Patents

Literature

120results about How to "Strong abrasion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Honeycomb flue gas denitrification catalyst and preparation method thereof

ActiveCN103143396AHigh mechanical strengthWear-resistantOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCellulosePtru catalyst

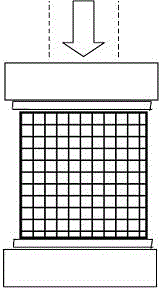

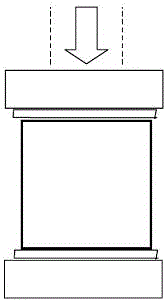

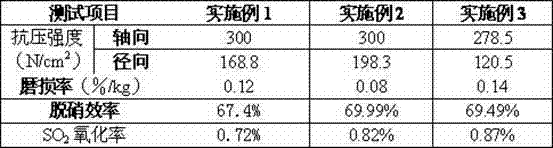

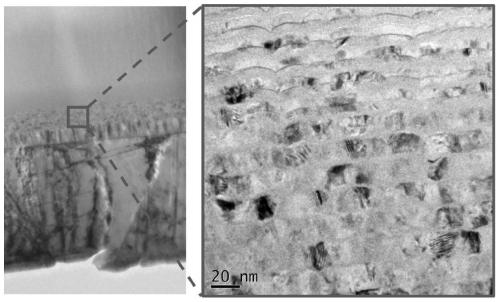

The invention relates to a honeycomb flue gas denitrification catalyst and a preparation method thereof, belonging to the technical field of inorganic new materials. The honeycomb flue gas denitrification catalyst is mainly prepared by carrying out extrusion molding and sintering on the following raw materials in parts by weight: 68-92.8 parts of nano TiO2, 3-10 parts of nano SiO2, 2-10 parts of glass fiber, 0.1-0.5 part of extrusion aid, 0.1-0.2 part of carboxymethyl cellulose, 0.1-0.3 part of polyoxyethylene and 0.1-0.2 part of sesbania powder. The preparation method comprises the following steps: (1) weighing the nano TiO2 and nano SiO2 powder, adding the extrusion aid, adding water while stirring to obtain paste, and adding ammonia water to regulate the pH value to 7-11; (2) adding the rest of raw materials, evenly mixing, and extruding with an extruding machine to obtain a honeycomb blank; (3) drying the blank at 30-70 DEG C under the relative humidity of 20-100% for 7-15 days; and (4) calcining the dried blank at 250-300 DEG C for 8-15 hours, calcining at 380-420 DEG C for 5-10 hours, and calcining at 580-620 DEG C for 8-12 hours to obtain the finished product.

Owner:河南康宁特环保科技股份有限公司

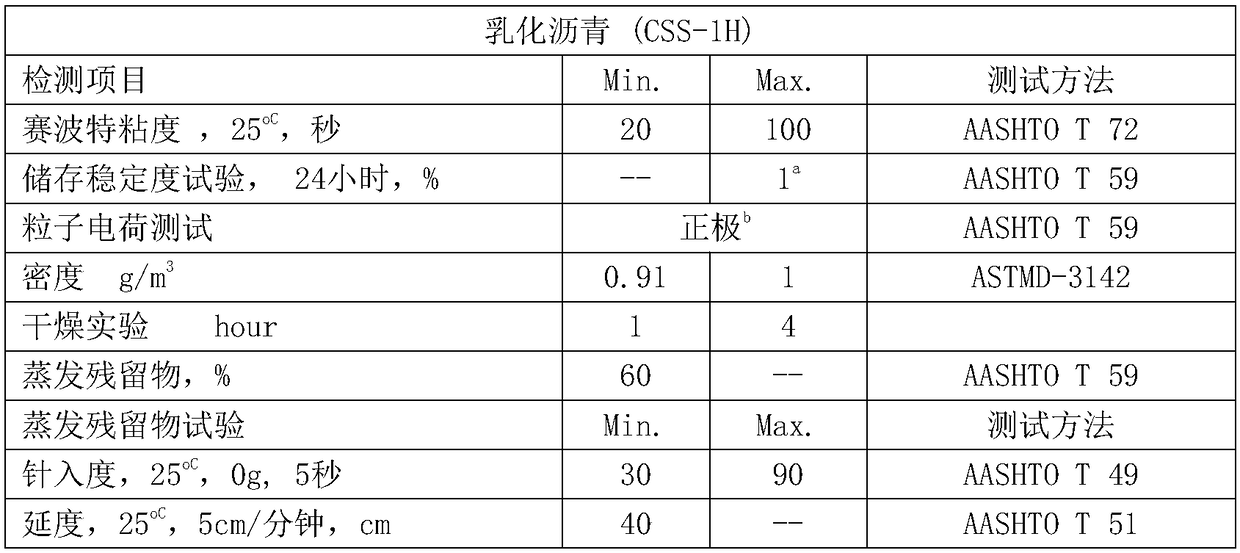

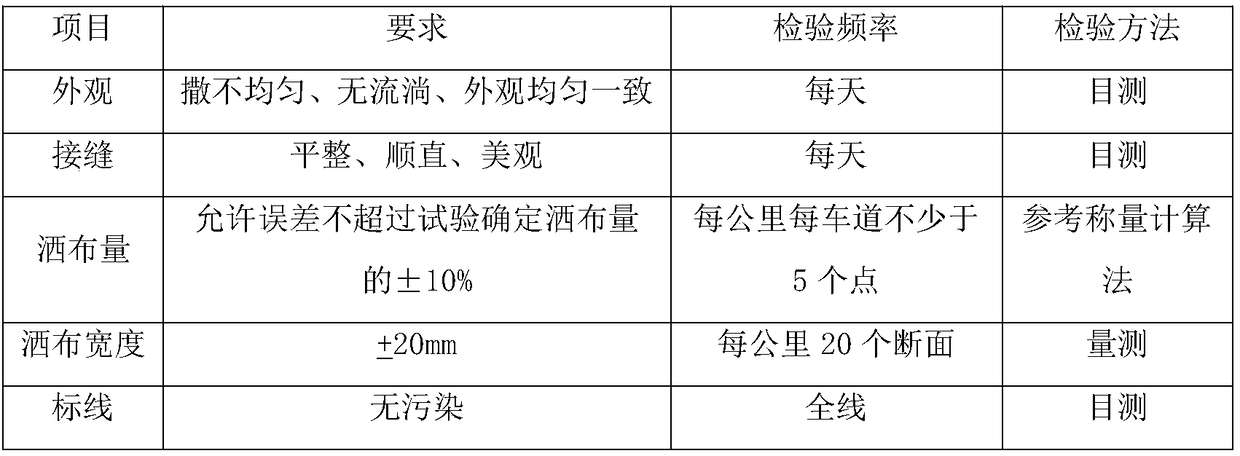

Anti-slide fog seal material and its construction method

ActiveCN102815892AImprove skid resistanceAvoid the problem of insufficient skid resistanceIn situ pavingsKaolin clayRoad surface

The invention relates to an anti-slide fog seal material and its construction method. The anti-slide fog seal material is obtained by the following steps of: mixing 15-30 parts by weight of composite kaolin, 35-70 parts by weight of water and 1.2-2.0 parts by weight of an asphalt emulsifier, adjusting the pH value into a range required by the corresponding asphalt emulsifier with a pH value conditioning agent, then emulsifying 25-40 parts by weight of hot melt asphalt so as to obtain a stable mixed emulsion, and finally mixing the emulsion with 50-80 parts by weight of sand and conducting stirring. When the anti-slide fog seal material is sprayed on a road surface uniformly by a spraying vehicle, it can bond well with the road surface. Thus, the material not only seals original road surface micro-cracks and voids, plays a strong waterproof role, but also prolongs the road service life. And the sand in the anti-slide fog seal material can substantially improve the anti-slide performance of the road surface.

Owner:GAOYUAN HIGHWAY MAINTENANCE TECH HENAN PROV

Honeycomb flue gas denitrification catalyst and preparation method thereof

ActiveCN103143396BHigh mechanical strengthWear-resistantOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCellulosePtru catalyst

The invention relates to a honeycomb flue gas denitrification catalyst and a preparation method thereof, belonging to the technical field of inorganic new materials. The honeycomb flue gas denitrification catalyst is mainly prepared by carrying out extrusion molding and sintering on the following raw materials in parts by weight: 68-92.8 parts of nano TiO2, 3-10 parts of nano SiO2, 2-10 parts of glass fiber, 0.1-0.5 part of extrusion aid, 0.1-0.2 part of carboxymethyl cellulose, 0.1-0.3 part of polyoxyethylene and 0.1-0.2 part of sesbania powder. The preparation method comprises the following steps: (1) weighing the nano TiO2 and nano SiO2 powder, adding the extrusion aid, adding water while stirring to obtain paste, and adding ammonia water to regulate the pH value to 7-11; (2) adding the rest of raw materials, evenly mixing, and extruding with an extruding machine to obtain a honeycomb blank; (3) drying the blank at 30-70 DEG C under the relative humidity of 20-100% for 7-15 days; and (4) calcining the dried blank at 250-300 DEG C for 8-15 hours, calcining at 380-420 DEG C for 5-10 hours, and calcining at 580-620 DEG C for 8-12 hours to obtain the finished product.

