PDM (positive displacement motor) drilling tool for well drilling

A screw drilling tool and drilling technology, which is applied to the drilling driving device, drilling equipment, earth-moving drilling and other directions in the wellbore, can solve the problems of weak corrosion resistance and abrasion resistance, short working life and high heat production, etc. Achieve the effect of strong bearing corrosion resistance and abrasion resistance, improving axial bearing capacity and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

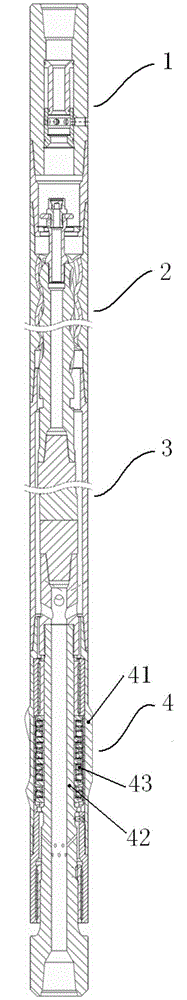

[0014] Such as figure 1 As shown, the screw drilling tool in this embodiment includes a bypass valve assembly 1, a motor assembly 2, a cardan shaft assembly 3 and a drive shaft assembly 4 connected in sequence, wherein the drive shaft assembly 4 includes a drive shaft The housing 41 , the hollow transmission shaft 42 , and the integral floating thrust bearing 43 connecting the transmission shaft 42 and the transmission shaft housing 41 .

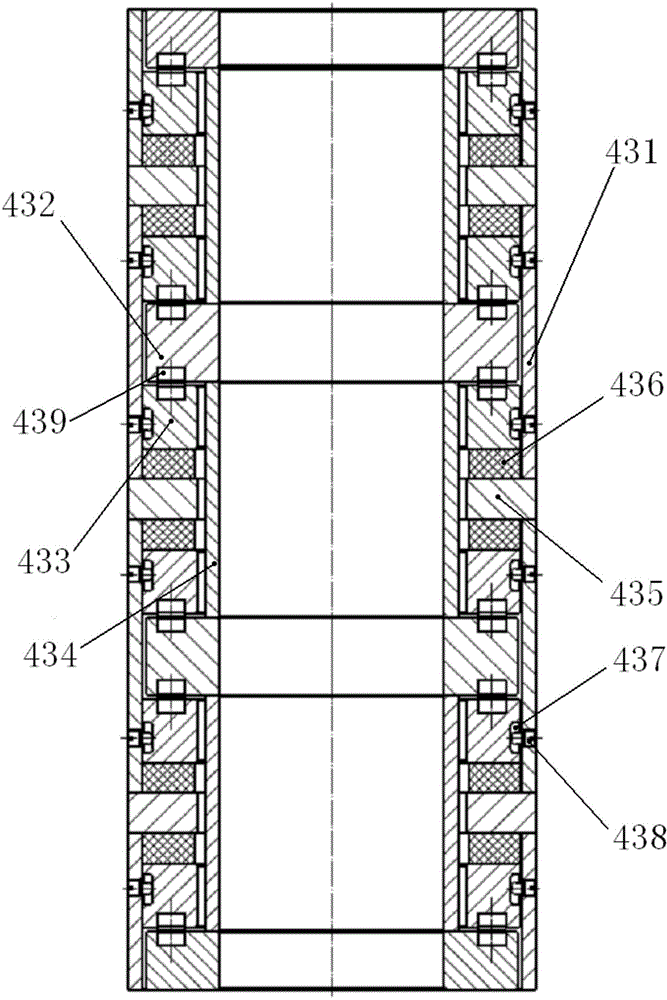

[0015] Such as figure 2 As shown, the integral floating thrust bearing 43 includes a cylindrical bearing housing 431 fastened to the inner wall of the transmission shaft housing 41, a plurality of moving bearing rings 432 located in the bearing housing 431, and a plurality of bearing rings 432 located in the bearing housing 41. The bearing static ring 433 in the housing 431. A shaft sleeve 434 is arranged between every two bearing moving rings 432, and the bearing moving rings 432 and the shaft sleeves 434 are all tightly sleeved on the t...

Embodiment 2

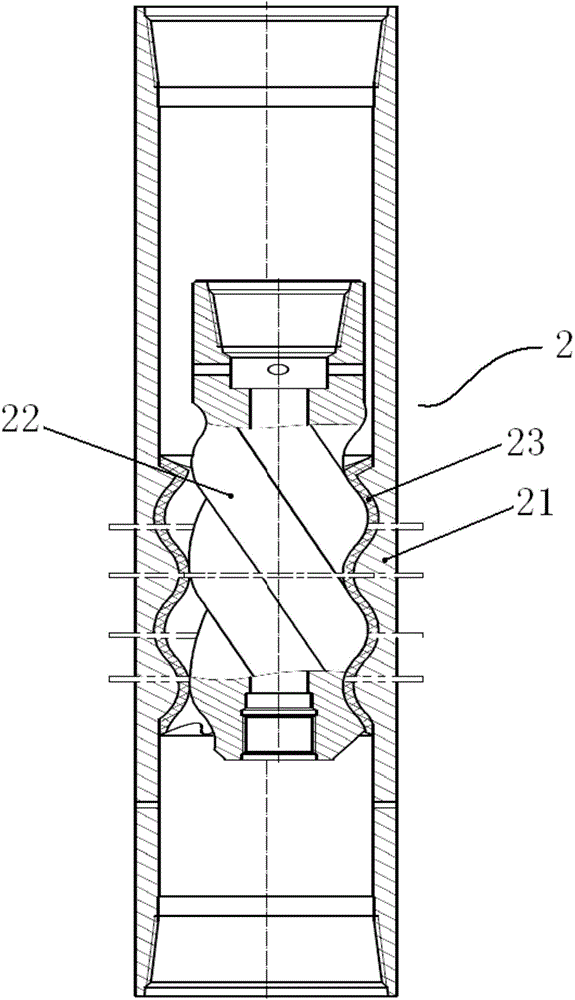

[0020] Such as image 3 As shown, in this embodiment, the motor assembly 2 of the screw drilling tool includes a stator 21, a rotor 22 and a rubber bush 23 vulcanized on the inner hole of the stator 21. The characteristic of this embodiment is that the inner hole surface of the rotor 21 It is a spiral curved surface, and the inner wall surface of the rubber bush 23 vulcanized on the inner hole of the stator is also a spiral curved surface, and the rubber bush 23 has a uniform thickness.

[0021] In this embodiment, the inner hole surface of the rotor 21 is set as a spiral curved surface, so that the rubber bushing 23 directly vulcanized on the inner hole surface can have a uniform thickness (in the prior art, the inner hole surface of the rotor is a round hole surface, and the vulcanization inside The thickness of the rubber bushing on the hole surface varies greatly), so that the additional deformation of the rubber bushing 23 under the working load is small, the heat generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com