High-hardness wear-resistant corrosion-resistant steel plate for slurry dredging and production method thereof

A production method and anti-corrosion technology, which is applied in the field of low-alloy steel manufacturing, can solve the problems of poor anti-corrosion performance, high cost, and increase the weight loss of materials due to abrasion, and achieve good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with embodiment.

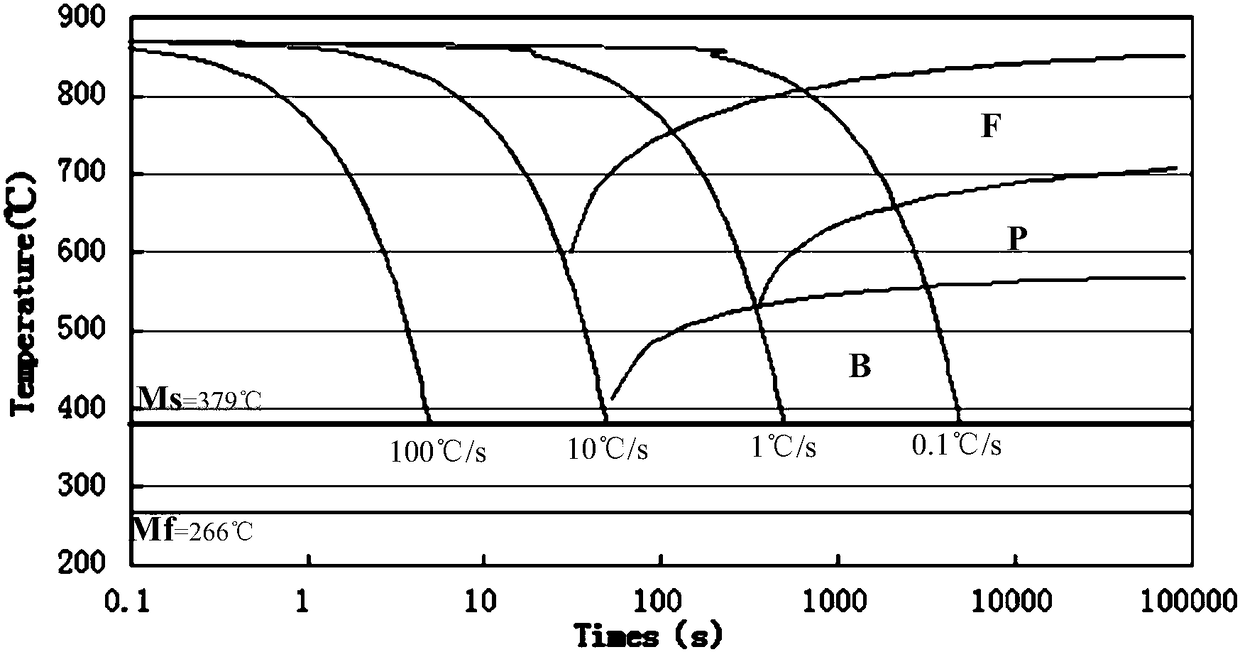

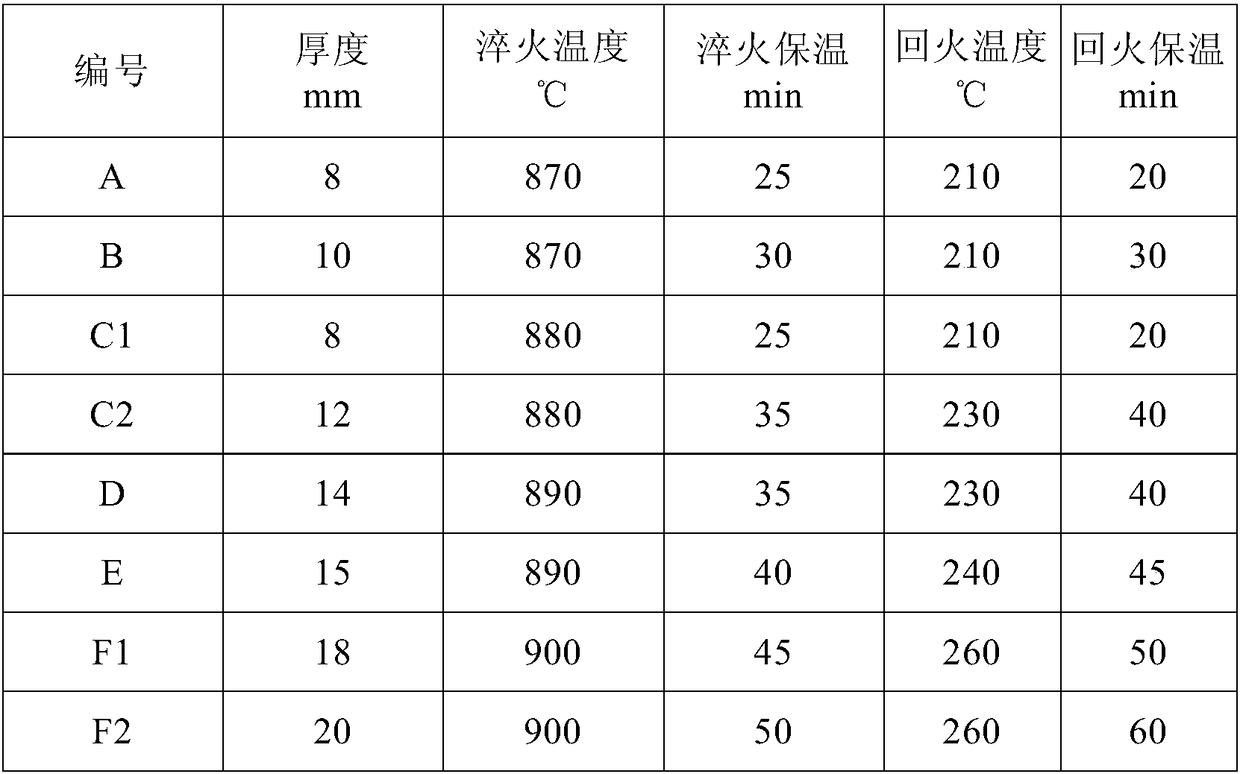

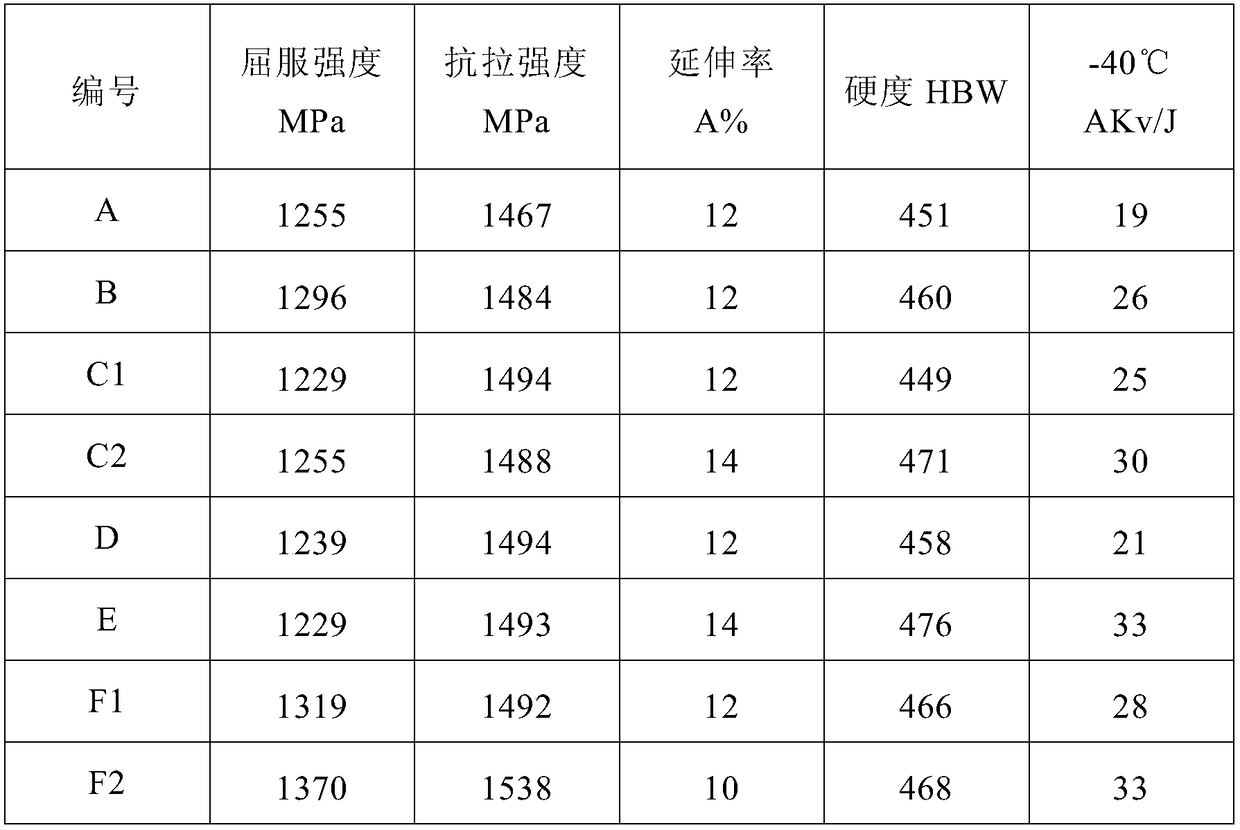

[0054] According to the chemical composition requirements of the corrosion-resistant steel plate involved in the present invention, steel plates with different thickness specifications are prepared. The chemical composition of the corrosion-resistant steel plate in the embodiment of the present invention is shown in Table 1, and the production process parameters are shown in Table 2.

[0055] The production method of the wear-resistant steel plate of the embodiment of the present invention is:

[0056] Deep desulfurization of molten iron (to ensure low S content in steel) → converter top-bottom compound blowing (control C content) → refining outside the furnace → continuous casting (machine cleaning) → slab reheating → controlled rolling → controlled cooling → coiling Taking→uncoiling→straightening→slab cutting→heat treatment (quenching+tempering)→finishing→delivery.

[0057] Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com