Patents

Literature

147results about "Gravity dams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

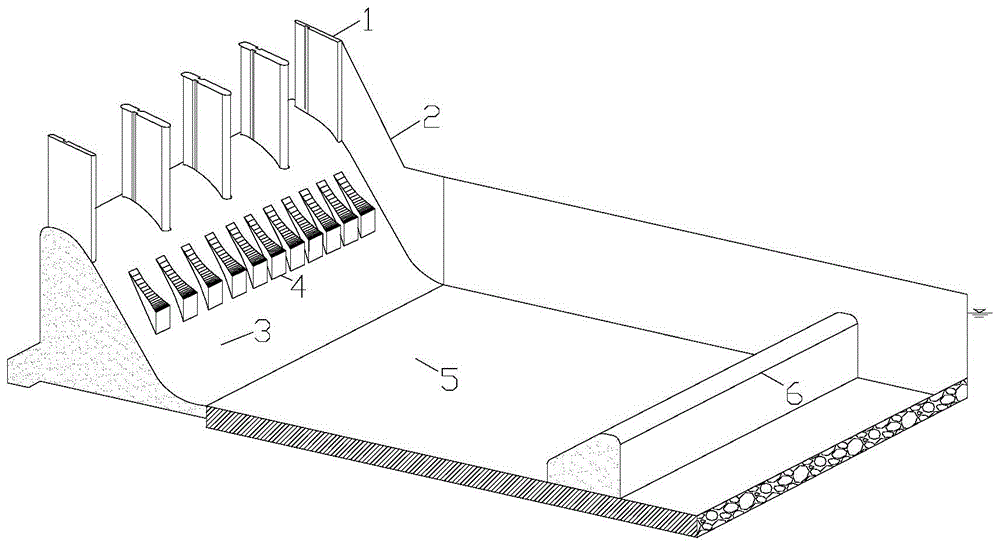

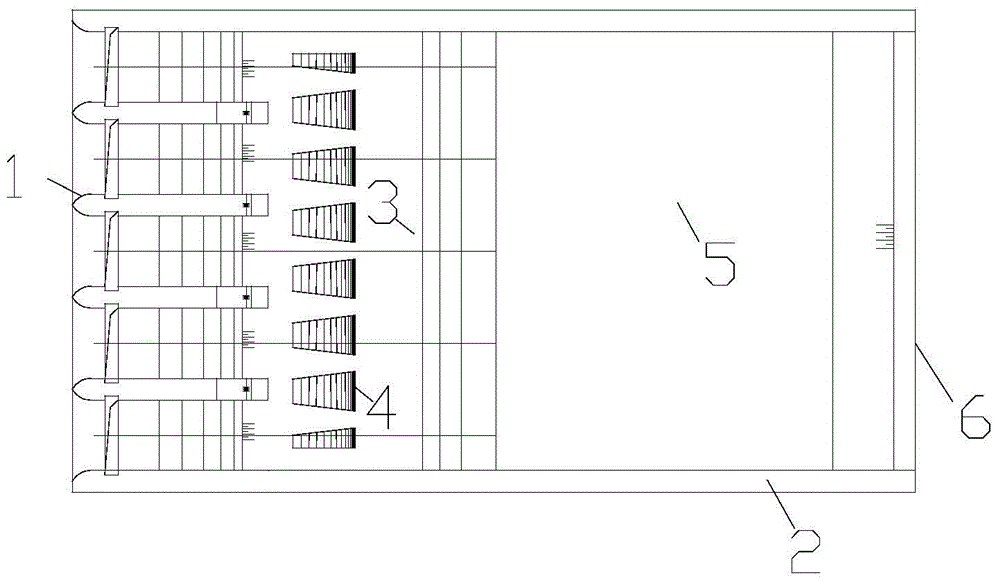

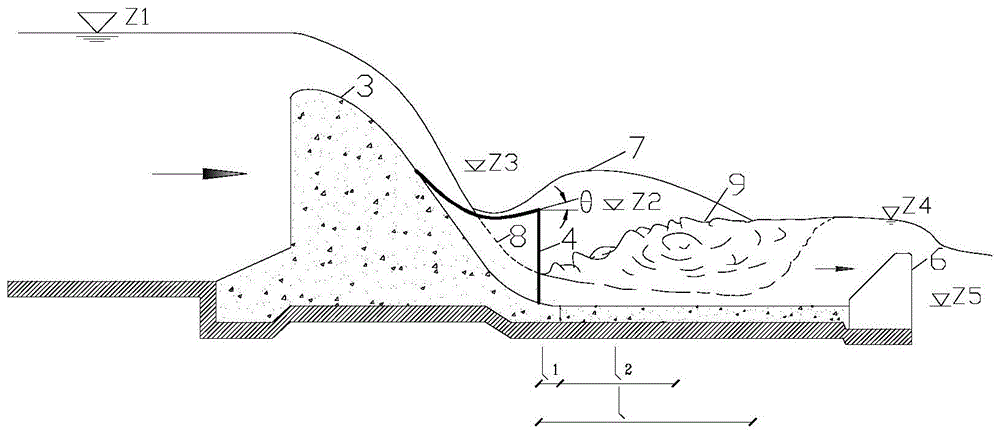

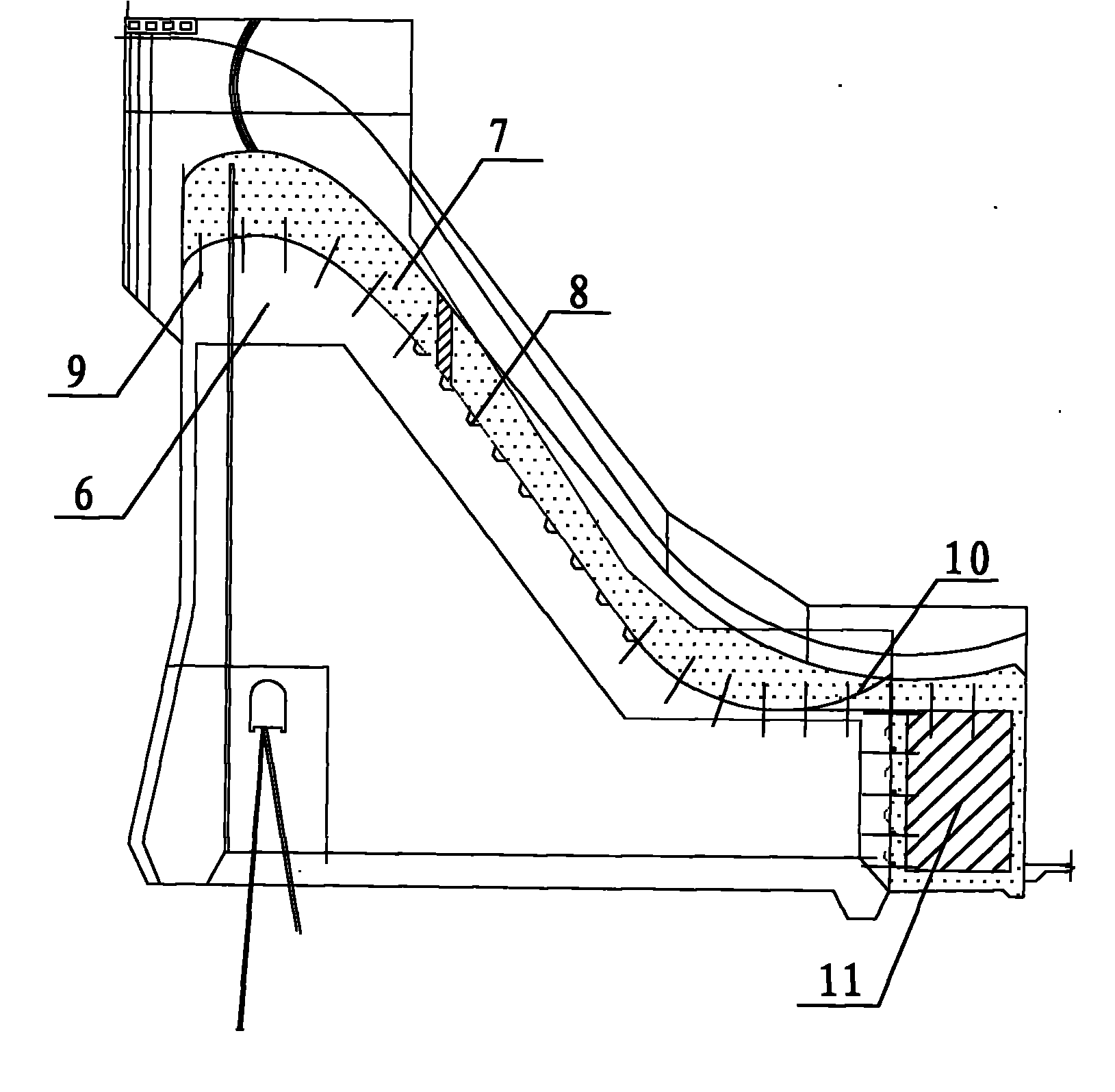

Overflow dam with dam face cantilever sills for current diversion and energy dissipation

ActiveCN104404926AImprove energy dissipation effectExtended Diffusion AngleBarrages/weirsGravity damsWater flowEngineering

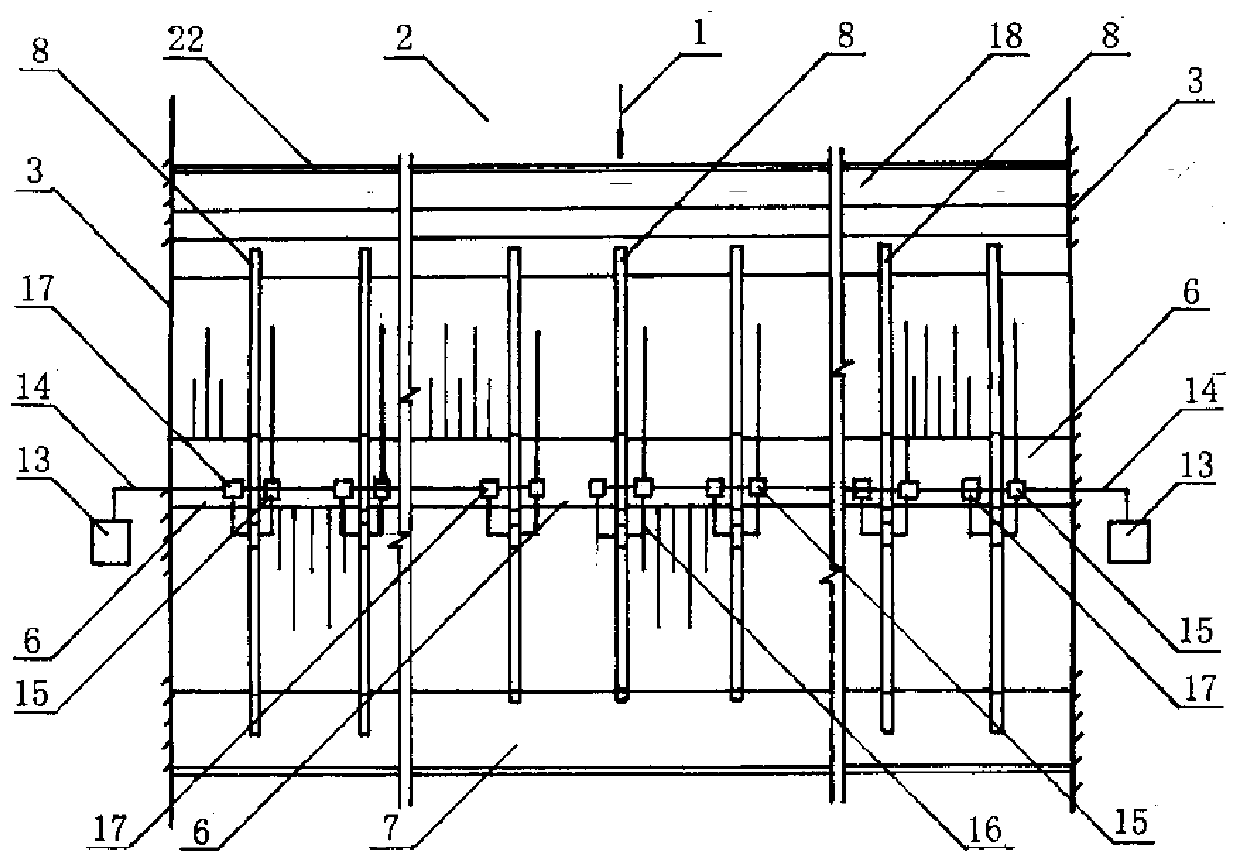

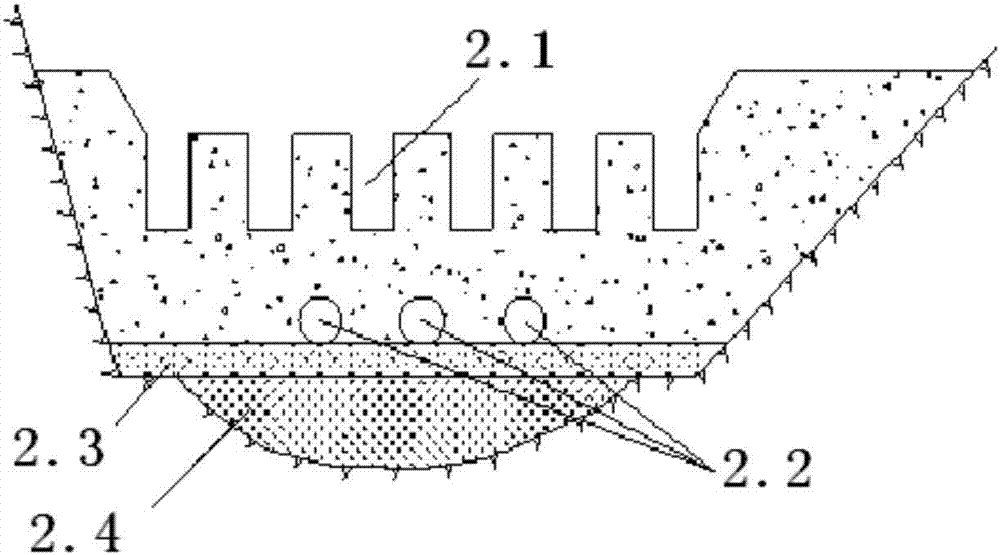

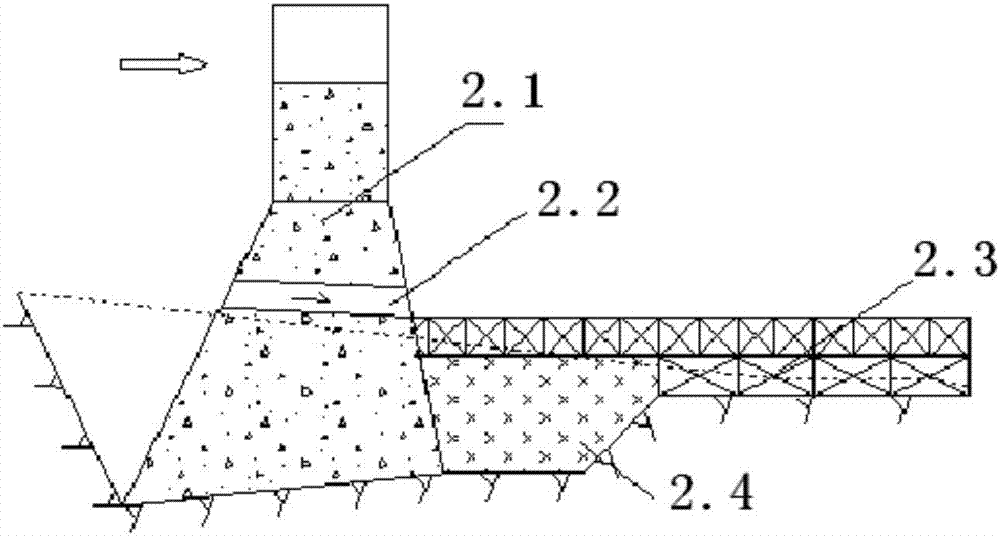

The invention discloses an overflow dam with dam face cantilever sills for current diversion and energy dissipation. The tank bottom of an energy dissipation tank is connected to the rear part of an overflow slop of the overflow dam. A protection side wall of the energy dissipation tank is connected to the rear part of a side wall of the overflow slope. A plurality of gate piers used for dividing a fluid flow-by area into a plurality spillway are arranged on the dam top of the overflow dam. The overflow slope of the overflow dam is provided with a plurality of current diversion cantilever sills distributed in a spaced manner, so that one part of water current coming from the spillways flows through the upper sill surfaces of the cantilever sills and enters the rear area of the energy dissipation tank in a form of cantilever current while the other part of water current flows into the front area of the energy dissipation tank through flow channels between each two cantilever sills and achieves energy dissipation through dispersion of the water current entering the energy dissipation tank. The energy dissipation mode provided by the invention is totally different from those in the prior art and is distinct in energy dissipation effect.

