Wear-resistant corrosion-resistant steel plate with hardness of 500 HB and for slurry dredging, and production method thereof

A 500HB, production method technology, applied in the field of low-alloy steel manufacturing, can solve the problems of difficulty in meeting abrasive requirements, deterioration of material wear resistance, low matrix hardness, etc., and achieve the effect of good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with embodiments.

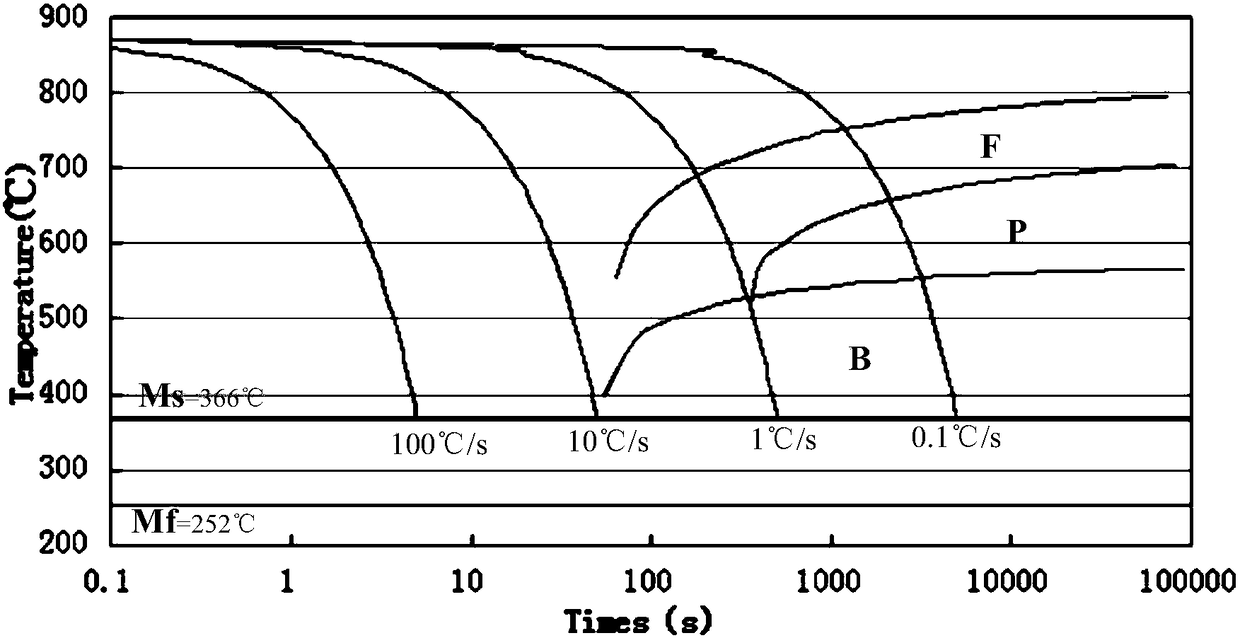

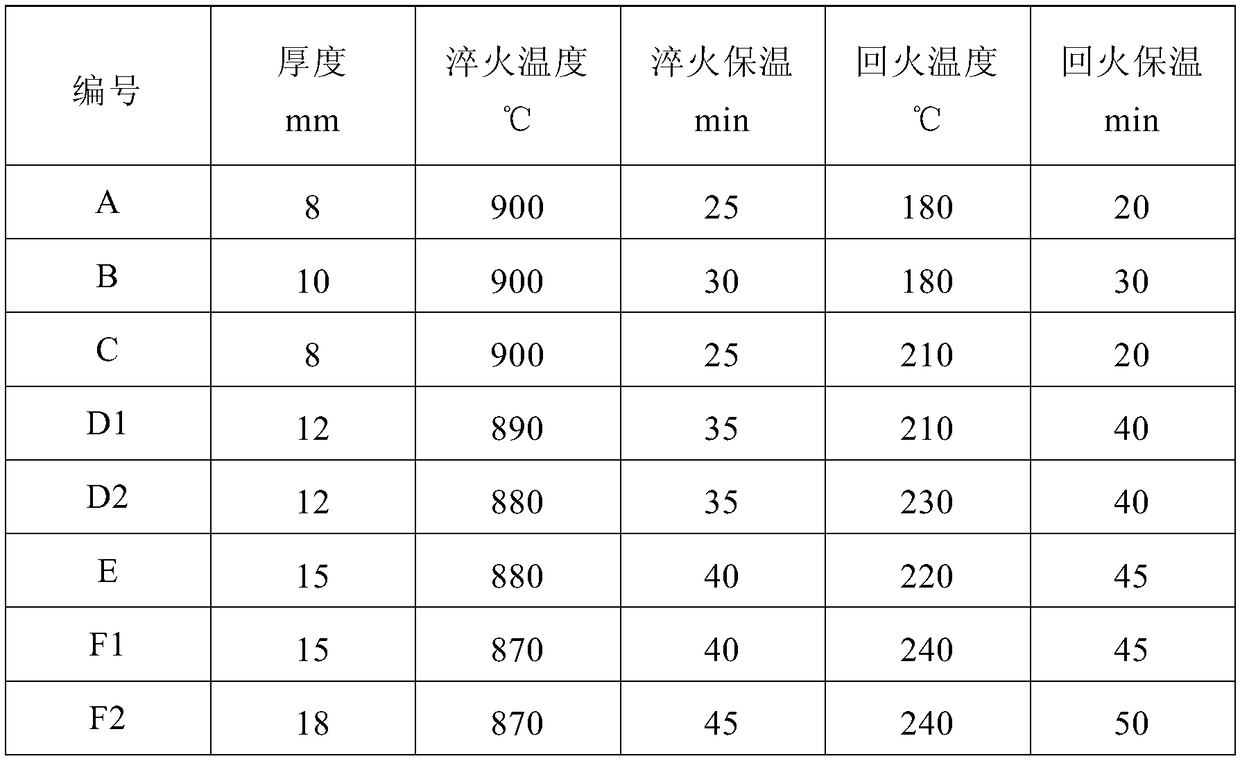

[0053] According to the chemical composition requirements of the wear-resistant steel plate involved in the present invention, steel plates of different thickness specifications are prepared. The chemical composition of the steel in the example of the present invention is shown in Table 1, and the production process is shown in Table 2.

[0054] The production method of this embodiment is as follows:

[0055] Deep removal of S in molten iron (to ensure low S content in steel) → converter top and bottom composite blowing (control C content) → refining outside the furnace → continuous casting (machine cleaning) → slab reheating → controlled rolling → controlled cooling → coil Take → uncoiling → straightening → cutting board → heat treatment (quenching + tempering) → finishing → delivery.

[0056] Among them, the heating temperature of the billet is 1200°C, and the final rolling temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com