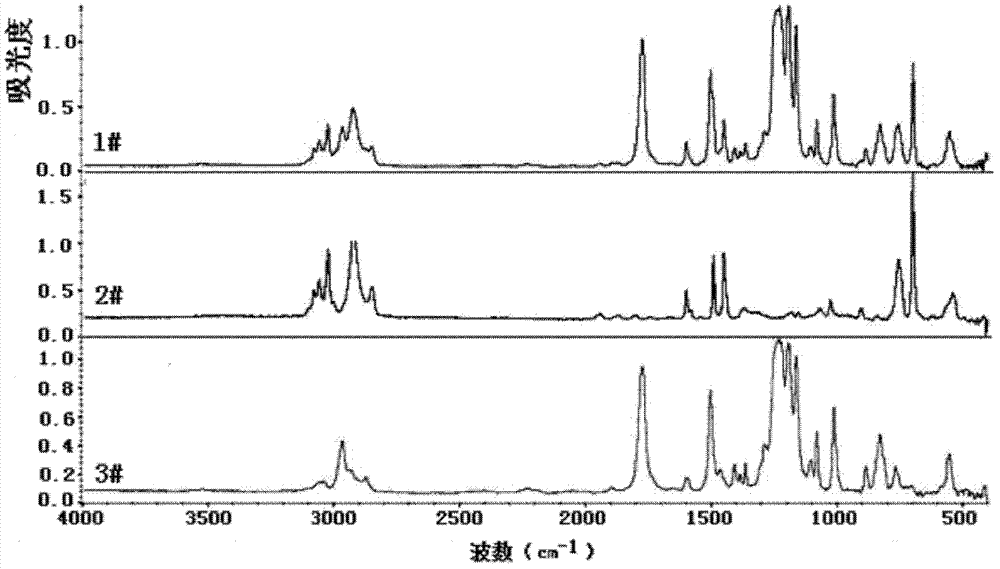

Embodiment 1

[0055] Wash the computer packaging with polystyrene foam and dry it for later use; wash and dry the polycarbonate plastic separated from the discarded discs for later use;

[0056] (1) Configure the oil phase: Weigh 2.376g of the above-mentioned polystyrene foam, add 0.024g of the above-mentioned polycarbonate into 59.4g of dichloromethane, completely dissolve the oil phase solute, and stir evenly to obtain the oil phase; The weight of the solute is 4% of the weight of the organic solvent, and the weight percentage of polystyrene in the oil phase solute is 99%; the weight percentage of polycarbonate is 1%;

[0057] (2) configure the dispersed water phase: add 2.0g gelatin and 1.0g sodium lauryl sulfate to 200ml distilled water, stir to make the water phase; wherein in the water phase, the weight percentage concentration of the dispersant is 1%, and the weight of the emulsifier is The percentage concentration is 0.5%; the oil-water ratio is 1:3.3

[0058] (3) Pour the water ph...

Embodiment 2

[0061] Wash and dry the polycarbonate plastic separated from the discarded discs for use;

[0062] (1) Configure the oil phase: Weigh 3.70 g of the above polycarbonate and add it to 92.4 g of dichloromethane to completely dissolve the oil phase solute, then add 0.185 g of petroleum phenyl sulfonate, and stir to obtain the oil phase; the oil phase The solute weight is 4% of the organic solvent weight, the polycarbonate weight percentage in the oil phase solute is 100%, and the plasticizer weight is 5% of the polycarbonate weight;

[0063] (2) configure the dispersed water phase: add 0.5g gelatin and 1.2g sodium lauryl sulfate to 400ml distilled water, stir to make the water phase; wherein the dispersant weight percentage concentration in the water phase is 0.125%, emulsifier weight The percentage concentration is 0.3%; the oil-water ratio is 1:4.2;

[0064] (3) Pour the water phase into a three-necked flask with a condensation recovery pipe, and put it into a water bath; adjus...

Embodiment 3

[0067] Wash the computer packaging with polystyrene foam and dry it for later use; wash and dry the polycarbonate plastic separated from the discarded discs for later use;

[0068](1) Configure the oil phase: Weigh 9g of the above-mentioned polystyrene foam, add 1g of the above-mentioned polycarbonate to 92.4g of 1,1-dichloroethane to completely dissolve the oil phase solute, and then add 0.03g of hexamethylene dichloride Dioctyl acid dioctyl ester is stirred evenly to obtain an oil phase; wherein the oil phase solute weight is 10.8% of the weight of the organic solvent, and the polystyrene weight percentage is 90% in the oil phase solute; the polycarbonate weight percentage is 10%, Plasticizer is 3% of polycarbonate weight;

[0069] (2) Configure the dispersed water phase: add 5.0g gelatin and 0.4g sodium dodecylbenzene sulfonate to 200ml distilled water, stir evenly to make the water phase; wherein the dispersant weight percentage concentration in the water phase is 2.5%, em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com