Three-point contact thrust ball bearing and design method

A thrust ball bearing and three-point contact technology, applied in the field of thrust bearings, can solve the problems of reduced service life of thrust ball bearings, large runout, and high bearing assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

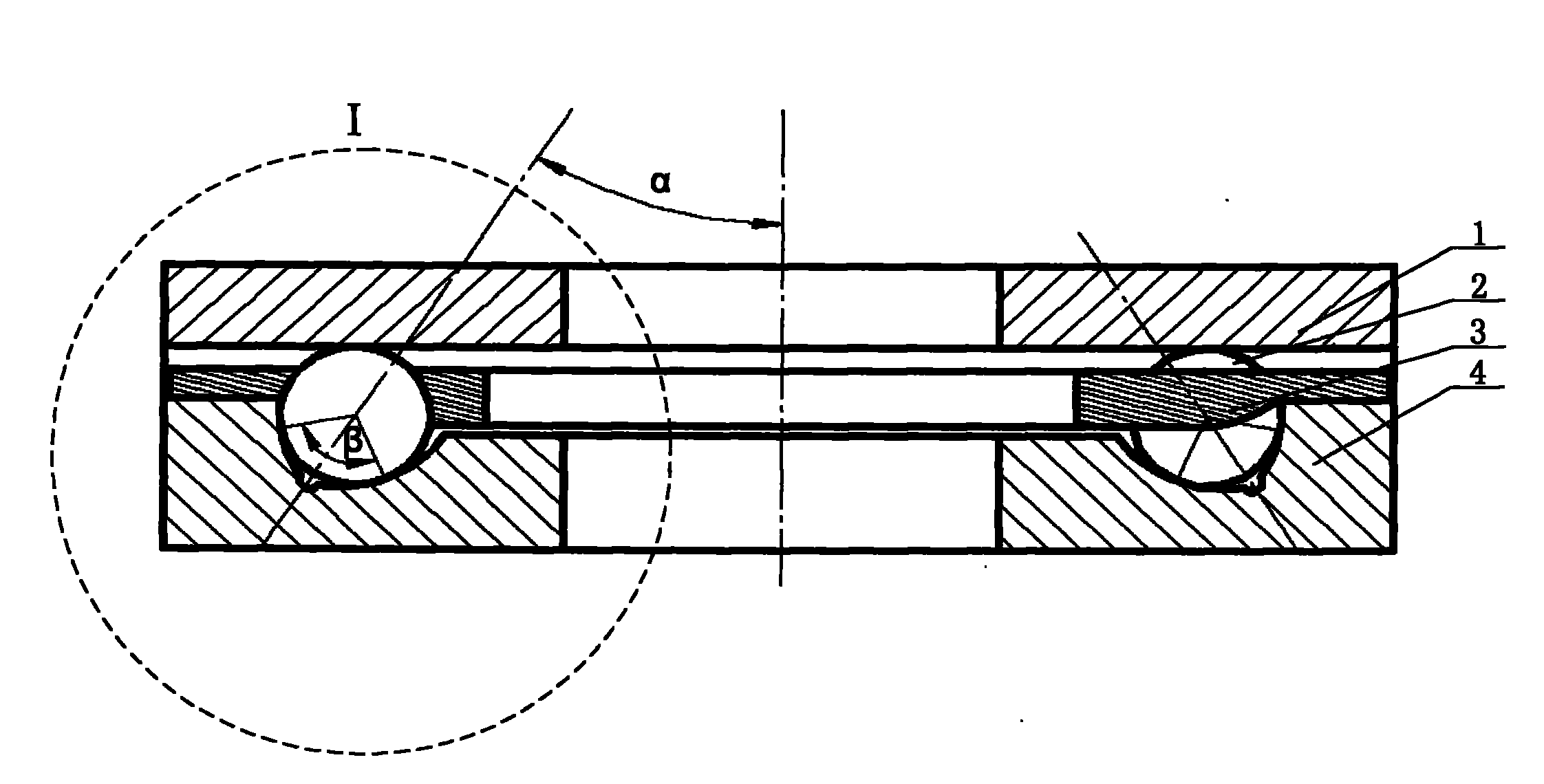

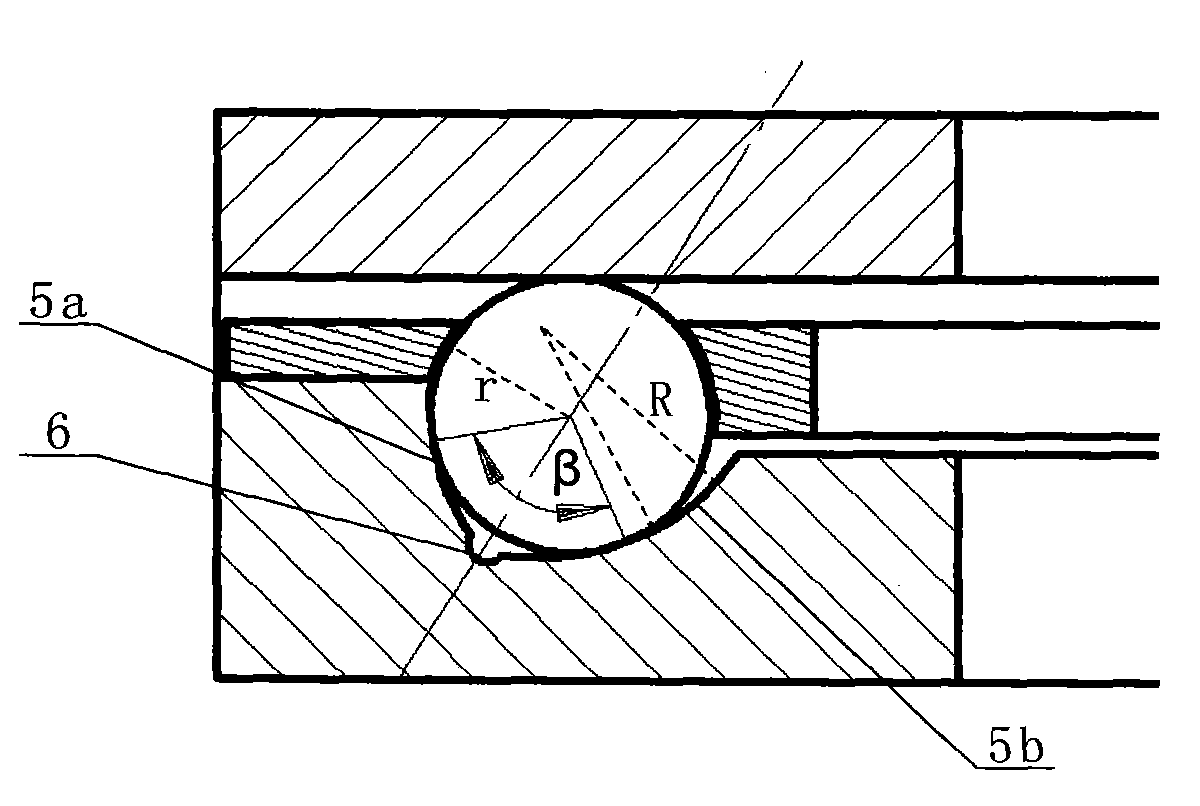

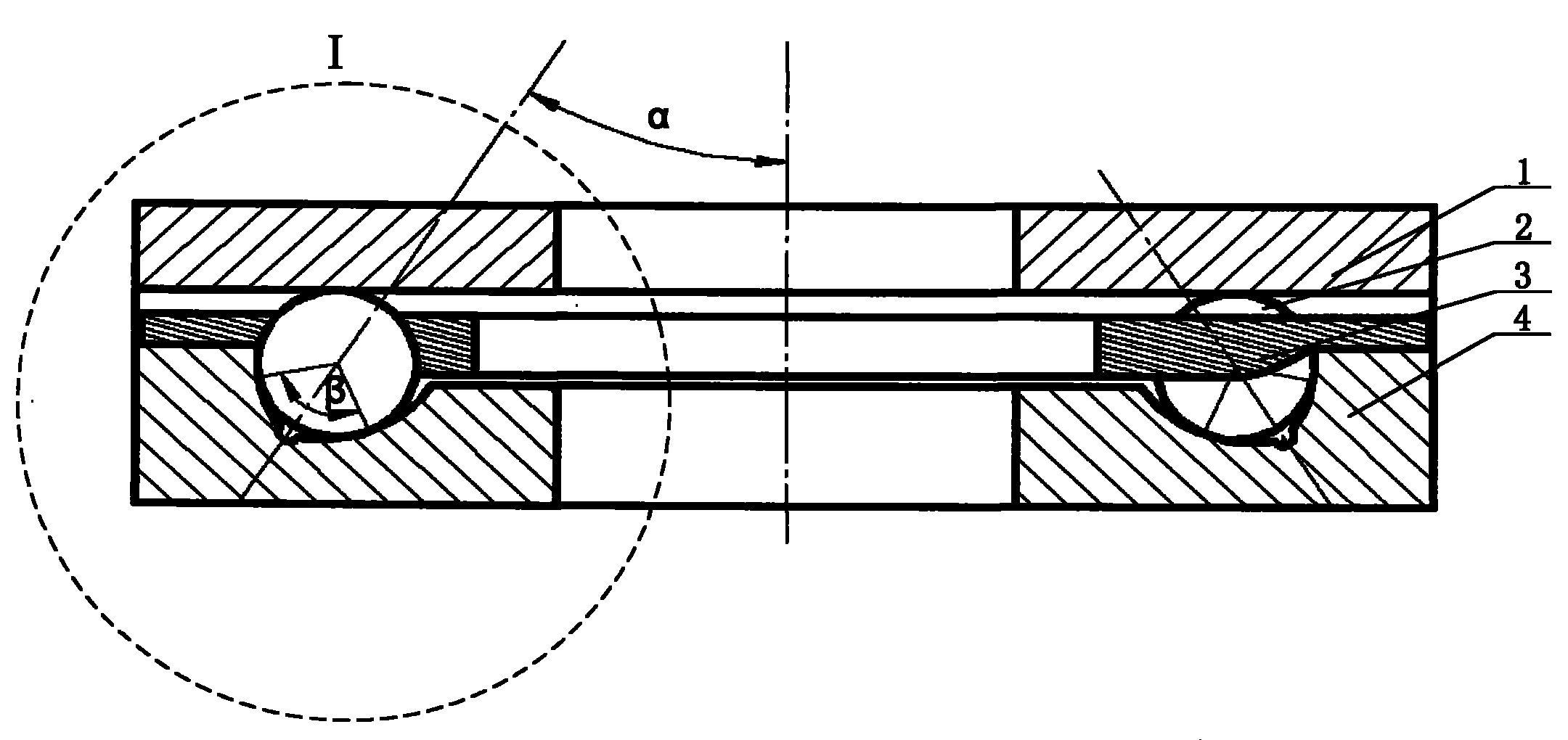

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 , 2 As shown in , the design method of the three-point contact thrust ball bearing of the present invention is based on improving the manufacturability of the bearing on the premise of ensuring the processing quality. The specific steps are as follows:

[0018] (1) Determine the outer dimensions of the bearing according to the allowable space of the bearing under specific working conditions, including the inner diameter d, outer diameter D and assembly height T of the bearing;

[0019] (2) Under the condition of ensuring the strength of the ring, the rated dynamic and static load of the bearing is used as the optimization objective function of the bearing design, and the steel ball diameter D of the bearing is determined w , the number of steel balls N and the pitch circle diameter D of the whole set of bearings pw ;

[0020] (3) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com