Plastic melting mosaic product and plastic melting mosaic method

A product and inlay technology, applied in the direction of coating, can solve the problems of poor impact resistance, difficult to clean, easy to stick to dust, etc., and achieve the effect of high wear resistance, easy maintenance, and enhanced firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

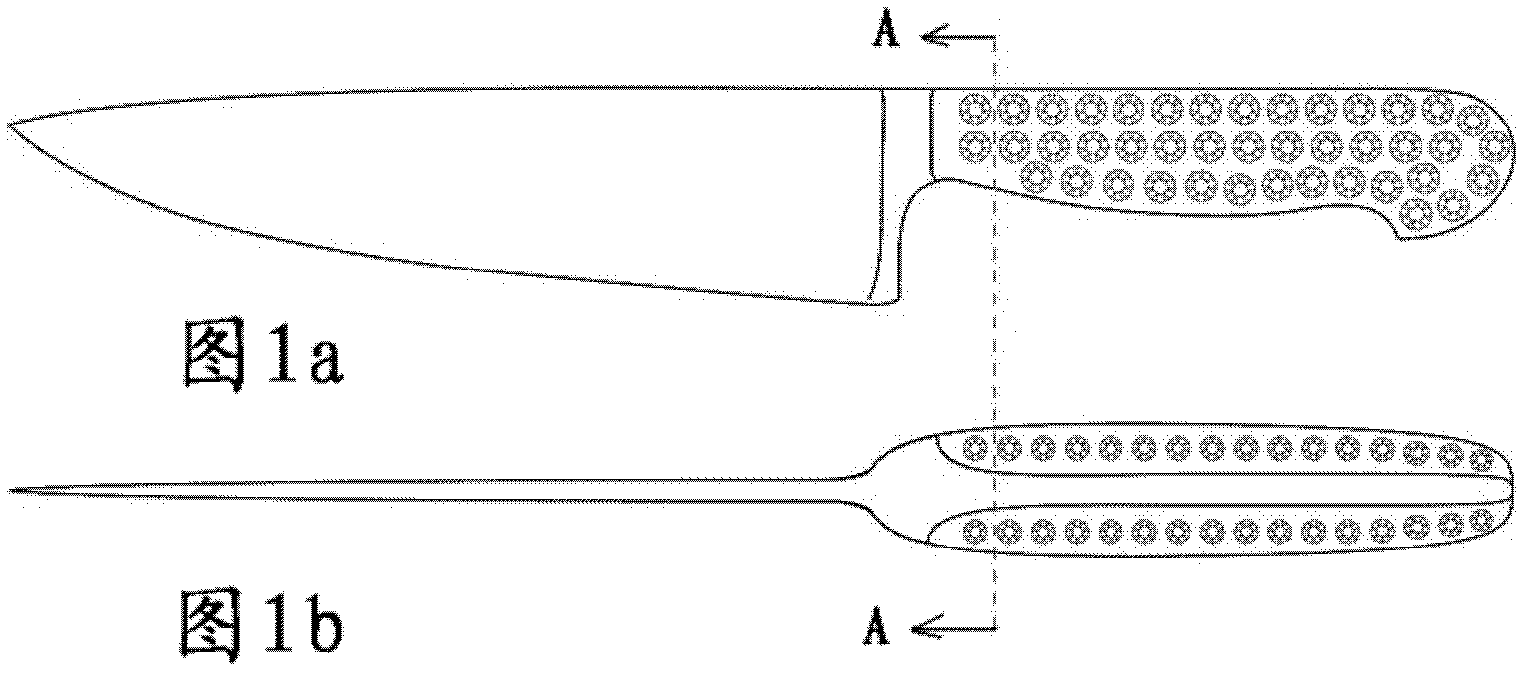

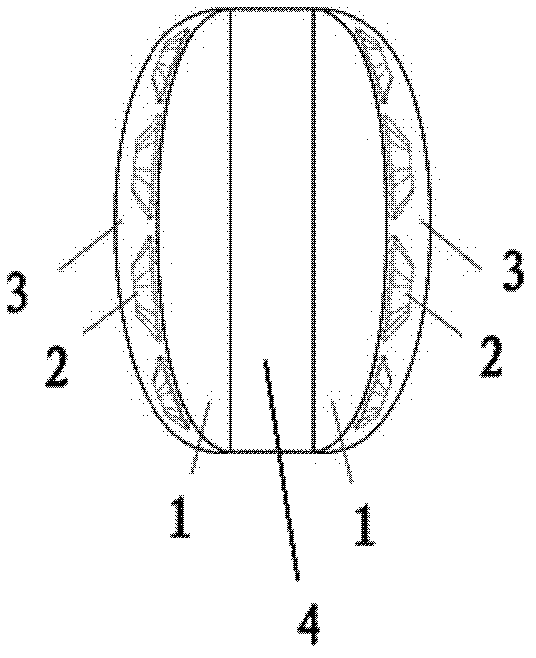

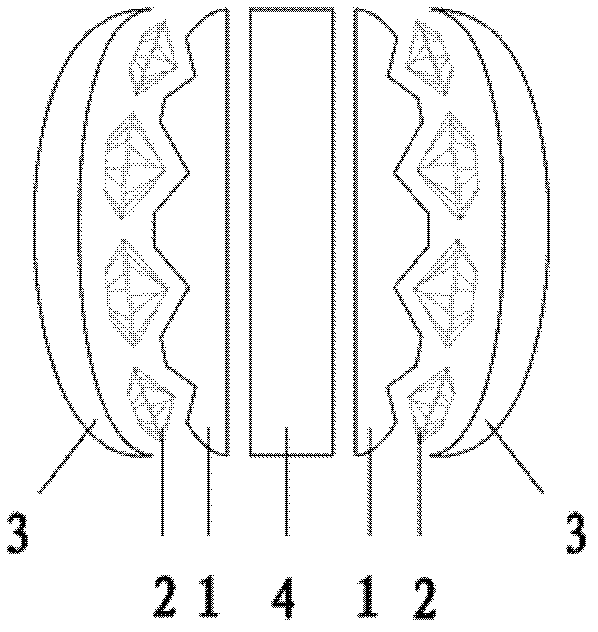

[0035] Figure 1a , 1b , 1c and 1d represent the embodiment of the present invention where the base is a tool, in which inserts are embedded in the handle of the tool, and the front view, top view, and edge of the tool are shown respectively Figure 1a , 1b A cross-sectional view of the handle taken at the middle section line A-A and an exploded view of the cross-sectional view.

[0036] The plastic melt-inlaid handle 4 of the tool includes an inner layer 1 injection molded with plastic material as a bottom mold, an outer layer 3 injection molded with a transparent plastic material on the inner layer 1, and many inserts 2 such as gems, Crystals, pearls, and artificial stones, where these inserts 2 are embedded in the recesses made on the inner layer 1 and are encapsulated between the inner layer 1 and the outer layer 3 through the injection molding, and the inner layer 1 and the outer layer 3 Since the injection molding is integrated, the other surface of the inner layer 1 opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com