Owner:河南康宁特环保科技股份有限公司

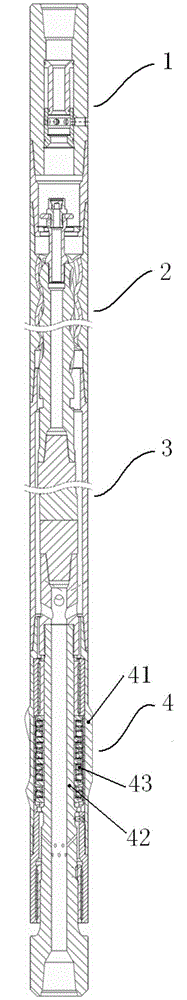

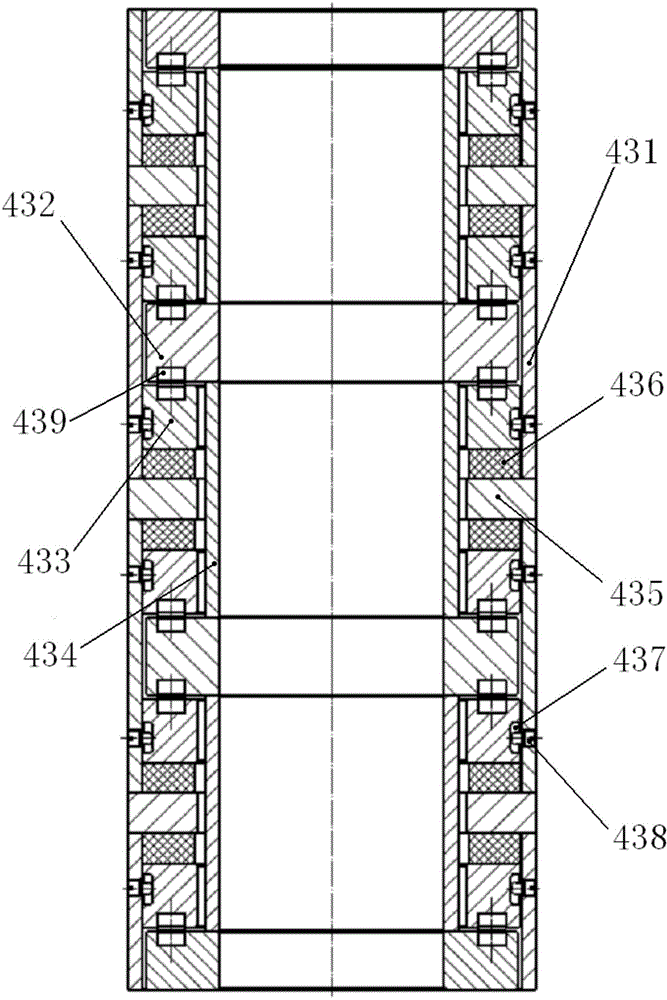

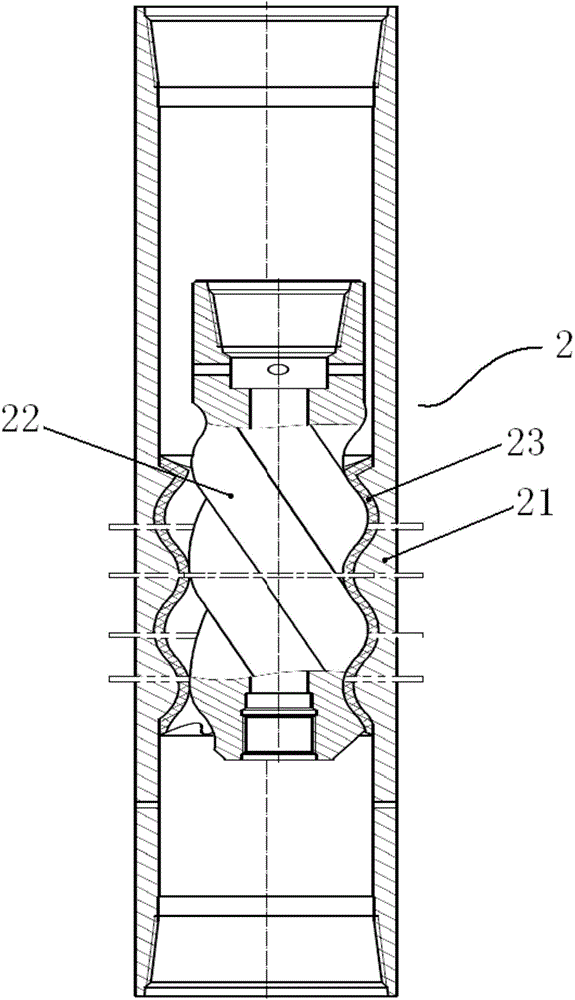

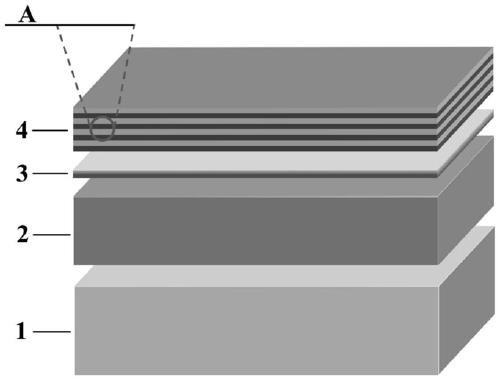

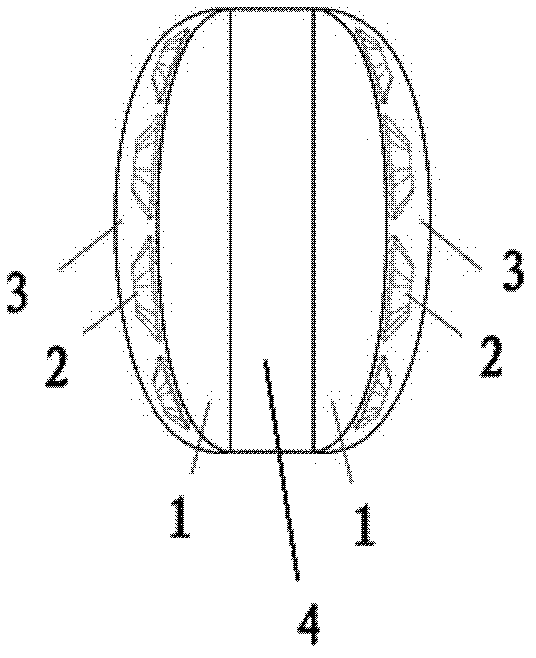

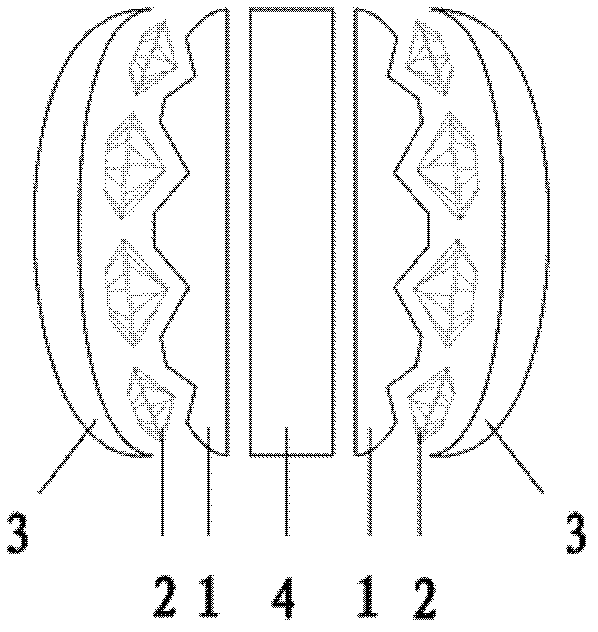

PDM (positive displacement motor) drilling tool for well drilling

InactiveCN104675324AImprove axial load capacityHighly corrosiveMagnetic circuit stationary partsBearing componentsDrive shaftWell drilling

The invention relates to a PDM (positive displacement motor) drilling tool for well drilling, comprising a bypass valve assembly, a motor assembly, a universal shaft assembly and a driving shaft assembly, wherein the driving shaft assembly comprises a driving shaft shell, a driving shaft and a whole floating type thrust bearing; the whole floating type thrust bearing comprises a bearing shell, a plurality of bearing moving rings and a plurality of bearing static rings; a shaft sleeve is arranged between every two bearing moving rings; the bearing moving rings and the bearing static rings are all fastened and sleeve the driving shaft; two bearing static rings sleeve each shaft sleeve at intervals; an annular flange is formed on the inner wall of the bearing shell positioned between every two bearing static rings; a shock-absorption energy storage body is respectively arranged between the annular flange and every two bearing static rings; a plurality of long slots are formed in the lateral wall of each bearing static ring along the axial direction of the bearing shell; a bolt is connected with the position, corresponding to each long slot, of the bearing shell; the end part of each bolt extends into the corresponding long slot; each bearing static ring is matched with the corresponding bearing moving ring through two diamond compacts; one diamond compact is arranged on the corresponding bearing static ring; the other diamond compact is arranged on the corresponding bearing moving ring.

Owner:CHINA NAT OFFSHORE OIL CORP +1

High-hardness and high-toughness metal ceramic composition and preparation method thereof

The invention provides a high-hardness and high-toughness metal ceramic composition and a preparation method thereof. The high-hardness and high-toughness metal ceramic composition comprises the following raw material components in percentage by weight: 40-70 percent of titanium carbide, 10-30 percent of tungsten carbide, 1-5 percent of tantalous carbide, 3-5 percent of chromium carbide, 10-20 percent of nickel and 5-10 percent of molybdenum. The preparation method of the high-hardness and high-toughness metal ceramic composition comprises the following steps of: 1, providing raw materials; 2, performing ball milling and stirring on each raw material component to obtain powder particles; 3, molding under a high pressure; 4, removing an adhesive and degreasing; and 5, sintering in vacuum at a high temperature. The high-hardness and high-toughness metal ceramic composition is prepared by adopting titanium carbide, tungsten carbide, tantalous carbide, chromium carbide, nickel and molybdenum, has high hardness, high toughness and high corrosion resistance, and is prevented from being broken and scratched.

Owner:邓湘凌

Abrasion-resistant composite protective coating for hard sealing surface of ball valve and preparation method of abrasion-resistant composite protective coating

ActiveCN111218638AReduce coefficient of frictionReduce internal stressMolten spray coatingVacuum evaporation coatingSurface engineeringInternal stress

The invention provides an abrasion-resistant composite protective coating for a hard sealing surface of a ball valve and a preparation method of the abrasion-resistant composite protective coating, and belongs to the field of surface engineering. The invention provides the abrasion-resistant composite protective coating for the hard sealing surface of the ball valve, a Cr3C2-NiCr coating, a Cr->Cr / C / WC dual-mode transition layer and a WC / a-C nano multilayer film are sequentially prepared on the surface of a metal matrix. According to the abrasion-resistant composite protective coating, the abrasion-resistant composite protective coating has a lower friction coefficient, ultralow internal stress, high bearing capacity and excellent abrasion resistance, is suitable for being used as an abrasion-resistant protective material for the hard sealing surface of the ball valve, and can remarkably improve the abrasion resistance and prolong the service life, so that the purposes of reducing thecost and improving the safety and reliability are achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

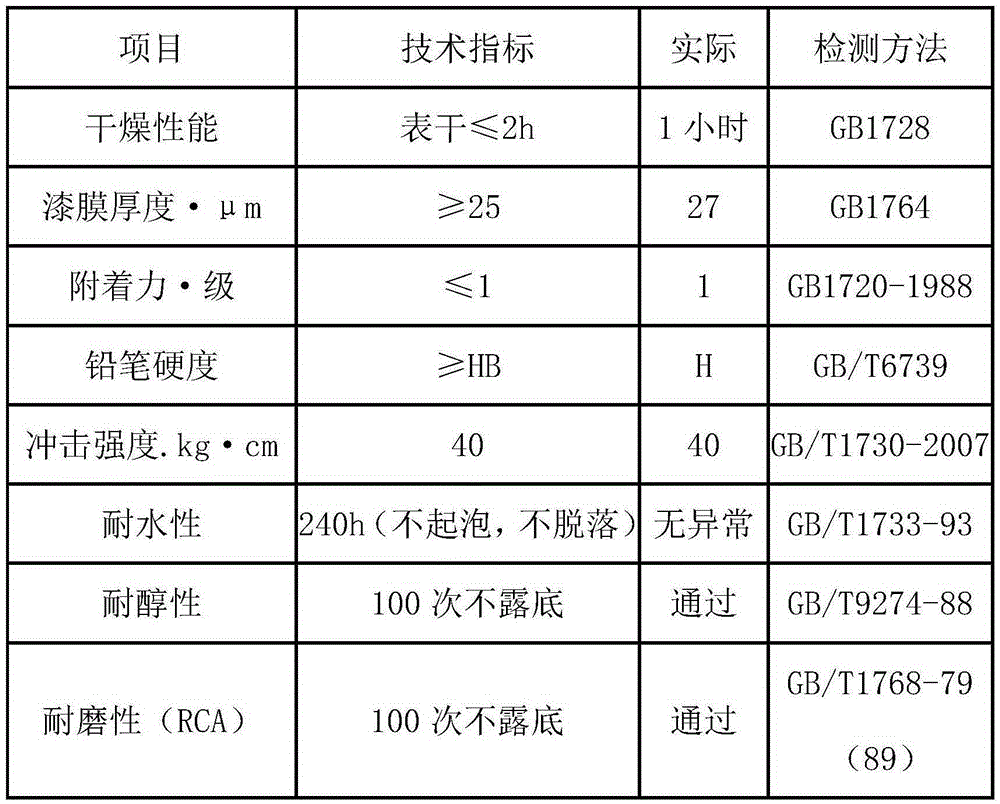

Good wear resistance and alcohol resistance acrylic resin for aqueous plastic cement

The present invention relates to the technical field of resin coatings, and in particular relates to good wear resistance and alcohol resistance acrylic resin for aqueous plastic cement, by reaction of epoxy groups of epoxy organosiloxane and carboxyl groups of an acrylic resin molecular chain, organosiloxane chain segments are introduced into the aqueous acrylic resin system, the organosiloxane chain segments have strong hydrophobicity, wear resistance and solvent resistance, and can wind the acrylic resin main chain to form a film, and a hydrophobic layer is formed between air and the film, acrylic monomers with excellent alcohol resistance and solvent resistance and polyol monomers are copolymerized into the aqueous acrylic resin chain segments for synthesis of the excellent water resistance, stain resistance, weather resistance, smoothness and wear resistance acrylic resin for the aqueous plastic cement.

Owner:王瑞莲

Rare earth chromium composite electroplating layer and preparing method and use thereof

InactiveCN1488783AStrong abrasion resistanceHigh hardnessElectrolytic coatingsIntermediate stageChromium

The present invention relates to a rare earth chrome composite electroplated coat, its preparation method and application. Said electroplated coat is formed from mixed rare earth chrome base phase and mixed rare earth sulfate and carbonate second phase. Said electroplating procedure includes electroplating earlier stage, middle stage and later stage, and said invention also provides its electroplating operation steps and time of every stage, and provides the composition of the electroplating solution. Said electroplated coat can be used as wear-resisting and corrosion-proofing coating of hydraulic turbine.

Owner:王飚

Preparation method of ceramic mould plate

InactiveCN102372494ASimple methodEasy to demouldCeramic shaping apparatusCeramicwareConstruction aggregateVacuum coating

The invention discloses a preparation method of a ceramic mould plate. The method is characterized by comprising the following steps: a) mixing the following raw materials by weight percent: 45-80% of ceramic aggregate, 0.5-15% of additive and 10-40% of pore forming agent to obtain mixed raw materials; b) firing the mixed raw materials at 1200-1300 DEG C, performing high temperature heat preservation for 0.5-2.5 hours; c) adopting a moulding method to mould and prepare a ceramic mould plate main body; and d) adopting the vacuum coating procedure to arrange a special diamond film on the inside of the ceramic mould plate main body. The preparation method of the ceramic mould plate, provided by the invention is simple; the demoulding of the prepared ceramic mould plate is easy to use, the mould plate has fewer burrs, high abrasion resistance, long service life and good moulding quality, is particularly suitable for the preparation of the ceramic tile mould; and the prepare ceramic tiles can be mirror ceramic tiles or ceramic tiles with relief patterns.

Owner:SUZHOU KABUL MOLD TECH

High-strength and high-toughness ceramic material

InactiveCN106747332AImprove bending strengthImprove fracture toughnessCeramic materials productionClaywaresTemperature resistanceThermal shock

The invention provides a high-strength and high-toughness ceramic material, which is prepared from the following raw materials: zirconite, kaoline, a fibrous material, silicon carbide, titanium dioxide, a composite admixture, aluminum nitride, calcium carbonate, a toughening agent, a foam stabilizer, acetate and a cosolvent. The high-strength and high-toughness ceramic material provided by the invention has good bending strength, fracture toughness and impact resistance, and is excellent in thermal stability and corrosion resistance; the high-strength and high-toughness ceramic material also has excellent high temperature resistance and thermal shock resistance, so that alumina titanate ceramics can be used in practical applications; therefore, the high-strength and high-toughness ceramic material can be widely applied to industrial production.

Owner:ANHUI RUIYAN NEW MATERIAL TECH RES INST

Preparation method for metal ceramic composite

A preparation method for a metal ceramic composite comprises the steps of preparation of aluminium oxide ceramic microencapsulated powder, preparation of ceramic particles, preparation of metal ceramic particles and preparation of the metal ceramic composite. The prepared metal ceramic composite is of a structure composed of a ceramic layer, a metal ceramic composite transition layer and a metal layer from inside to outside, an even and compact product with the smooth surface is formed at a high temperature, the composite with the high hardness of ceramics and high toughness and plasticity of metal is formed, and the metal ceramic composite not only has good corrosion resistance and high temperature resistance of the ceramics, but also has the toughness and impact resistance of the metal, and has the characteristics of long service life and low mass.