Owner:SICHUAN UNIV

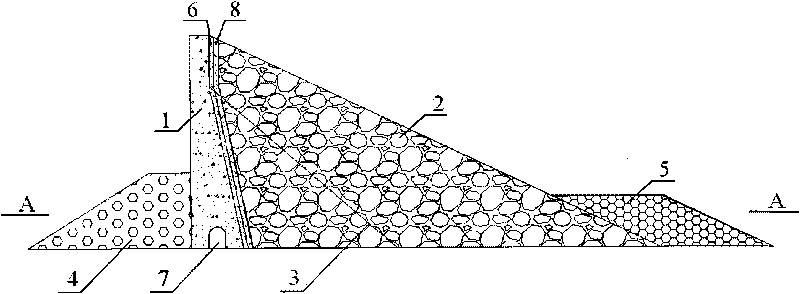

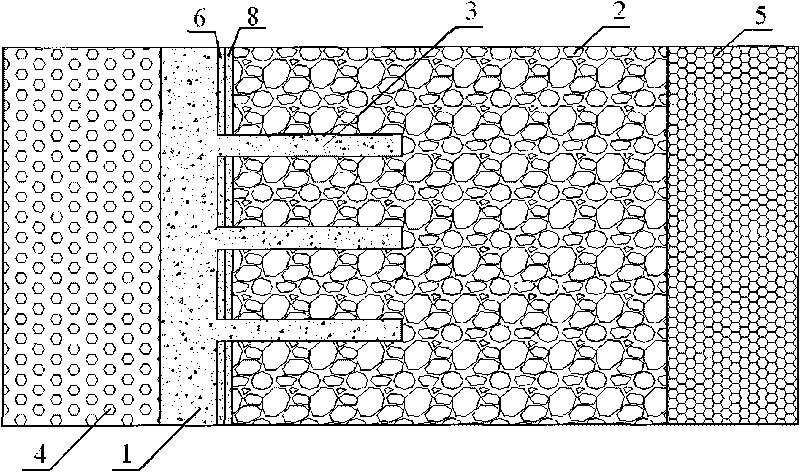

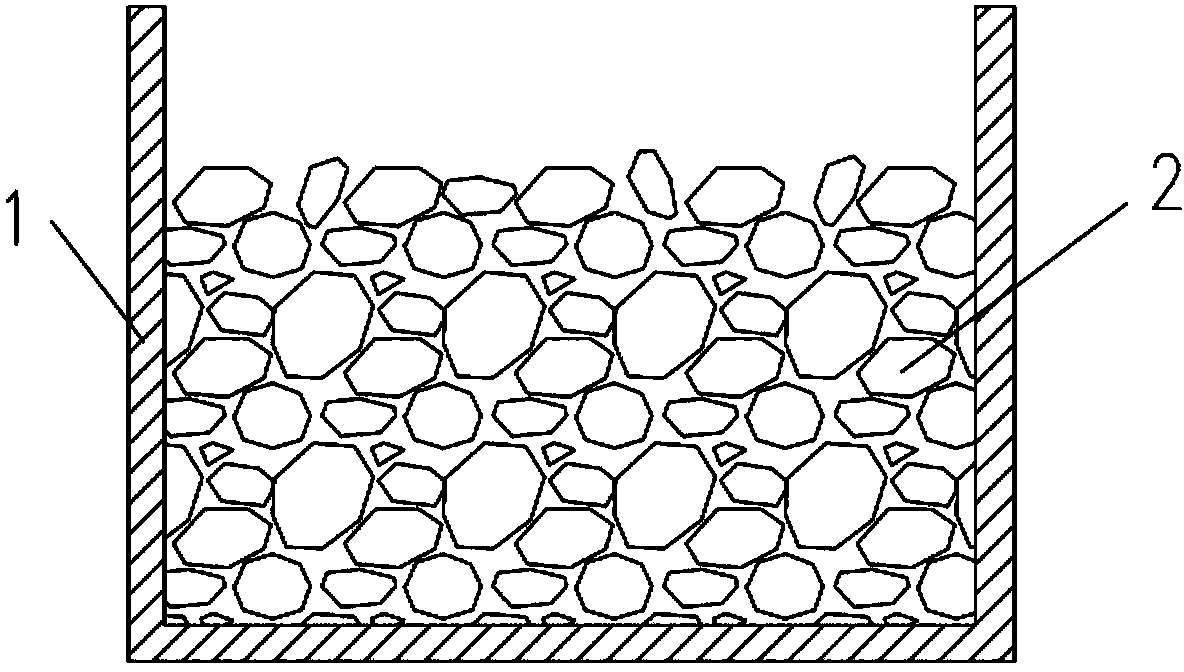

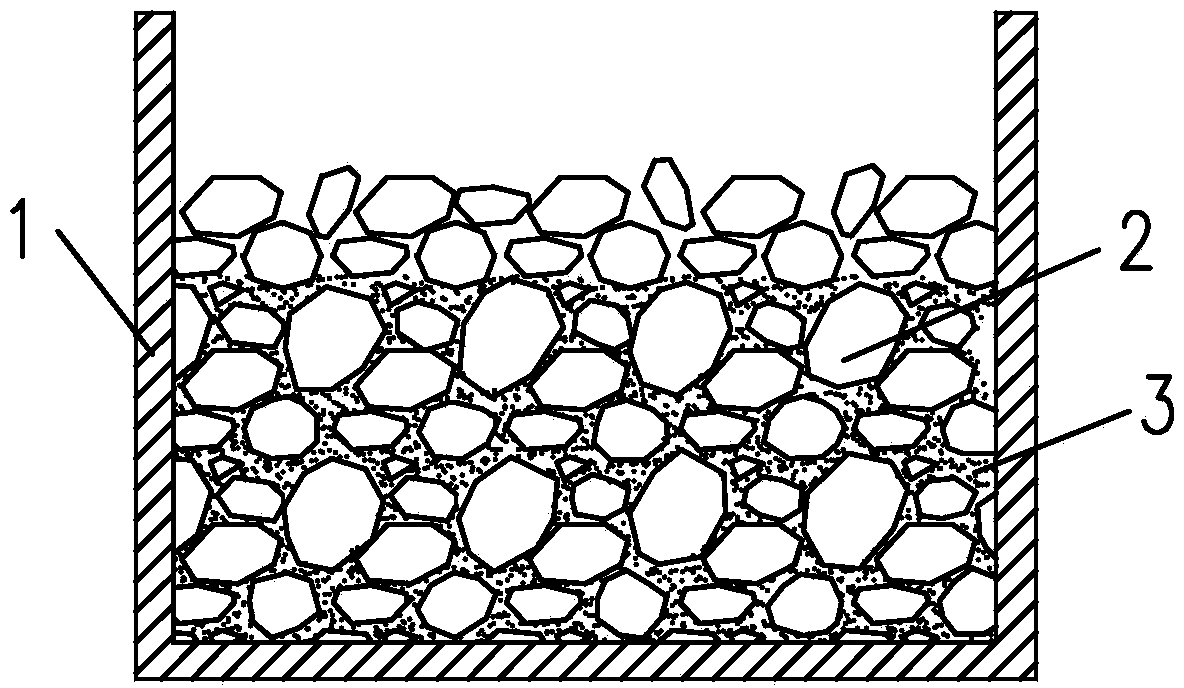

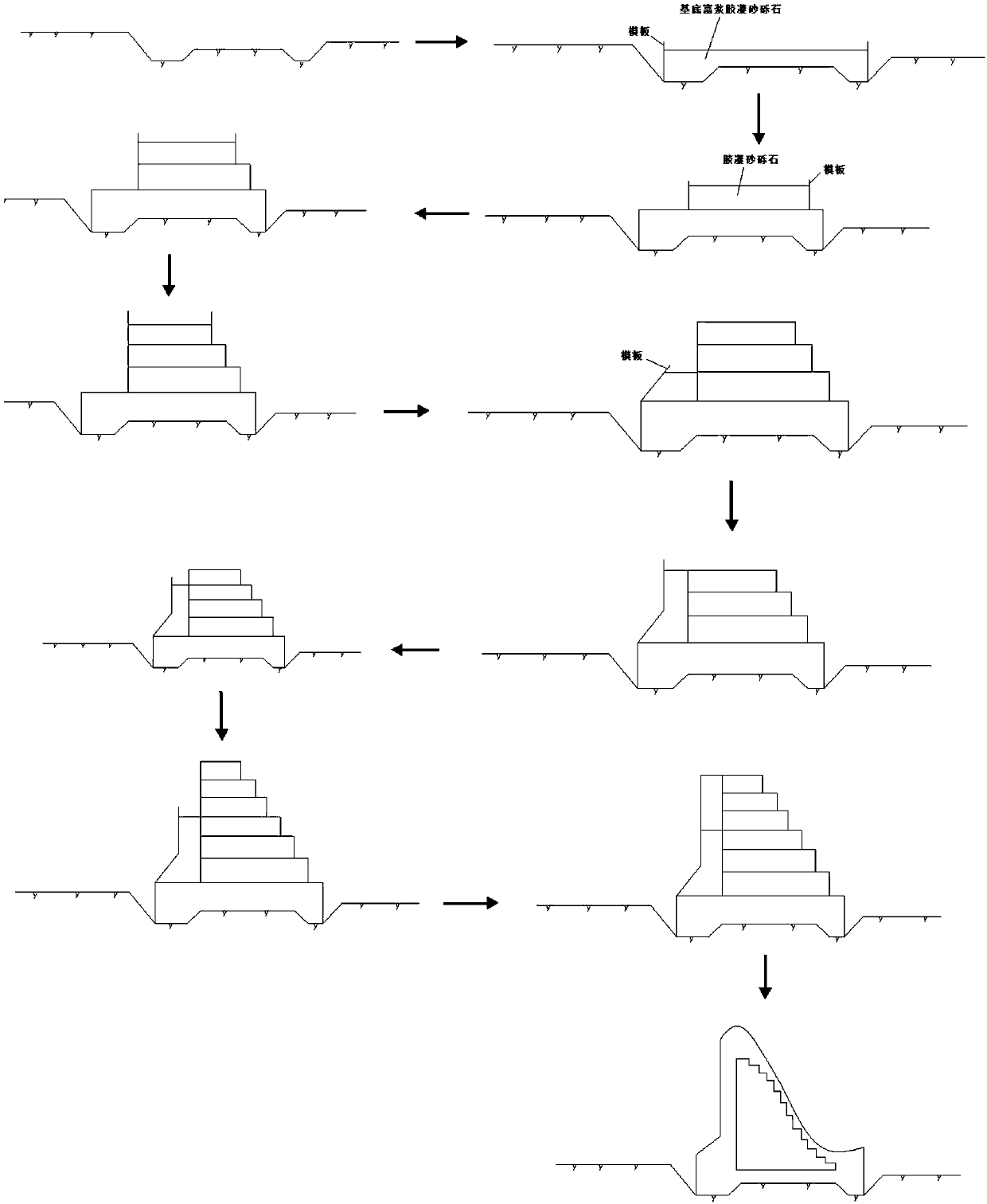

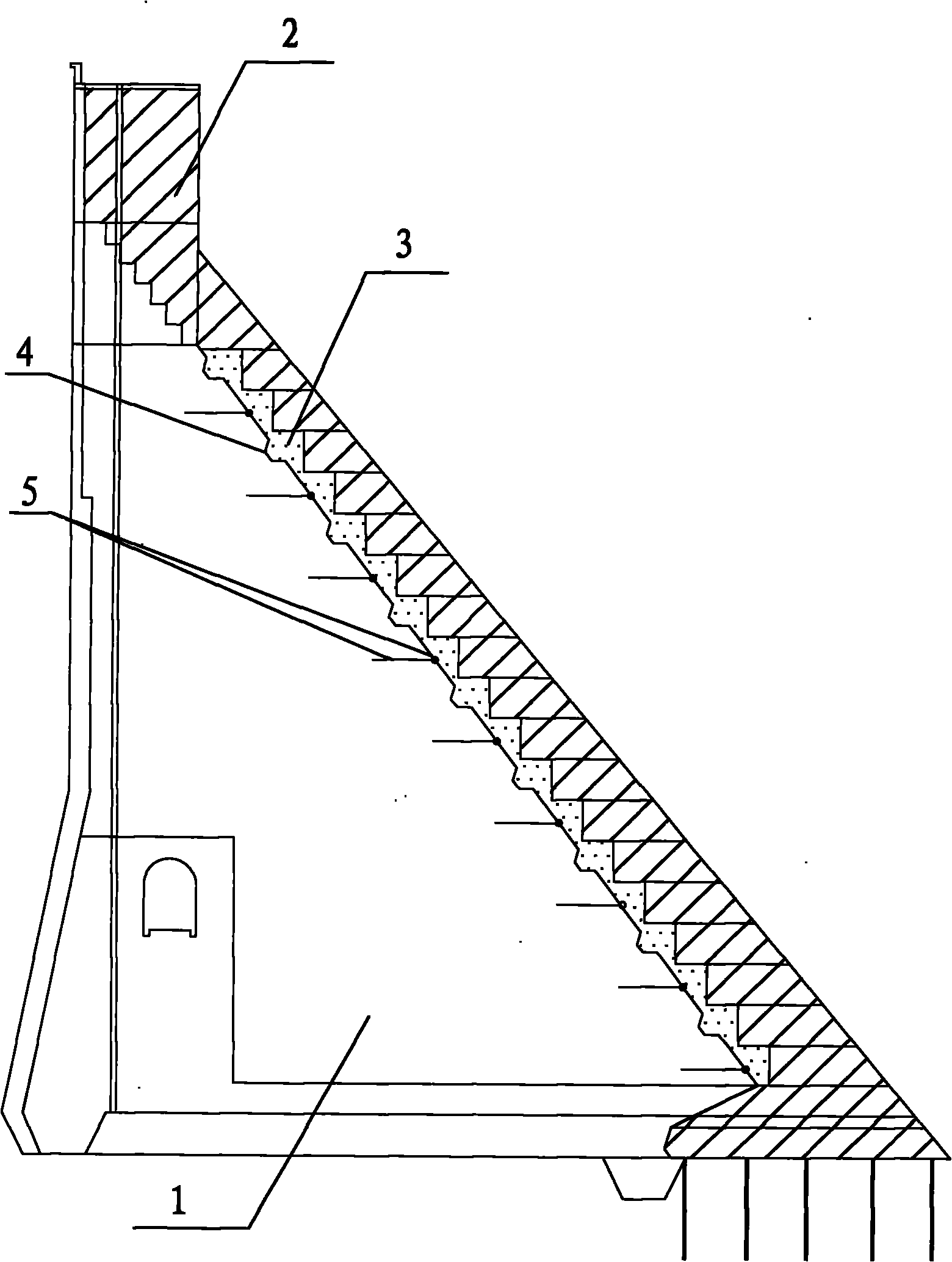

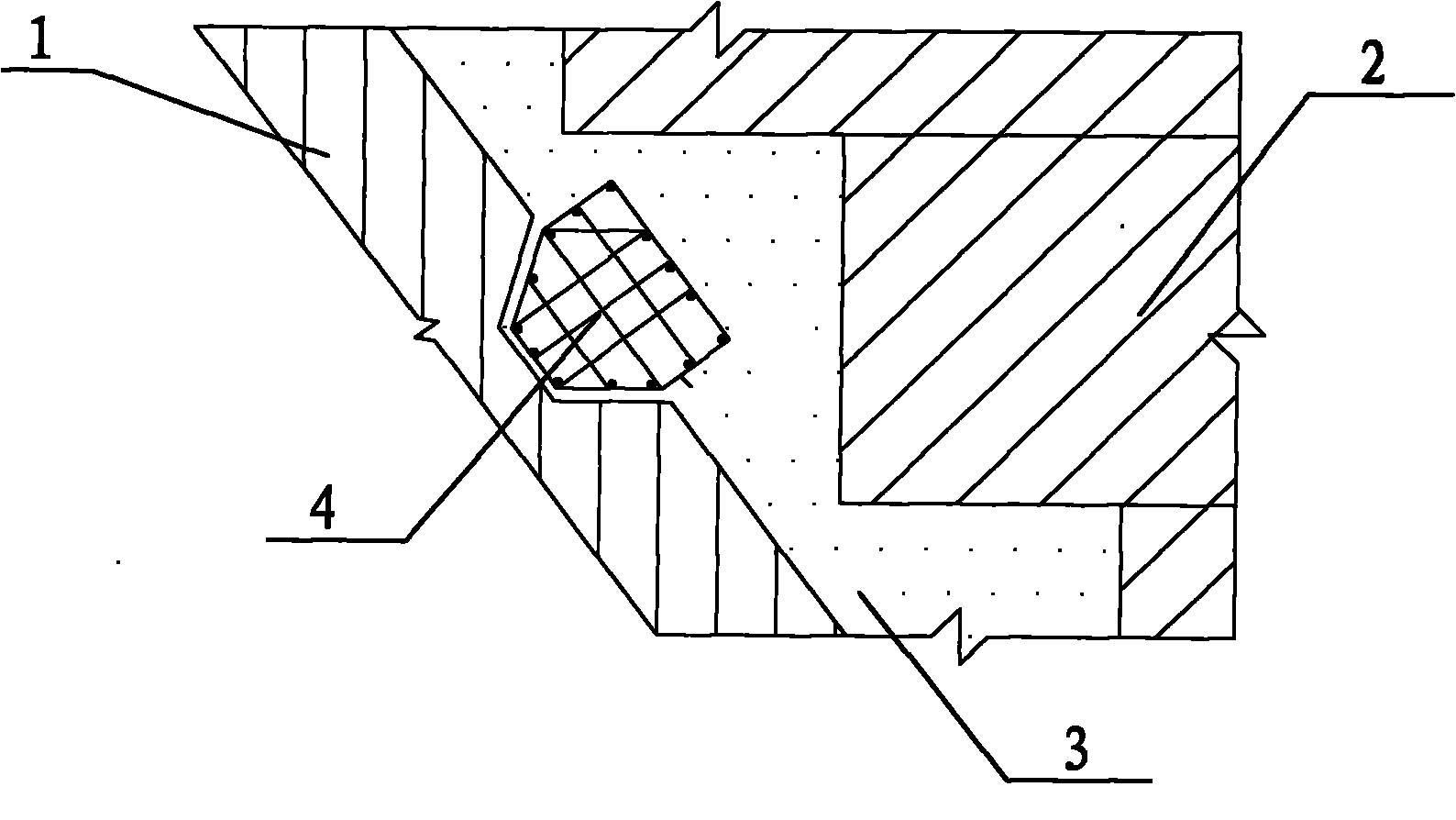

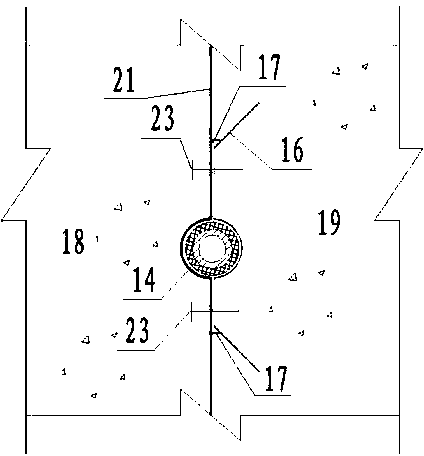

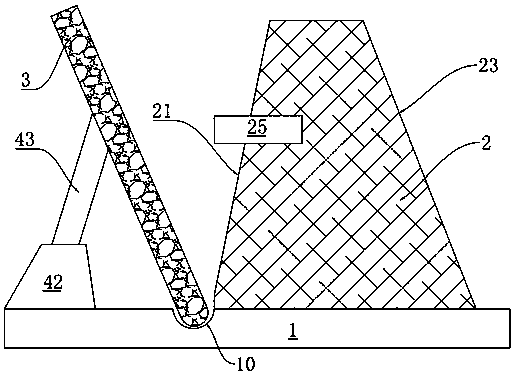

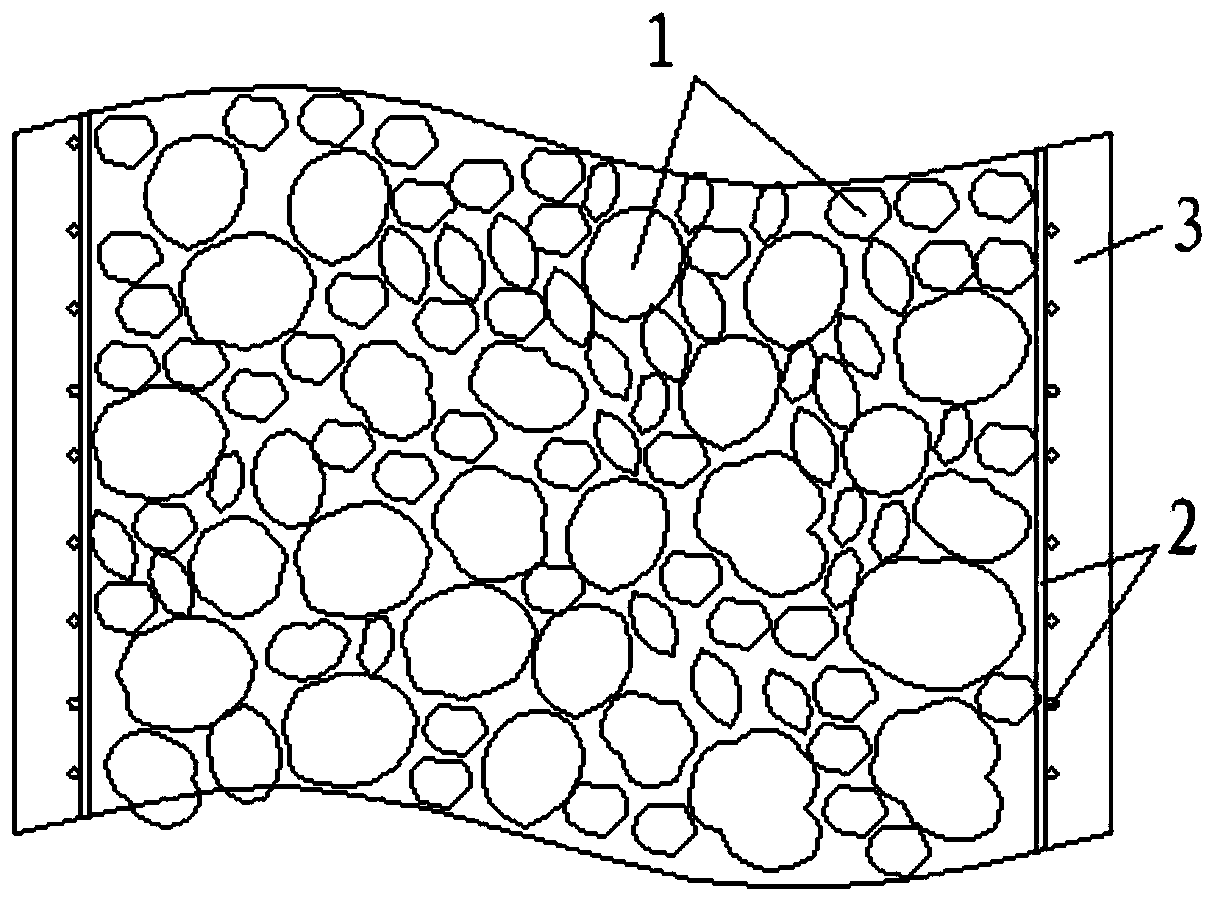

Concrete-enrockment mixed dam and construction method thereof

ActiveCN101718086ALower the volumeSave amountEarth-fill damsRock-fill damsManufacturing cost reductionEngineering

The invention discloses a concrete-enrockment mixed dam and a construction method thereof. The mixed dam has a novel dam body structure formed by combining a concrete dam body and a rockfill dam body. The dam body thereof comprises the concrete dam body, the rockfill dam body, pectinate connection section, a subcrust and a transition layer, wherein the pectinate connection section is arranged in the rockfill dam body, is subjected to one-piece pouring with the concrete dam body and is embedded into the rockfill dam body; and the subcrust and the transition layer are arranged between the concrete dam body and the rockfill dam body. The concrete-rockfill mixed dam absorbs the advantages of rock-fill dams and concrete dams, overcomes the disadvantages of the two dam types, and has the advantages of simple structure and convenient construction and manufacturing cost reduction, which is an economical and practical dam type.

