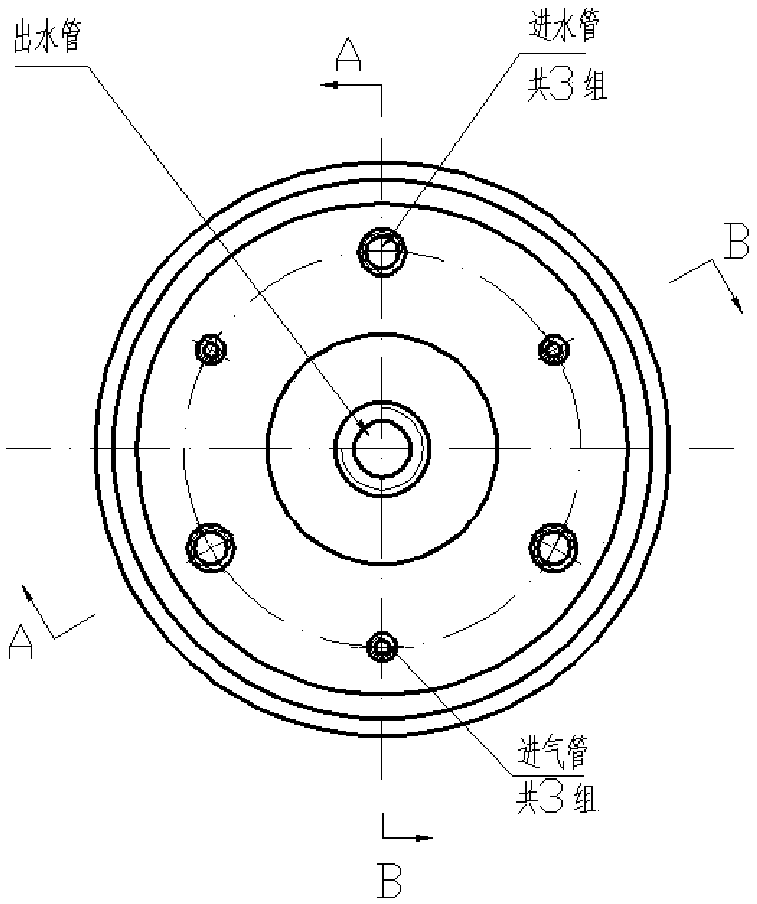

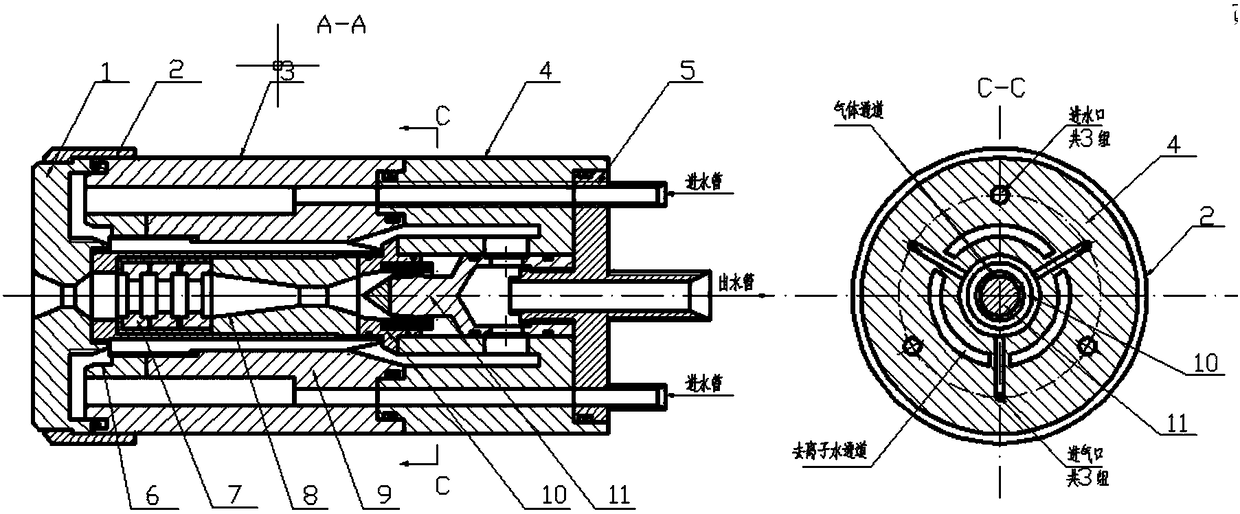

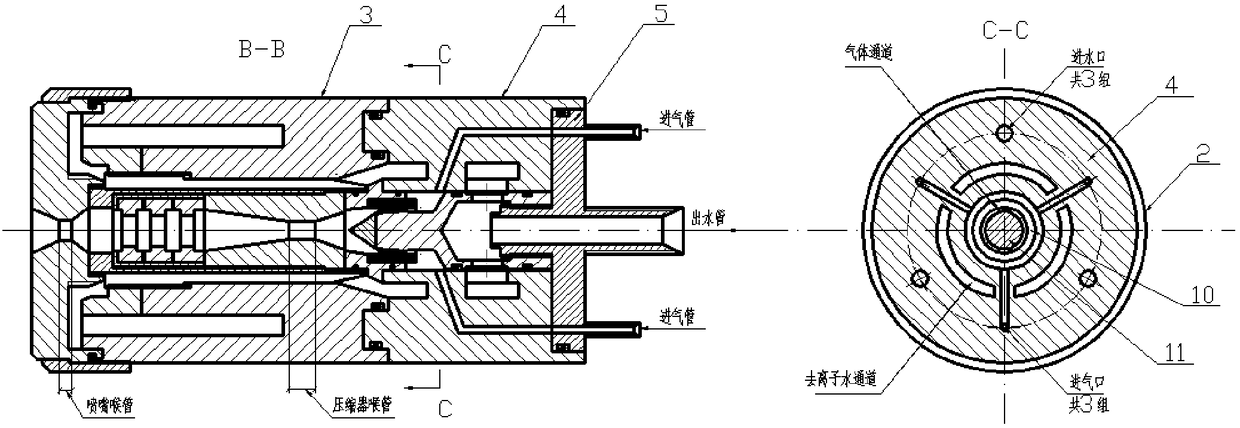

Novel hypersonic-speed high-enthalpy-value plasma gun and preparation process of WC-based composite coating layer

A technology of plasma spray gun and speed of sound, which is applied in metal material coating process, coating, molten spraying, etc., can solve the problems of shortened service life of electrodes, and achieve the effect of improving corrosion resistance, improving performance, and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. Pretreatment

[0056] The surface of the substrate 0Cr13Ni5Mo stainless steel is cleaned with deionized water, acetone and alcohol degreasing, dried, and sand blasted (30 mesh white corundum sand, sand blast pressure 0.6MPa), after the treatment, the surface meets the cleanliness requirement of Sa3 .

[0057] 2. Preheat the substrate. After preheating, the surface temperature of the substrate is about 100°C.

[0058] 3. The WC10Co4Cr nano-coating was sprayed with a new type of ultra-high-speed high-enthalpy plasma, the angle between the spray gun and the surface of the substrate was 90°, the spraying distance was 160mm, and the moving speed of the spray gun was 800mm / s.

