Abrasion-resistant composite protective coating for hard sealing surface of ball valve and preparation method of abrasion-resistant composite protective coating

A protective coating and hard sealing technology, applied in the field of surface engineering, can solve the problems of poor wear resistance and short service life, and achieve the effect of prolonging service life, improving service performance and avoiding pitting corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

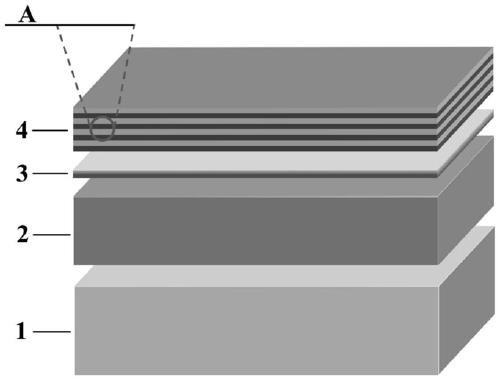

[0046] The present invention also provides a method for preparing the anti-corrosion composite protective coating on the hard sealing surface of the ball valve described in the above technical solution, comprising the following steps:

[0047] Supersonic flame spraying is carried out on the surface of the metal substrate to obtain Cr 3 C 2 -NiCr coating;

[0048] With Cr target, WC target and C target as sputtering targets, in the Cr 3 C 2 -Closed-field unbalanced magnetron sputtering on the surface of the NiCr coating to obtain a Cr→Cr / C / WC dual-mode transition layer;

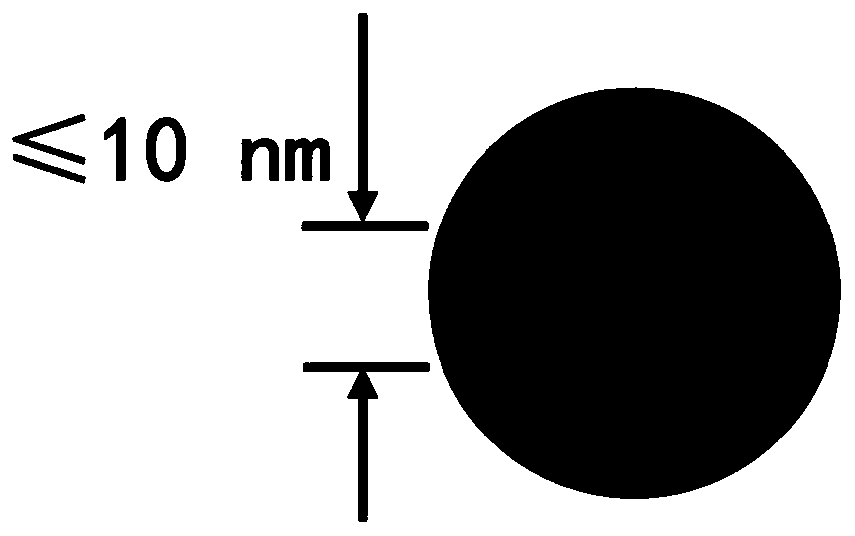

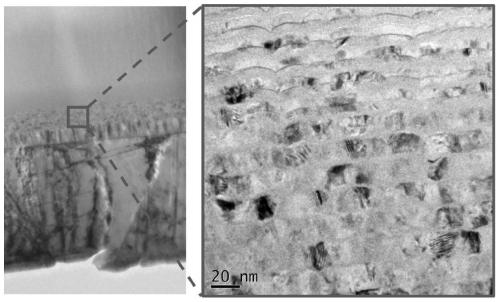

[0049] The C target and the WC target are used to carry out unbalanced magnetron sputtering deposition on the surface of the Cr→Cr / C / WC dual-mode transition layer to obtain a WC / a-C nanometer multilayer film.

[0050] The present invention carries out supersonic flame spraying on the surface of metal substrate, obtains Cr 3 C 2 -NiCr coating.

[0051] In the present invention, the oxygen flow rate of th...

Embodiment 1

[0061] An anti-corrosion composite protective coating on the hard sealing surface of a ball valve. The composite coating is made of Cr with a thickness of 240 μm on the metal substrate of 316L stainless steel. 3 C 2 -NiCr coating, based on Cr 3 C 2 -A Cr→Cr / C / WC dual-mode transition layer with a thickness of 300 nm on the NiCr coating and a WC / a-C nano-multilayer film with a thickness of 3.0 μm on the Cr→Cr / C / WC dual-mode transition layer 3 production.

[0062] Its preparation method comprises the following steps:

[0063] (1) After polishing the surface of 316L stainless steel, use acetone cleaning solution to ultrasonically clean for 20 minutes under the conditions of ultrasonic power of 500 W and temperature of 20°C to obtain a metal matrix.

[0064] (2) Spray a layer of Cr with a thickness of 240 μm on the surface of the metal substrate by supersonic flame spraying technology. 3 C 2 -NiCr coating.

[0065] Among them: the condition of supersonic flame spraying means...

Embodiment 2

[0079] An anti-corrosion composite protective coating on the hard sealing surface of a ball valve. The composite coating is composed of Cr with a thickness of 260 μm on the metal substrate of 316L stainless steel. 3 C 2 -NiCr coating, based on Cr 3 C 2 -A Cr→Cr / C / WC dual-mode transition layer with a thickness of 350 nm on the NiCr coating and a WC / a-C nano-multilayer film with a thickness of 4.0 μm on the Cr→Cr / C / WC dual-mode transition layer become.

[0080] Its preparation method comprises the following steps:

[0081] (1) After polishing the surface of 316L stainless steel, use acetone cleaning solution to ultrasonically clean it for 15 minutes under the conditions of ultrasonic power of 800 W and temperature of 30°C to obtain a metal matrix.

[0082] (2) Spray a layer of Cr with a thickness of 260 μm on the surface of the metal substrate by supersonic flame spraying technology. 3 C 2 -NiCr coating.

[0083] Among them: the condition of supersonic flame spraying mean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com