Owner:HOHAI UNIV

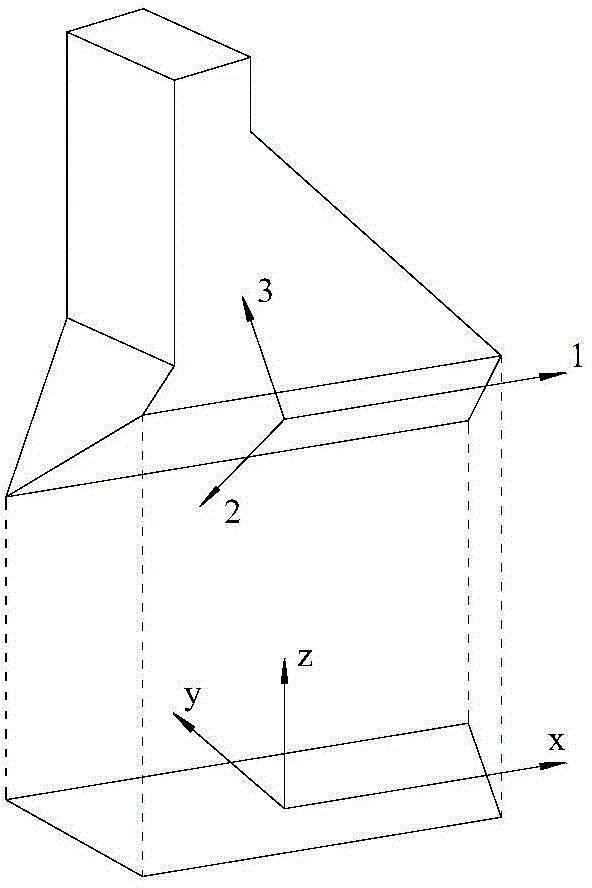

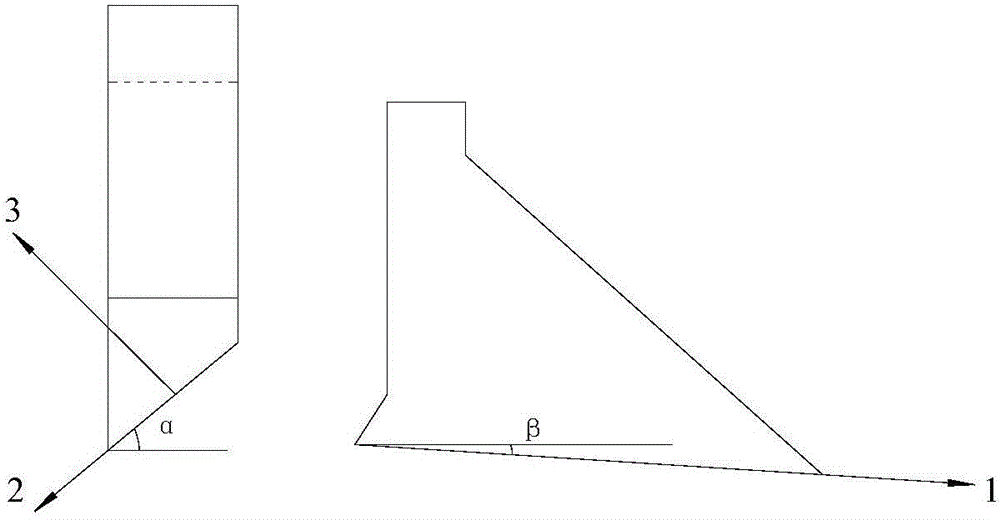

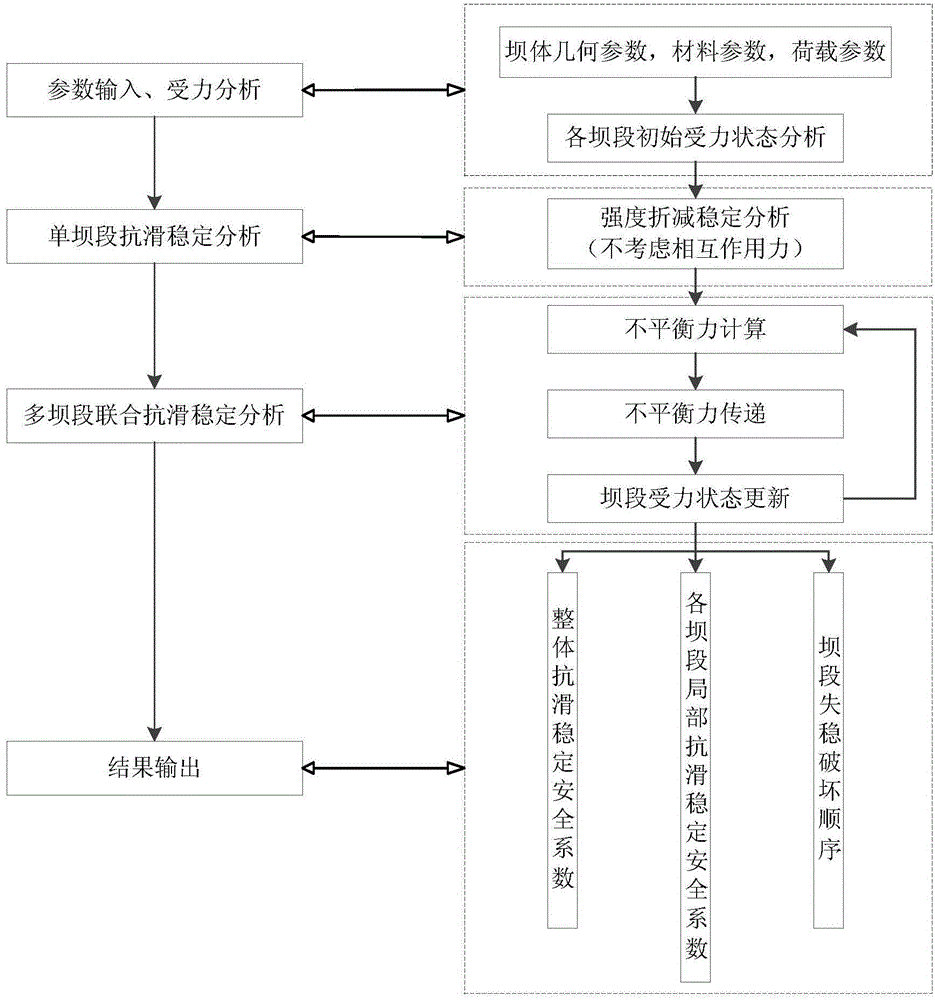

Method for calculating stability safety factor of concrete gravity dam under multi-dam-section combined skid resistance condition

ActiveCN104652373AClear conceptAssume reasonableInformaticsSpecial data processing applicationsStatically indeterminateEngineering

The invention relates to a method for calculating the stability safety factor of a concrete gravity dam under a multi-dam-section combined skid resistance condition and belongs to the field of gravity dam stability analysis. According to the method, a three-dimensional stability analysis calculation model is established on the basis of a three-dimensional rigid body limit balance analysis and strength reduction method by aiming at a situation that key slots are formed or grouting is performed between dam sections of the concrete gravity dam so as to combine slide resistance; by introducing a plurality of reasonable assumption and unbalanced force transfer concepts, the statically indeterminate problem of combined anti-sliding stability of multiple dam sections along a dam foundation surface is converted into a statically determinate problem; on the basis of solving out the independent anti-sliding safety factor of the dam sections, the transfer of unbalanced forces of adjacent dam sections on a river valley side is considered, circulation calculation is performed, and the overall stability safety factor of combined slide resistance of multiple dam sections, the sequence of sequentially achieving limit balance by each dam section and the local stability safety factor of the dam sections are solved out. The method has the characteristics of easiness for realization of programming, reasonable calculation result and the like, and is convenient in popularization and application in practical engineering.

Owner:HOHAI UNIV

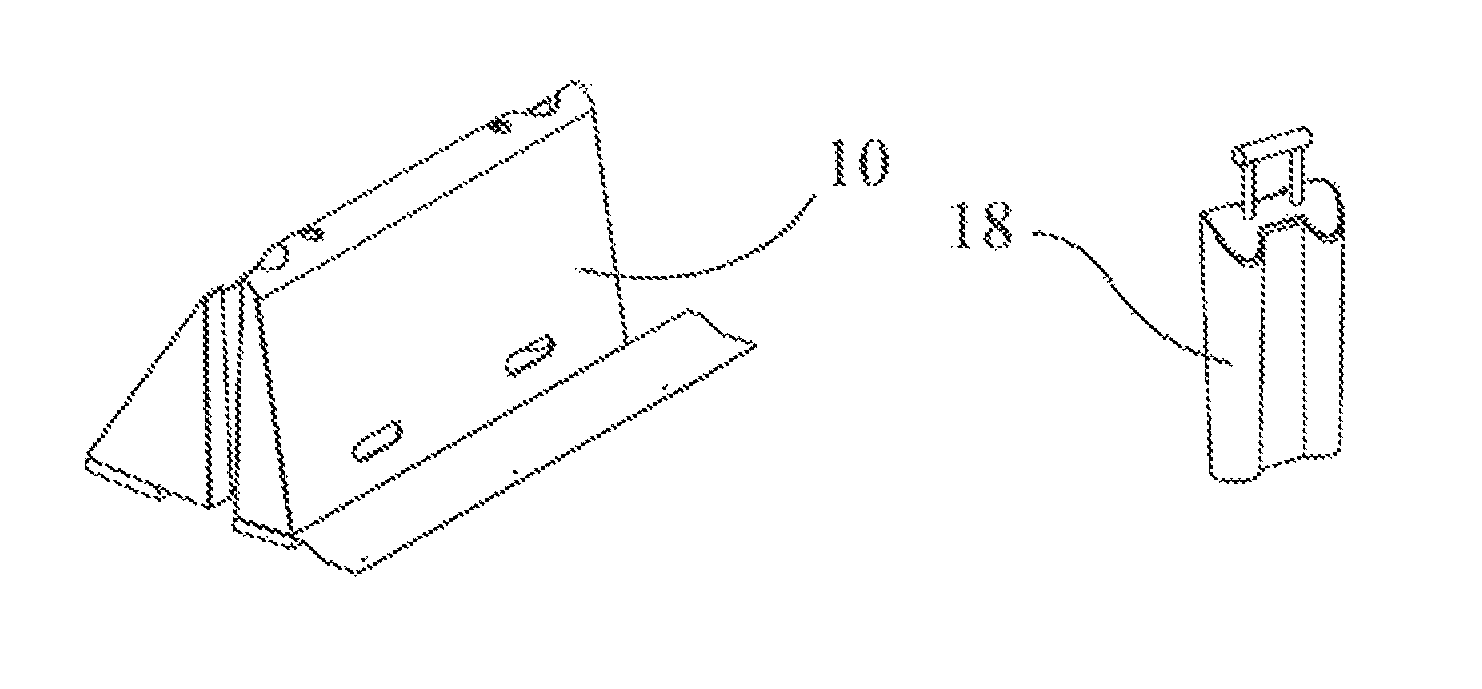

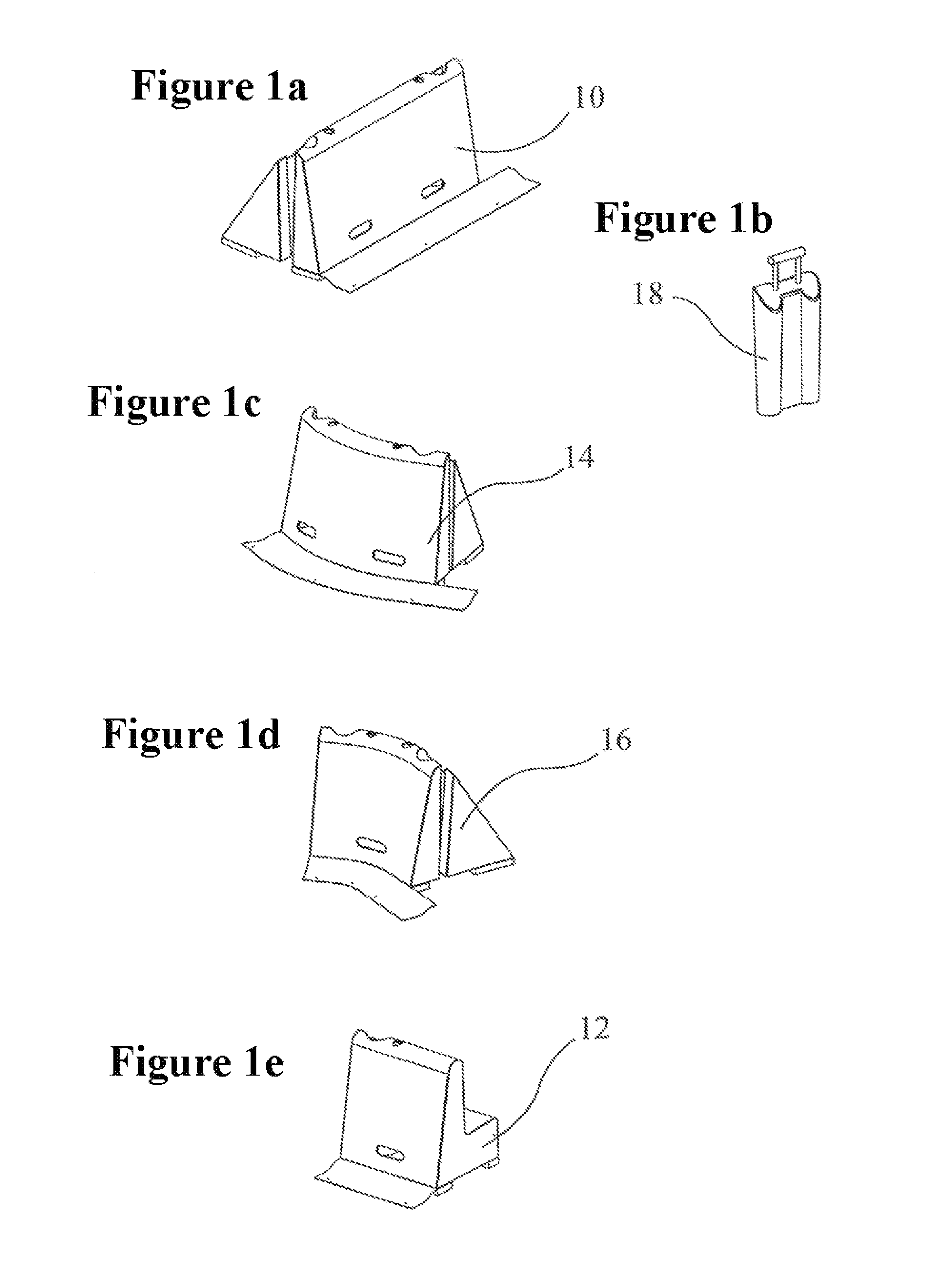

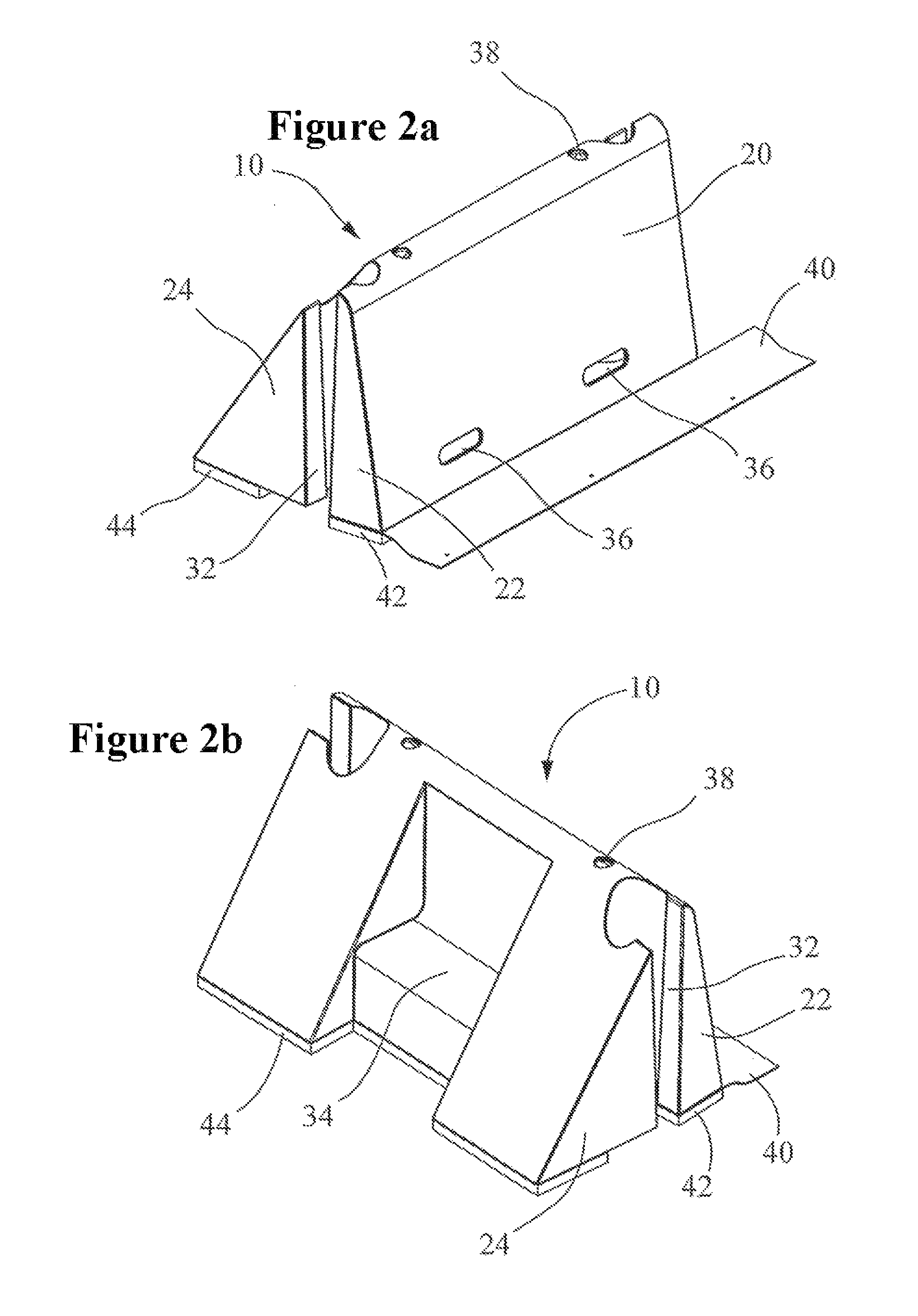

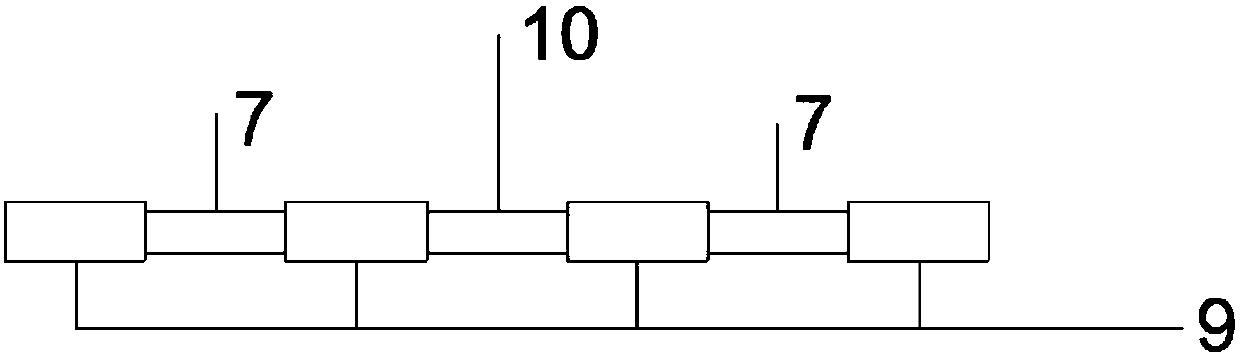

Self-filling modular barrier

A flood barrier comprises hollow self-filling units (10, 12, 14, 16) placed end-to-end and connected at their ends by downwardly tapered bilobal (46) keys inserted into sockets (26, 28) at the ends of the units, wherein the keys incorporate concrete or other ballast for negative buoyancy.

Owner:BU INNOVATIONS LTD

Rock-fill concrete construction method

ActiveCN103898877AImprove liquidityImprove compactnessBarrages/weirsGravity damsStructural engineeringFree flow

The invention provides a rock-fill concrete construction method. The rock-fill concrete construction method comprises the first step of stacking rocks inside a predetermined groove to form a rock-fill body, the second step of pouring self-compacting concrete on the upper surface of the rock-fill body until gaps between the rocks of the rock-fill body are filled with the self-compacting concrete, the third step of grinding the upper surface of the rock-fill body before the self-compacting concrete is initially solidified, and the fourth step of solidifying the self-compacting concrete to form rock-fill concrete. According to the rock-fill concrete construction method, the self-compacting concrete is poured on the upper surface of the rock-fill body directly, the gaps between the rocks of the rock-fill body are filled with the self-compacting concrete in a free-flow mode, and the upper surface of the rock-fill body is ground, so that the flowability of the self-compacting concrete in the rock-fill body is improved, air in the self-compacting concrete and air in the rock-fill body are conveniently exhausted, and the compactibility of the rock-fill concrete is improved.