Owner:洛阳鹏飞耐磨材料股份有限公司

Plastic melting mosaic product and plastic melting mosaic method

The invention relates to a plastic melting mosaic product. The plastic melting mosaic product comprises an inner layer which is fixed on such a matrix as a cutter, a notebook computer, a stud earring, a switch control panel, a card case, a digital picture frame, an automobile central control air outlet or a bowl or integrated with the matrix to be as the bottom mold, an outer layer injected on the inner layer by using transparent plastic material and an insert such as a diamond, a crystal or a synthetic stone, wherein the insert is encapsulated between the inner layer and the outer layer through the plastic injection, and the inner layer and the outer layer form an integer due to plastic injection so that the matrix and the insert are connected with the inner and the outer layers. The invention further relates to a method for producing the plastic melting mosaic product. According to the plastic melting mosaic product and the plastic melting mosaic method, the impact bearing capacity of the insert is improved through the plastic injection of the insert, the insert of the product is ensured not to fall off during use, the firmness is enhanced, dust and stains are difficultly adhered, the maintenance is easy, and the permeability and glossiness of the insert can be kept for long time.

Owner:傅其峰

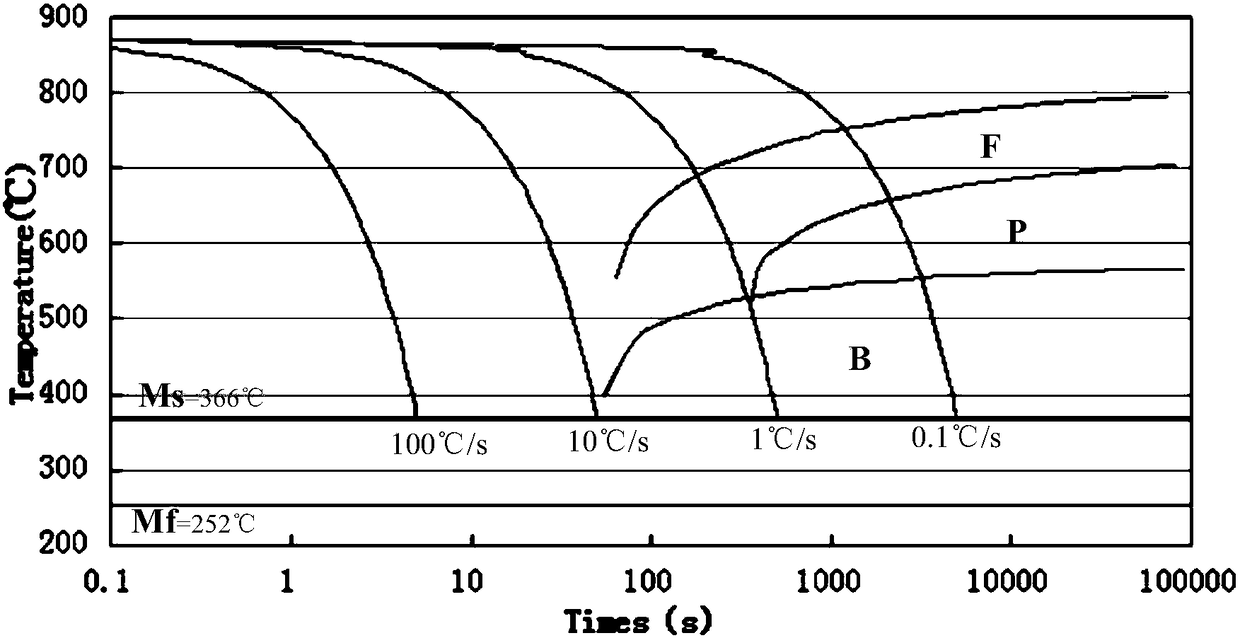

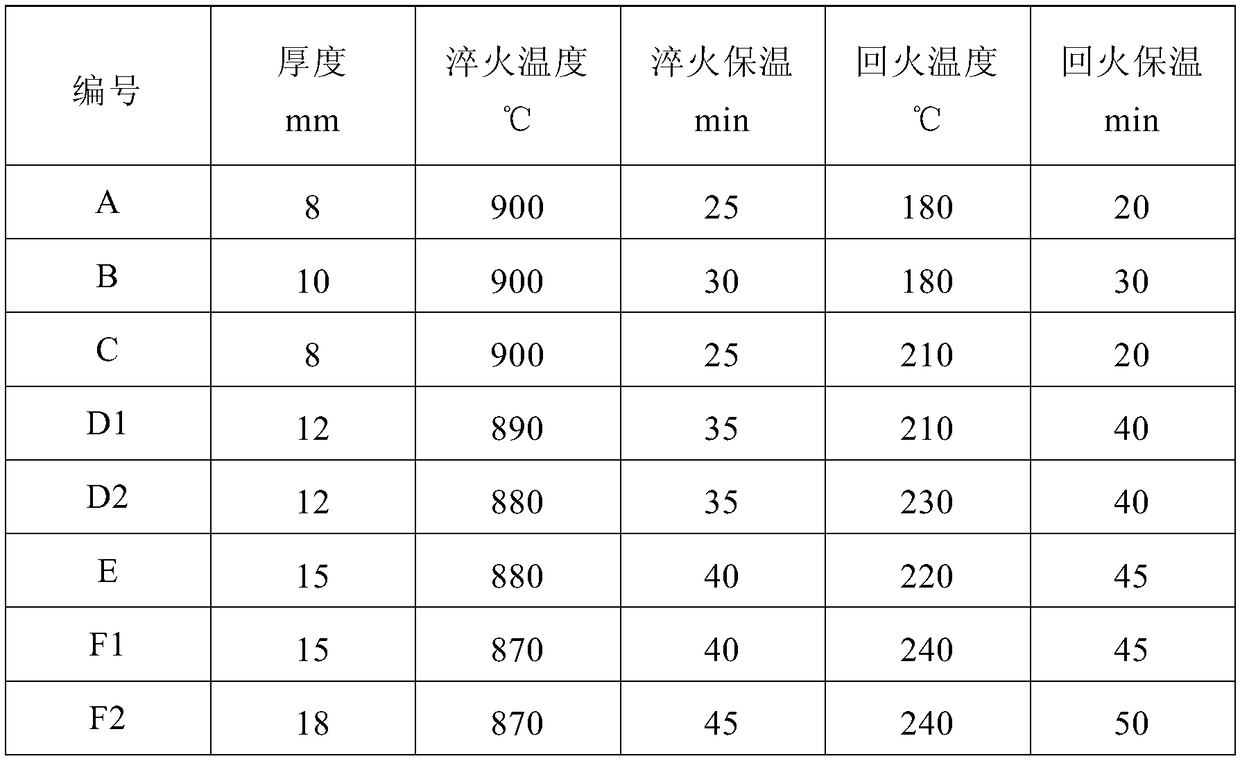

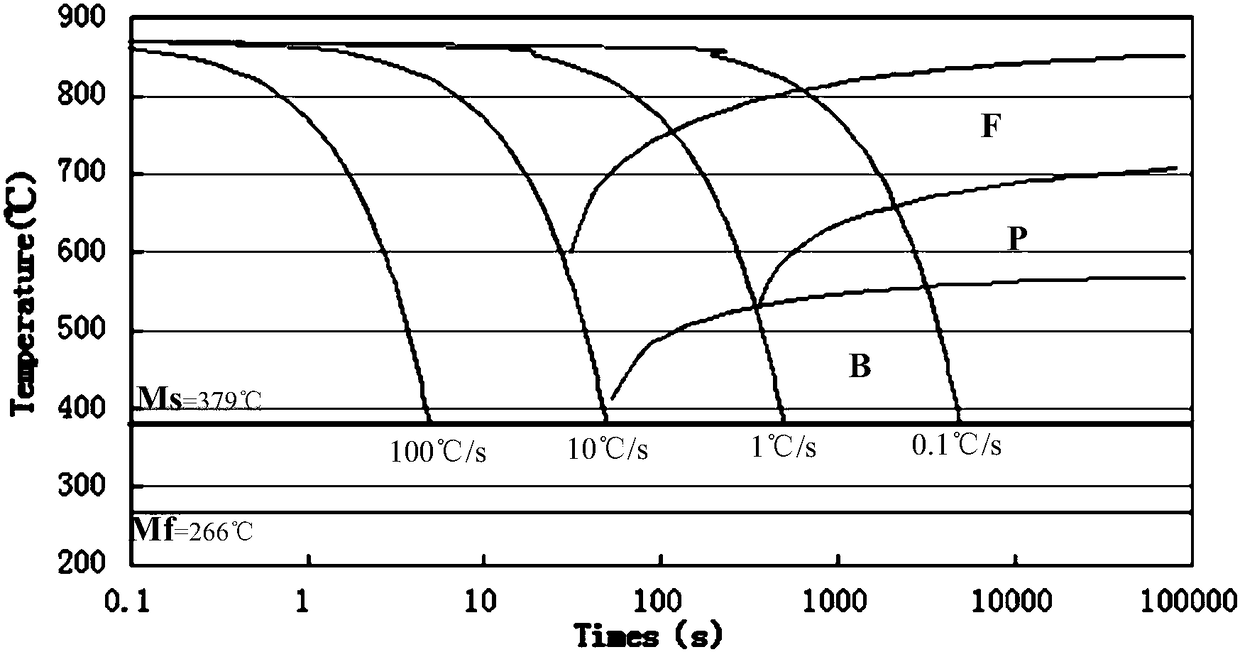

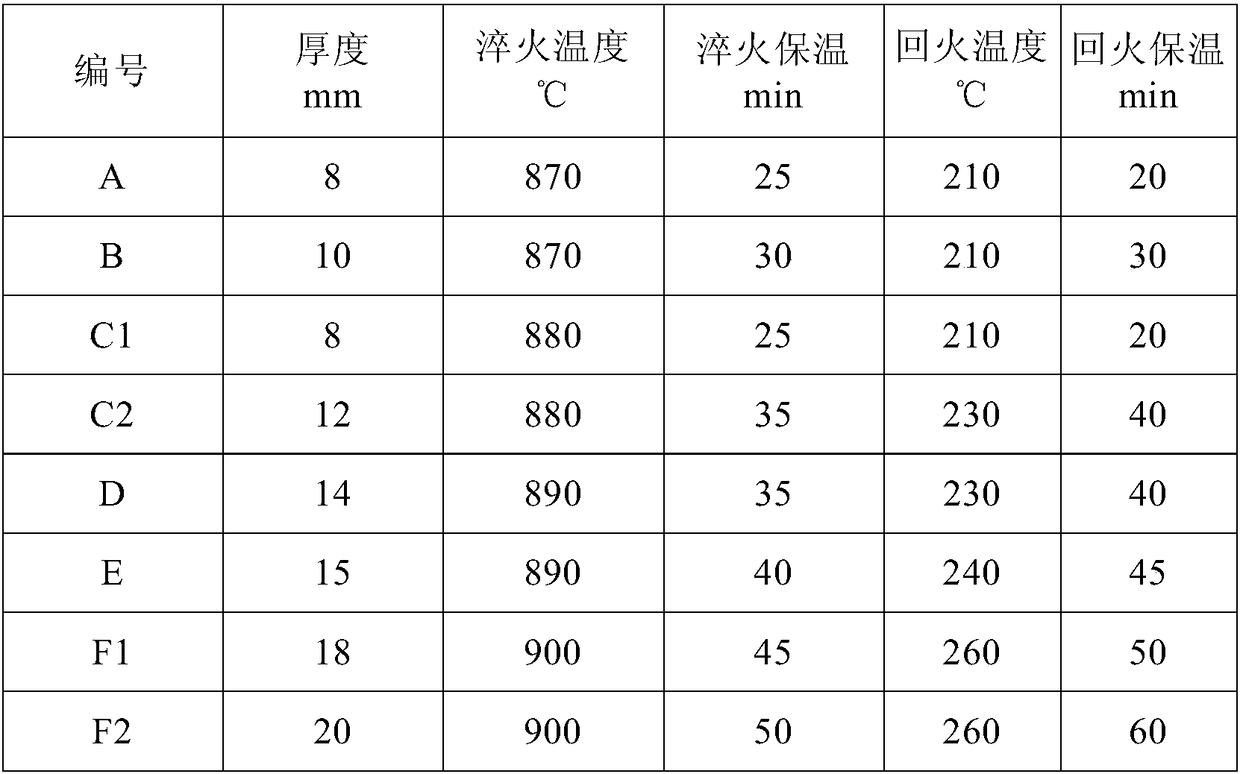

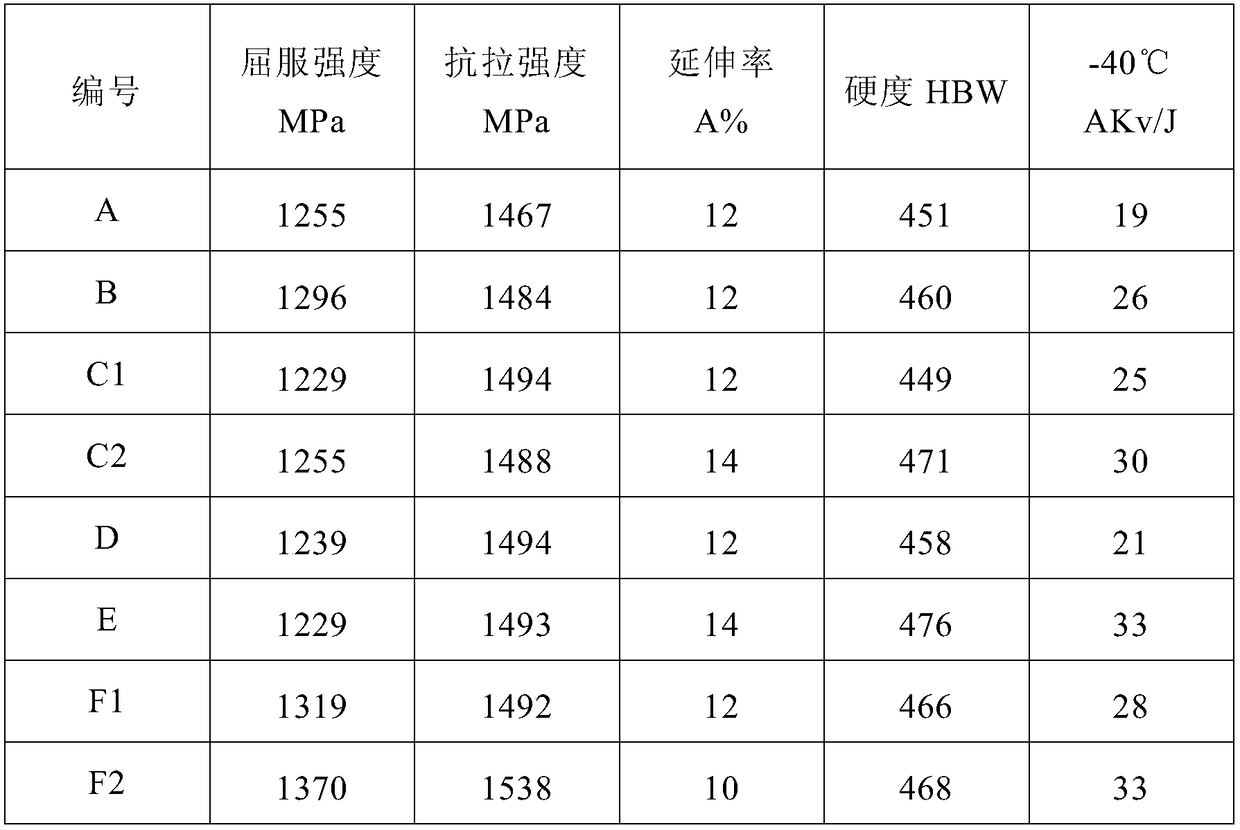

Wear-resistant corrosion-resistant steel plate with hardness of 500 HB and for slurry dredging, and production method thereof

