Cam shock wave double-stage planar steel ball reducer

A technology of reducer and shock wave, applied in the direction of belt/chain/gear, transmission device, transmission device parts, etc., can solve the problems of small single-stage flat steel ball reducer, not very suitable for application, and increased mechanism size, etc. Achieve the effect of reducing the weight of the whole machine, shortening the axial dimension and shortening the axial distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to detail the technical content, structural features, purpose and effect of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

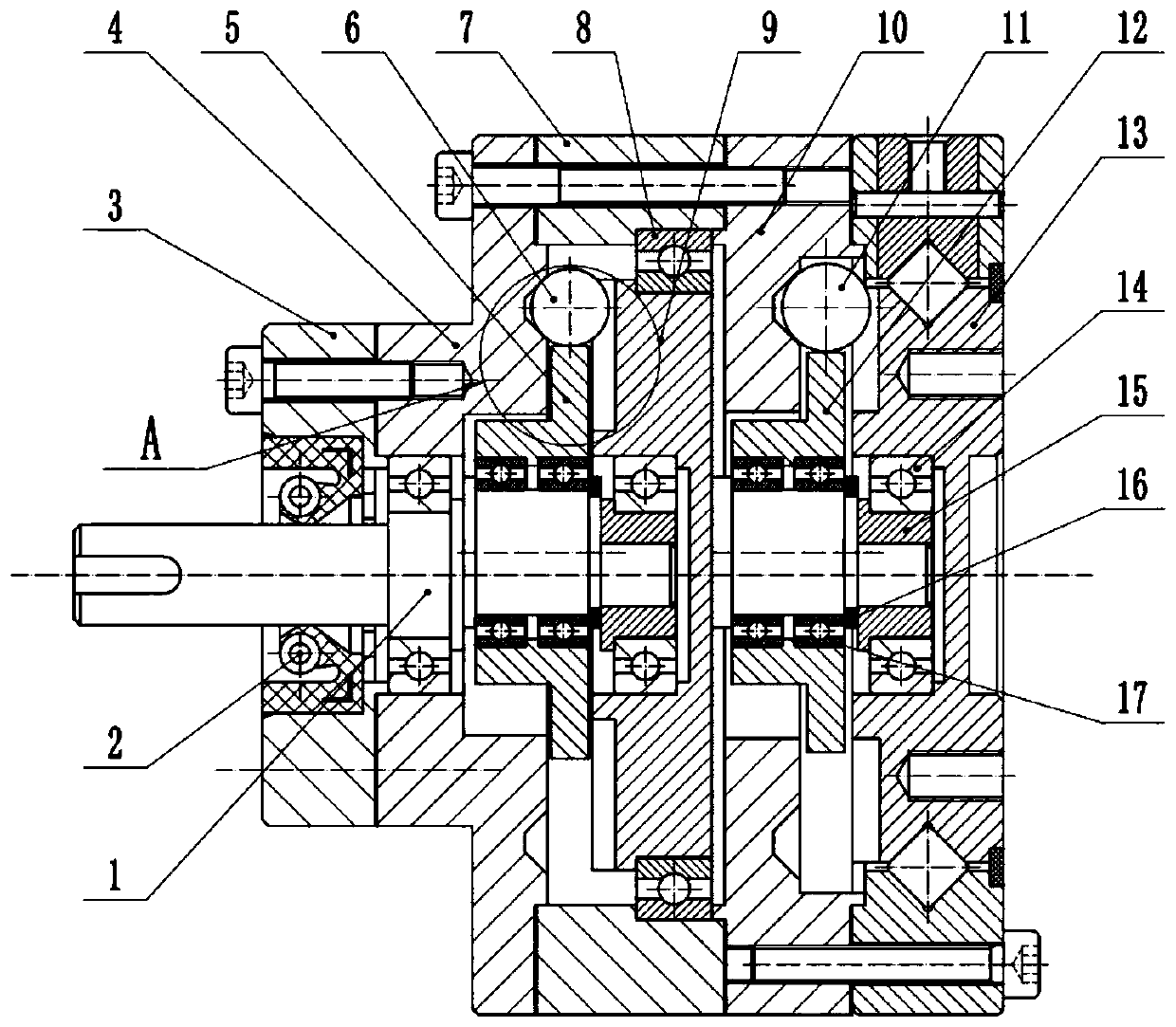

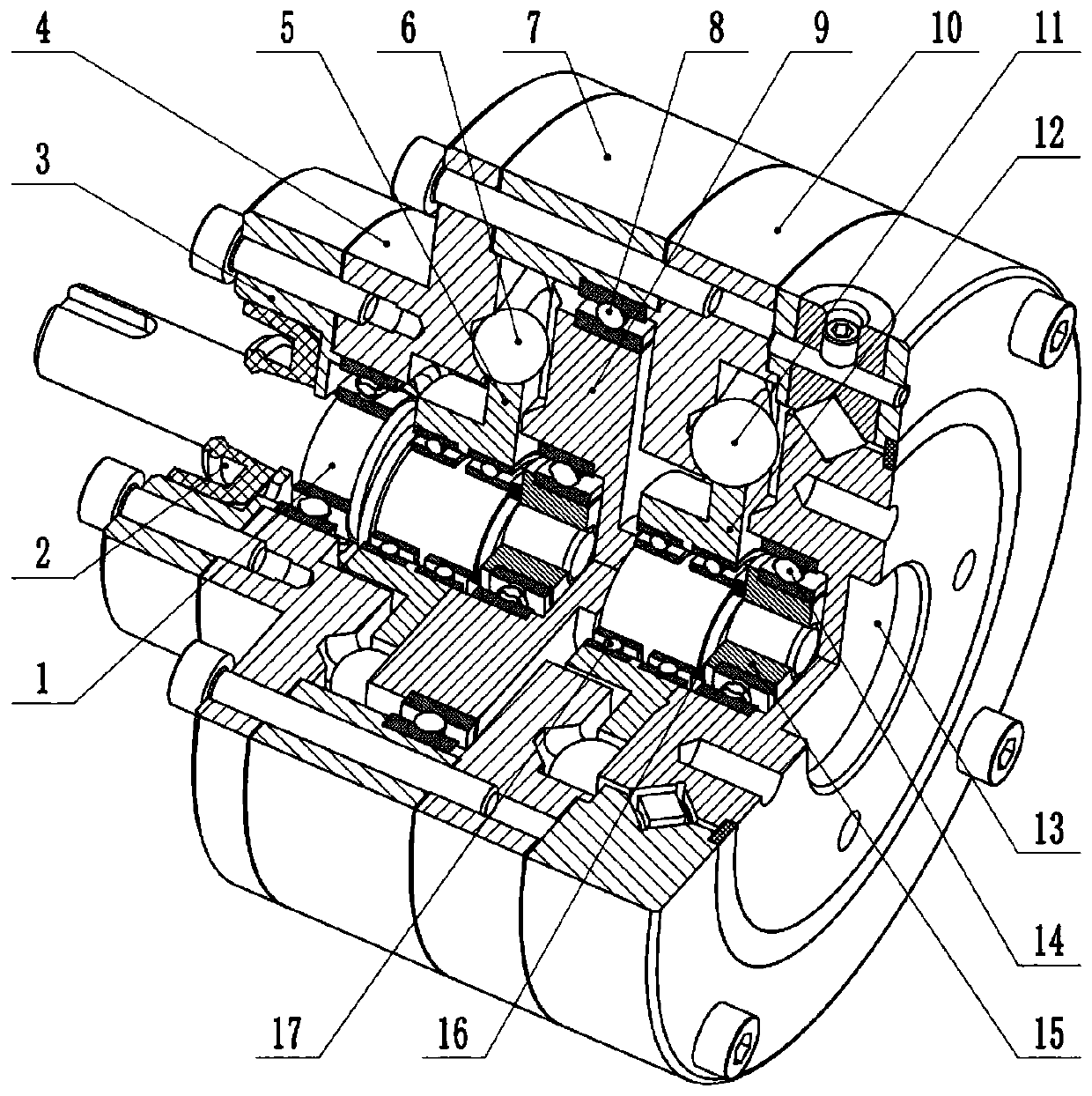

[0052] Cam shock wave type double-stage planar steel ball reducer of the present invention, such as figure 1 As shown, it includes input shaft 1, lip seal ring 2, left end cover 3, primary center wheel 4, primary shock cam 5, primary steel ball 6, housing 7, first thin-walled bearing 8, a Stage guide frame 9, secondary center wheel 10, secondary steel ball 11, secondary shock cam 12, cross roller bearing 13, deep groove ball bearing 14, sleeve cup 15, retaining ring 16 and second thin-walled bearing 17 .