Owner:TSINGHUA UNIV

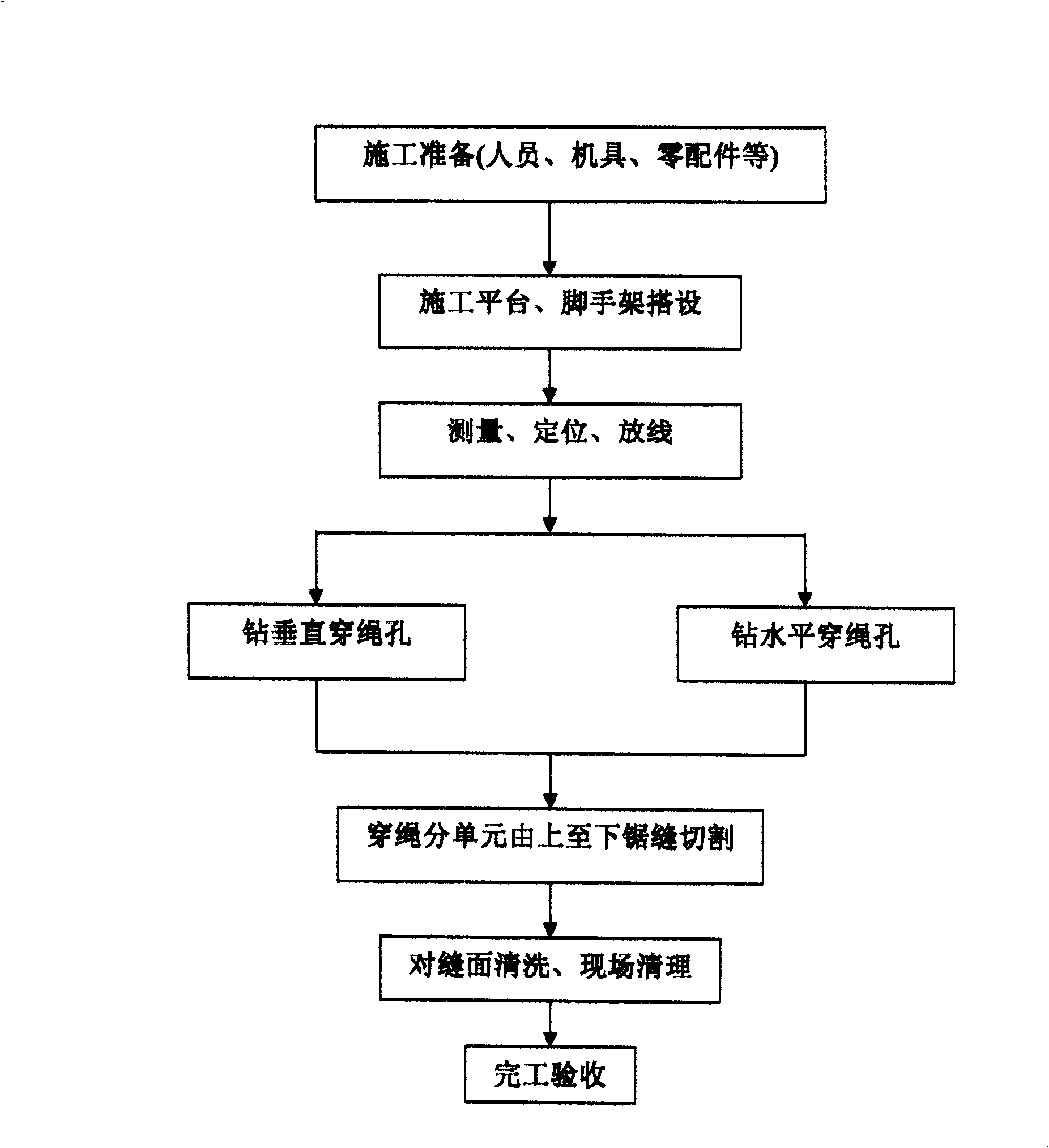

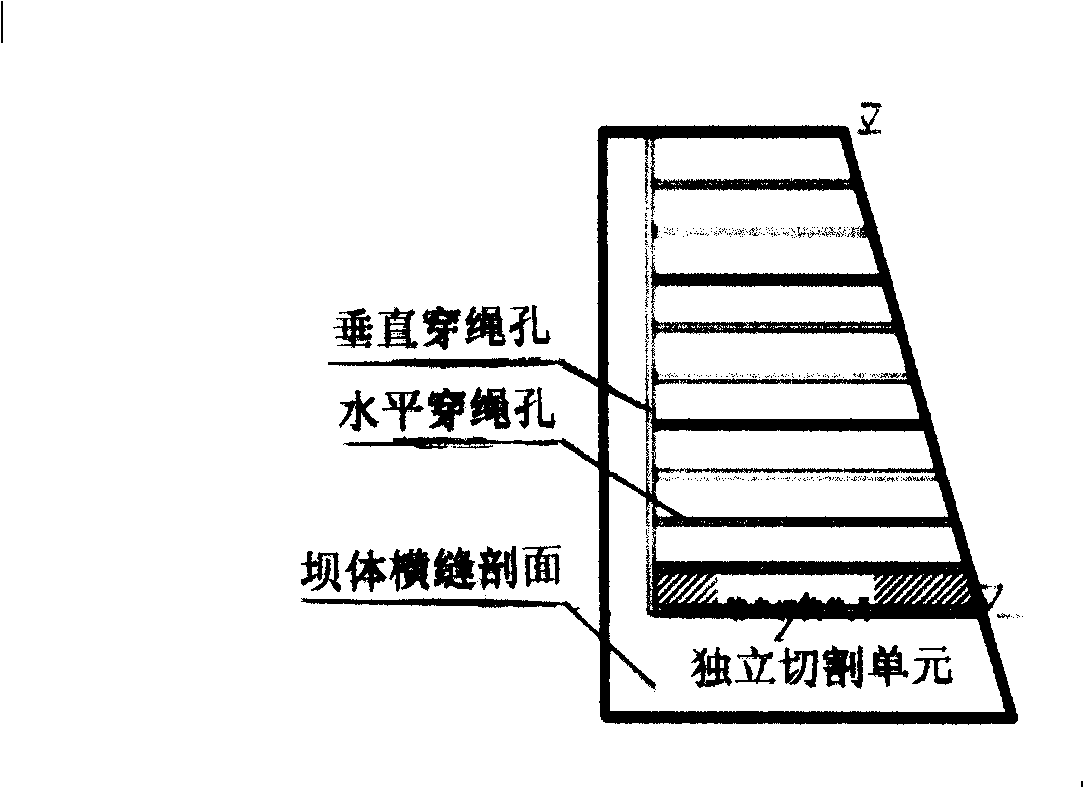

Large area sawed joint cutting construction method of concrete gravity dam cross joint

ActiveCN101270573ADoes not affect safe operationLow costStone-like material working toolsDrilling machines and methodsRock coreEngineering

The invention discloses a concrete gravity dam transverse joint large area sawing and cutting construction method which consists two parts of drilling and cutting; the construction method is carried out according to the following steps: selecting a full hydraulic drill as a drilling tool; confirming the drilled parameters; drilling and fetching the core; cataloging the fetched rock core; measuring the hole deviation of drilling; selecting a diamond wire saw to sew and cut; the cutting method, selecting horizontal drilling to finish the transverse joint cutting of the dam, selecting a diamond rope and confirming the cutting parameters; the linear speed of cutting should reach 18m / s to 22m / s; the cutting washing liquid pump amount at least reaches 70L / min, then the dam can be under a normal running state; the sawing construction does not affect the dam to run safely, does not damage the dam body structure, does not damage the transverse joint of the dam body to stop water, has a low cost, has a fast construction speed, has a high construction precision and can be broadly applied in the reinforcing and alternation constructions of the old dams and disabled dams in the engineering fields of water conservancy and hydropower.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD +1

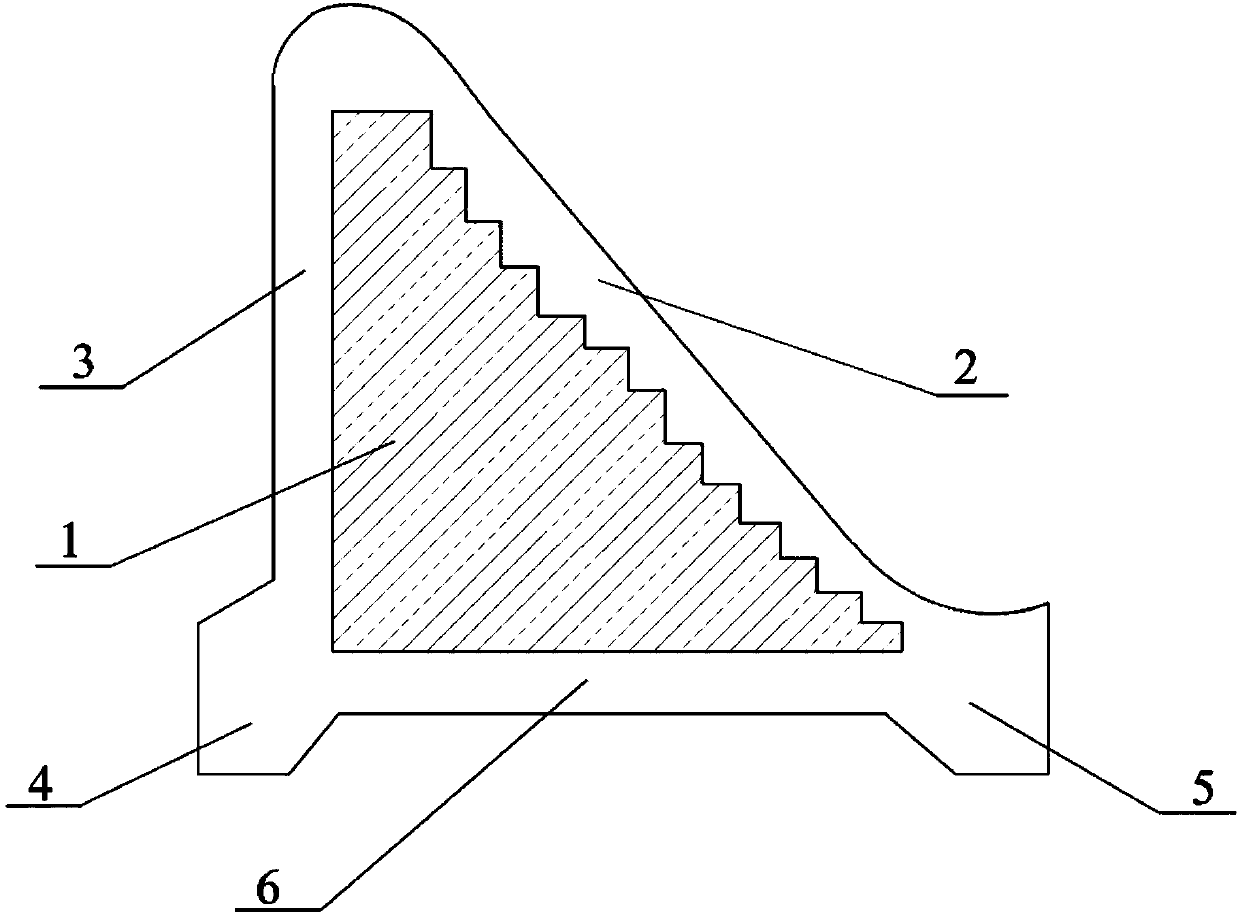

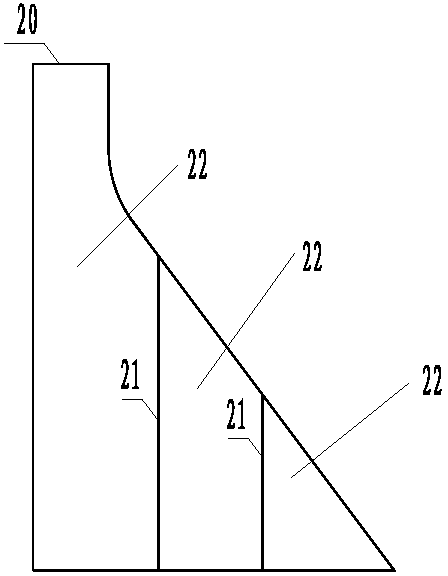

Gravity type cement-sand-gravel dam and construction method thereof

InactiveCN108018830AAvoid destructionImprove bite abilityGravity damsOcclusion effectReinforced concrete

The invention discloses a gravity type cement-sand-gravel dam and a construction method thereof. The cement-sand-gravel dam comprises an upstream dam surface which is vertically arranged; key walls are arranged at the positions of a dam toe and a dam heel; the contact surface of a dam body and an overflow surface is of a step-shaped structure; the upstream dam surface, the dam toe and the dam heelare composed of slurry-rich cement-sand-gravel; the dam body is composed of cement-sand-gravel; and the overflow surface is provided with a reinforced concrete layer. According to the gravity type cement-sand-gravel dam and the construction method thereof, the contact surface of the dam body and the overflow surface is of the step-shaped structure, so that the occlusion effect between two materials can be improved, and the phenomenon that the dam body is damaged along the contact surface under the action of dynamic water pressure can be avoided; and the earth volume of the dam body can be decreased, direct discharge can be realized, and a discharge facility is not required to be additionally constructed.