The invention provides a wear-resistant corrosion-resistant steel plate with hardness of 500 HB and for slurry dredging, and a production method thereof. The steel plate comprises, by weight, 0.25 to0.28% of C, no more than 0.01% of Si, 1.3 to 1.6% of Mn, no more than 0.015% of P, no more than 0.005% of S, 0.2 to 1.0% of Al, 0.3 to 1.2% of Cr, 0.001 to 0.002% of B, no more than 0.005% of N, and one or more selected from a group consisting of 0.01 to 0.03% of Nb and 0.01 to 0.025% of Ti, with the balance being Fe and unavoidable impurity elements, wherein the sum of Nb and Ti is more than 6.65N and no more than 0.045. The wear-resistant corrosion-resistant steel plate has yield strength of 1200 MPa or more, tensile strength of more than 1500 MPa, elongation of no less than 8%, hardness of500+ / -30 HBW, and the impact energy value at -40 DEG C of more than 20 J. The composition design of the wear-resistant corrosion-resistant steel plate allows the steel plate to have both corrosion resistance and wear resistance; and the steel plate is mainly applied to manufacturing of dredging pipelines applied to reclamation of land from water, navigation channel dredging and other fields and has wear and corrosion resistance 2.5 times higher than the wear and corrosion resistance of conventional common pipes, so dredging efficiency is greatly improved and operation cost is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

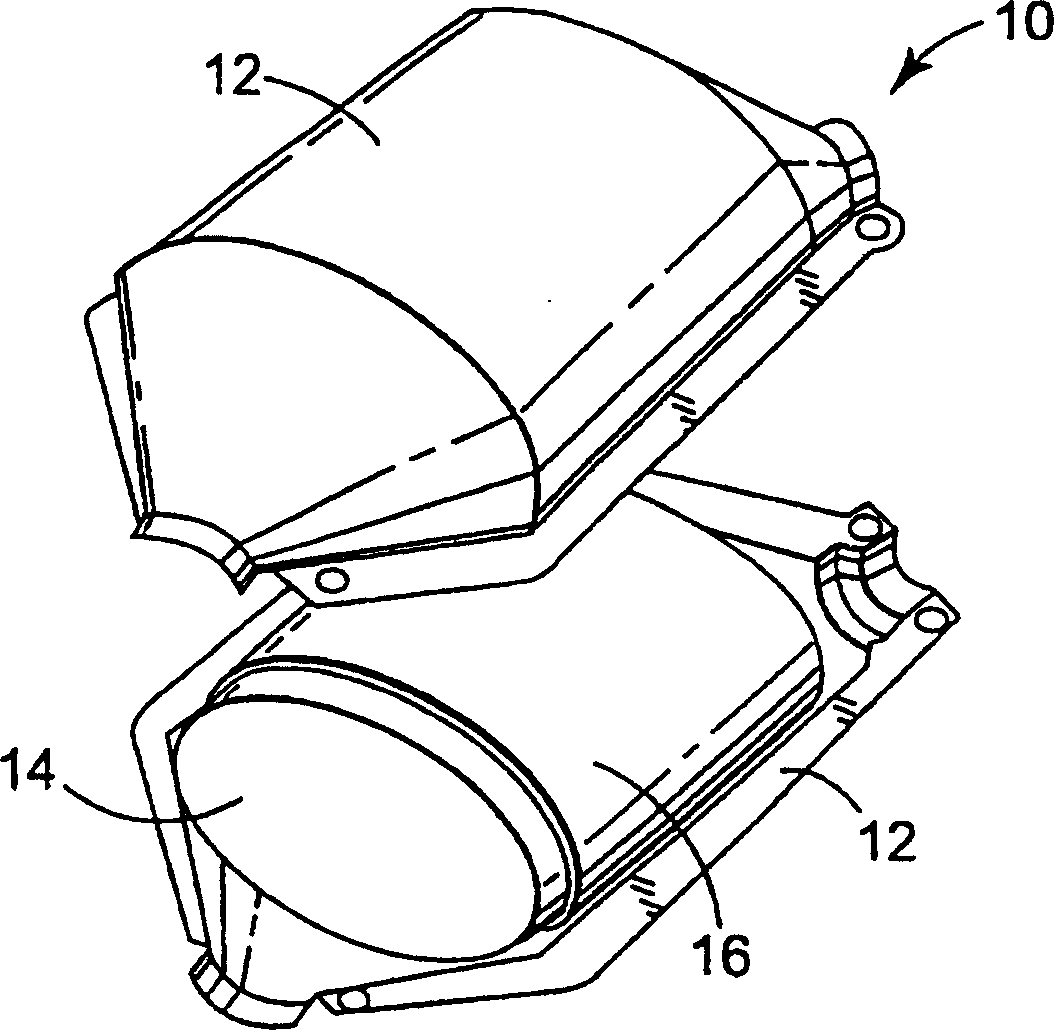

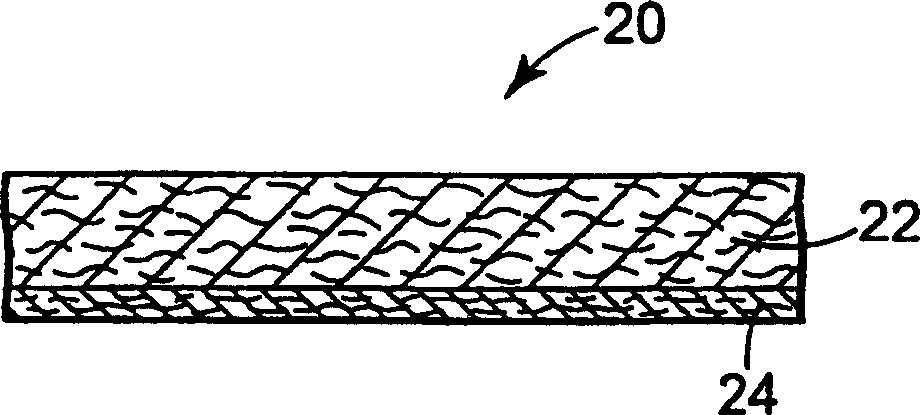

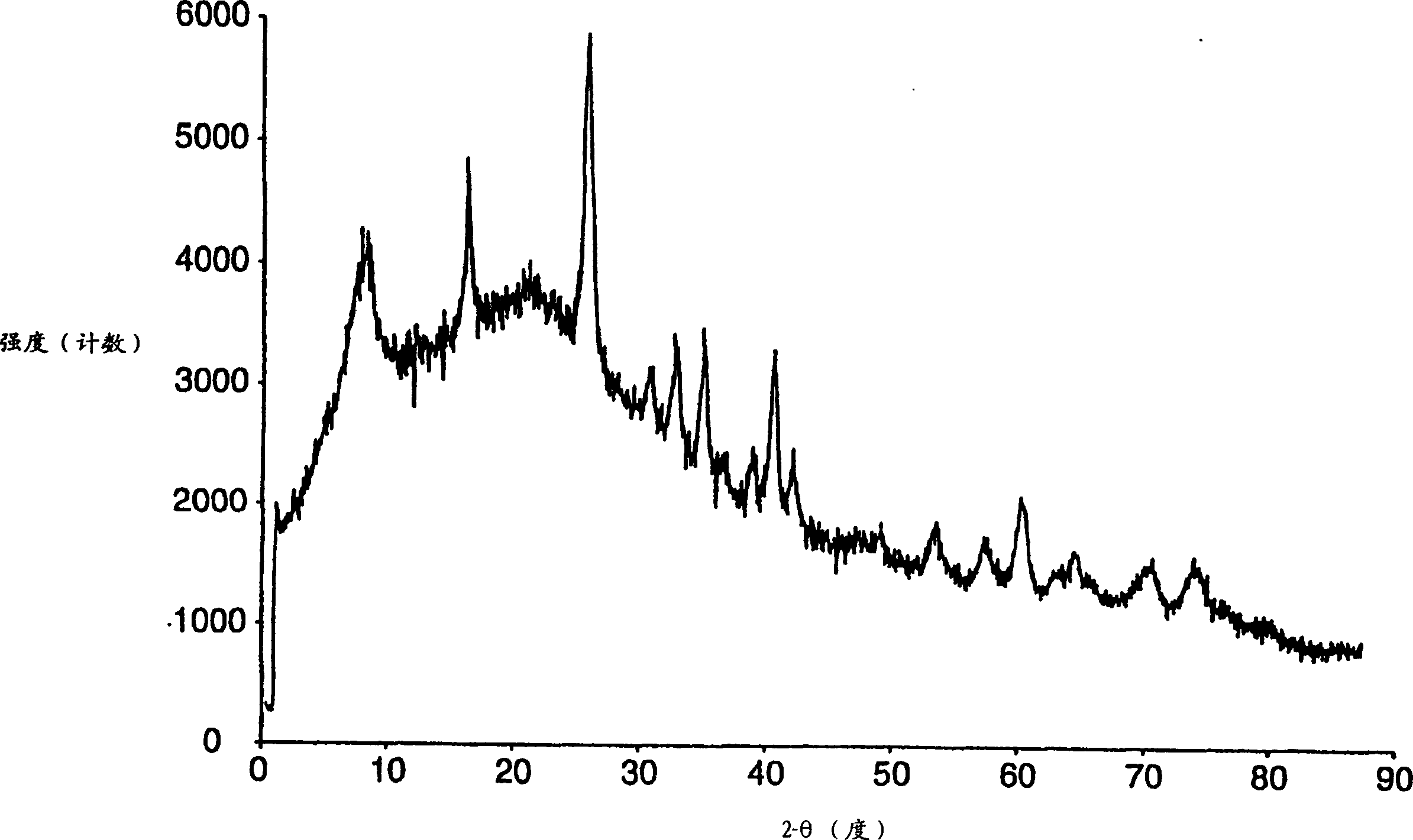

High temperature mat for a polltion control device

InactiveCN1128923CStrong abrasion resistanceInorganic fibres/flakesCatalyst protectionFiberMetallurgy

