Rare earth chromium composite electroplating layer and preparing method and use thereof

A technology of composite electroplating and electroplating layer, applied in the direction of coating, electrolytic coating, etc., can solve the problem of small improvement and achieve the effect of reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: The electroplating of rare earth chromium is carried out to the needle nozzle (heavy 65kg) and the retaining ring (heavy 17kg) of the impact turbines of Yilihe Hydropower Plant and Yuanjiang Huashiban Power Plant in Yunnan Province.

[0029] First prepare the electroplating solution, the composition of the electroplating solution is: CrO 3 (Chromic anhydride): 140g / liter, H 2 SO 4 : 1.5g / liter, soluble rare earth additive mainly composed of mixed rare earth oxides purchased by Inner Mongolia Research Institute: 2g / liter, insoluble mixed rare earth salt additive mainly composed of sulfate and carbonate purchased by Inner Mongolia Research Institute: 3g / L, and the rest is water.

[0030]The electroplating technology consists of polishing, alkali cleaning, pickling, periodic reverse-phase electroplating of rare earth chromium, and finishing processes. Among them, polishing, alkali washing, pickling, and finishing processes are all carried out according to...

Embodiment 2

[0032] Example 2: Electroplating of the anti-wear plate (φ2m) of the Xiaohedi Hydropower Plant in Yuanjiang.

[0033] First prepare the electroplating solution, the composition of the electroplating solution is: CrO 3 (Chromic anhydride): 158g / liter, H 2 SO 4 : 1.75g / liter, the soluble rare earth additive mainly composed of mixed rare earth oxides purchased by the Inner Mongolia Research Institute: 2.25g / liter, the insoluble mixed rare earth salt additive mainly composed of sulfate and carbonate purchased by the Inner Mongolia Research Institute: 3.25g / liter, the rest is water.

[0034] The electroplating process is basically the same as in Example 1, except that the temperature of the plating solution is 50°C, and the current density is 28 amps / dm 2 The rare earth chromium coating of the plated parts reaches 0.35mm.

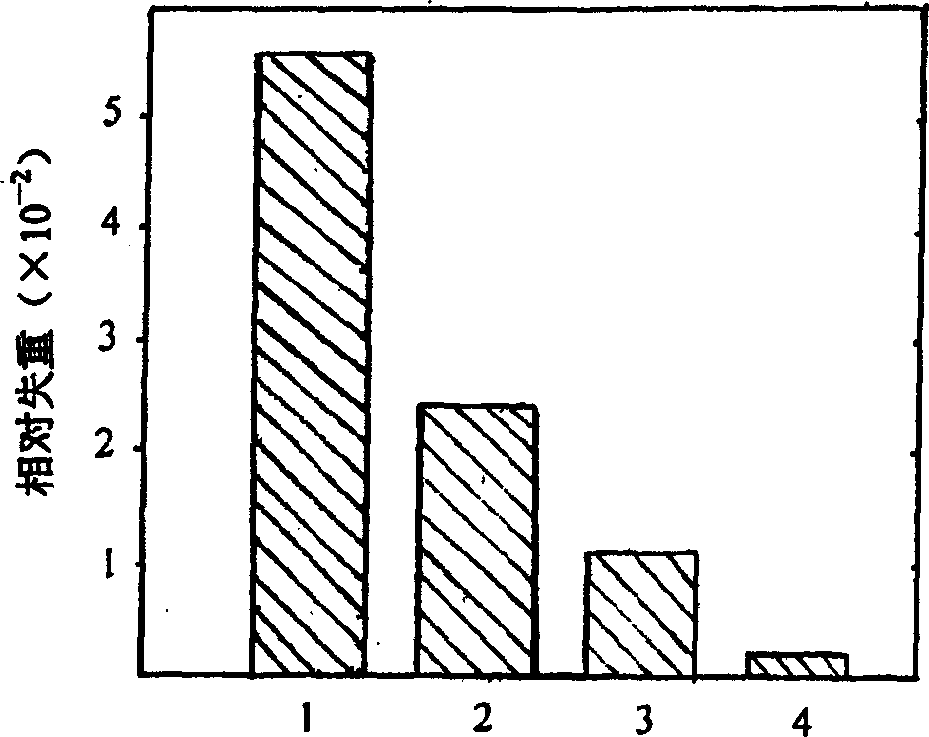

[0035] After the above process, the rare earth chromium composite electroplating layer of the mixed rare earth chromium base phase and the second phase of m...

Embodiment 3

[0036] Embodiment 3: Electroplating the mixed-flow runner of Qujing Tianshengba Hydropower Plant.

[0037] First prepare the electroplating solution, the composition of the electroplating solution is: CrO 3 (Chromic anhydride): 170g / liter, H 2 SO 4 : 2.0g / liter, the soluble rare earth additive mainly composed of mixed rare earth oxides purchased by the Inner Mongolia Research Institute: 2.5g / liter, the insoluble mixed rare earth salt additive mainly composed of sulfate and carbonate purchased by the Inner Mongolia Research Institute: 3.5g / liter, the rest is water.

[0038] The electroplating process is basically the same as in Example 1, except that the temperature of the plating solution is 54°C, and the current density is 30 amps / dm 2 The rare earth chromium coating of the plated parts reaches 0.4mm.

[0039] After the above process, the rare earth chromium composite electroplating layer of the mixed rare earth chromium base phase and the second phase of mixed rare earth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com