Owner:SICHUAN UNIV

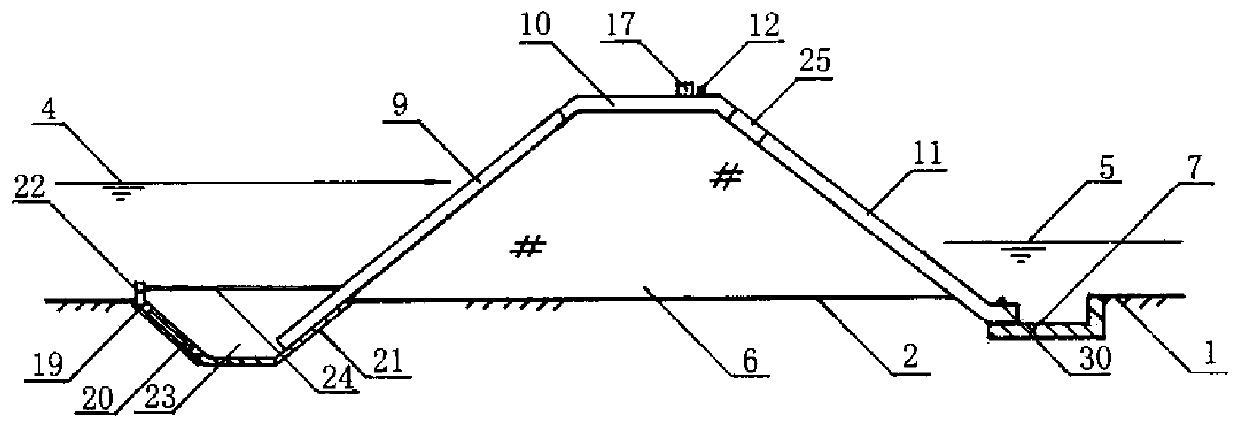

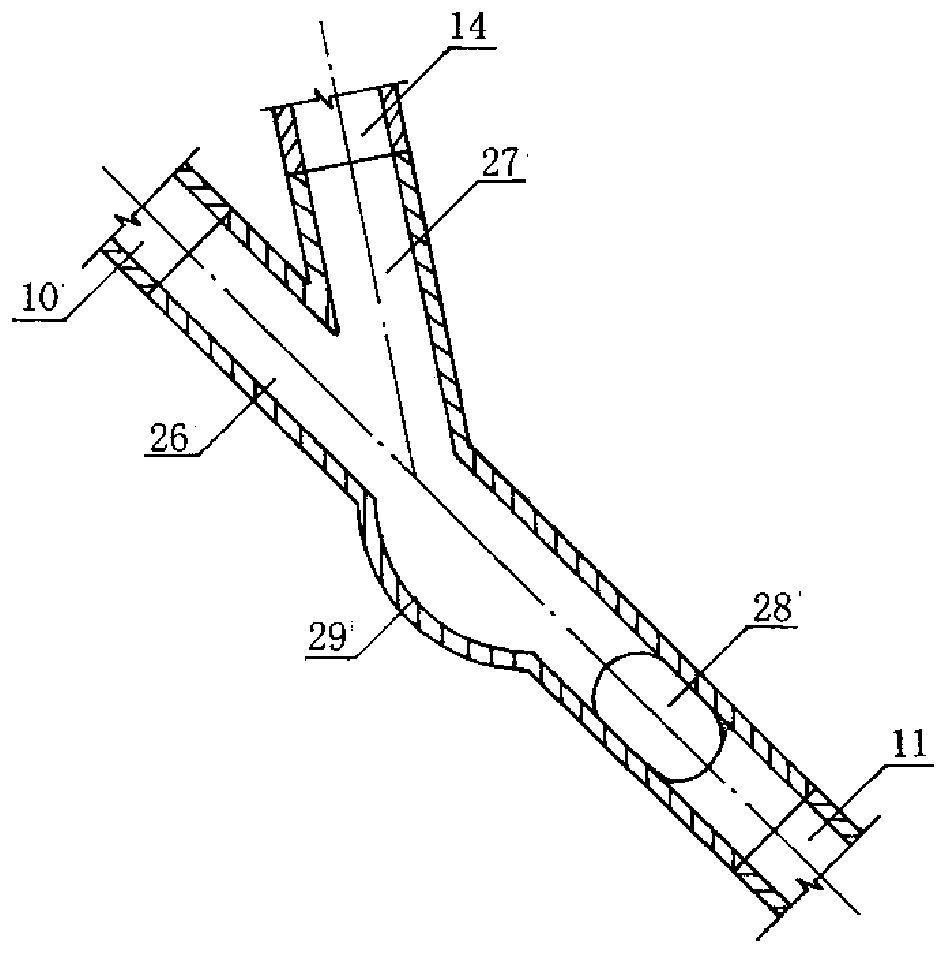

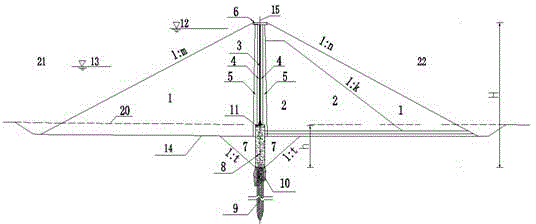

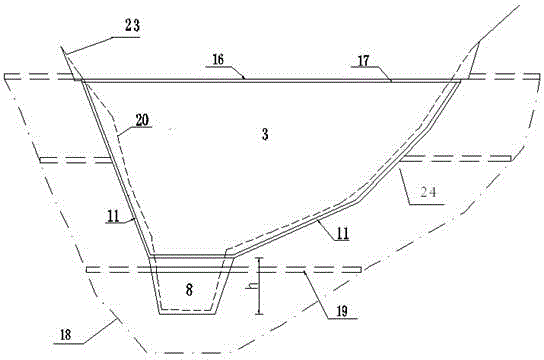

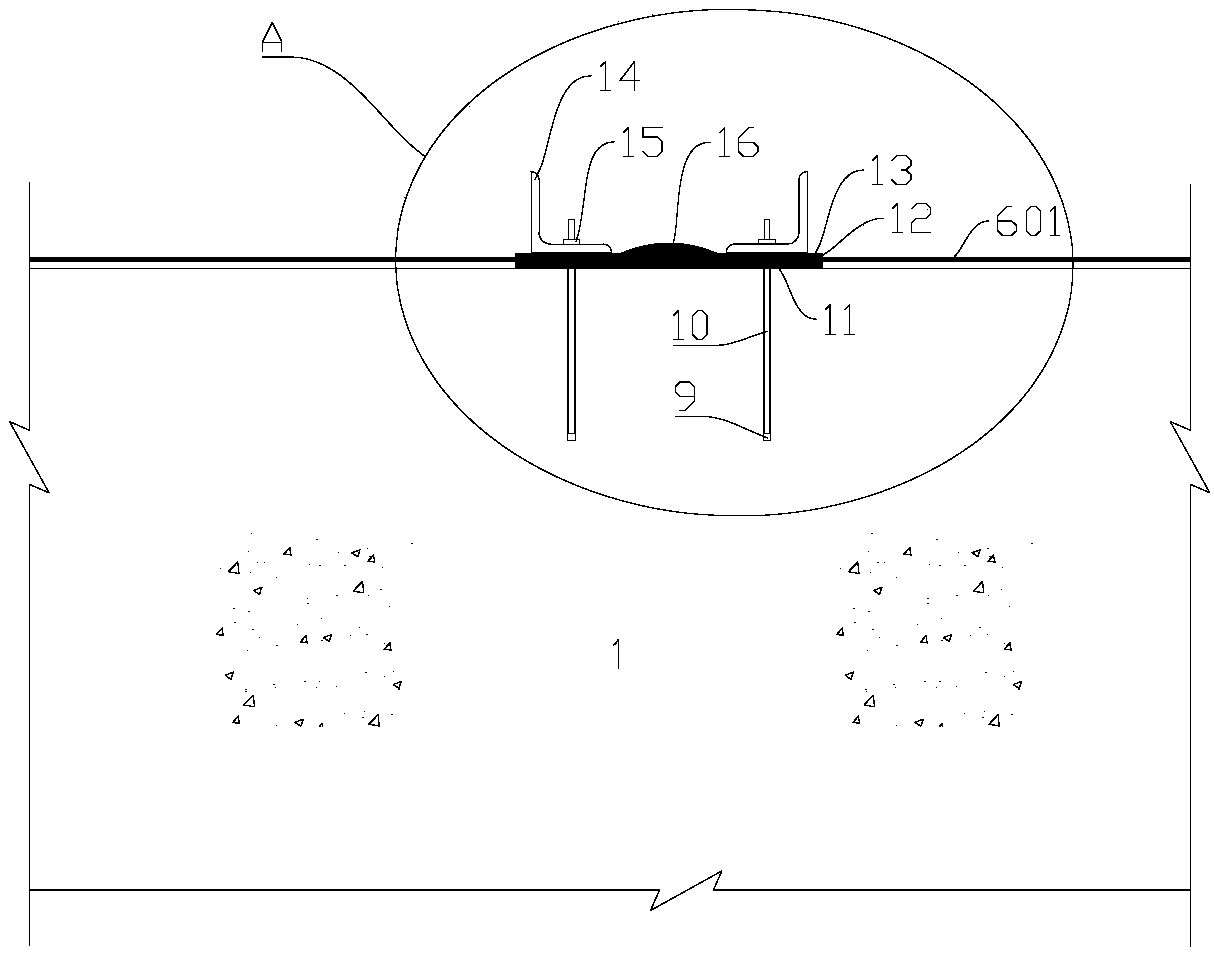

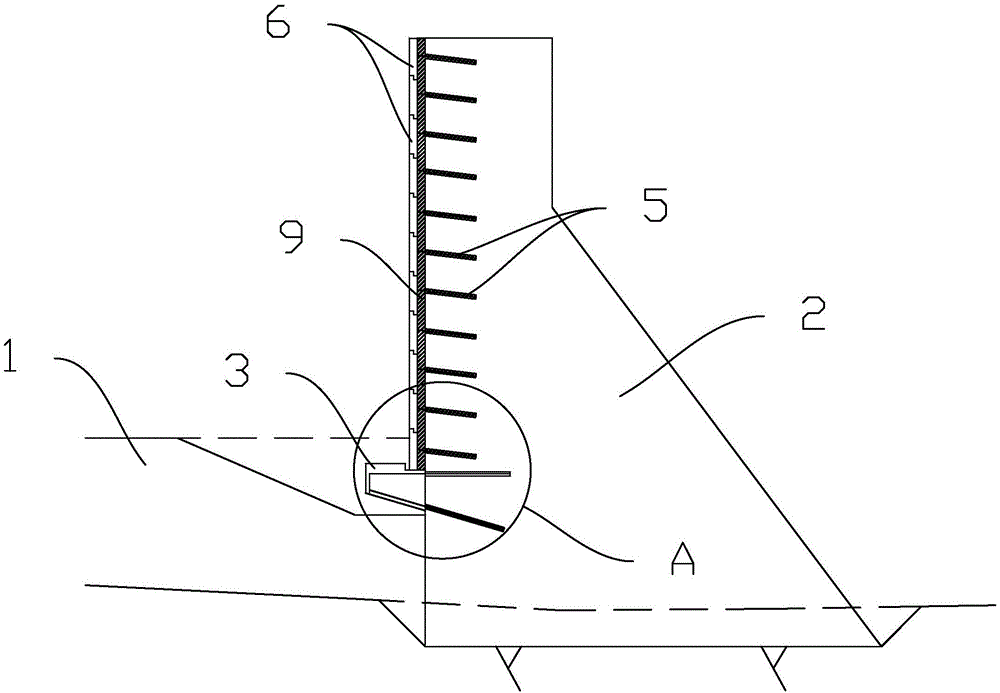

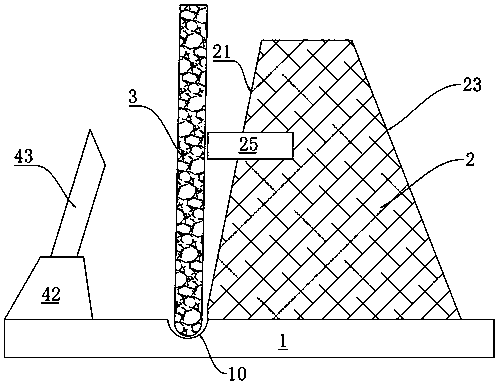

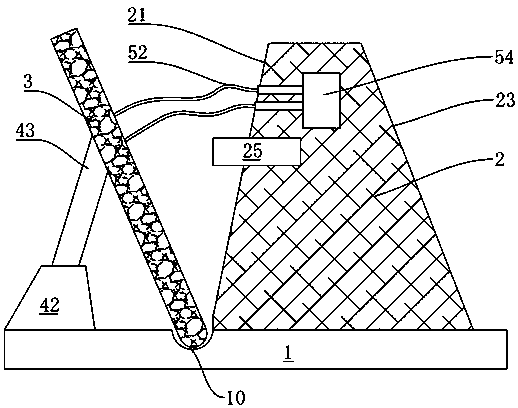

Facility and method for siphon water changing in reservoir by using rain-flood resources

ActiveCN109930548AIncrease pressureImprove the effect of replacing poor-quality water in underground reservoirsBarrages/weirsGeneral water supply conservationSiphonWater storage

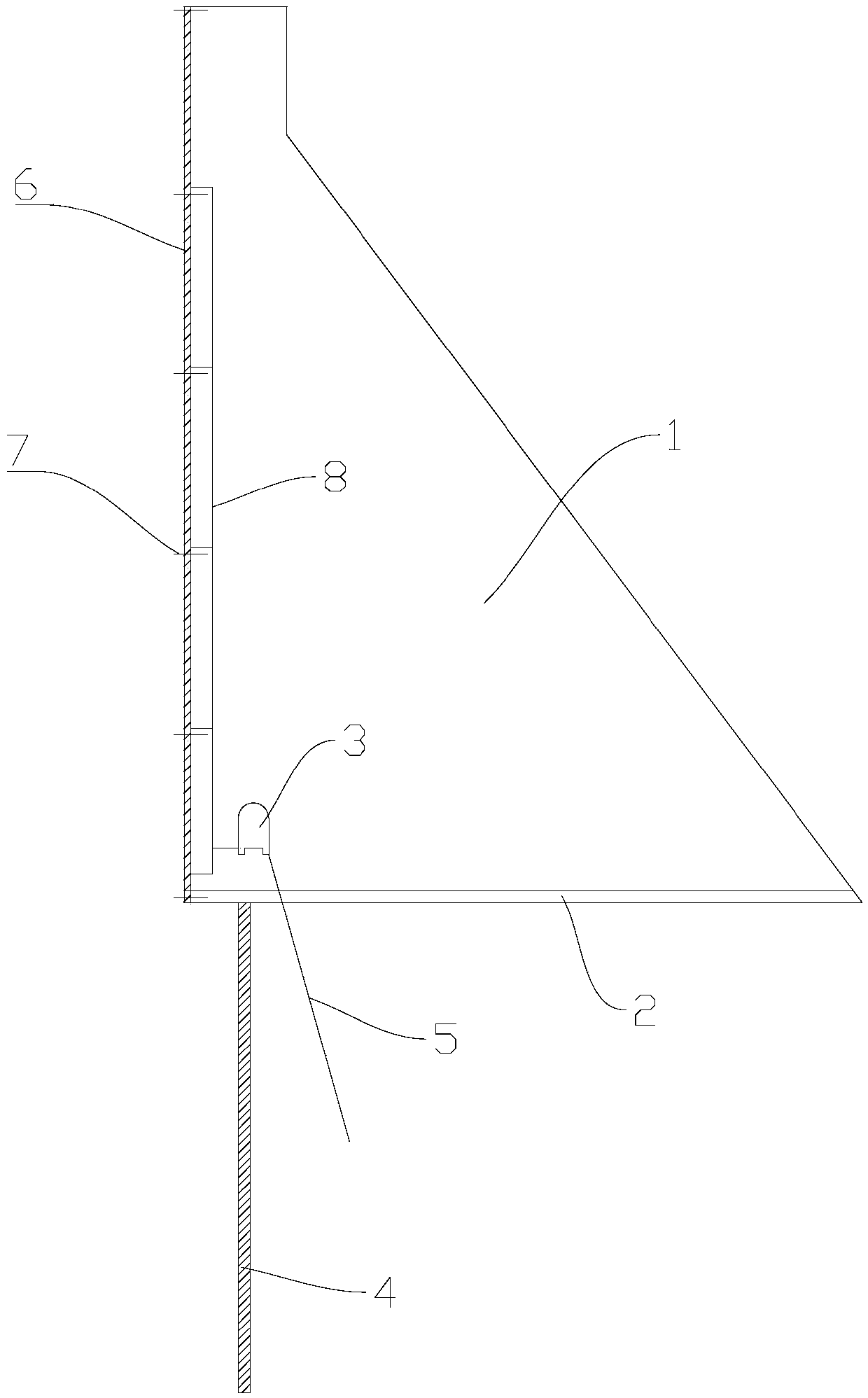

The invention discloses a facility and a method for siphon water changing in a reservoir by using rain-flood resources. The facility is characterized in that a collecting pool is arranged at the upstream dam toe of a reservoir dam, an apron is arranged at the downstream dam toe of the dam, a row of siphons are installed on the dam, and each siphon is connected by a water inlet pipe, a hump pipe, adrainage device and a water outlet pipe in sequence from the upstream to the downstream. When an upstream water level is higher than a downstream water level, control cabinets start water storage pools and water pumps to deliver water to the drainage devices, and the drainage devices initiate the siphons to siphon and release water. The facility uses the rain-flood resources to change water for the reservoir in a flood season, and negative pressure sensors and water outlet sensors are arranged on the siphons for intelligent control, so that the facility has the characteristics of safety, reliability, simple structure, all-weather siphoning water changing, large discharge flow, low energy consumption, easy operation, intelligent control and the like, and is an advanced water conservancy and environmental protection facility.

Owner:NANJING HYDRAULIC RES INST

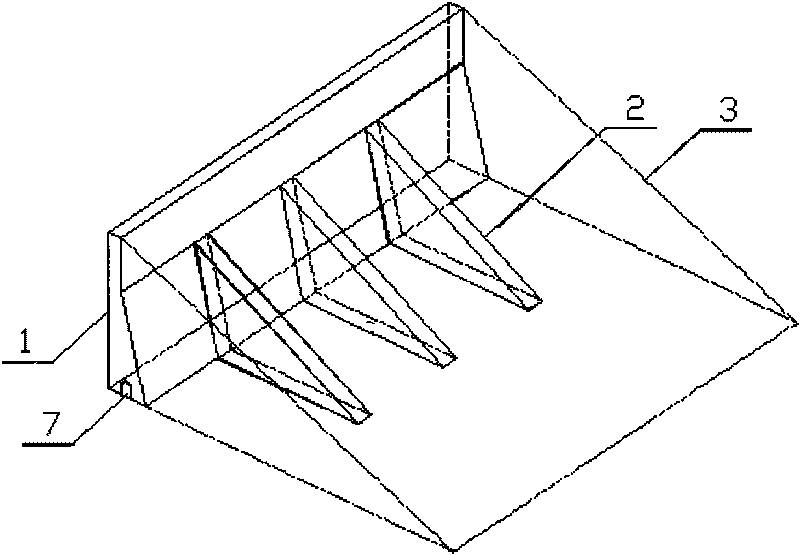

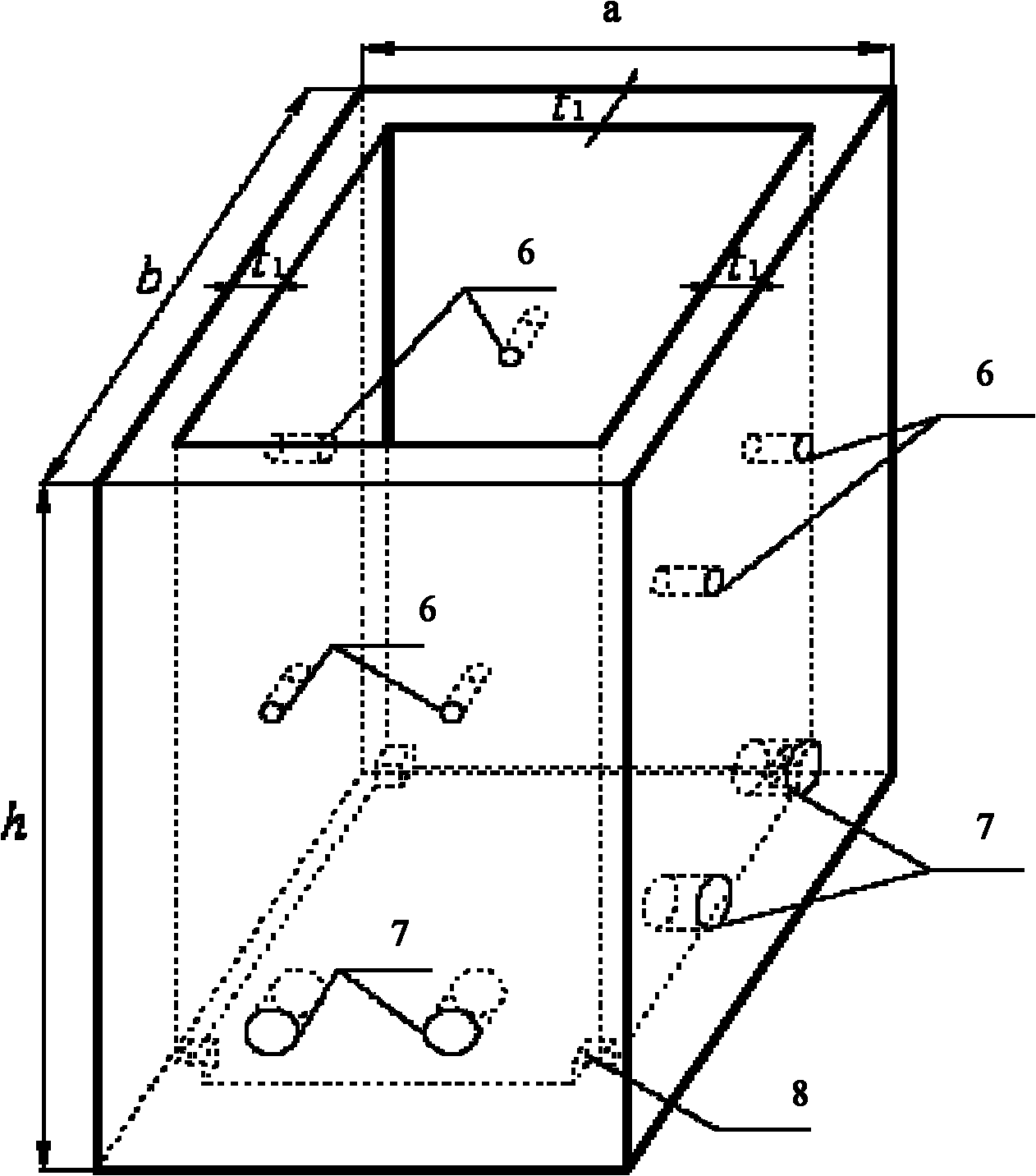

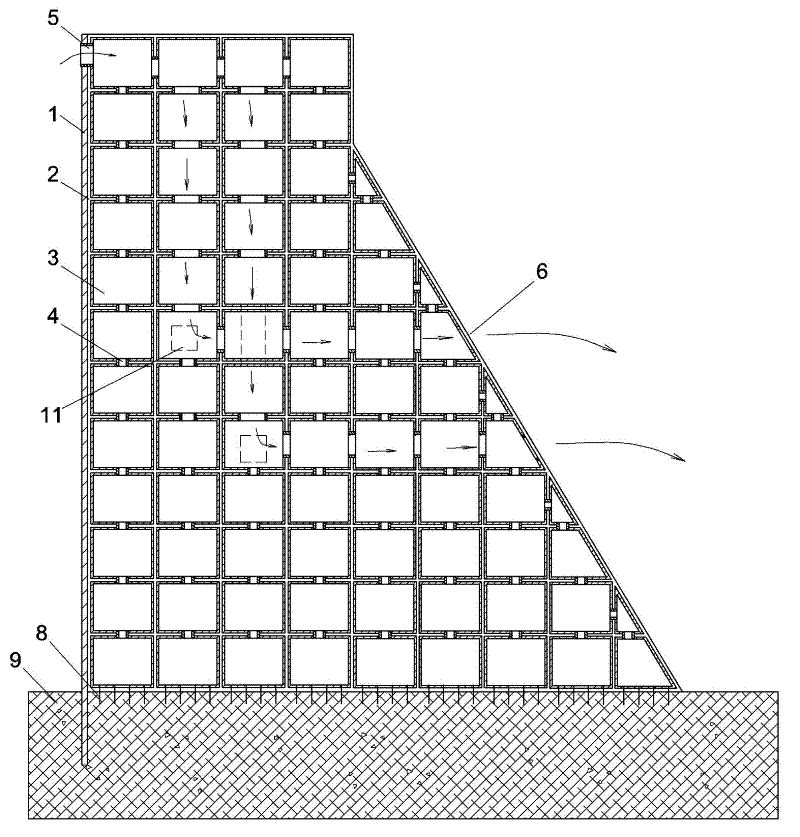

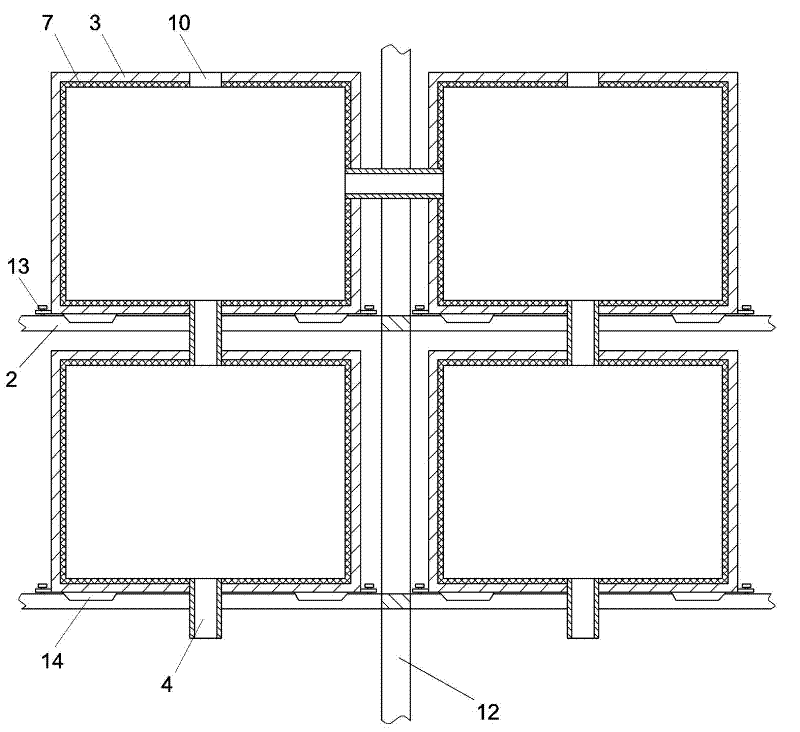

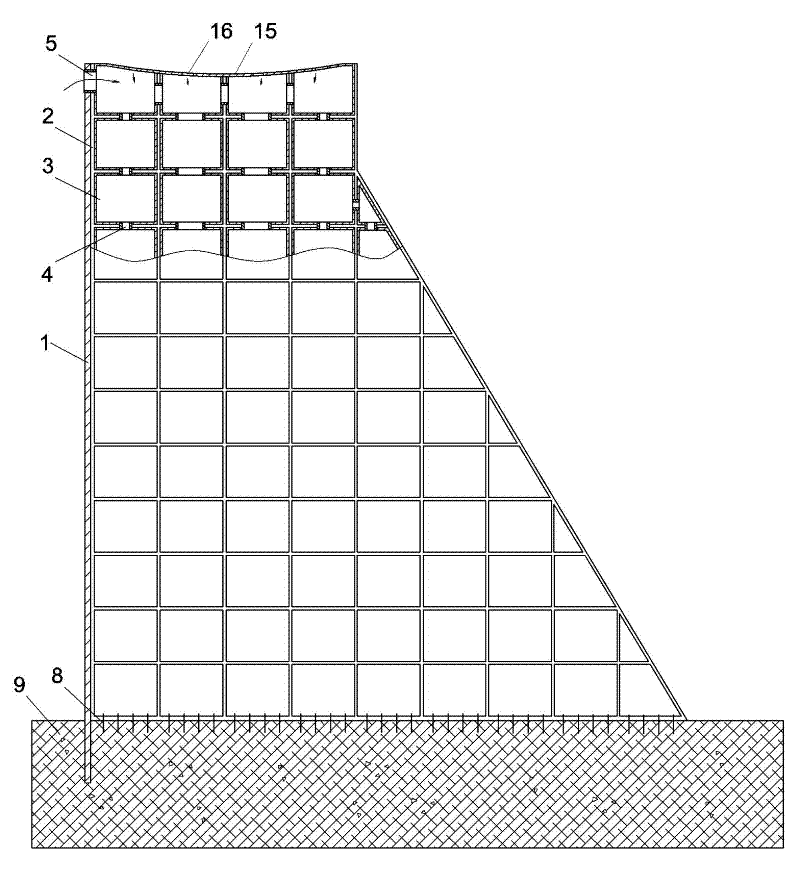

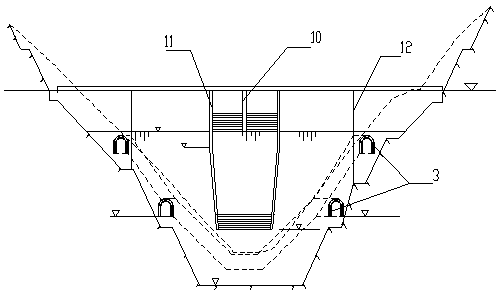

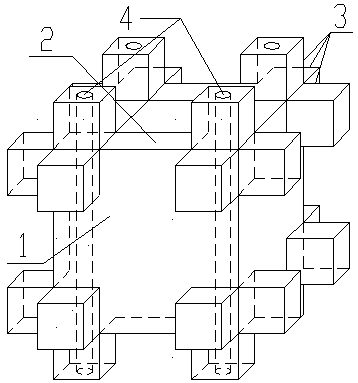

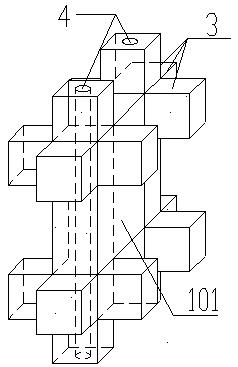

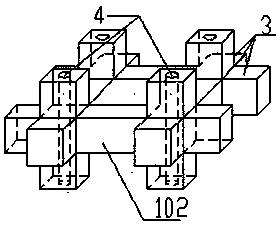

Assembled type debris flow silt dam and construction method thereof

InactiveCN102182163AReduce the impactSolve shipping problemsBarrages/weirsExcavationsReinforced concreteAbutment

The invention discloses an assembled type debris flow silt dam and a construction method thereof. The silt dam comprises a dam main body which is formed by vertically and horizontally connecting a plurality of prefabricated reinforced concrete rectangular box bodies; the top surface of each rectangular box body is opened, the rest five surfaces are sealed, and soil is filled into the rectangular box body; the dam main body is arranged on a dam body foundation; the dam abutment foundation of the silt dam and the inside slope of the dam body are filled with grouted stone or concrete; and the dam top is a grouted stone or concrete sealed top surface. Compared with the prior art, the invention fully utilizes the rapid assembly characteristic of the rectangular box bodies, can enable the rectangular box bodies to be prepared in the field far away from the slit dam in advance during the construction of the dam body foundation of the silt dam, thereby shortening the construction period and reducing the influence to the field peripheral environment of the silt dam; the rectangular box bodies can be directly filled with the current soil in a ditch, and thereby, the problem of great transportation of construction materials is solved; and compared with the traditional silt dam, the assembled type debris flow silt dam has the advantages of saving the engineering investment by 20-50 percent and shortening the construction period by 20-80 percent.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

Novel belt spring support debris flow protective wall and construction method thereof

The invention discloses a novel belt spring support debris flow protective wall and a construction method thereof. The debris flow protective wall comprises a front gravity retaining wall, a rear gravity retaining wall, a belt spring support and waterproof cover plates. The belt spring support comprises an inner pipe structure. The inner pipe structure is composed of first inner pipes and second inner pipes, and the first inner pipes and the second inner pipes are of different sizes and are connected in a staggered and nested mode. The outer side of the inner pipe structure is sleeved with outer casing pipes and springs which are arranged in a staggered mode. The two ends of each spring are fixed to the two adjacent outer casing pipes correspondingly. The space between the front gravity retaining wall and the rear gravity retaining wall is filled with gravel filler. The upper portion and the two sides of the whole protective wall are covered with the waterproof cover plates. Compared with a traditional support, the novel support composed of the inner pipes, the springs and the outer casing pipes can guarantee stability more easily when bearing impact loads. Compared with a traditional gravity retaining wall, the debris flow protective wall of the design can block debris flow more effectively, less power impact is borne by the protective wall through the flexible structure, andreliable stability is achieved.

