Preparation method of ceramic mould plate

A technology for ceramic molds and mold plates, applied in the field of preparation of ceramic mold plates, can solve the problems of low mechanical strength, poor acid resistance, poor alkali resistance, rough surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

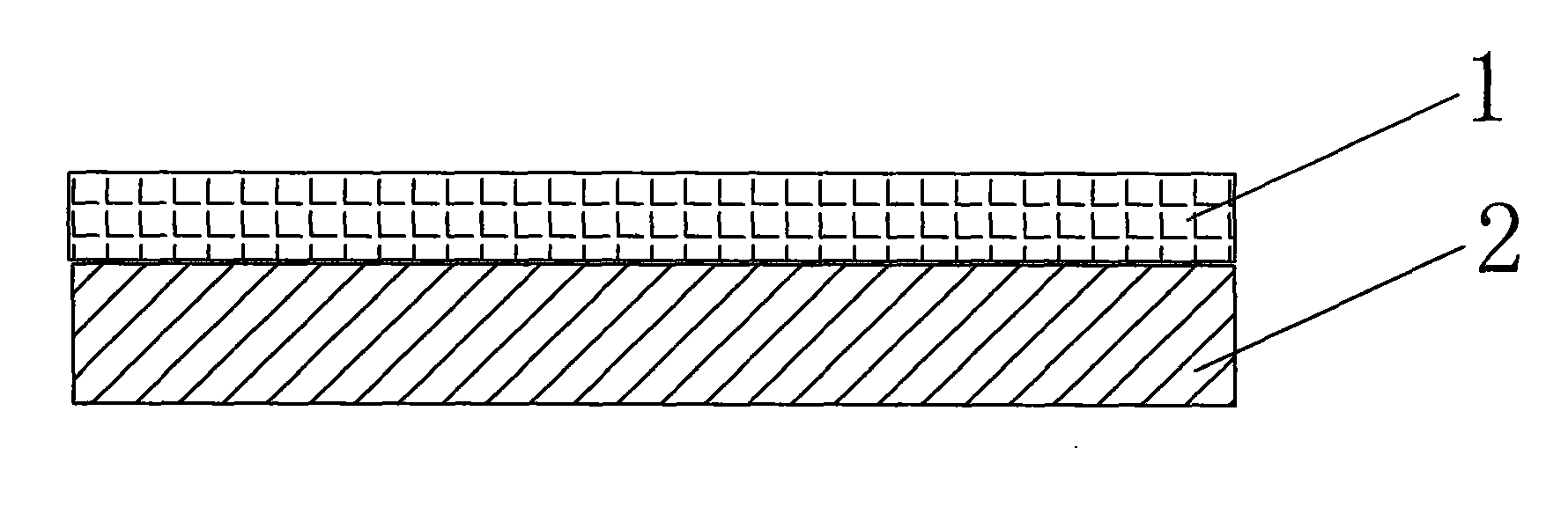

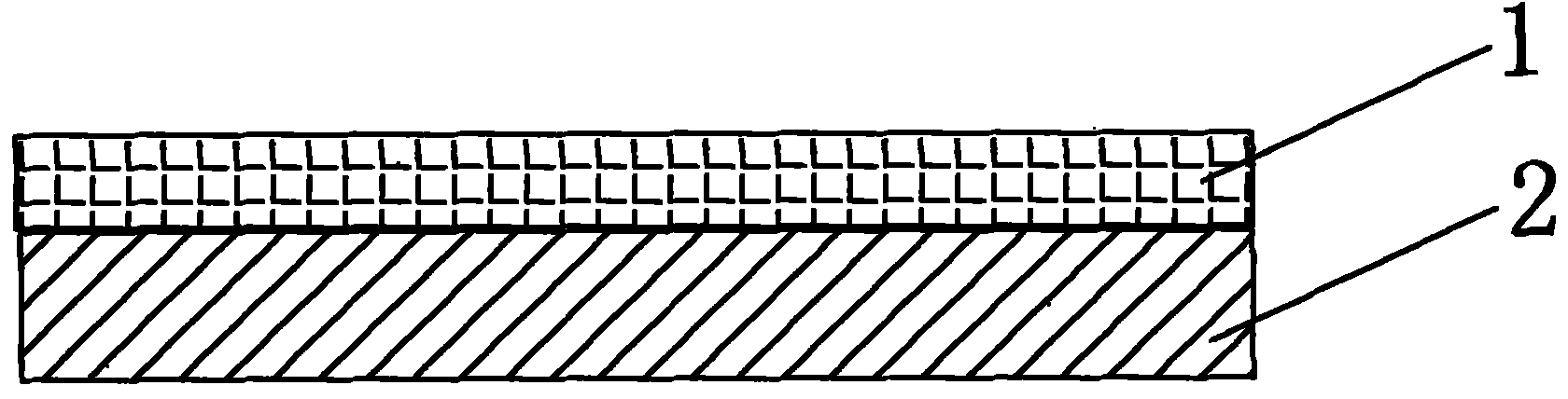

[0022] Such as figure 1 As shown, it is a schematic flow diagram of a ceramic mold plate preparation method in a preferred embodiment of the present invention. The present invention provides a kind of ceramic mold plate preparation method, comprising the following steps:

[0023] a. Mixing materials: 45-80% of ceramic aggregates, 0.5-15% of additives, and 10-40% of pore-enhancing agents are mixed with each other to form mixed raw materials;

[0024] b. Firing the above mixed raw materials at a firing temperature of 1200-1300°C, and then heat-preserving at a high temperature for 0.5-2.5 hours;

[0025] c. Forming with a forming method to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com