Owner:3M INNOVATIVE PROPERTIES CO

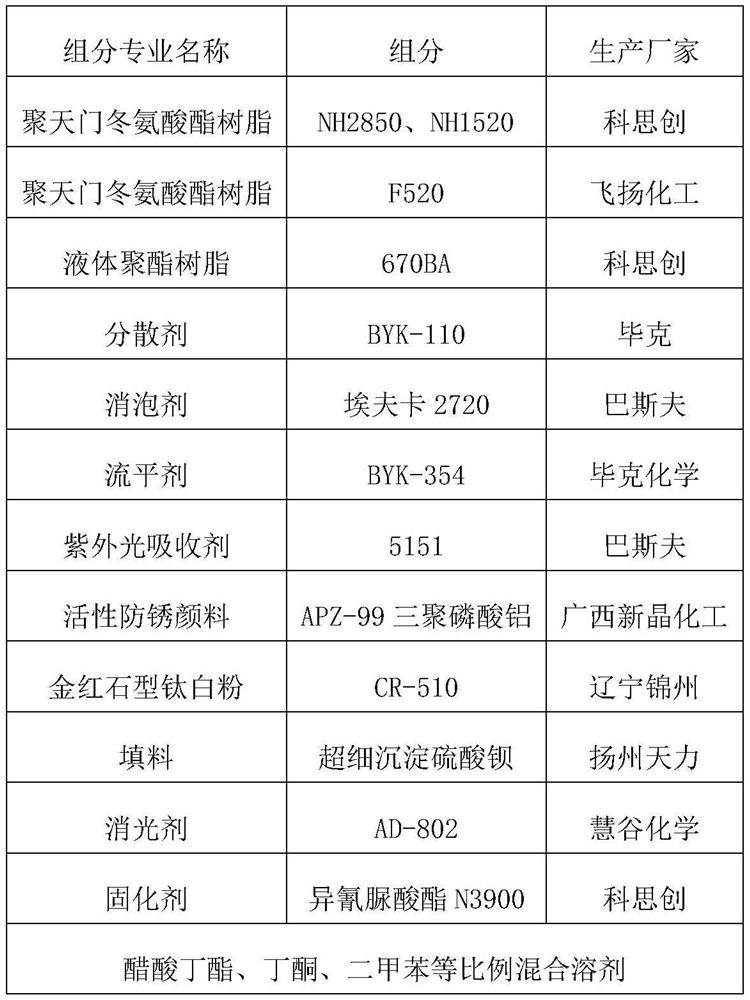

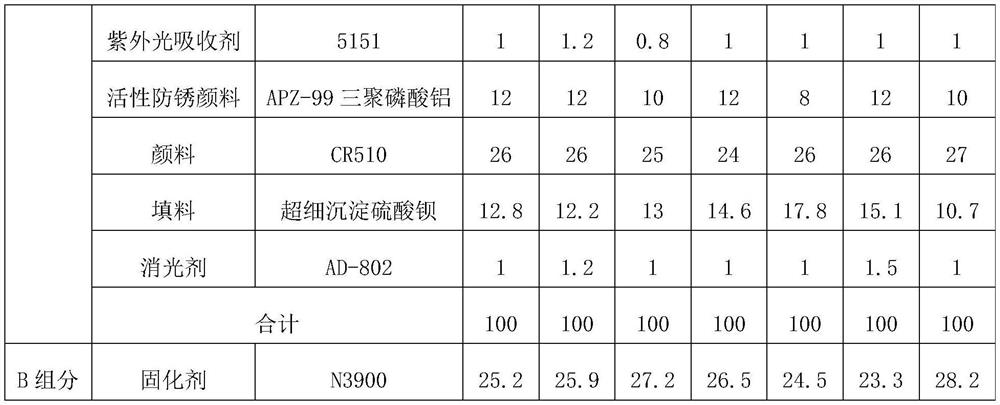

High-solid-content and low-viscosity polyaspartic acid ester primer-topcoat coating suitable for high-pressure airless spraying and preparation method thereof

ActiveCN112210279ANormal levelingImprove general performanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer sciencePolyaspartic acid

The invention relates to a high-solid-content and low-viscosity polyaspartic acid ester primer-topcoat coating suitable for high-pressure airless spraying and a preparation method thereof. The high-solid-content low-viscosity polyaspartic acid ester primer-topcoat coating comprises the following components in percentage by mass: 30-40% of polyaspartic acid ester resin; 10%-20% of polyester resin;0.3%-1.5% of a dispersing agent; 0.3%-1.0% of a defoaming agent; 1%-3% of a dehydrating agent; 0.3%-0.8% of a leveling agent; 0.4%-1.5% of an anti-sagging agent; 1%-3.0% of an ultraviolet absorber; 34%-45% of pigment; 10%-25% of a filler; 6%-10% of a solvent; 20%-29% of curing agent. Conventional high-pressure airless spraying equipment can be adopted for construction, it is guaranteed that the mixed paint can be normally constructed after 30 min at the environment temperature of 30 DEG C, the surface of a paint film is leveled normally, the defects of pinholes, shrinkage cavities, bubbles andthe like are avoided, the weather resistance, gloss retention, color retention and weather resistance are excellent, the solid content is high, and the requirements of environment-friendly paint aremet; the one-time film forming thickness can reach 150-350mu m, the surface drying and hard drying time is fast, and the working life is long.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD +1

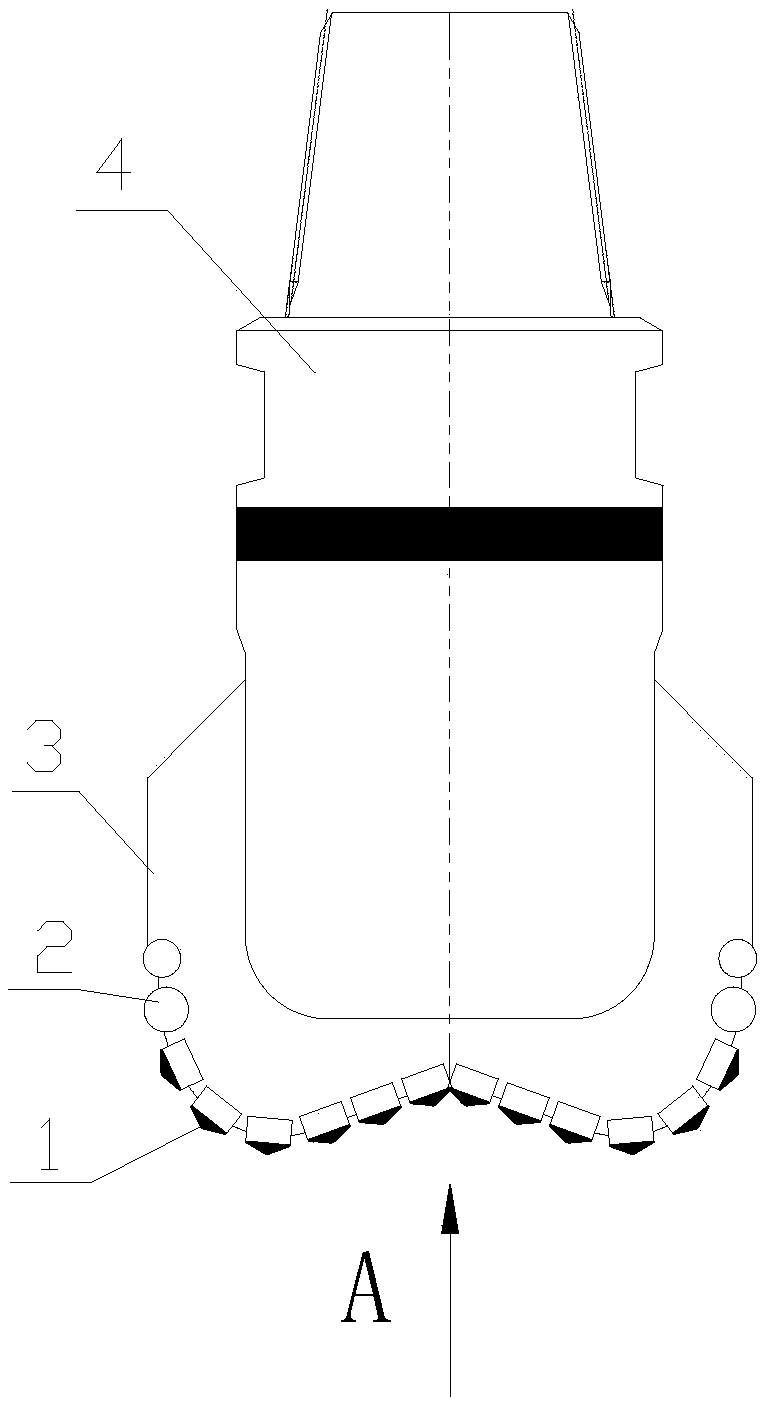

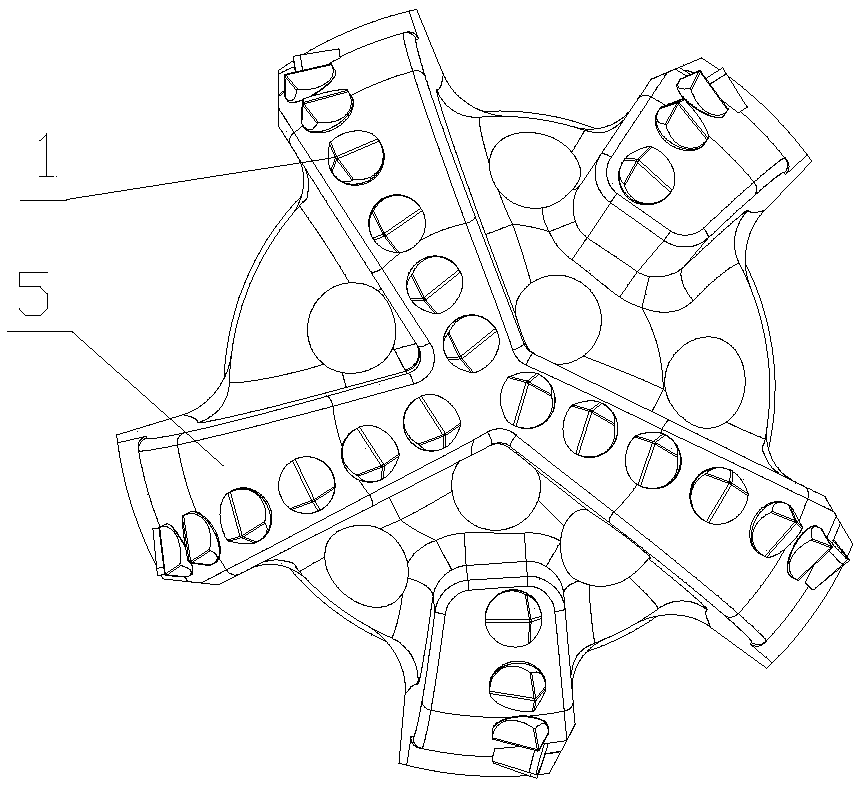

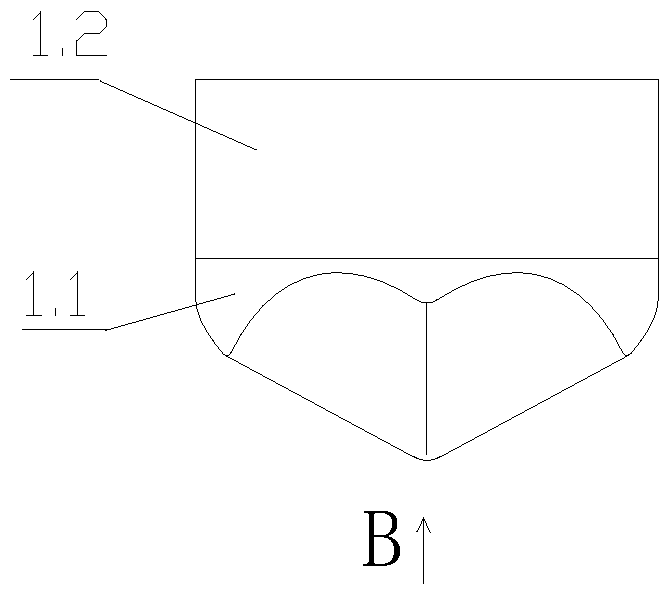

Special tooth PDC drill bit

PendingCN109630025AStrong anti-abrasion performanceExtended bit lifeConstructionsDrill bitImpact resistance

The invention provides a special tooth PDC drill bit, belongs to rotary drilling drill bits for petroleum and geology, and particularly relates to a drill bit of a special tooth special structure. Thespecial tooth PDC drill bit comprises a drill bit body and a connector. The drill bit body is composed of multiple knife wings and a gage. PDC special teeth are further brazed on the knife wings, diamond layers are arranged on base bodies of the PDC special teeth, and the diamond layers are vertical to respective normal directions. The diamond layers are provided with front bulging ridges, rear bulging ridges and sharp corners. The special tooth PDC drill bit has the advantages that the diamond layers of the PDC special teeth are vertical to the respective normal directions, all the diamond layers can participate in cutting, the drill bit has higher grinding resistance, and the service life of the drill bit is prolonged. The force bearing mode of the diamond layers is changed, the axial impact resistance of the drill bit can be improved in multiples, and the possibility that the drill bit is damaged by bit bouncing and percussion drilling is reduced.

Owner:四川川石金刚石钻头有限公司

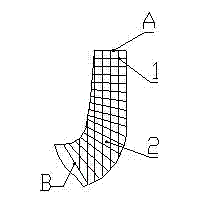

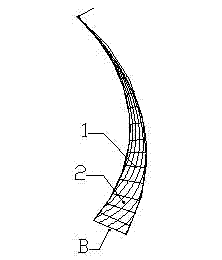

Abrasion-resistant heat shock resistant impeller type fluid mechanical blade and preparation method

InactiveCN102865243AStrong abrasion resistanceInhibit sheddingPump componentsPumpsMetal gridMetal mesh

The invention relates to an abrasion-resistant heat shock resistant impeller type fluid mechanical blade. The surface of the blade is sprayed with ceramic or metal ceramic, metal nets are clamped in spraying layers, a layer of a metal net is welded on the surface of the blade, metal meshes are sprayed with ceramic or metal ceramic, and finally metal nets which protrude out of the spraying layers are polished smooth. The process blade has good abrasion-resistant performance and strong heat shock resistant performance. The blade processing method is also suitable for surface protection processing of other flow passage components of fluid machines.

Owner:JIANGSU UNIV

High-hardness and high-toughness metal ceramic composition and preparation method thereof

The invention provides a high-hardness and high-toughness metal ceramic composition and a preparation method thereof. The high-hardness and high-toughness metal ceramic composition comprises the following raw material components in percentage by weight: 40-70 percent of titanium carbide, 10-30 percent of tungsten carbide, 1-5 percent of tantalous carbide, 3-5 percent of chromium carbide, 10-20 percent of cobalt and 5-10 percent of molybdenum. The preparation method of the high-hardness and high-toughness metal ceramic composition comprises the following steps of: 1, providing raw materials; 2, performing ball milling and stirring on each raw material component to obtain powder particles; 3, molding under a high pressure; 4, removing an adhesive and degreasing; and 5, sintering in vacuum at a high temperature. The high-hardness and high-toughness metal ceramic composition is prepared by adopting titanium carbide, tungsten carbide, tantalous carbide, chromium carbide, cobalt and molybdenum, has high hardness, high toughness and high corrosion resistance, is prevented from being broken and scratched, and is non-irritant to human bodies.