Owner:ZHEJIANG UNIV

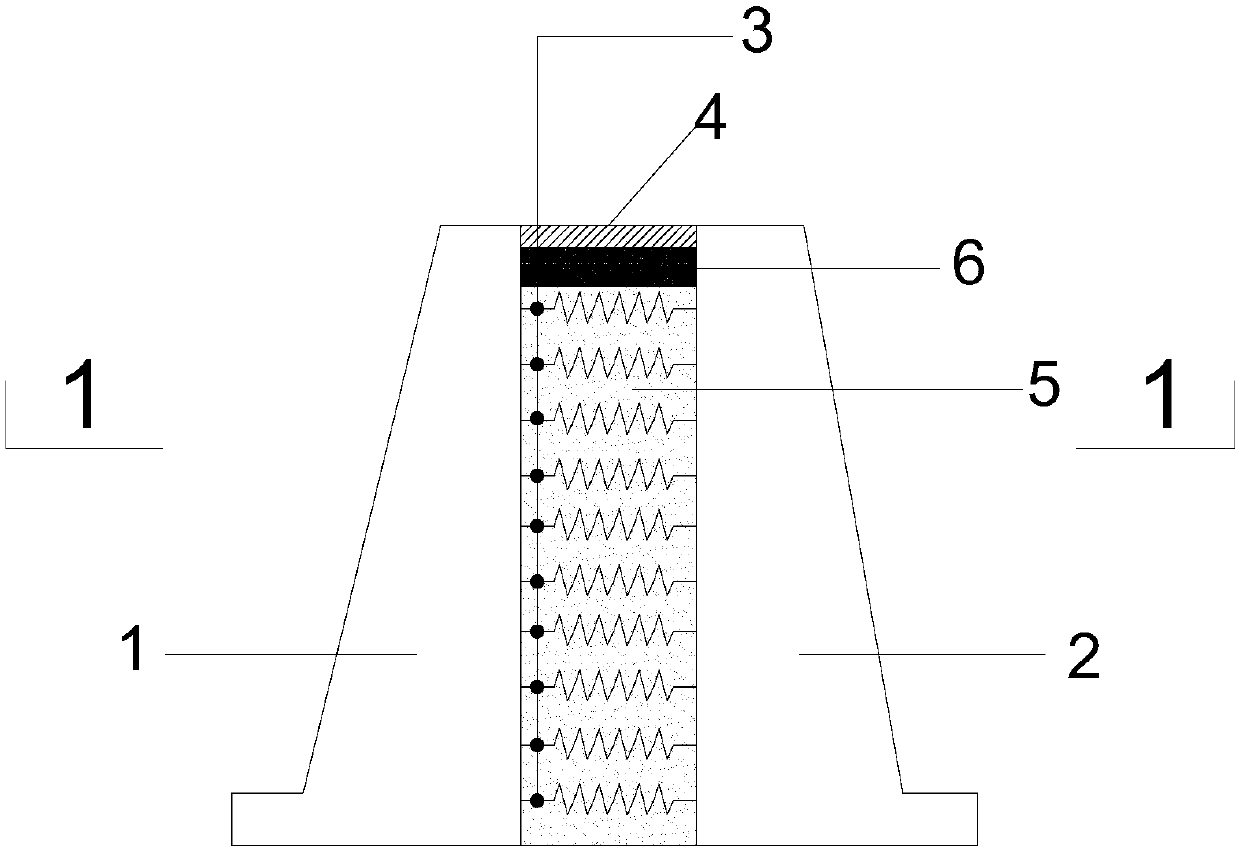

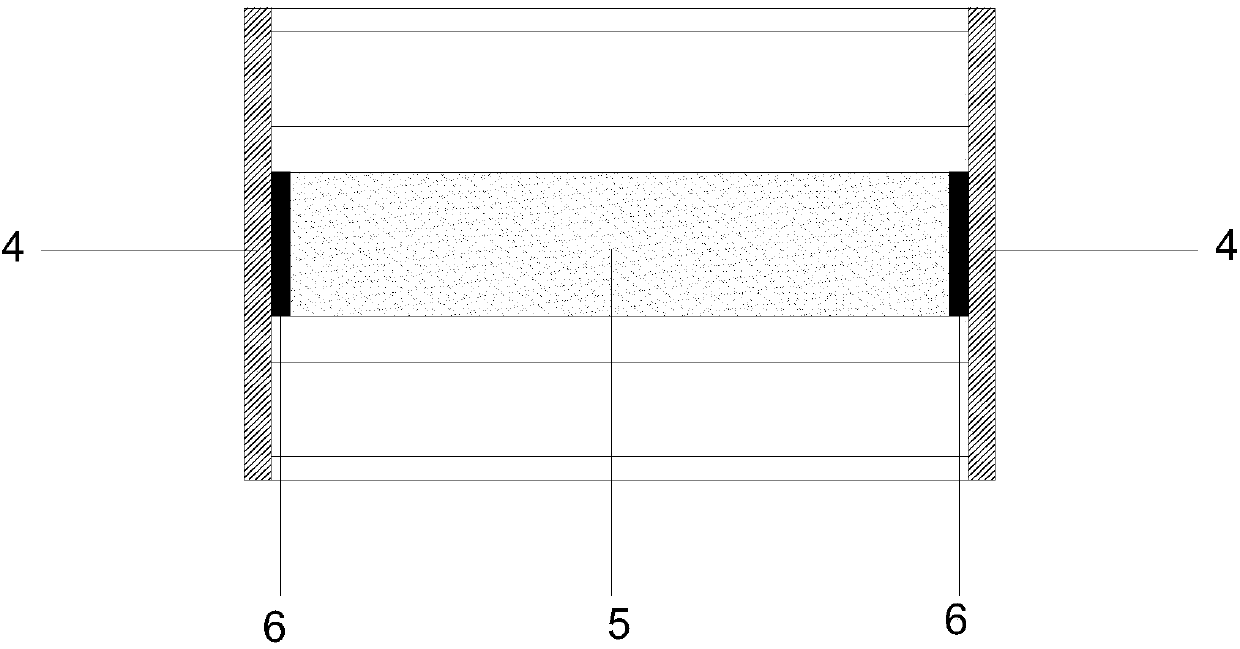

High-base asphalt concrete core wall dam

ActiveCN104099903AReduce stressIncrease stressWall damsGravity damsEarthquake resistanceRockfill material

The invention relates to a high-base asphalt concrete core wall dam. The high-base asphalt concrete core wall dam is characterized by comprising a high base, a core wall, a base of an anti-seepage asphalt concrete wall, two first transition areas, second transition areas, a first stone stacking area, a second stone stacking area, a riverbed low-compression material area and an anti-wave wall. The core wall is arranged on the base of the anti-seepage asphalt concrete wall, the base of the anti-seepage asphalt concrete wall is arranged on the high base, and the anti-wave wall is arranged at the top of the core wall; the first transition areas are respectively arranged on the upstream side and downstream side of the core wall and are tightly fitted to the core wall; the second transition areas are arranged on the outer sides of the two first transition areas; the heights of the first and second transition areas are the same as the height of the core wall; the height of the high base is larger than 10cm. Advantages and comprehensive superiority of the asphalt concrete, high base, low-compression material and stacked stone material are played completely, the problem of the feasibility of the high-base asphalt concrete core wall dam with narrow lower portion and wider upper portion is solved technically, and reliability, durability, anti-seismic performance and safety of a dam anti-seepage structure can be improved significantly.

Owner:POWERCHINA XIBEI ENG

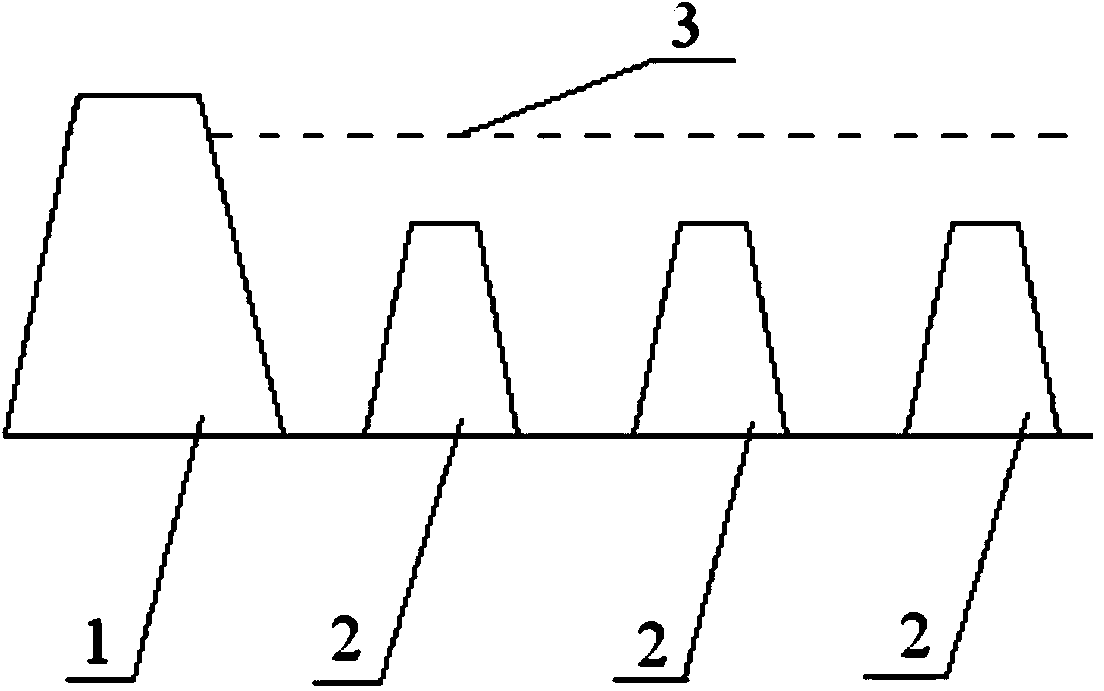

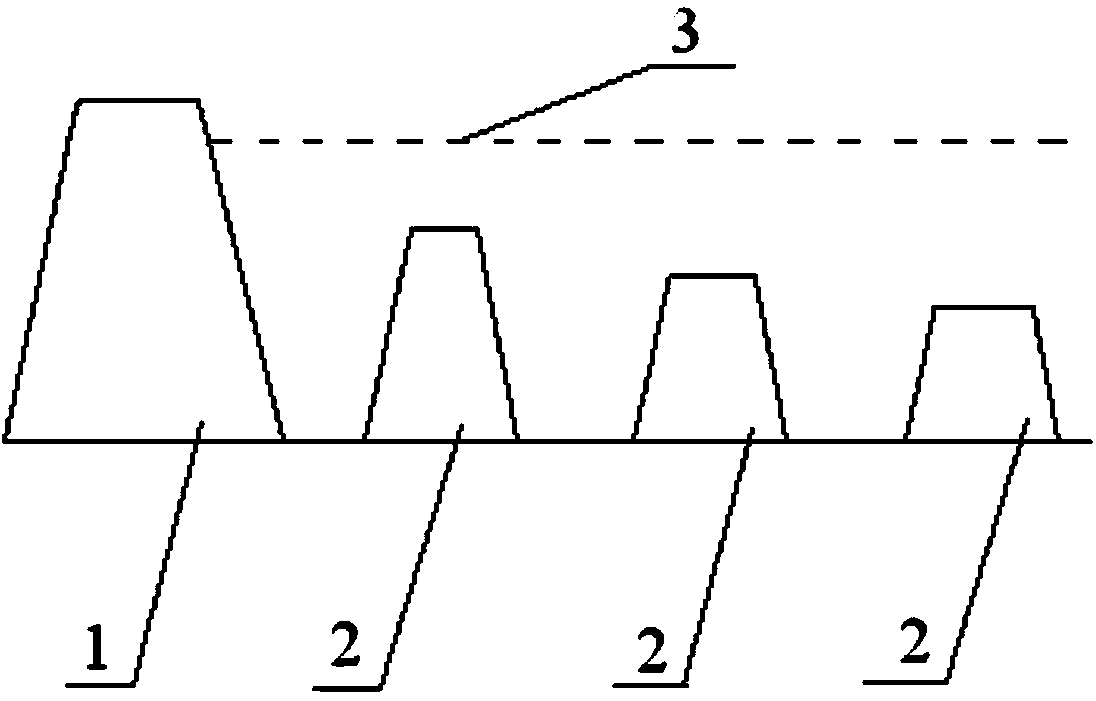

Reservoir dam

The invention discloses a reservoir dam, which comprises a main dam and a plurality of sub dams, wherein the main dam is transversely arranged in a reservoir, all of the sub dams are sequentially and uniformly ranged at the upper stream of the main dam, and the tops of the sub dams are lower than the lowest liquid level of the water flow at the upper steam of the main dam. The reservoir dam has the advantages that the water flow is segmented through the sub dams, and the water flow pressure is shared, so the main dam and each sub dam respectively bear smaller pressure, the damage to the main dam and the sub dams is smaller, the trimming frequency of the main dam and the sub dams is reduced, in addition, the dam collapse cannot easily occur, and the safety guarantee is added to residents and lands at the down stream; in addition, even when the main dam collapses, the sub dams at the upper stream can prevent most river water at the upper stream from downwards flowing, only a small part of river water downwards flows, and the impact on the down stream river bed is smaller, so the lower stream flood possibility is reduced; in addition, the tops of the sub dams are lower than the lowest liquid level of the water flow at the upper stream of the main dam, the navigation on the water level is also not influenced, and the actual application advantage is obvious.

Owner:蔡燕春

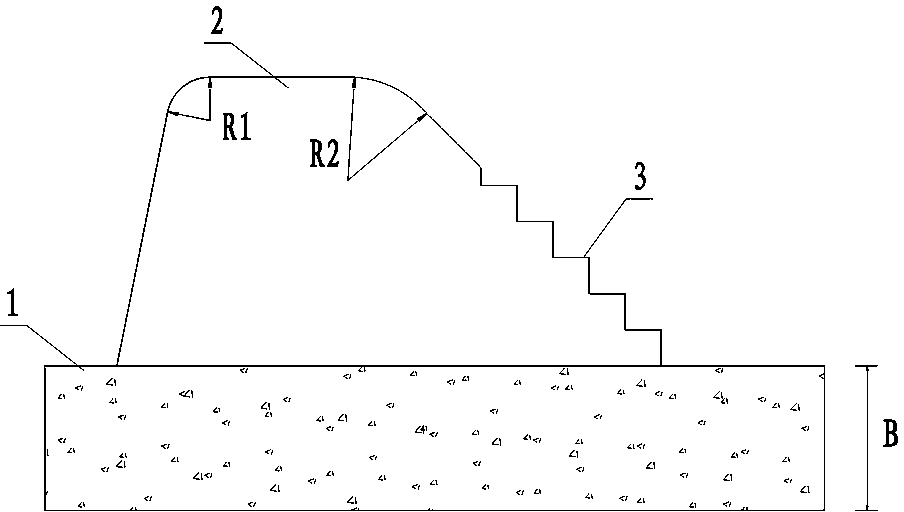

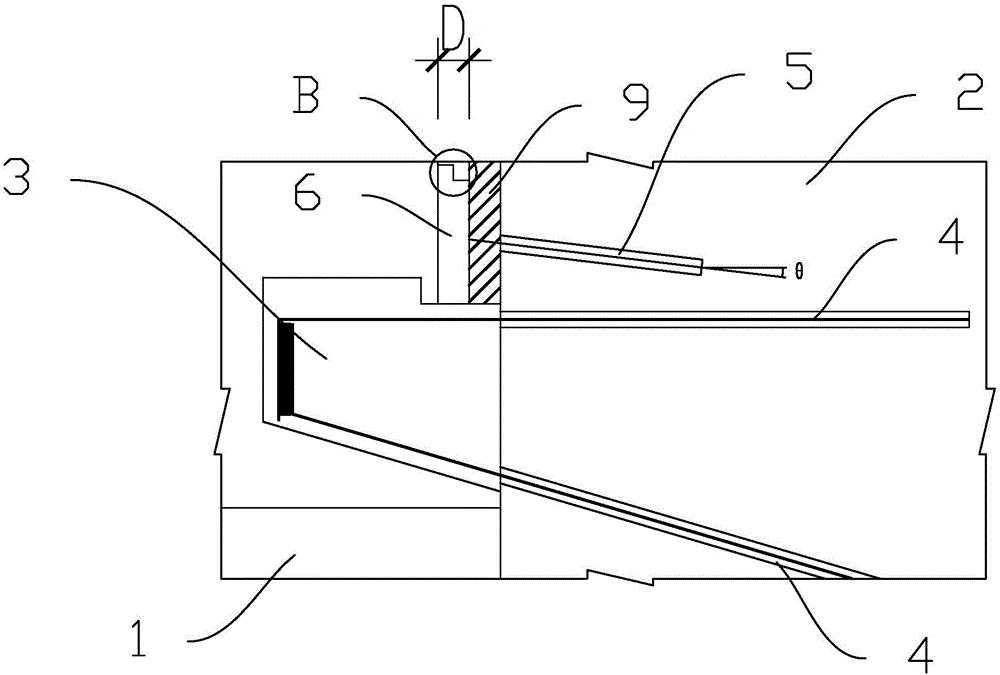

Overflow dam building structure suitable for ecological water landscape

InactiveCN103243685AImprove anti-scourabilityImprove stabilityBarrages/weirsGravity damsEngineeringErosion

The invention discloses an overflow dam building structure suitable for an ecological water landscape. The overflow dam overflow dam comprises a gravity type overflow dam built on a plain concrete foundation and built by concrete or masonry-mortar-stones, and the downstream side of a dam body of the gravity type overflow dam is of a slope type multistage energy dissipation step structure. The overflow dam building structure has the advantages that the retaining dam is set to be the gravity type overflow dam and the downstream side of the dam body is designed to be of the slope type multistage energy dissipation step structure so that erosion resistibility and stability of the gravity type overflow dam are improved and the whole building structure is led to be simple in form, small in steel bar consumption and fast in construction. In addition, perfect combination of landscape performance and ecological performance is achieved, and the project benefits of sufficiently utilizing hydroelectric resources, greatly saving project investment and improving the river way embankment water landscape are achieved.

