Non-field cage-shape tap changer for transformer

A technology of tap changer and transformer, which is applied in transformers, variable transformers, electric switches, etc., can solve the problems of low positioning accuracy of moving contacts, difficult contact shunting, affecting the performance of switches, etc., and achieves structural rigidity improvement, The effect of low production cost and small operating torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

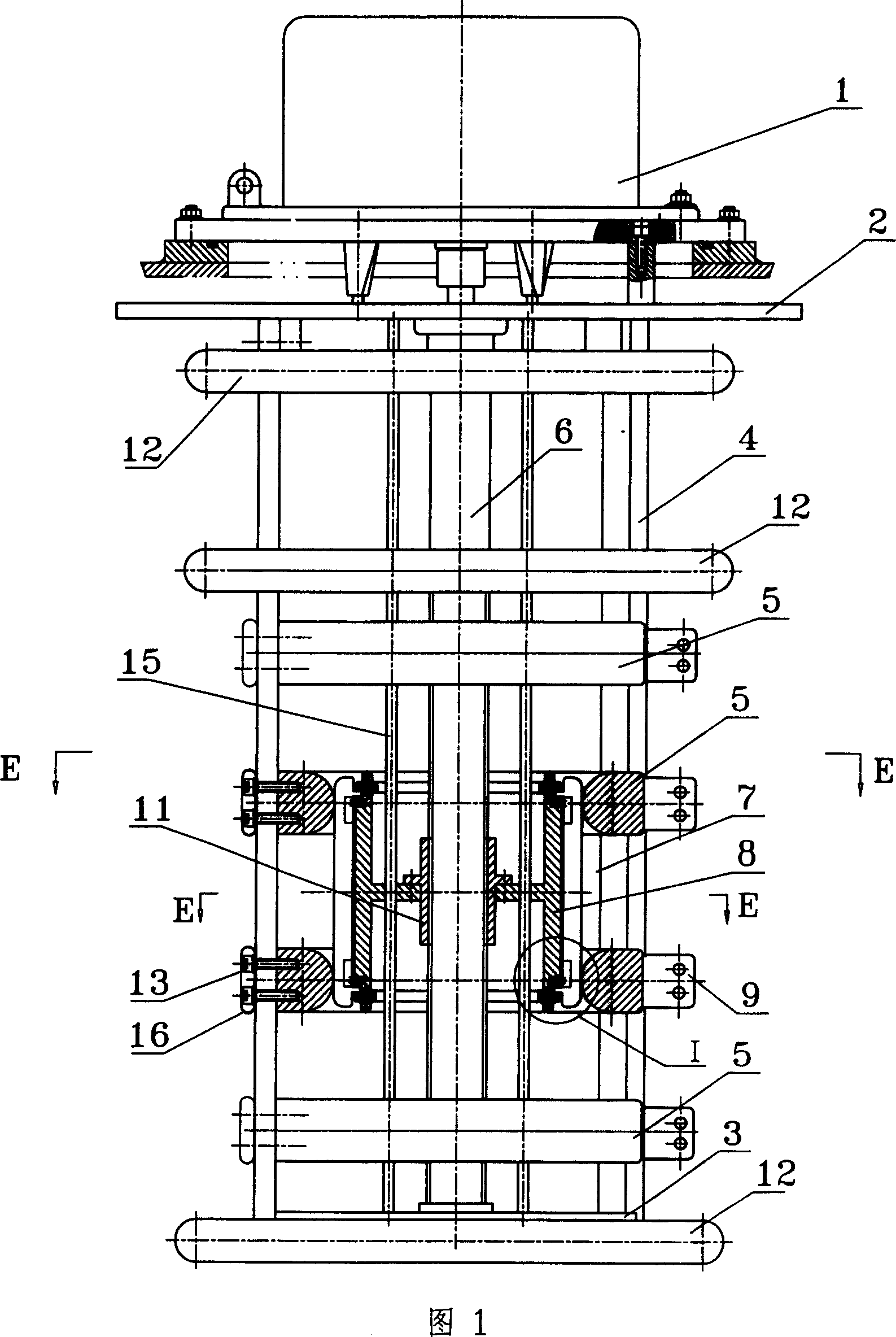

