Underwater repairing coating material for concrete structure

A technology of concrete structure and coating materials, applied in the field of coatings, can solve the problems of difficult balance of resistance to dispersion and fluidity of repair materials, poor underwater construction performance, and unsatisfactory durability, etc., to achieve short curing time and fluidity Good, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

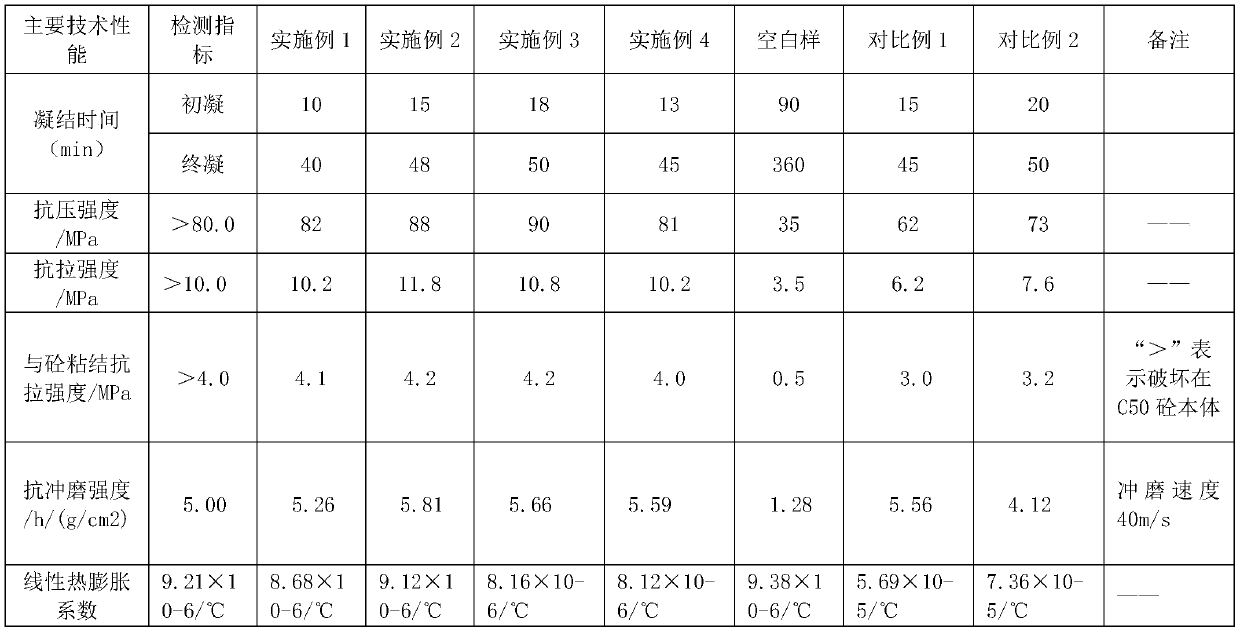

[0030] Table 1 Embodiment 1-4 each component raw material and its mass percentage content

[0031]

[0032] According to the raw material ratio in Table 1, prepare the concrete structure underwater repair coating material,

[0033] The preparation method is as follows:

[0034] River sand, cement and silica fume are pre-dry-mixed uniformly according to the target mixing ratio to make aggregate. Mix AG-70 low-viscosity four-functional epoxy resin, additives and aggregate evenly, add curing agent in proportion when using, and add different amounts of reactive diluent according to the fluidity requirements of the mortar during construction. The above materials were added in proportion to prepare the underwater repair coating materials for the environment-friendly solvent-free concrete structure of Examples 1-4 respectively.

Embodiment 5

[0035] Embodiment 5 Preparation of underwater repair coating material test block:

[0036] Put the concrete structure underwater repair coating material of the above-mentioned embodiments 1-4 into a plastic bucket, and stir evenly with a pistol drill; put the steel mold into water after cleaning, the water surface is higher than the surface of the mold by more than 20cm, and mix well The underwater repair coating material of the concrete structure is poured into the steel mold, and after 7 days of underwater curing, the mold is removed and the surface moisture of the sample is wiped dry.

