Self-lubricating double-layer fabric and application thereof

A double-layer fabric, self-lubricating technology, applied in the direction of fabric, multi-strand fabric, textile, etc., can solve the problems of self-lubricating bearing failure, thin single-layer fabric thickness, failure of bearing moving parts, etc., and achieve good wear resistance. , the effect of high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

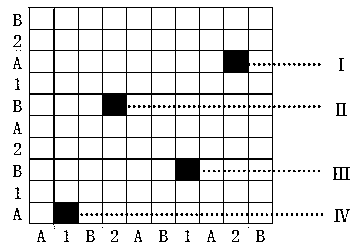

Image

Examples

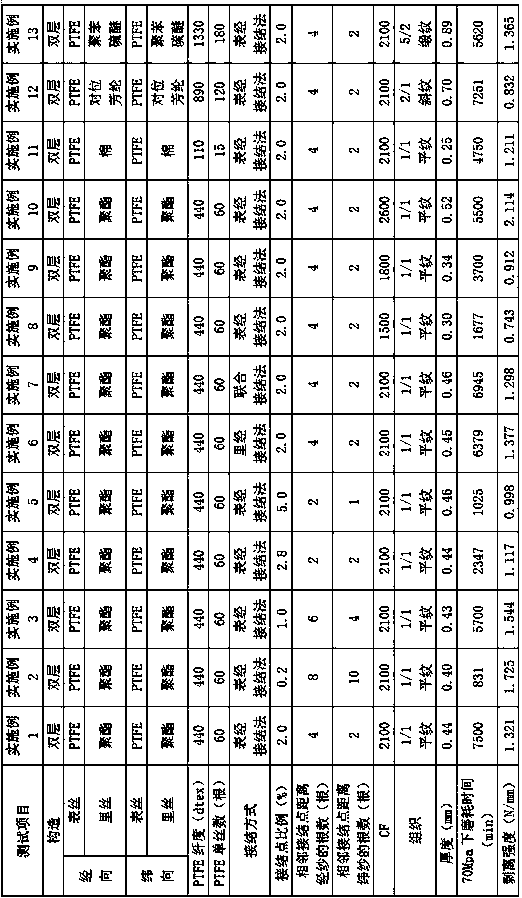

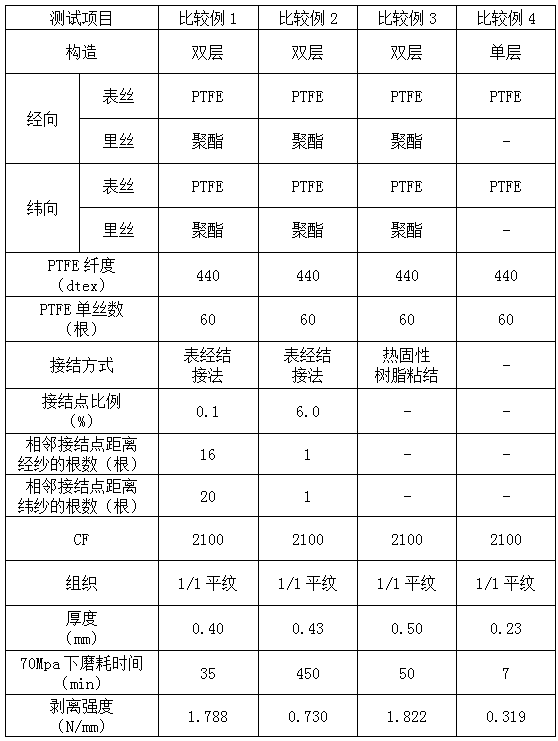

Embodiment 1

[0054] The surface warp and surface weft yarns are all made of polytetrafluoroethylene filaments with a denier of 440dtex and 60 filaments, and the inner warp and weft yarns are all polyester fibers with a denier of 110dtex and 48 filaments. The surface layer and the inner layer are set to adopt 1 / 1 plain weave, and the above-mentioned polytetrafluoroethylene fiber layer and the polyester fiber layer are bonded together by the surface warp bonding method, and then weaved by a rapier loom to obtain a covering Self-lubricating double layer fabric with factor 2100. In the double-layer fabric, the number of junction points in a complete loop organization accounts for 2.0% of the total number of stitches, and there are at least 4 warp yarns and 2 weft yarns between two adjacent junction points. The prepared self-lubricating double-layer fabric was placed in an environment with a temperature of 20 ± 2°C and a humidity of 65 ± 4% for humidity conditioning treatment, and the character...

Embodiment 2

[0056] The surface warp and surface weft yarns are all made of polytetrafluoroethylene filaments with a denier of 440dtex and 60 filaments, and the inner warp and weft yarns are all polyester fibers with a denier of 110dtex and 48 filaments. The surface layer and the inner layer are set to adopt 1 / 1 plain weave, and the above-mentioned polytetrafluoroethylene fiber layer and the polyester fiber layer are bonded together by the surface warp bonding method, and then weaved by a rapier loom to obtain a covering Self-lubricating double layer fabric with factor 2100. In the double-layer fabric, the number of joints within a complete loop organization accounts for 0.2% of the total number of weaves, and the distance between two adjacent joints is at least 8 warp yarns and 10 weft yarns. The prepared self-lubricating double-layer fabric was placed in an environment with a temperature of 20 ± 2°C and a humidity of 65 ± 4% for humidity conditioning treatment, and the characteristics of...

Embodiment 3

[0058] The surface warp and surface weft yarns are all made of polytetrafluoroethylene filaments with a denier of 440dtex and 60 filaments, and the inner warp and weft yarns are all polyester fibers with a denier of 110dtex and 48 filaments. The surface layer and the inner layer are set to adopt 1 / 1 plain weave, and the above-mentioned polytetrafluoroethylene fiber layer and the polyester fiber layer are bonded together by the surface warp bonding method, and then weaved by a rapier loom to obtain a covering Self-lubricating double layer fabric with factor 2100. In the double-layer fabric, the number of joints within a complete loop organization accounts for 1.0% of the total number of weaves, and the distance between two adjacent joints is at least 6 warp yarns and 4 weft yarns. The prepared self-lubricating double-layer fabric was placed in an environment with a temperature of 20 ± 2°C and a humidity of 65 ± 4% for humidity conditioning treatment, and the characteristics of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com