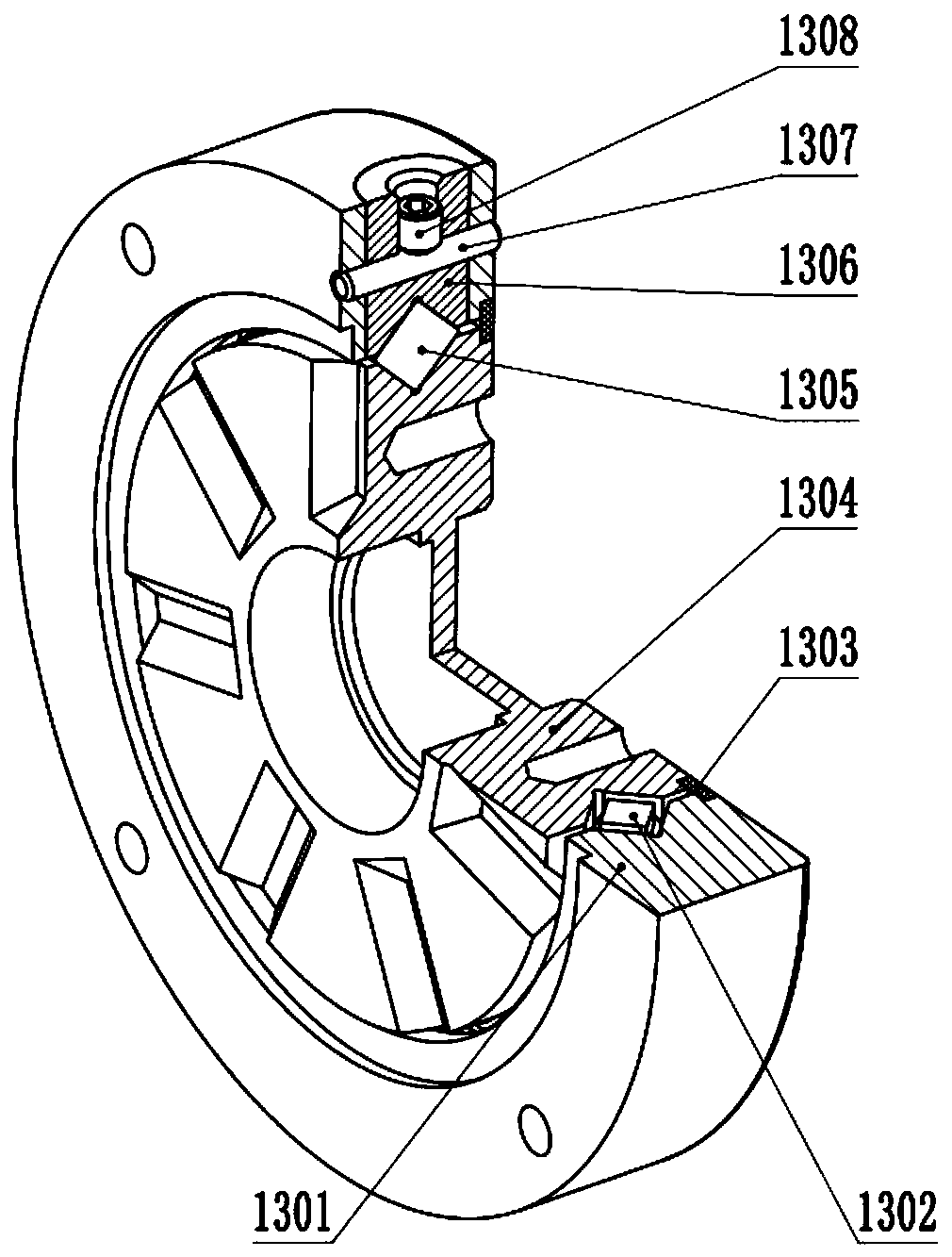

[0053] Such as figure 2 As shown, the left end cover 3 is connected with the left end of the primary center wheel 4 by screws, the right end of the primary center wheel 4 and the housing 7 are fixed on the left end of the secondary center wheel 10 by screws, and the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com