Submarine power cable with insulating composite layer

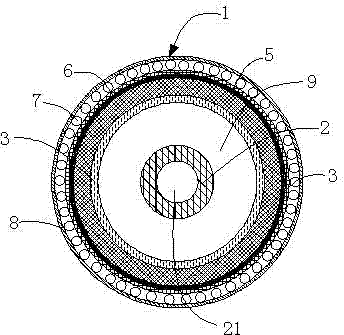

A technology for submarine power cables and insulating composite materials, which is applied to power cables with shielding/conducting layers, submarine cables, insulated cables, etc. performance, effect of suppressing internal air gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

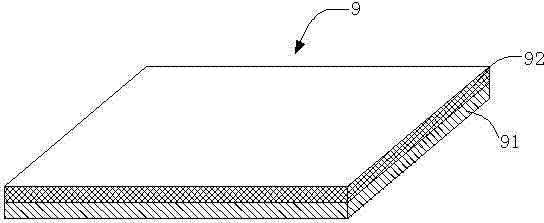

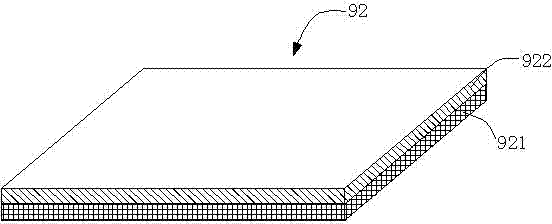

[0033] Take 90 parts of nano-modified epoxy resin, 140 parts of methyl tetrahydrophthalic anhydride, 200 parts of 400 mesh silicon powder, 30 parts of Qishi toughening agent, 6 parts of nano-silicon oxide, 80 parts of polyimide, and 20 parts of nano-titanium dioxide. 2 parts, 2 parts of bis(2-ethylhexyl) phthalate, mix evenly and put it into an open mixer or internal mixer, heat at 100°C, and process for 20 minutes to form an insulating material layer.

[0034] Take polyolefin compound: 60 parts of polyethylene-vinyl acetate copolymer, composite antioxidant: 0.5 parts of antioxidant 1010 and antioxidant 168, coupling agent: 0.5 part of vinyltrimethoxysilane, 2 parts of silica gel Inorganic flame retardant: 40 parts of magnesium hydroxide are mixed evenly and processed into a reinforcing layer.

[0035] First wrap the cable conductor with an insulating composite material layer, then vacuum dry, soak in oil, and then wrap a metal sheath for continuous extrusion, then wrap the ca...

Embodiment 2

[0038] Take 90 parts of nano-modified epoxy resin, 150 parts of methyl tetrahydrophthalic anhydride, 200 parts of 400 mesh silicon powder, 25 parts of Qishi toughening agent, 6 parts of nano silicon oxide, 85 parts of polyimide, and 24 parts of nano titanium dioxide. 2 parts, 3 parts of bis(2-ethylhexyl) phthalate, mixed evenly and put into an open mixer or internal mixer, heating temperature 100 ℃, processing time 20 minutes to process and form an insulating material layer.

[0039] Take polyolefin compound: 70 parts of polyethylene-vinyl acetate copolymer, composite antioxidant: 0.8 parts of antioxidant 1010 and antioxidant 168, coupling agent: 1 part of vinyltrimethoxysilane, 5 parts of silica gel Parts, inorganic flame retardant: 45 parts of magnesium hydroxide are mixed evenly and processed into a reinforcement layer.

[0040] First wrap the cable conductor with an insulating composite material layer, then vacuum dry, soak in oil, and then wrap a metal sheath for continuo...

Embodiment 3

[0043] Take 90 parts of nano-modified epoxy resin, 160 parts of methyl tetrahydrophthalic anhydride, 250 parts of 400 mesh silicon powder, 30 parts of Qishi toughening agent, 8 parts of nano silicon oxide, 90 parts of polyimide, and 25 parts of nano titanium dioxide. Parts, 5 parts of bis(2-ethylhexyl) phthalate, mixed evenly, put into an open mixer or internal mixer, heating temperature 100 ℃, processing time 20 minutes to process and form an insulating material layer.

[0044] Take polyolefin compound: 80 parts of polyethylene-vinyl acetate copolymer, composite antioxidant: 1 part of antioxidant 1010 and 1 part of antioxidant 168, coupling agent: 1.5 parts of vinyltrimethoxysilane, 10 parts of silica gel Parts, inorganic flame retardant: 50 parts of magnesium hydroxide are mixed evenly and processed into a reinforcement layer.

[0045] The general chemical formula of the silica gel used in all the examples is mSiO2·nH2O.

[0046] First wrap the cable conductor with an insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com