Rectangular fully welded U-shaped tube type heating network heater

A heat network heater and U-shaped tube technology, applied in the direction of indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve the problems such as no new progress, achieve simple structure, easy to drain, low The effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

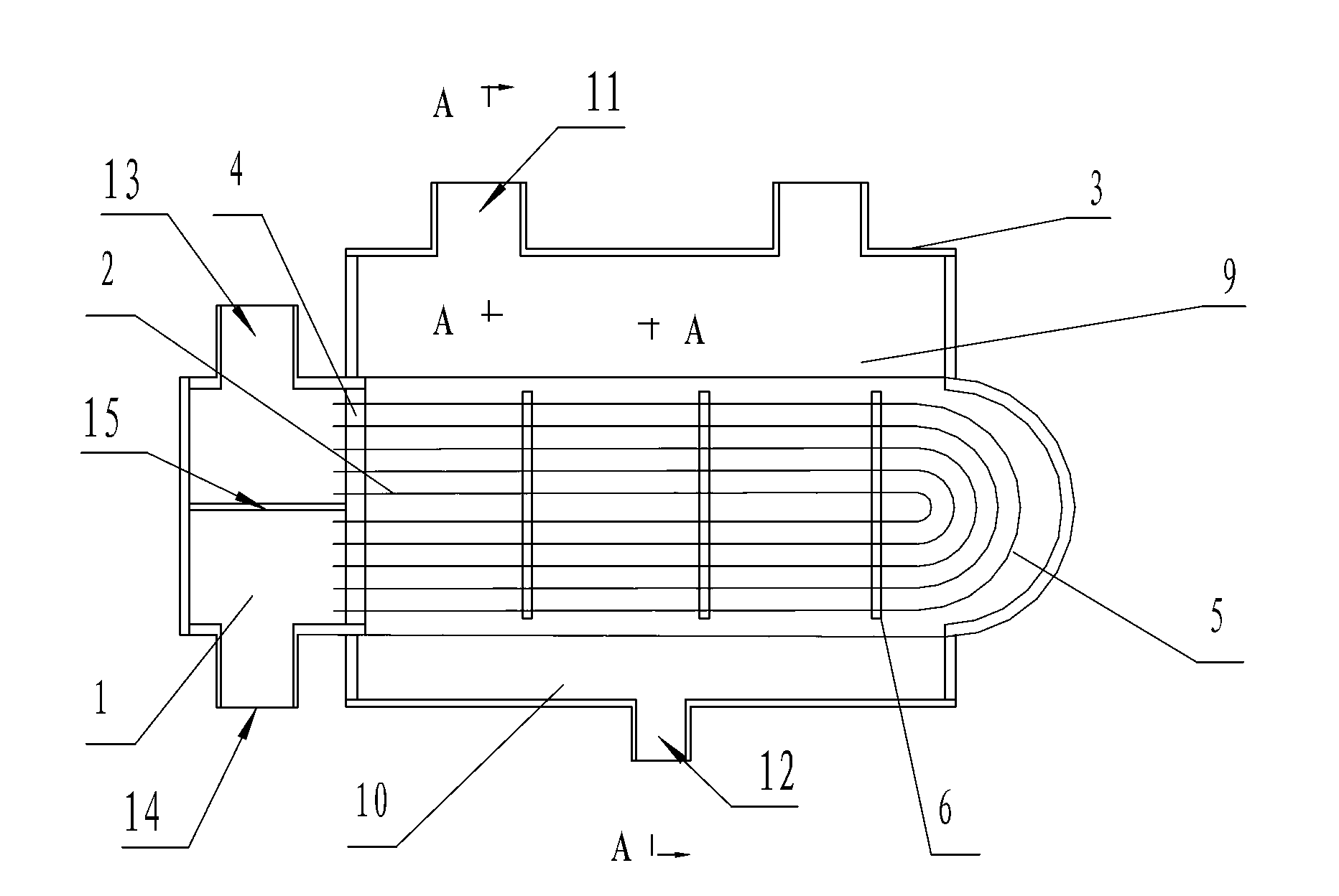

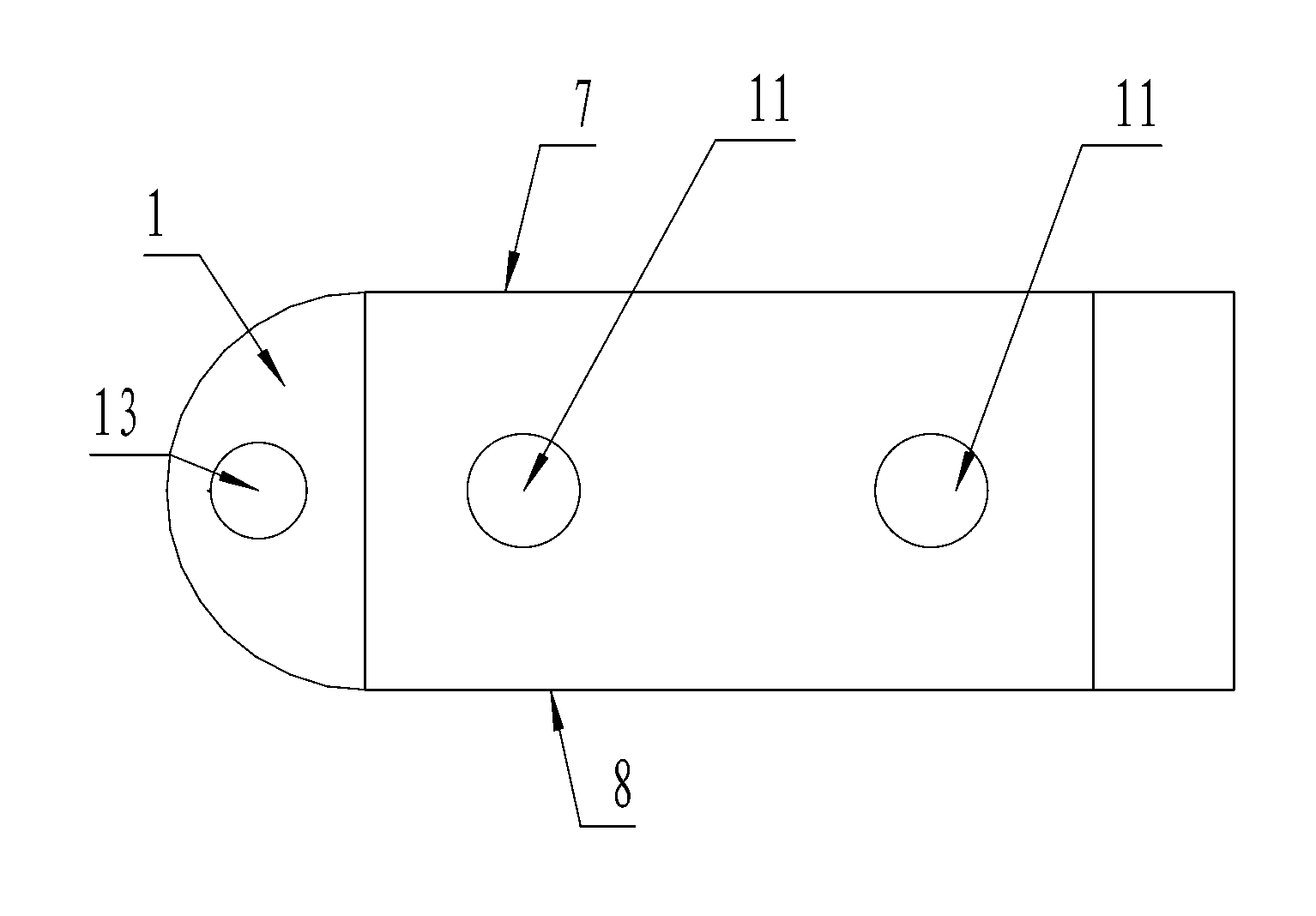

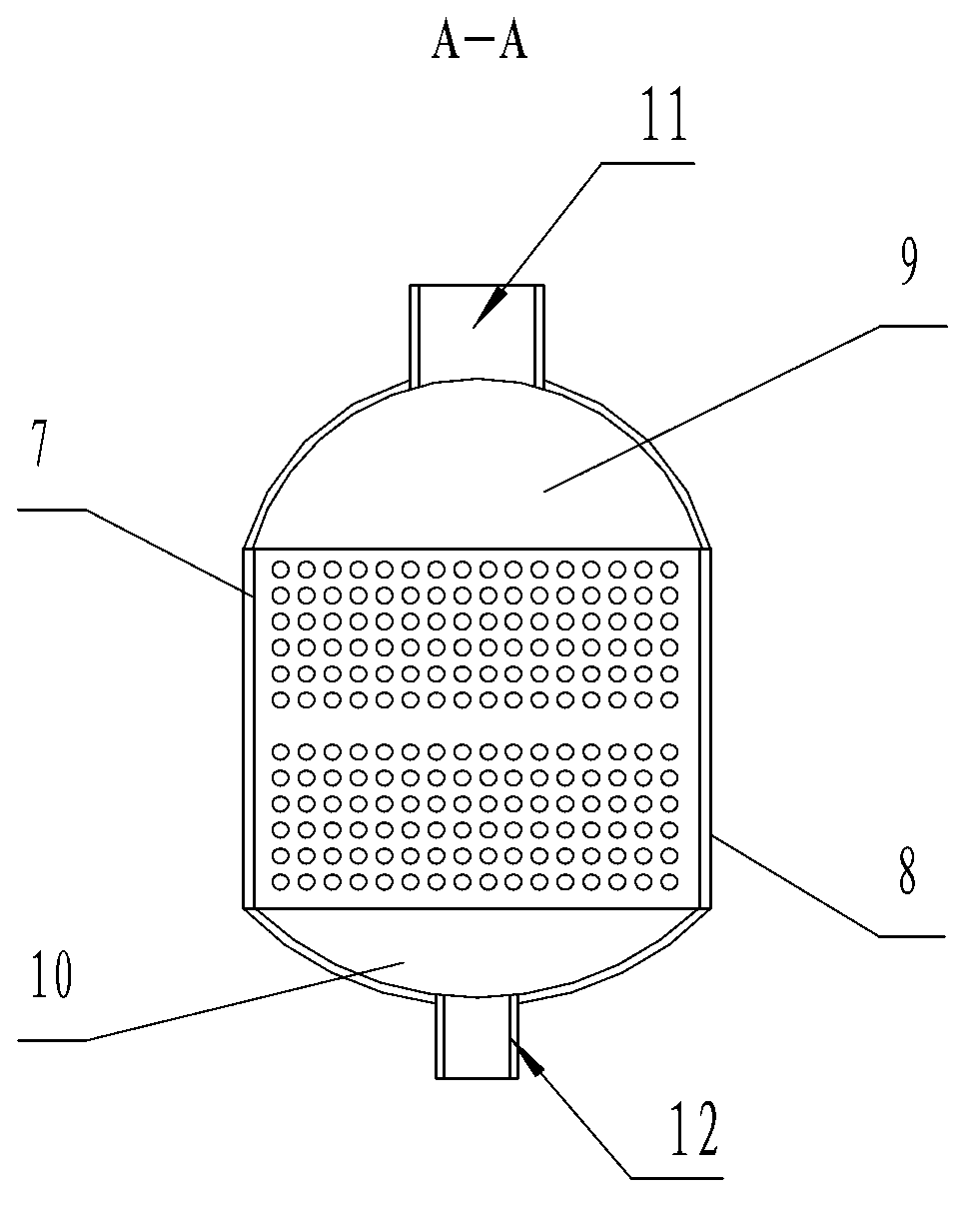

[0012] Embodiment 1, a rectangular all-welded U-shaped tube heating network heater, including a heat exchange tube bundle 2 composed of U-shaped heat exchange tubes 5 installed in the shell 3, and a secondary heat medium is installed at one end of the shell The pipe box 1 of the inlet and outlet is characterized in that: the heat exchange tube bundle is composed of a rectangular tube plate 4, a U-shaped heat exchange tube 5, and a rectangular support plate 6, and the U-shaped heat exchange tube passes through at least two rectangular support plates and then Pass through the rectangular tube plate and connect it with welded expansion joints; the side plate A7 and side plate B8 parallel to each other of the shell are welded above a semicircular steam inlet header 9 with a steam inlet 11, and a semicircular steam inlet 9 is welded below A cylindrical hydrophobic header 10 with a hydrophobic outlet 12, one end of which is welded to a rectangular tube plate is welded to a semi-cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com