Owner:邓湘凌

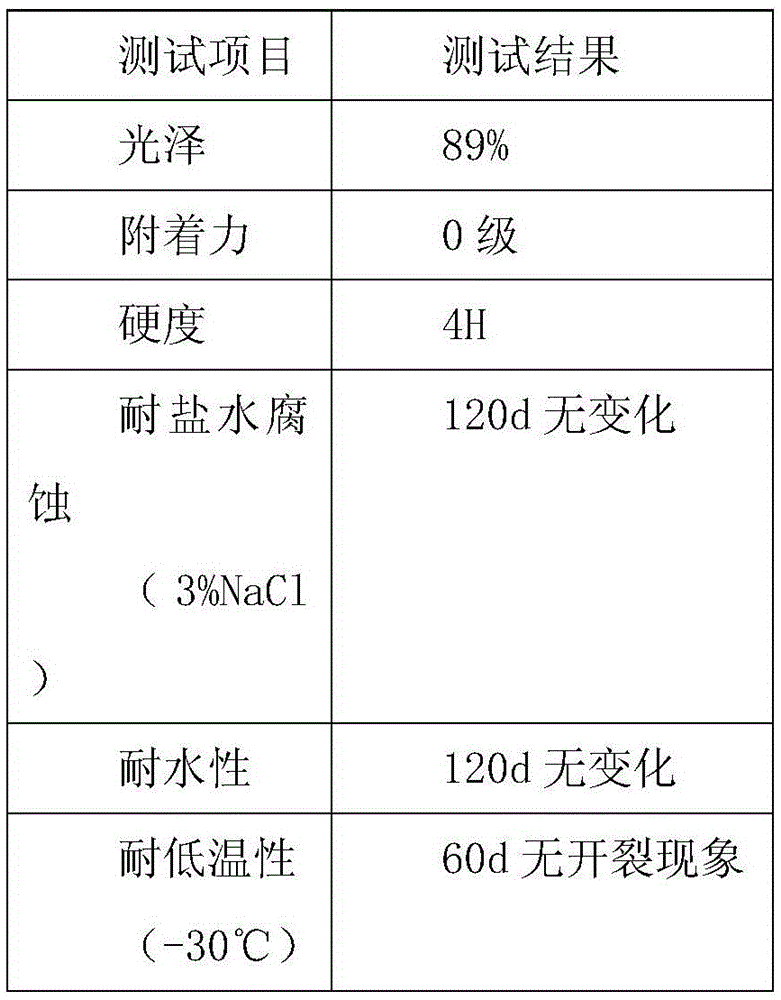

Low temperature resistant anti-crack powder coating used for water pumps and preparation method thereof

InactiveCN105482641AGood compatibilityHigh hardnessAnti-corrosive paintsPowdery paintsCavitationSodium Bentonite

The invention discloses a low temperature resistant anti-crack powder coating used for water pumps. The powder coating is prepared from the following raw materials in parts by weight: 40-50 parts of bisphenol A type epoxy resin, 3-5 parts of cellulose acetate butyrate, 1-2 parts of acetyl tributyl citrate, 20-30 parts of bentonite, 5-10 parts of talcum powder, 3-5 parts of styrene-acrylic emulsion, 1.5-2.5 parts of zirconium sol, 4-6 parts of aluminium sol, 3-5 parts of waterborne polyurethane emulsion, 3-5 parts of a phenolic curing agent and 3-5 parts of a film-forming additive. The powder coating has the advantages that the powder coating used for water pumps has excellent cavitation and corrosion resistance; formed coats have strong binding capacities with metallic matrices, are not easy to peel off or crack, also have good low temperature resistance, are suitable to use in cold regions and have a wide range of application and good durability.

Owner:TONGLING JINGWEI FLUID SCI & TECH

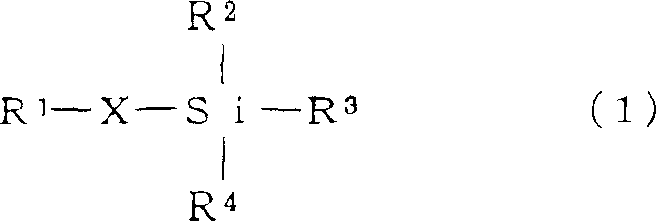

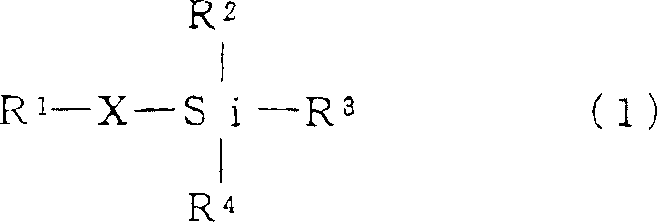

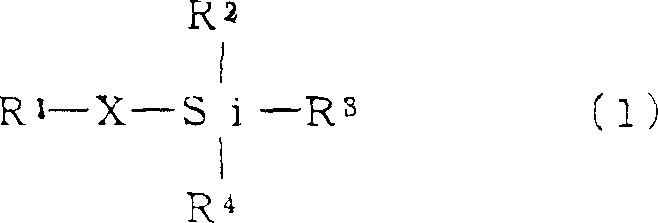

Surface treated metal board

ActiveCN1743085AImprove corrosion resistanceGood coating performanceLiquid surface applicatorsPolyurea/polyurethane coatingsPolymer scienceCarboxylic acid

The surface-treated metal sheet according to the present invention is a surface-treated metal sheet with a resin film prepared with an aqueous resin solution, characterized in that the aqueous resin solution contains an aqueous carboxyl group-containing polyurethane resin solution and an aqueous ethylene-unsaturated carboxylic acid copolymer dispersion in an amount of 5 to 45 parts by mass as nonvolatile resin components, and silica particles having an average particle size of 4 to 20 nm in an amount of 55 to 95 parts by mass, in the total amount of 100 parts by mass, and additionally a silane-coupling agent in an amount of 5 to 25 parts by mass with respect to the total amount of 100 parts by mass, a compounding ratio of the nonvolatile resin component in the aqueous polyurethane resin solution (PU) to the nonvolatile resin component in the aqueous ethylene-unsaturated carboxylic acid copolymer dispersion (EC) (PU:EC) being 9:1 to 2:1. The surface-treated metal sheet according to the present invention is superior in corrosion resistance, coating property (film adhesiveness), abrasion resistance, alkaline degreasing resistance, and conductivity.

Owner:KOBE STEEL LTD

Anti-high-temperature and abrasion-resistant electric arc spraying cored wire containing cerium oxide and rhenium, coating and preparation method of coating

ActiveCN105803377AStrong abrasion resistanceHigh strengthMolten spray coatingSupercritical steam generatorPorosity

The invention discloses an anti-high-temperature and abrasion-resistant electric arc spraying cored wire containing cerium oxide and rhenium. The cored wire is formed by rolling a stainless steel coated flux core. The flux core comprises, by mass percentage, 15-25 wt% of Cr, 6-10 wt% of B, 1-3 wt% of Ni, 0.5-2 wt% of CeO2, 5-10 wt% of Re, and the balance Fe. The invention further discloses a preparation method for preparing an anti-high-temperature and abrasion-resistant coating through the electric arc spraying of the cored wire. The porosity of the coating is smaller than 1%, the microhardness of the coating is greater than 720HV0.2, the bonding strength of the coating is 55 MPa or more, the use temperature of the coating is increased by 200-300 DEG C compared with that of an ordinary coating, the production cost is low, the preparation method is reliable, performance is stable, and the coating is suitable for being applied and popularized in the field of high-temperature use environments such as four walls of supercritical and ultra-supercritical boilers.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

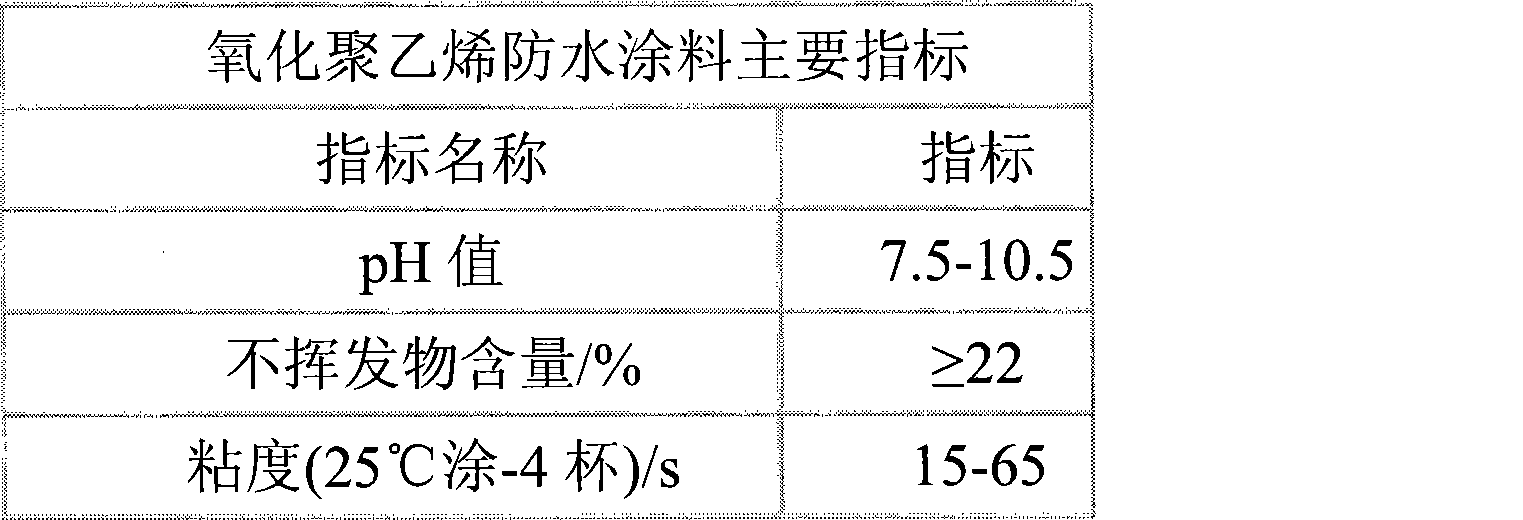

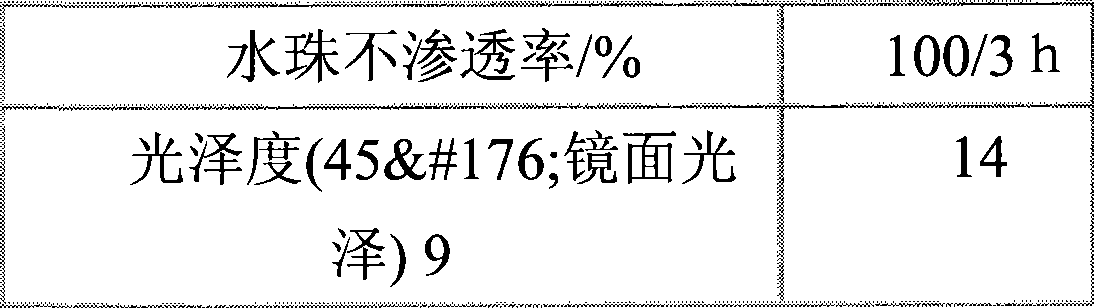

Waterproof coating material for paper pallet and water-proof paper pallet thereof

ActiveCN101476260AGood mirror effectStrong adhesionPaper coatingCoatingsPulp and paper industryHeavy load

The invention discloses a paper pallet waterproof paint, the method for using the paint to prepare waterproof paper pallet and waterproof paper pallet prepared by the method. The paper pallet waterproof paint comprises: Thinner (4.0-5.0 weight parts) and smoothing oil (0.8-1.5 weight parts). the waterproof paper pallet product prepared by the method in the invention has superior waterproof performance, also achieves the advantages of light, heavy load, convenient for manufacturing, and low in cost; and can be used in package, storage and transportation fields.