[0037] According to the above method, the test blocks of the environmental protection solvent-free concrete structure underwater repair materials of Embodiment 1-4 were respectively obtained; the "blank sample" test blocks were obtained (raw materials and ratios are: cement: graded river sand: water=1: 3:0.6).

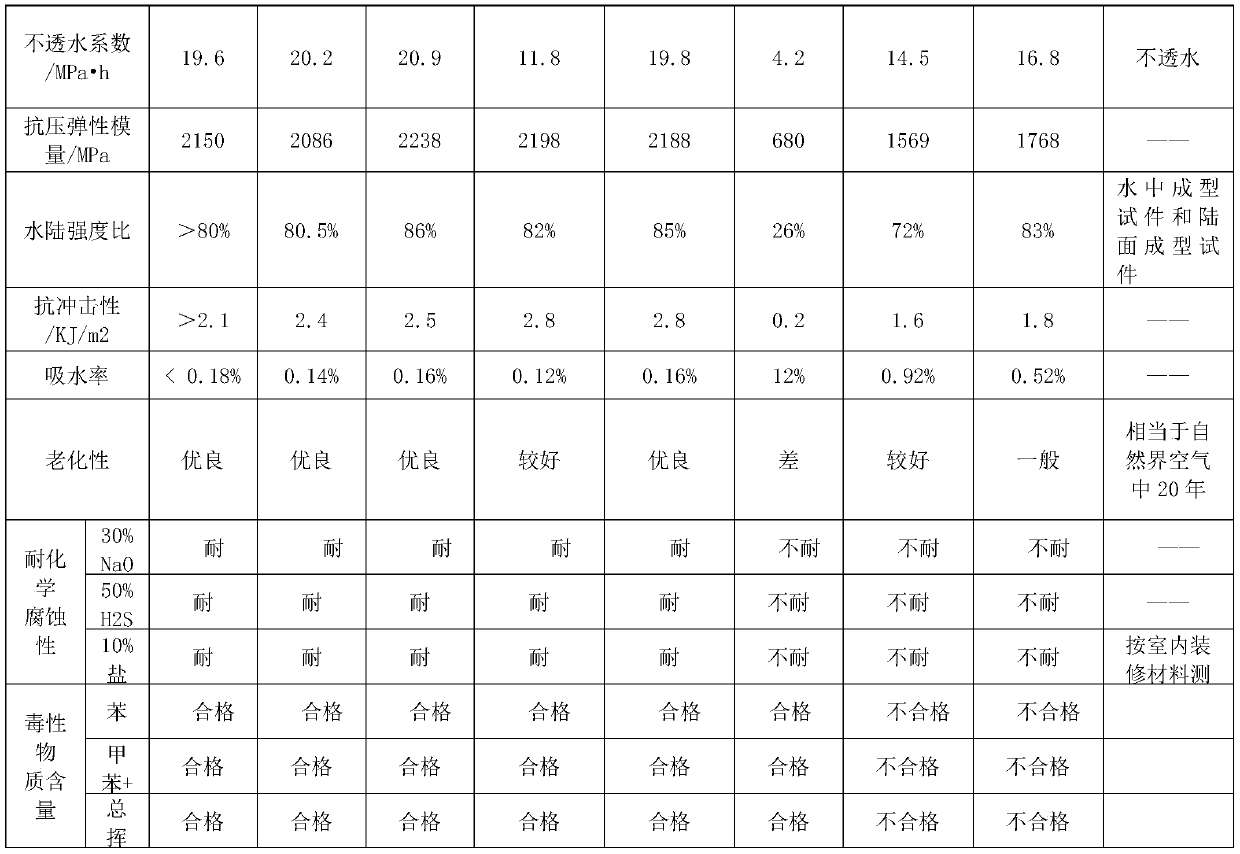

[0038] The mechanical properties of the test blocks obtained above were tested....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com