Owner:YELLOW RIVER ENG CONSULTING

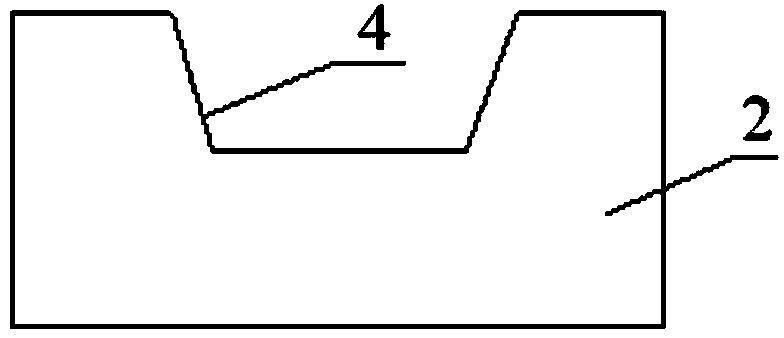

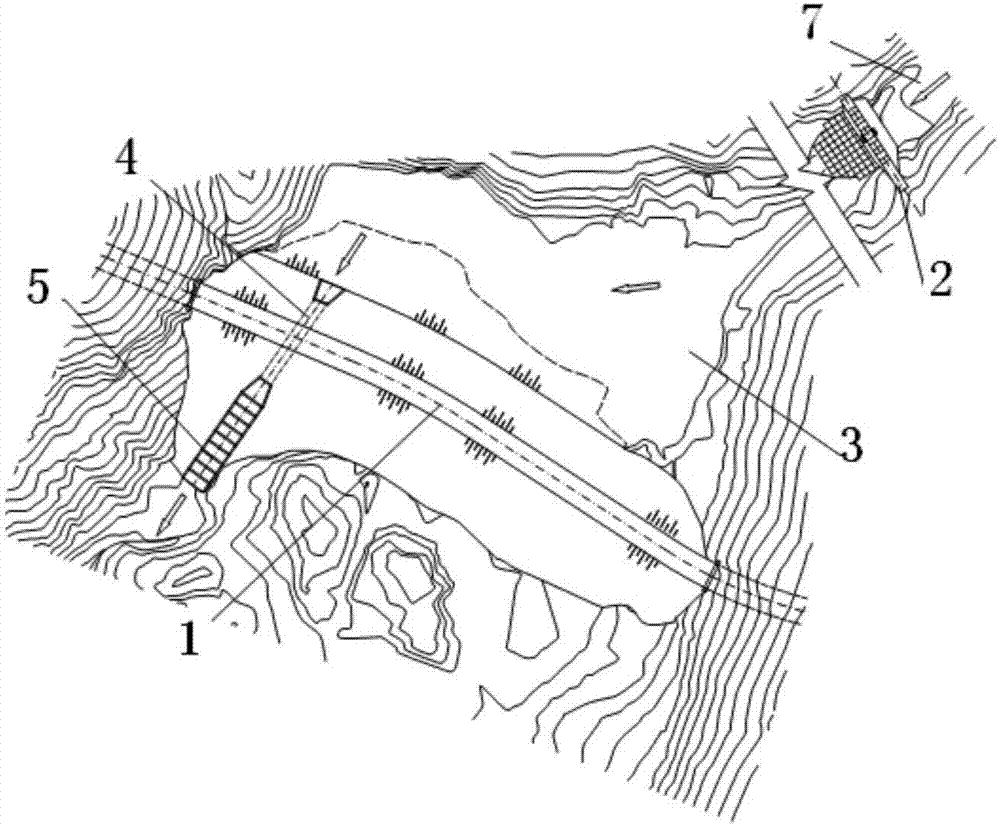

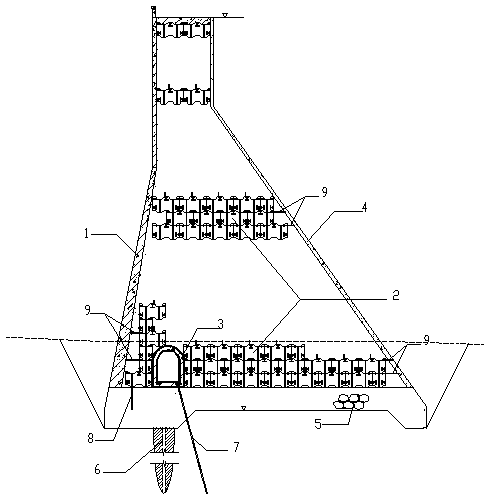

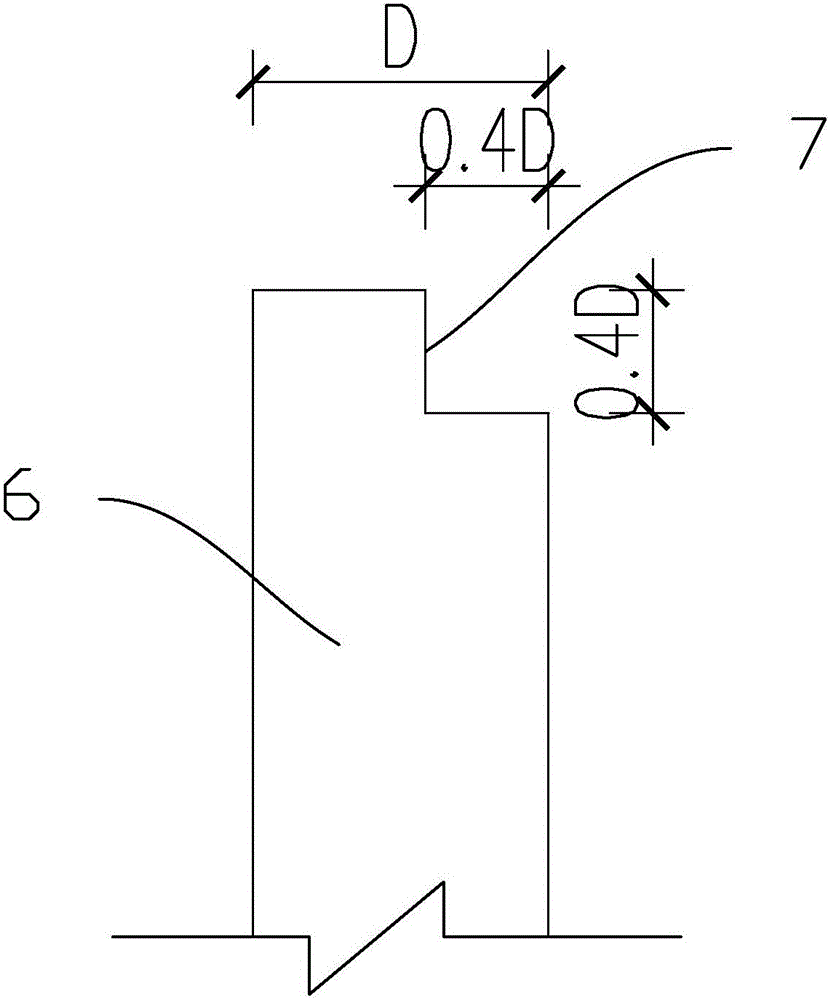

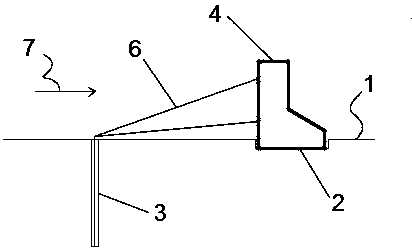

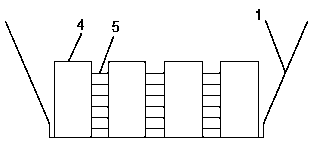

Roadbed protective system in debris flow gully and implementation method for roadbed protective system

InactiveCN107100130ALeak preventionReduce peak volumeGround-workClimate change adaptationEngineeringDebris flow

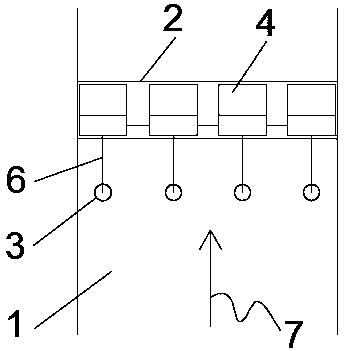

The invention discloses a roadbed protective system in a debris flow gully and an implementation method for the roadbed protective system, and the roadbed protective system is arranged along the debris flow gully (7). The roadbed protective system comprises a blocking dam (2), a stop and deposit field (3), a drainage guide culvert (4) and an energy dissipation slot (5), wherein the blocking dam (2) is positioned in an upstream channel of the debris flow gully (7); the stop and deposit field (3) is positioned between the blocking dam (2) and a roadbed filling body (1) arranged at the downstream; an inlet of the drainage guide culvert (4) is mutually jointed with the stop and deposit field (3); the drainage guide culvert (4) transversely penetrates through the roadbed filling body (1); and a downstream slope surface at the outlet of the drainage guide culvert (4) is jointed with the energy dissipation slot (5). The roadbed protective system overcomes the defects that a drainage guide structure in the prior art is easily damaged and finally causes the roadbed to be destroyed by rush of water, and has the advantages of reducing scouring, on the both sides of the channel, of debris flow, and prevents most of rock blocks from discharging.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

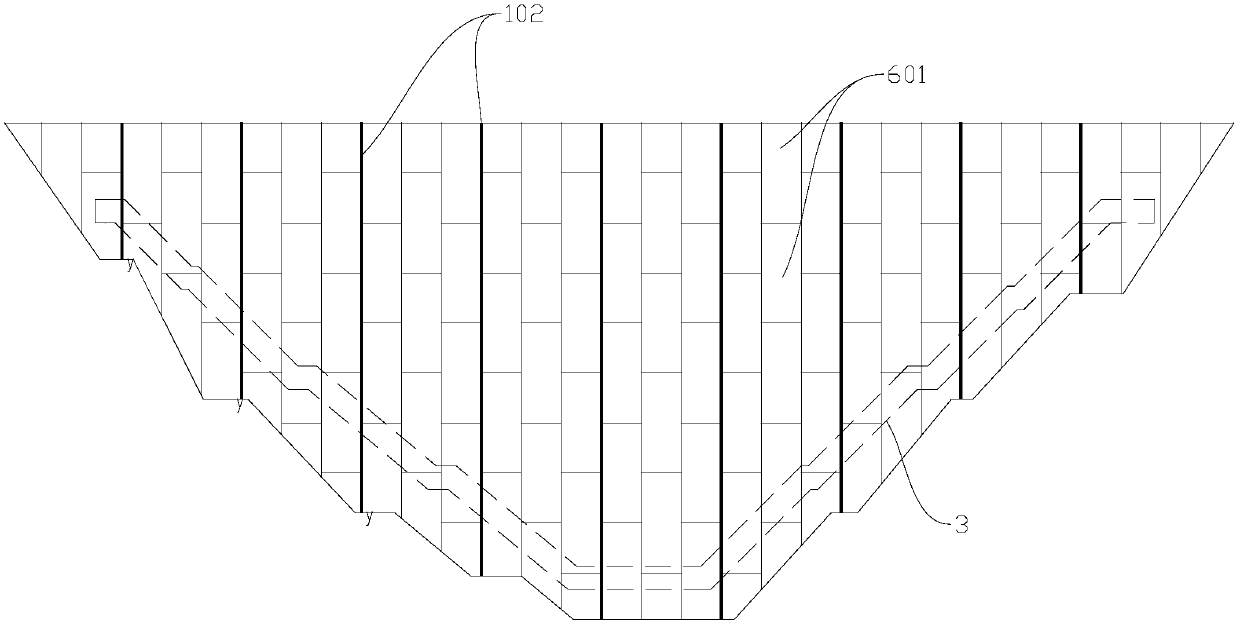

Gravity dam upstream face geomembrane anti-seepage and drainage structure and construction method thereof

Owner:POWERCHINA HUADONG ENG COPORATION LTD

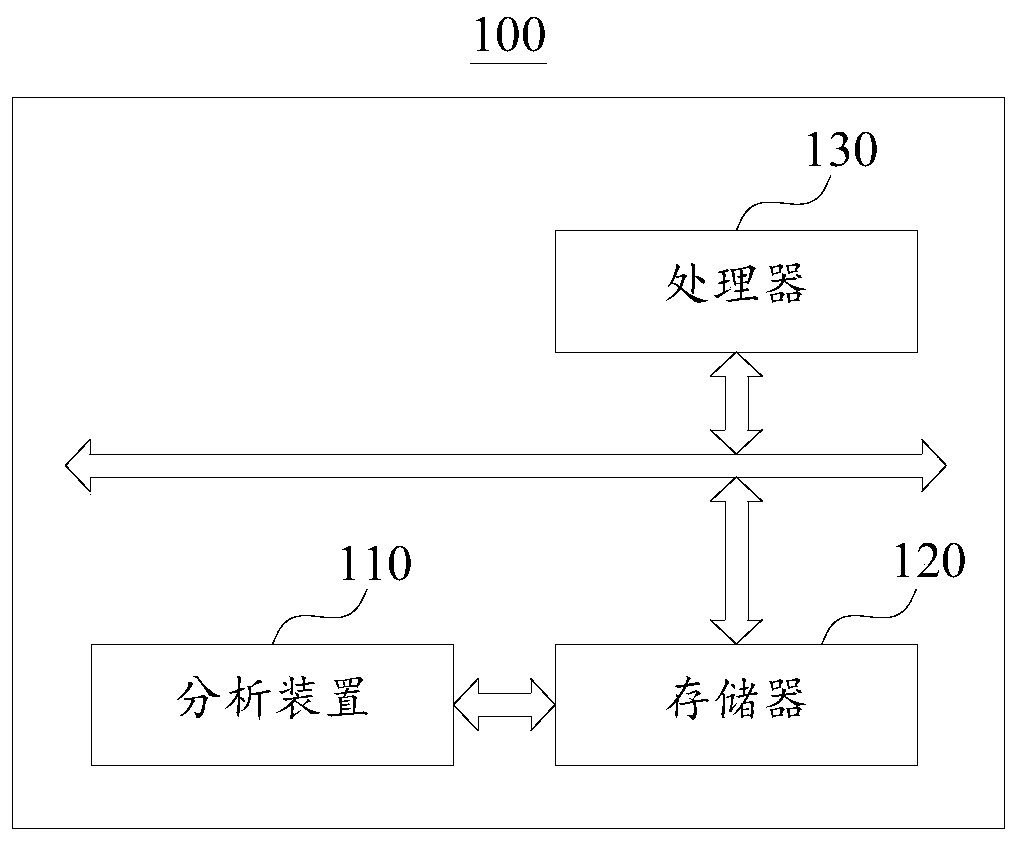

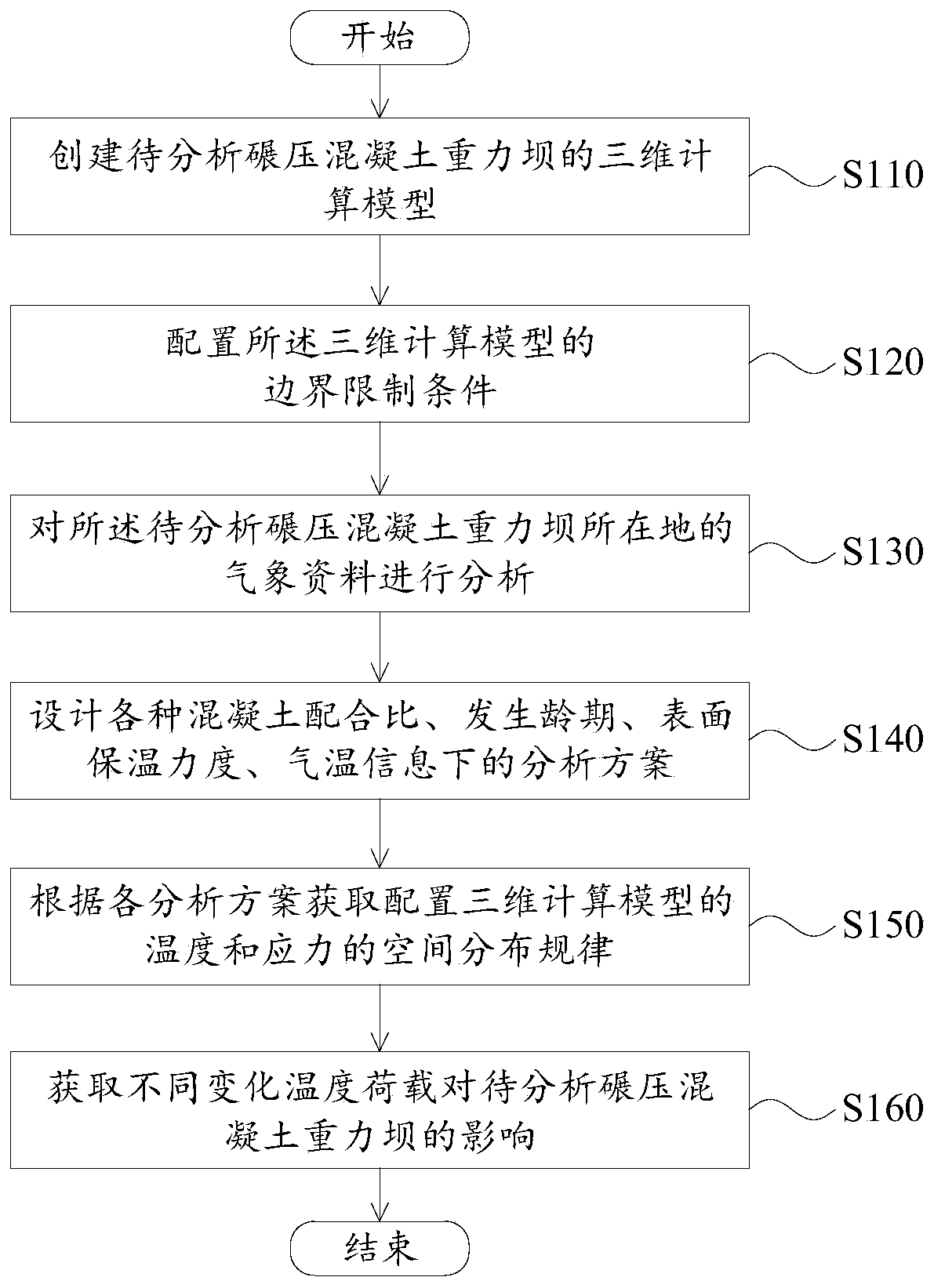

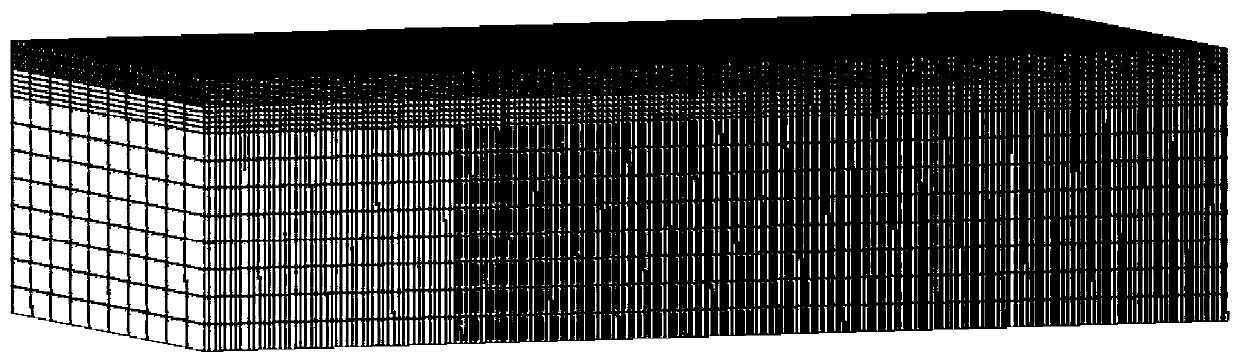

Method and device for analyzing the influence of variable temperature load on roller compacted concrete gravity dam

ActiveCN110119585AAvoid crackingGeometric CADDesign optimisation/simulationRoller-compacted concreteEngineering

The invention discloses a method and a device for analyzing the influence of a variable temperature load on a roller compacted concrete gravity dam. According to the scheme, by analyzing different conditions of the roller compacted concrete gravity dam, the influence conditions of different change temperature loads on the roller compacted concrete gravity dam to be analyzed can be obtained. According to the scheme, a three-dimensional calculation model of the roller compacted concrete gravity dam to be analyzed is created. Boundary limiting conditions of the three-dimensional calculation modelare configured, meteorological data of the place where the roller compacted concrete gravity dam to be analyzed is analyzed and then analysis schemes under different conditions are designed. The configured three-dimensional calculation model is calculated under each analysis scheme to obtain the spatial distribution rule of the temperature and the stress of the three-dimensional calculation modelunder each analysis scheme. Finally, the calculation result of the three-dimensional calculation model is analyzed under the analysis scheme to obtain the influence of different change temperature loads on the roller compacted concrete gravity dam to be analyzed.

Owner:华电福新周宁抽水蓄能有限公司 +1

Novel key groove for back-upper heightening of stone-laying gravity dam

ActiveCN102011377AStrong shear resistanceOvercomes the adverse effects of the initial heat of hydrationGravity damsTemperature stressEngineering

The invention provides a reinforced key groove for back-upper heightening of a stone-laying gravity dam and relates to a novel key groove in a hydro-structure. The key groove for the back-upper heightening of the stone-laying gravity dam is characterized in that before being heightened, the original water-retaining dam sections are heightened, a plurality of shear keys are buried in the orginal water-retaining dam sections, wherein one parts of shear keys are buried in the original water-retaining dam sections, and the other parts of shear keys are exposed, and then the dam is heightened. When the dam is heightened, a backfill cavity is formed between the original water-retaining dam sections and the heightened parts thereof so that the exposed parts of the shear keys drop in the backfill cavity, and finally micro-expansive concrete is filled in the backfill cavity finally. The novel key groove overcomes the adverse influences caused by the initial hydration heat of concrete as well as the defect of the difficult process of digging steps on original dams so that the dams are convenient to rapidly construct, and simultaneously also improves the temperature stress of newly cast large-size concrete so that the joint surface between a new dam body and an old dam body has stronger shearing resistance.