Owner:深圳华生创新包装有限责任公司

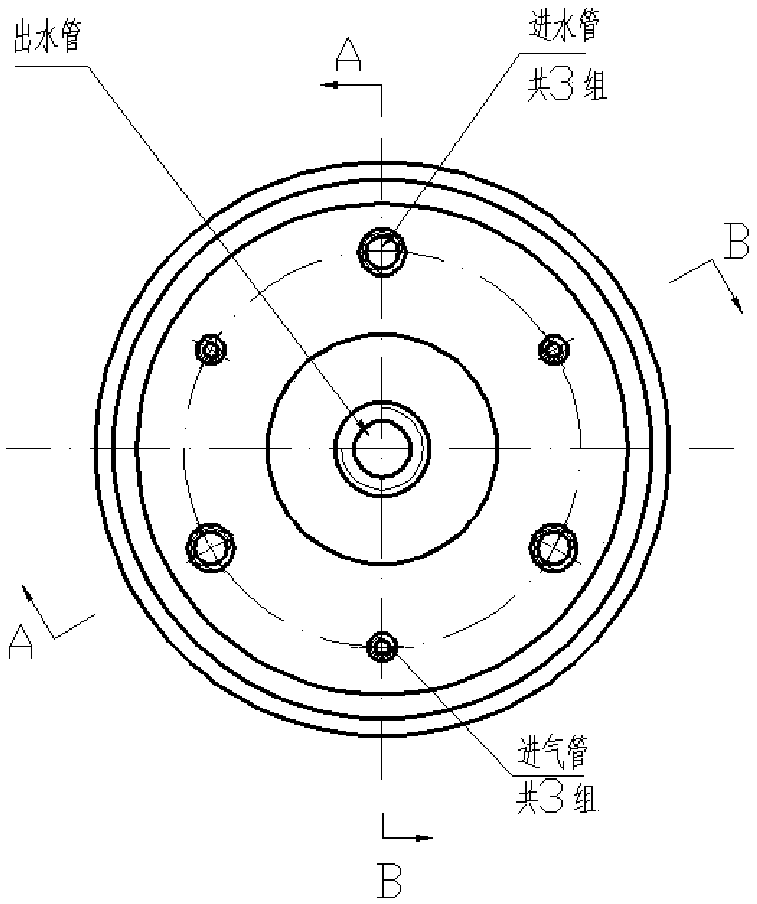

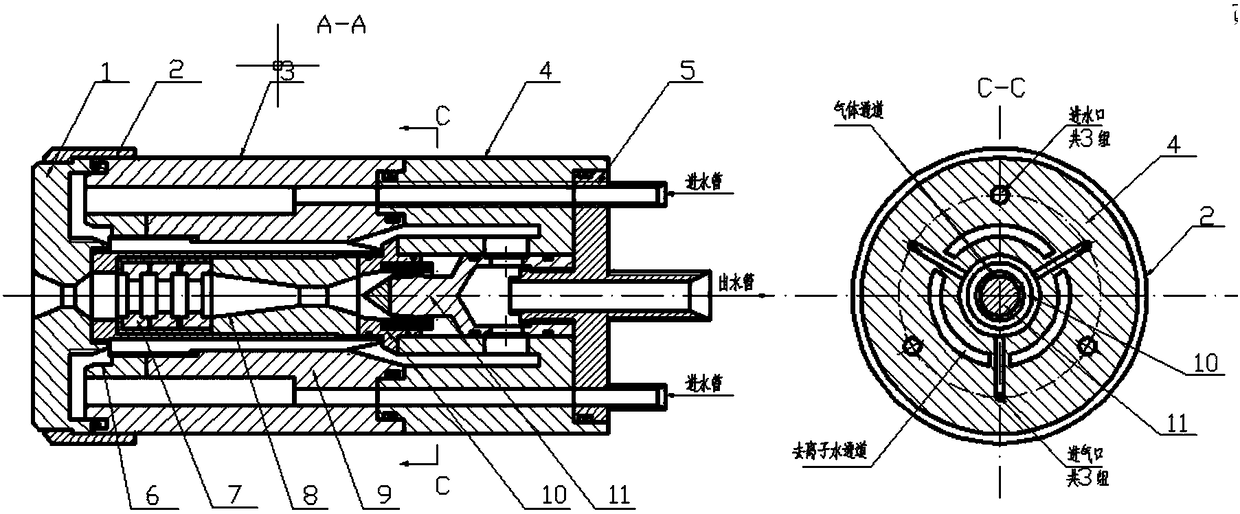

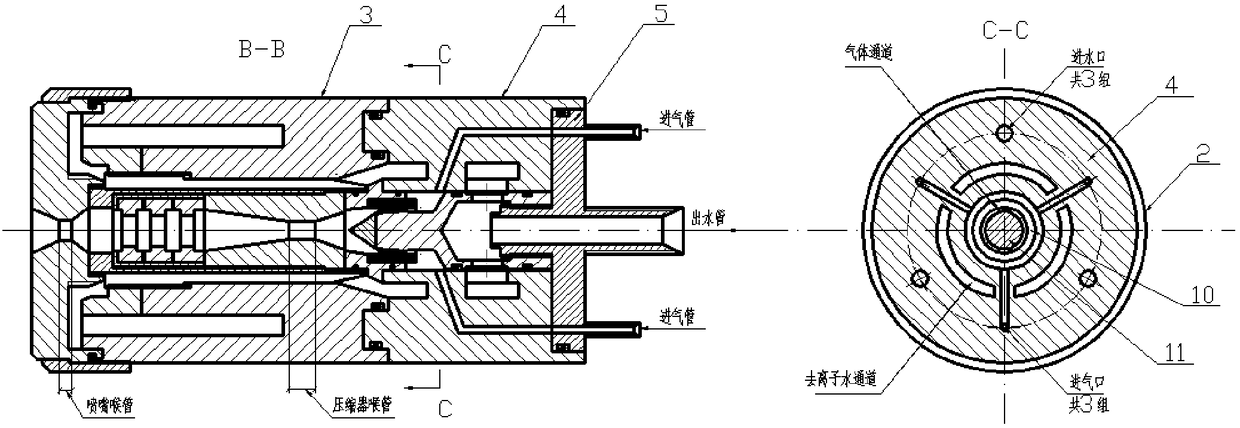

Novel hypersonic-speed high-enthalpy-value plasma gun and preparation process of WC-based composite coating layer

The invention discloses a novel hypersonic-speed high-enthalpy-value plasma gun and a preparation process of a WC-based composite coating layer. The novel hypersonic-speed high-enthalpy-value plasma gun comprises a nozzle, a fixed ring, a shell 1, a shell 2, an integrator, a water dividing sleeve, an anode, a compressor, a water cooling sleeve, a spacer sleeve and a cathode, wherein the compressoris added between the cathode and the anode to enlarge the gap between the cathode and the anode. The novel hypersonic-speed high-enthalpy-value plasma gun and the preparation process disclosed by theinvention have the beneficial effects that the arc length is prolonged, simultaneously the stability of an arc can be improved, the speed of flame flow of plasma spraying is increased, and finally, the flame-flow speed can reach 6-7 Mach (2040-2380m / s); the coating layer powder is heated to be in a molten and semi-molten state in a high-speed flame, impacts the surface of a workpiece by a high speed, and is deposited to form a dense coating layer; based on the device and process provided by the invention, the WC-based coating layer with high deposition efficiency, high bonding strength, highhardness, low porosity, high abrasion resistance, high corrosion resistance and high wear resistance can be obtained and can be applied on the surfaces of the workpieces such as a water turbine, a water pump, a ball valve, a gate and a piston rod and the like.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

High-hardness wear-resistant corrosion-resistant steel plate for slurry dredging and production method thereof

ActiveCN108930001AGood abrasion resistanceImprove corrosion resistanceSteel platesCorrosion resistant

The invention provides a high-hardness wear-resistant corrosion-resistant steel plate for slurry dredging and a production method thereof. The steel plate comprises, by weight, 0.18 to 0.24% of C, nomore than 0.01% of Si, 1.3 to 1.6% of Mn, no more than 0.015% of P, no more than 0.005% of S, 0.2 to 1.0% of Al, 0.3 to 1.2% of Cr, 0.001 to 0.002% of B, no more than 0.005% of N, and one or more selected from a group consisting of 0.01 to 0.03% of Nb and 0.01 to 0.025% of Ti, with the balance being Fe and unavoidable impurity elements, wherein the sum of Nb and Ti is more than 6.65 N and no morethan 0.045. The composition design of the wear-resistant corrosion-resistant steel plate allows the steel plate to have both corrosion resistance and wear resistance; and the steel plate is mainly applied to manufacturing of dredging pipelines applied to reclamation of land from water, navigation channel dredging and other fields and has wear and corrosion resistance two times higher than the wearand corrosion resistance of conventional common pipes, so dredging efficiency is greatly improved and operation cost is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

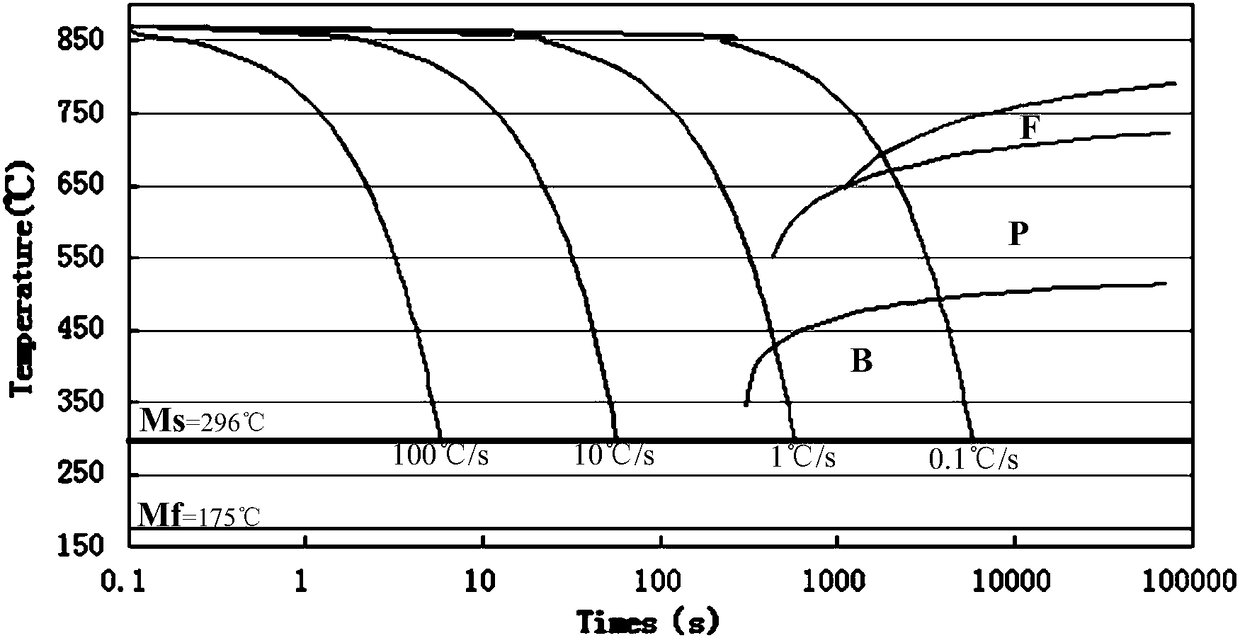

600HB hardness wear-corrosion-resistant steel plate used for slurry dredging pipes, and production method thereof

The invention discloses a 600HB hardness wear-corrosion-resistant steel plate used for slurry dredging pipes, and a production method thereof. The 600HB hardness wear-corrosion-resistant steel platecomprises, by weight, 0.36 to 0.42% of C, Si<=0.01%, 1.6 to 2.0% of Mn, P<=0.015%, S<=0.005%, 0.2 to 1.0% of Al, 0.3 to 1.2% of Cr, 0.001 to 0.002% of B, N<=0.005%, one element or two elements selected from 0.01 to 0.03% of Nb or 0.01 to 0.025% of Ti, and the balance Fe and unavoidable impurities, wherein 6.65N<Nb+Ti<=0.045. Both the wear resistance and the corrosion resistance are taken into consideration in preparation; the 600HB hardness wear-corrosion-resistant steel plate possesses excellent wear resistance, and is mainly used for preparation of dredging pipes used in reclamation projectand navigation channel dredging; the corrosion resistance degree is 5 times of that of common pipes, so that dredging efficiency is increased greatly, and operation cost is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

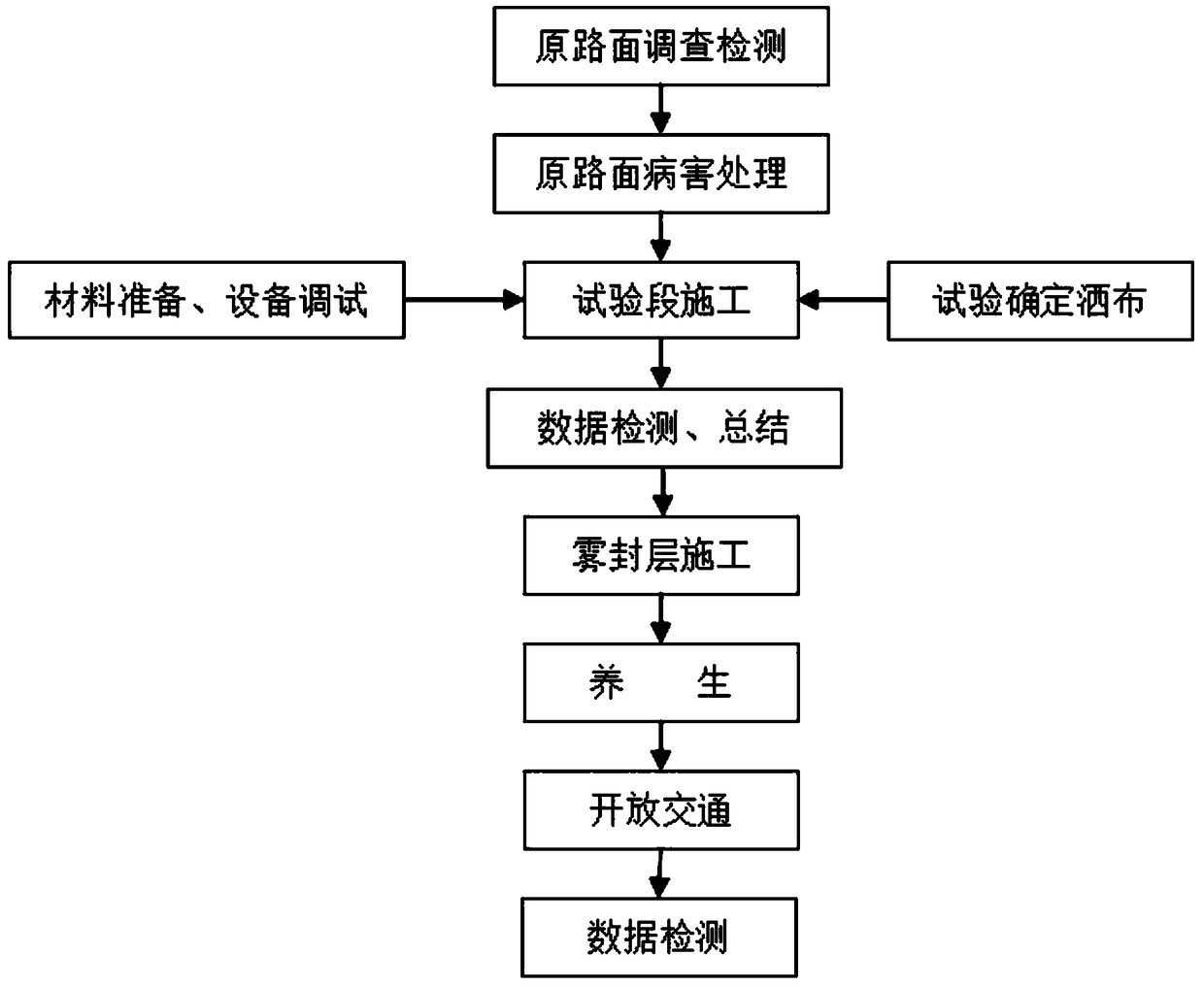

Grout sealing process of pavement construction

InactiveCN108914748ADelay agingRestore performanceRoads maintainenceMaterials preparationPhysical health

The invention relates to the technical field of roads, in particular to a grout sealing process of pavement construction. The grout sealing process of pavement construction comprises the following steps of 1, material preparation stage, wherein materials are (1) AXYS asphaltic liquid, (2) sand, and (3) water; 2, equipment preparing stage: the equipment is a spreading truck which is manufactured byNantong Keheng construction engineering Co. , Ltd. and whose model is KH0126; 3, mixing the AXYS asphaltic liquid, the sand and the water in the step 1 to form a mixed liquid material; 4, setting paving amount; 5, adding the mixed liquid material in the step 3 to the spreading equipment in the step 2 according to the total amount required in the step 4; and 6, sand-containing seal construction procedure. According to the grout sealing process of pavement construction, rapid paving can be realized, the construction time is short, the speed is high, volatile substances harmful to the environment and human body cannot be generated in construction so that the environment and physical health of construction personnel cannot be affected.

