Movement of dental high-speed turbine handpiece

A high-speed, turbine technology, used in dentistry, dental drilling, medical science, etc., can solve the problems of unstable movement, shortened service life, shock absorption and buffering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

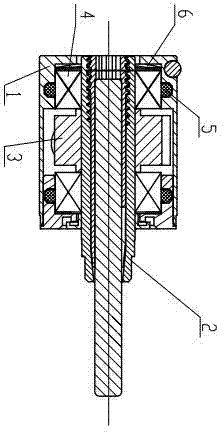

[0011] The movement of the dental high-speed turbine handpiece of the present invention includes a cylinder body 1, a rotating shaft 2, a wind wheel 3 and two bearings 4 that are sleeved on the rotating shaft 2, and the bearings 4 are respectively located on both sides of the wind wheel 3. Annular grooves are respectively provided on the positions corresponding to the bearings 4 on the cylinder body 1, and "O"-shaped rubber rings 5 are arranged in the annular grooves, and the "O"-shaped rubber rings 5 are made of fluororubber material. Fluorine rubber is preferably VITON A fluorine rubber. In order to enhance the stability of the movement, a saddle spring washer 6 pressed against the bearing 4 is provided at the bottom of the barrel 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com