Honeycomb flue gas denitrification catalyst and preparation method thereof

A denitrification catalyst and honeycomb technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems affecting the normal operation of thermal power plant units, excessive wear of catalysts, poor wear resistance, etc., to achieve application Guaranteed strength, low defect rate, and improved high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

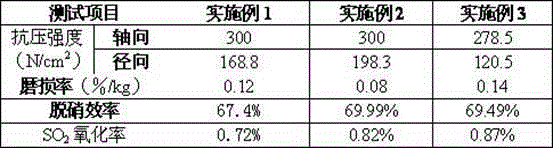

Embodiment 1

[0030] A honeycomb flue gas denitrification catalyst, which is formed by extruding and sintering the following raw materials in parts by weight: nano-TiO 2 (1~10μm) 83 parts, nano-SiO 2 (1~10nm) 8.3 parts, ammonium metatungstate and WO 3 10 parts by weight, ammonium metavanadate in V 2 o 5 1 weight, 6.7 parts of glass fiber, 0.42 part of extrusion aid (stearic acid), 0.17 part of carboxymethyl cellulose, 0.25 part of polyethylene oxide, and 0.17 part of squash powder.

[0031] Its preparation method comprises the following steps:

[0032] (1) Weigh nano-TiO 2 , nano-SiO 2 Powder, ammonium metatungstate and ammonium metavanadate, add extrusion aid, add water while stirring to form a paste, and add ammonia water to adjust the pH value of the material to 7.5;

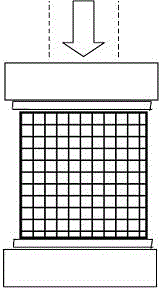

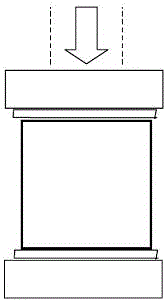

[0033] (2) Add the remaining raw materials and mix evenly, and use a vacuum extruder to extrude a honeycomb embryo body with a cross-section of 150mm×150mm, a number of holes of 15×15, and a length of 1000mm;

[003...

Embodiment 2

[0037] A honeycomb flue gas denitrification catalyst, which is formed by extruding and sintering the following raw materials in parts by weight: nano-TiO 2 (1~10μm) 92.8 parts, nano-SiO 2 (1~10nm) 7.4 parts, ammonium metatungstate and WO 3 7.4 parts by weight, ammonium metavanadate with V 2 o 5 0.8 parts by weight, 9.3 parts of glass fibers, 0.46 parts of extrusion aid (stearic acid), 0.19 parts of carboxymethyl cellulose, 0.28 parts of polyethylene oxide, and 0.19 parts of squash powder.

[0038] Its preparation method comprises the following steps:

[0039] (1) Weigh nano-TiO 2 , nano-SiO 2 Powder, ammonium meta / paratungstate and ammonium metavanadate, add extrusion aid, add water while stirring to form a paste, and add ammonia water to adjust the pH value of the material to 8;

[0040] (2) Add the remaining raw materials and mix evenly, use a vacuum extruder to extrude a honeycomb embryo body with a section of 150mm×150mm, a number of holes of 15×15, and a length of 1...

Embodiment 3

[0044] A honeycomb flue gas denitrification catalyst, which is formed by extruding and sintering the following raw materials in parts by weight: nano-TiO 2 (1~10μm) 68 parts, nano-SiO 2 (1~10nm) 3.4 parts, ammonium paratungstate and WO 3 2.7 parts by weight, ammonium metavanadate in V 2 o 50.48 parts by weight, 3.4 parts of glass fibers, 0.14 parts of extrusion aid (glycerin), 0.14 parts of carboxymethyl cellulose, 0.2 parts of polyethylene oxide, and 0.14 parts of scallop powder.

[0045] Its preparation method comprises the following steps:

[0046] (1) Weigh nano-TiO 2 , nano-SiO 2 Powder, ammonium paratungstate and ammonium metavanadate, add extrusion aid, add water while stirring to form a paste, and add ammonia water to adjust the pH value of the material to 7;

[0047] (2) Add the remaining raw materials and mix evenly, and use a vacuum extruder to extrude a honeycomb embryo body with a cross-section of 150mm×150mm, a number of holes of 20×20, and a length of 1000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com