Owner:JIANGSU ZENGGUANG COMPOSITE MATERIAL TECH

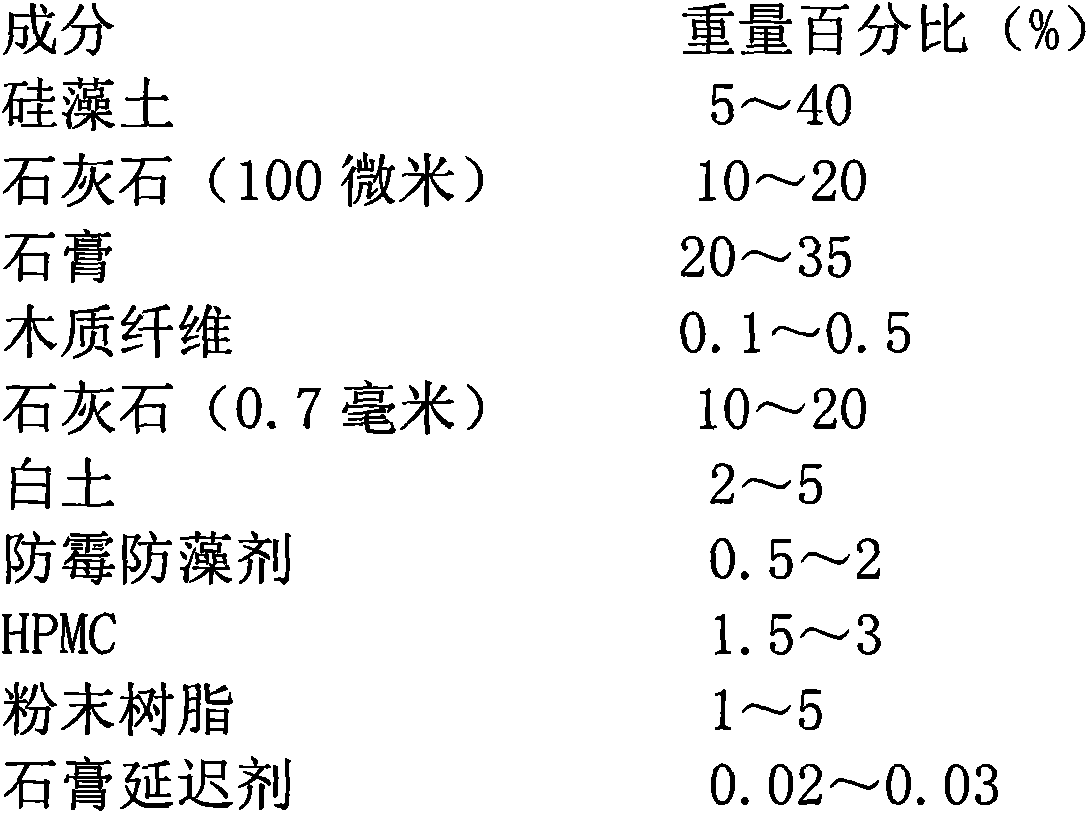

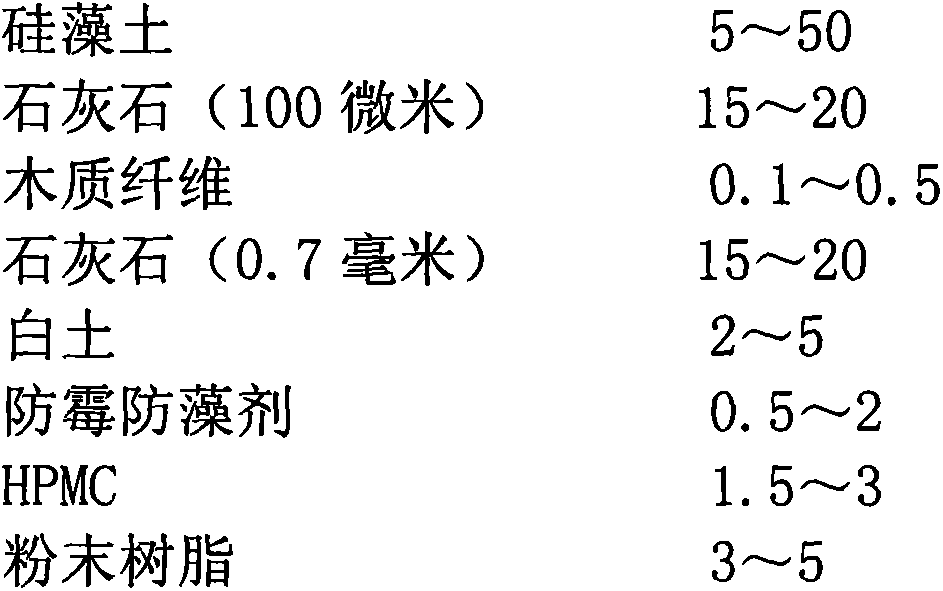

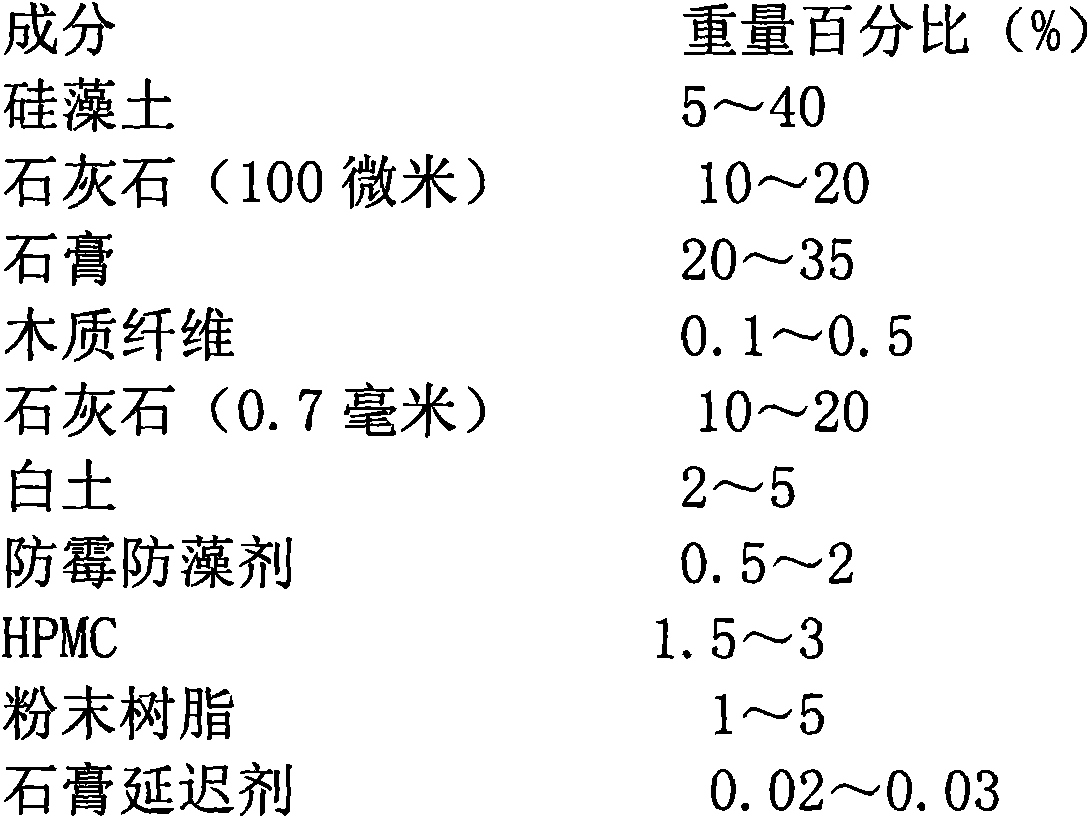

Substrate material capable of adjusting moisture and manufacturing method of substrate material

The invention discloses a substrate material capable of adjusting moisture and a manufacturing method thereof, and discloses a substrate material for painting indoor walls of buildings. The substrate material contains sintered and non-sintered diatomite ingredients and auxiliary materials, such as gypsum, limestone, wood fiber, carclazyte, anti-mildew algicide, hydroxypropyl methylcellulose and powdered resin, and the like. The method is simple and easy to implement. Since having reasonable material proportion, the substrate material has strong crack resistance, adhesion, abrasion resistance, moisture absorption and moisture releasability; the root cause is as follows: the diatomite is used as the main raw material; since the diatomite is porous and has big specific surface area, the diatomite can store moisture and has excellent moisture retention; the moisture can be released in dry condition. Since having wood fiber and powdered resin, and the like, the crack resistance and abrasion resistance are strengthened; the fastness of the substrate material to a wall surface is improved. Moist and mildew can be effectively avoided by adding the anti-mildew algicide, and thus indoor environment is more environment friendly. The substrate material capable of adjusting moisture is ideal, and solves the problems of the existing substrate material.

Owner:营口盼盼硅藻材料集团有限公司

Technology for processing lightweight anti-crack aluminum alloy for manufacturing vehicle body

The invention provides a technology for processing lightweight anti-crack aluminum alloy for manufacturing a vehicle body. The lightweight anti-crack aluminum alloy comprises the following components in percentage by mass: 1.2-2% of Cu, 0.3-5% of Zn, 0.1-9% of Li, 1.1-2.1% of Ni, 0.2-0.5% of Zr, 0.3-0.5% of Ti, 0.1-0.7% of Hf, 1.5-3.2% of Si, 0.3-1% of V, 0.6-1.2% of Mg, 3.2-15% of rare earth and the balance being Al. The processing technology has the beneficial effects that an original component proportion and an original technology are adopted for ensuring that the alloy does not shrink during cooling solidification, thus effectively avoiding defects such as shrinkage voids and shrinkage porosity; meanwhile, the remarkable improvement of processability and a mechanical property is further ensured due to the fine microscopic structures of the alloy; the processing cost of castings is reduced; and the vehicle body manufactured by utilizing the alloy is lightweight, has excellent crack resistance and corrosion-erosion resistance and can promote the rapid development of automobile casting technologies.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

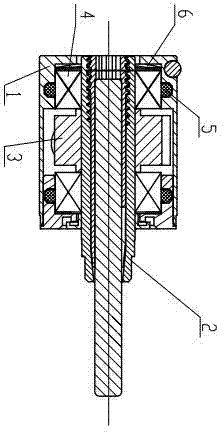

Movement of dental high-speed turbine handpiece

The invention relates to a movement of a dental high-speed turbine handpiece. The movement comprises a rotating shaft, and a wind wheel and two bearings which are sleeved on the rotating shaft, the bearings are respectively positioned at two sides of the wind wheel, positions on a cylinder corresponding the bearings are respectively provided with an annular groove, an O-shaped rubber ring is arranged in the annular groove, and the O-shaped rubber ring is made by using a fluorubber material. The movement of the dental high-speed turbine handpiece has the advantages of stable running and long service life.

Owner:GUILIN WOODPECKER MEDICAL INSTR

PVC composite material for drainage pipeline and preparation method of PVC composite material

InactiveCN104530513ARaw materials are easy to getNew formula designDiphenylsilanediolTemperature resistance

The invention discloses a PVC composite material for a drainage pipeline and a preparation method of the PVC composite material, and relates to the technical field of drainage pipeline production formulas. A tire tread is prepared from the following raw materials, namely butadiene styrene rubber composite materials, in parts by mass: 80-95 parts of butadiene styrene rubber, 8-10 parts of phenolic resin, 3-8 parts of 2,6-di-tert-butyl-4-methylphenol, 2-5 parts of aedelforsite, 3-6 parts of magnesium carbonate, 4-8 parts of calcium stearate, 1-3 parts of trioctyltrimellitate, 1.5-4 parts of diphenyl silanediol, 2-7 parts of coumarone resin, 0.5-1.5 parts of rosin, 1-3 parts of maleic anhydride, 2-5 parts of ammonium persulfate, 1.5-3 parts of phthalic anhydride, 0.5-2 parts of sulfur and 3-8 parts of nano calcium carbonate. The PVC composite material for the drainage pipeline is easily available in raw materials, novel in formula design and simple in production process; and the obtained PVC composite material for the drainage pipeline has strong high temperature resistance, wear resistance and ageing resistance and good mechanical properties.

Owner:郎溪县恒通塑业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com