[0059] 4. The main process parameters are adjusted as follows: power: 80KW, argon flow: 410SCFH, nitrogen flow: 100SCFH, hydrogen flow: 70SCFH, powder feeding volume: 4RPM, spraying distance: 160mm.

[0060] 5. Spray 16 times, and the final thickness of the coating is 250μm.

[0061] 6. Coating p...

Embodiment 2

[0064] 1. Pretreatment

[0065] The surface of the substrate 0Cr13Ni5Mo stainless steel is cleaned with deionized water, acetone and alcohol degreasing, dried, and sand blasted (30 mesh white corundum sand, sand blast pressure 0.6MPa), after the treatment, the surface meets the cleanliness requirement of Sa3 .

[0066] 2. Preheat the substrate. After preheating, the surface temperature of the substrate is about 100°C.

[0067] 3. The WC12Co nano-coating is sprayed with a new type of ultra-high-speed high-enthalpy plasma, the angle between the spray gun and the surface of the substrate is 90°, the spraying distance is 160mm, and the moving speed of the spray gun is 800mm / s.

[0068] 4. The main process parameters are adjusted as follows: power: 95KW, argon gas flow: 410SCFH, nitrogen gas flow: 110SCFH, hydrogen gas flow: 80SCFH, powder feeding volume: 3RPM, spraying distance: 160mm.

[0069] 5. Spray 18 times, and the final thickness of the coating is 250μm.

[0070] 6. Coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com