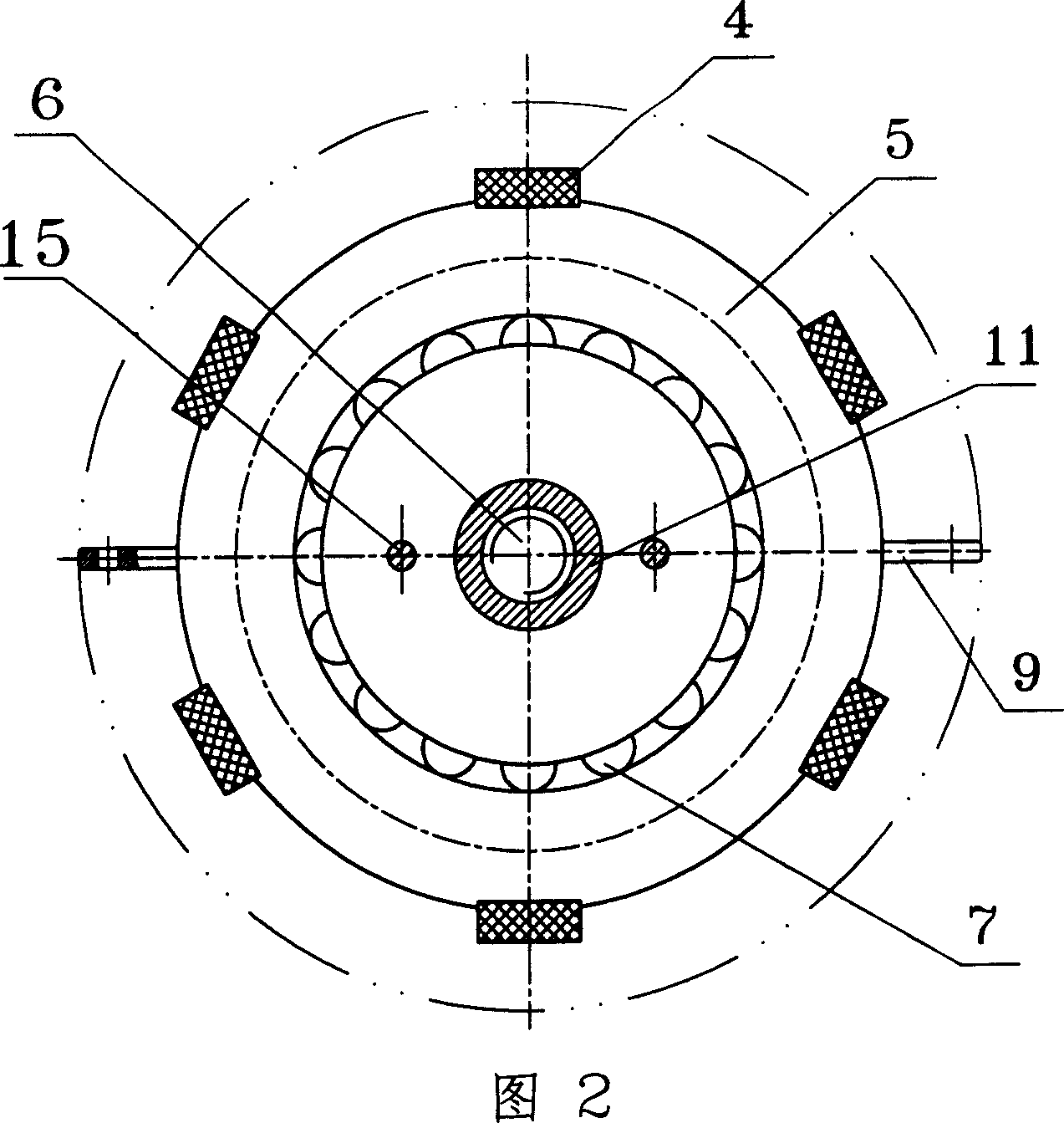

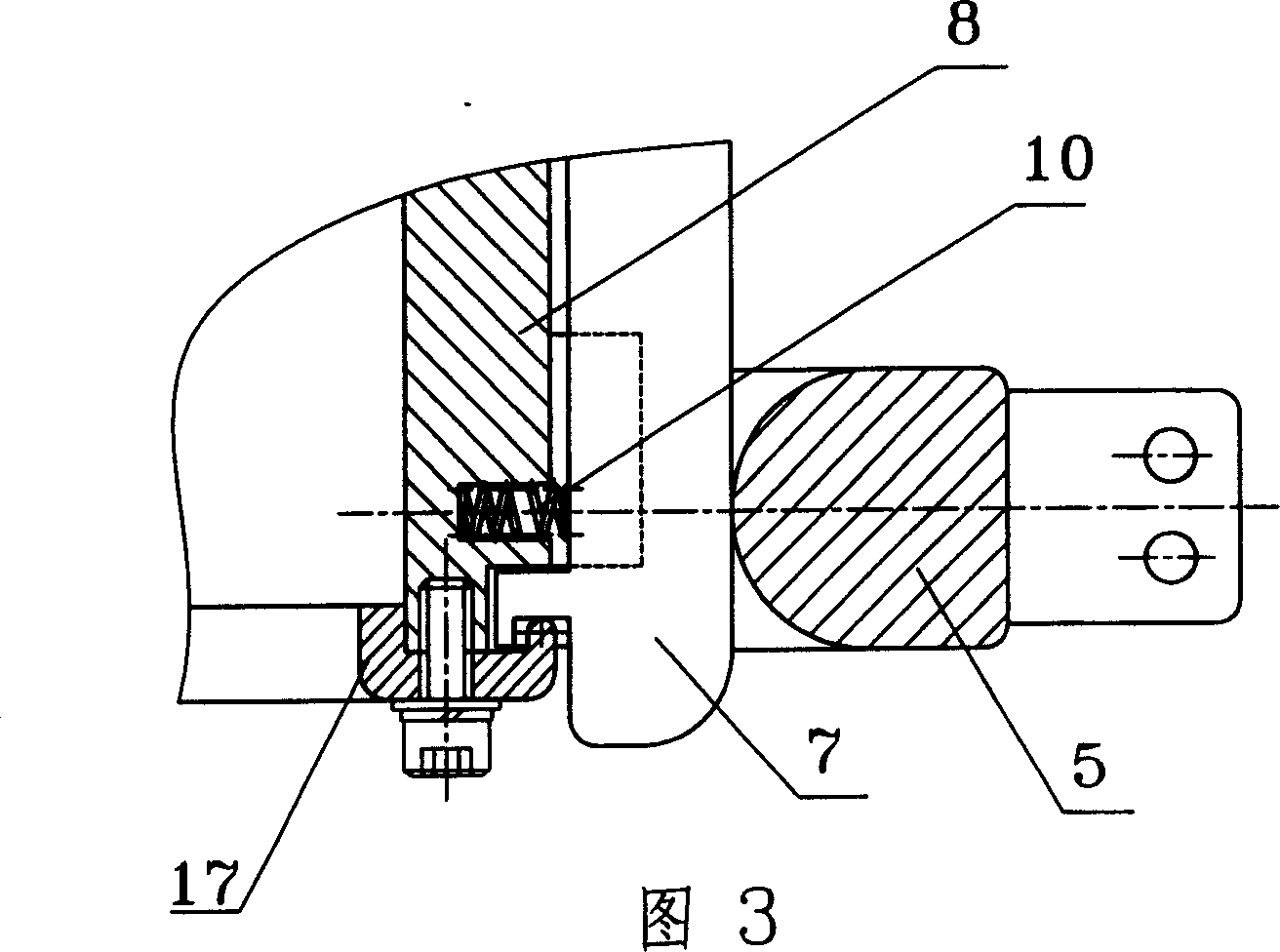

[0018] One embodiment of the present invention, as shown in Figures 1, 2, and 3, is a single-phase off-excitation cage tap changer with upper and lower supports 2, 3, and a transmission screw 6 is installed between the upper and lower supports. , the upper part of the transmission screw is connected with the operating mechanism 1, and the transmission screw is arranged with the screw sleeve 11 connected with the support to form a screw type upper and lower transmission device; 6 to 8 pieces are installed around the upper and lower supports. Insulating rods 4, ring-shaped static contacts 5 are arranged at intervals along the axial direction on the inside of the insulating rods, the ring-shaped static contacts are connected with each insulating rod through screws 13, and multiple ring-shaped static contacts can be arranged in the axial direction, usually 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com