Owner:广东省水利电力勘测设计研究院有限公司

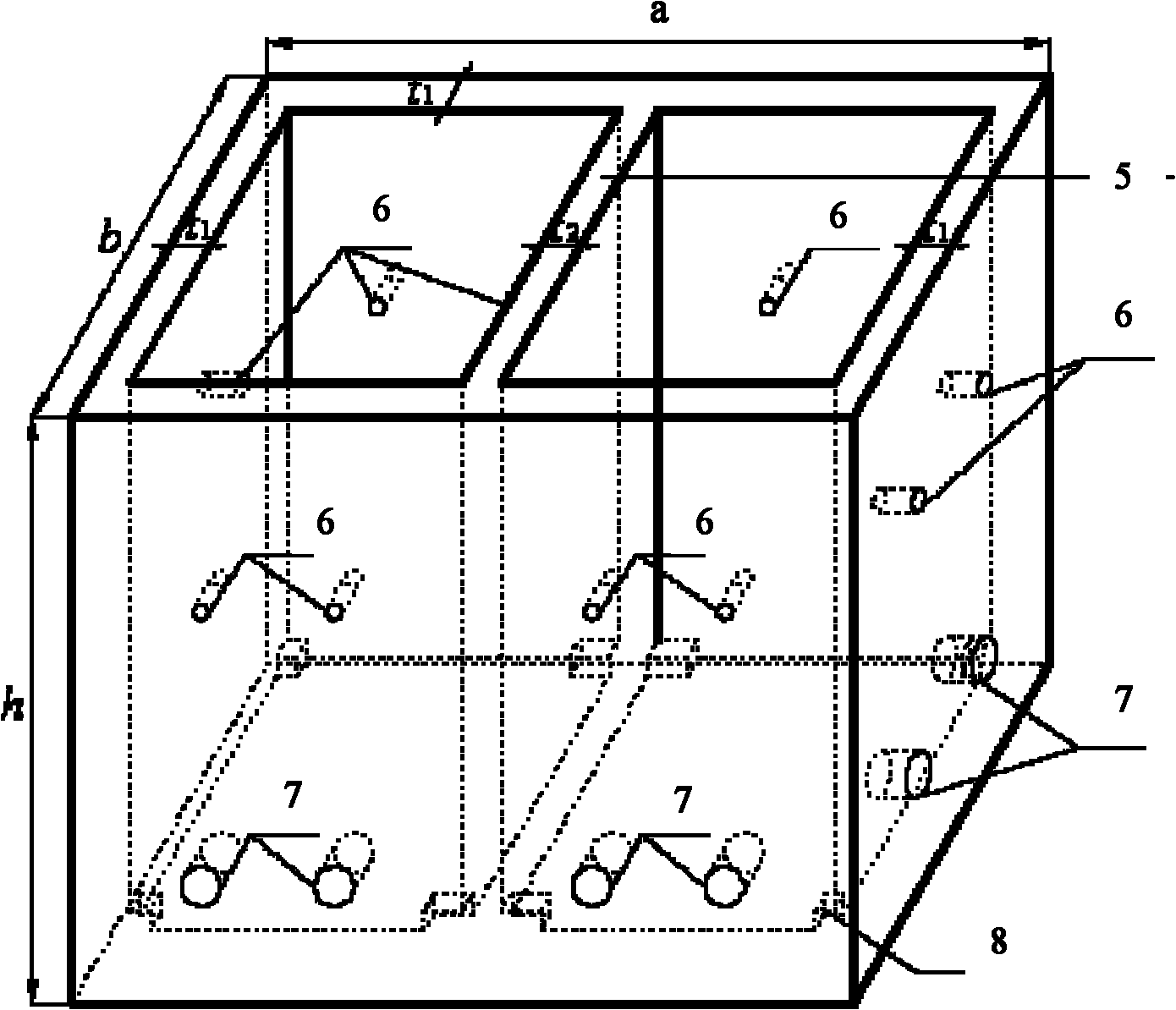

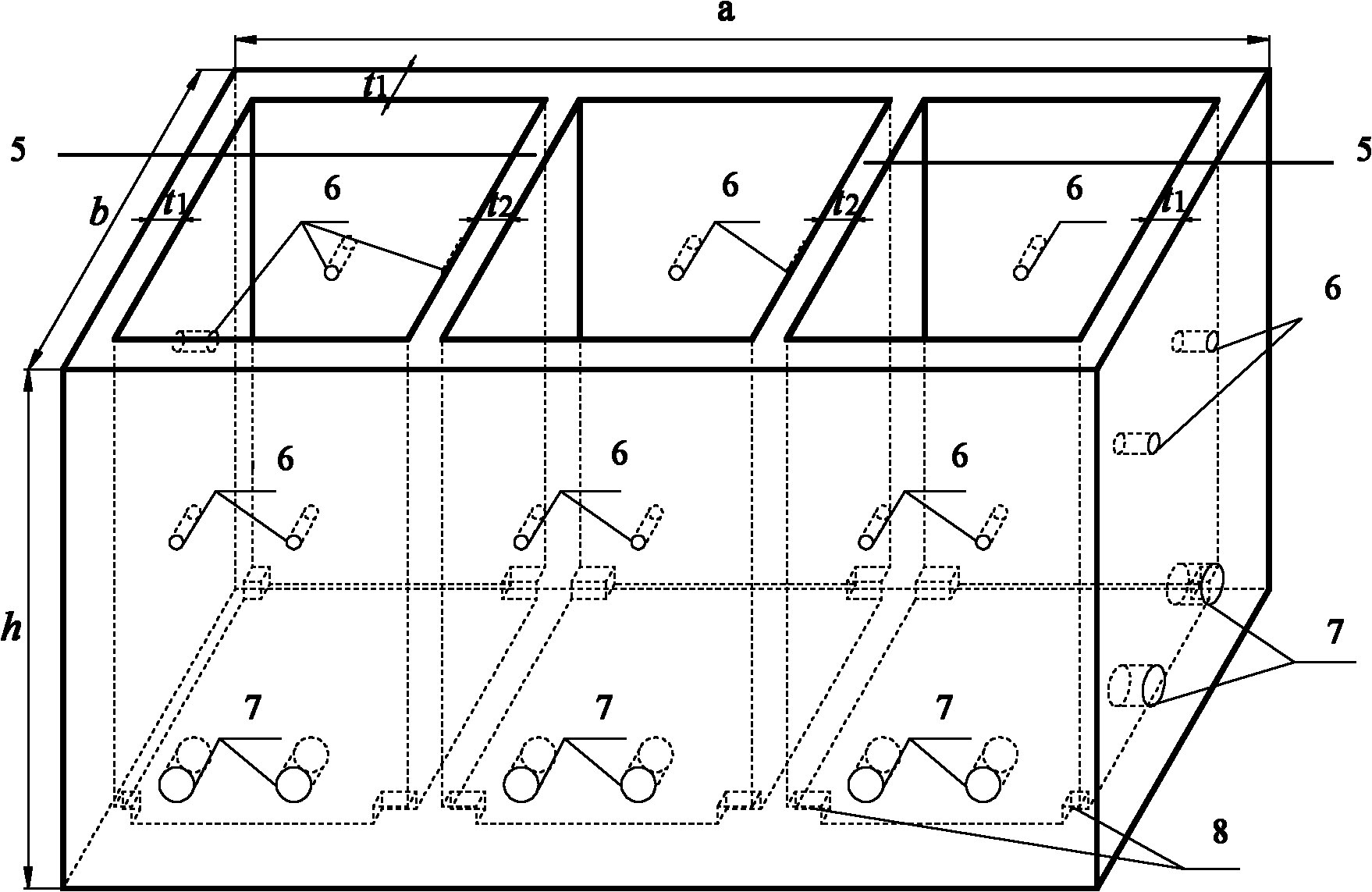

Water storage tank type steel structural dam

ActiveCN102251502ASimple structure and stable and reliableExtended service lifeGravity damsWater storageStructural water

The invention relates to a water storage tank type steel structural dam, which comprises a truss structural dam body and a steel structural water retaining panel, wherein the lower end of the truss structural dam body is fixed on an inner concrete bearing platform of a riverbed, the steel structural water retaining panel is fixed on the water retaining surface of the truss structural dam body, a matched water tank is fixedly arranged in each cell encircled by the truss structure, the water tanks are communicated with one another, and the water tank at the upper end of the truss structure is provided with a water inlet and a water pump. The water storage tank type steel structural dam has simple, stable and reliable structure and simultaneously has the advantages of a steel structural dam and a gravity dam; and the lower end and two sides of the truss of the water storage tank type steel structural dam are easily fixed with the bearing platform and the side slope, so that the water storage tank type steel structural dam is easy in construction and maintenance. The water tanks can be industrially produced and constructed on site, so the construction efficiency is high. The dam has long service life and low cost, and is very suitable for popularization and implementation.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

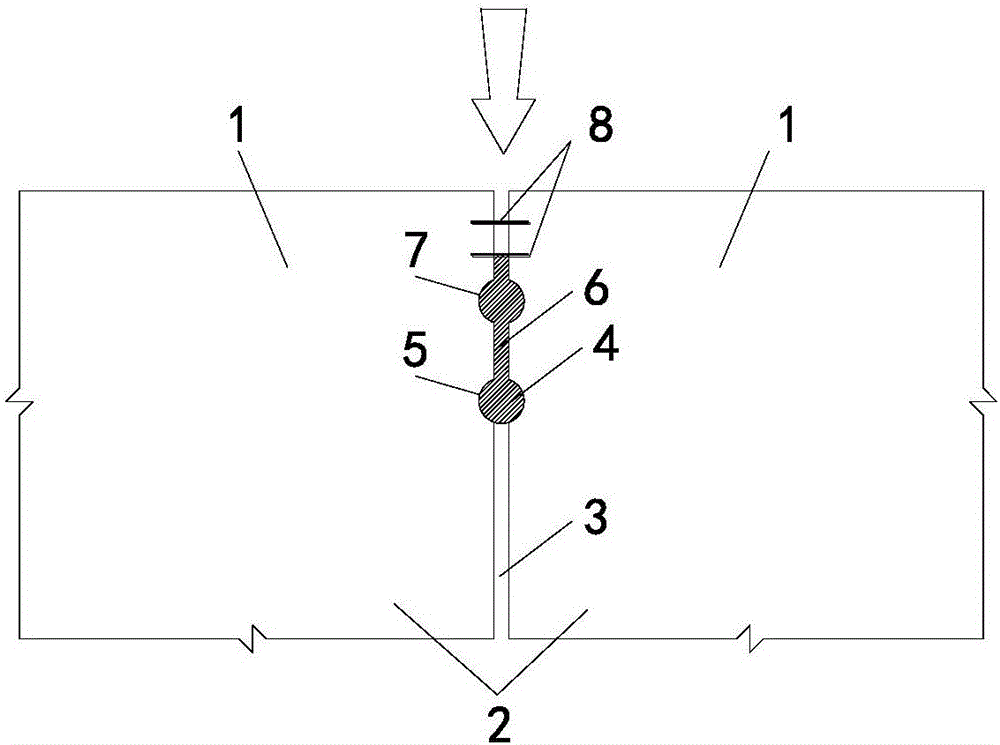

Water leakage treatment structure for transverse seam of concrete gravity dam

ActiveCN106498905AConvenient and efficient constructionGood water blocking effectGravity damsLeaking waterChemical grouting

The invention discloses a water leakage treatment structure for a transverse seam of a concrete gravity dam, relates to the field of water conservancy and hydropower engineering, and provides the water leakage treatment structure, which can meet water blockage requirements and can quickly and efficiently construct, for the transverse seam of the concrete gravity dam. The structure comprises a gravity dam with a plurality of dam sections, wherein the transverse seam is arranged between adjacent two dam sections; a water stop band for preventing the transverse seam from leaking water is formed in the gravity dam; a cement grouting hole and a water-blocking plug grouting hole are formed in the gravity dam; the water-blocking plug grouting hole and the cement grouting hole are formed across the transverse seam, and extend to the dam bottom from the dam top of the gravity dam; the water stop band, the cement grouting hole and the water-blocking plug grouting hole are sequentially formed from the upstream to the downstream in the water flow direction; a water blocking plug formed by chemical grouting is formed in the water-blocking plug grouting hole; and a cement filling structure formed by cement grouting is arranged in cement grouting hole and the transverse beam from the water stop band and the water blocking plug. The water leakage treatment structure can be used for sealing the transverse seam when the transverse seam of the concrete gravity dam leaks water.

Owner:POWERCHINA CHENGDU ENG

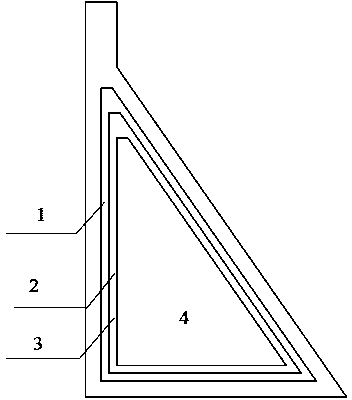

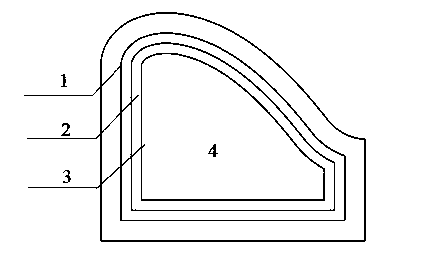

Composite material dam

InactiveCN103437326AImprove anti-seepage effectHigh strengthEarth-fill damsRock-fill damsRoller-compacted concreteRockfill material

The invention discloses a composite material dam, comprising a concrete dam shell, wherein a rockfill material is filled in the inner cavity of the concrete dam shell; a cushion layer and a transition layer are orderly arranged from outside to inside between the inner wall of the concrete dam shell and the rockfill material. The composite material dam has the combined advantages of a rolled rockfill dam and a rolled concrete gravity dam, and is good in impermeability, small in size, simple and convenient for construction, low in manufacture cost, and simple and beautiful in appearance; the composite material dam is mainly applicable to low dams having the dam height of less than 50 m.

Owner:POWERCHINA ZHONGNAN ENG

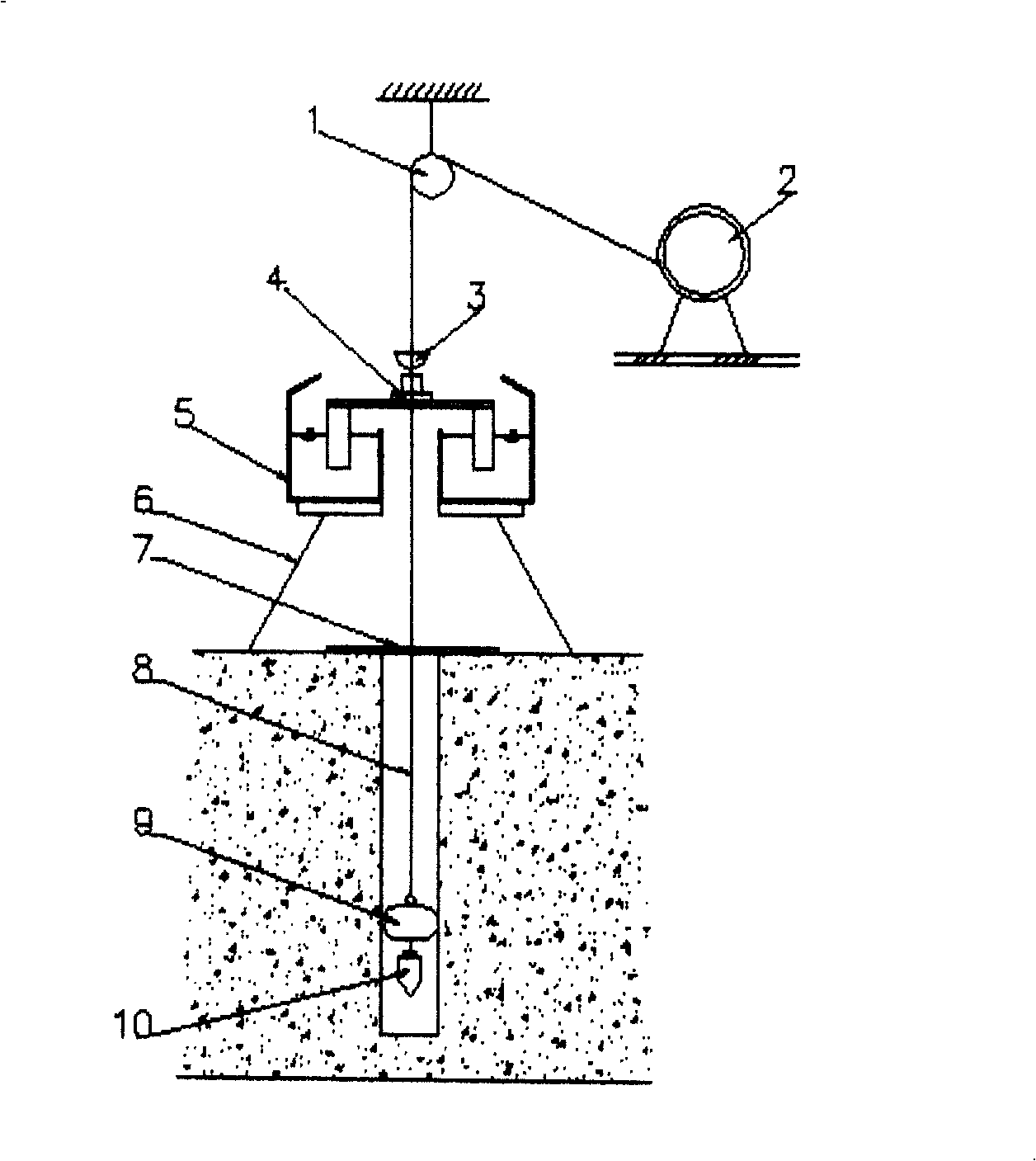

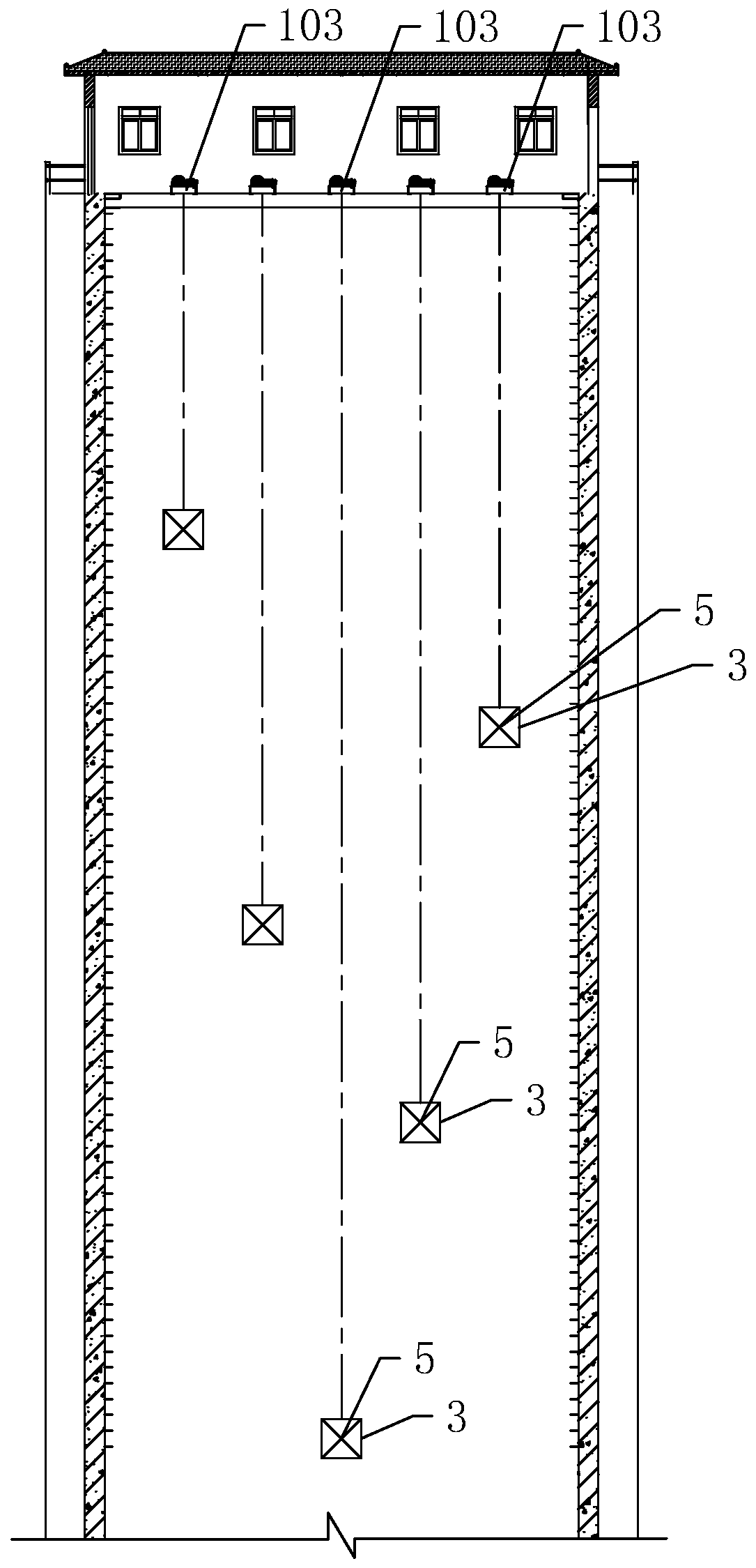

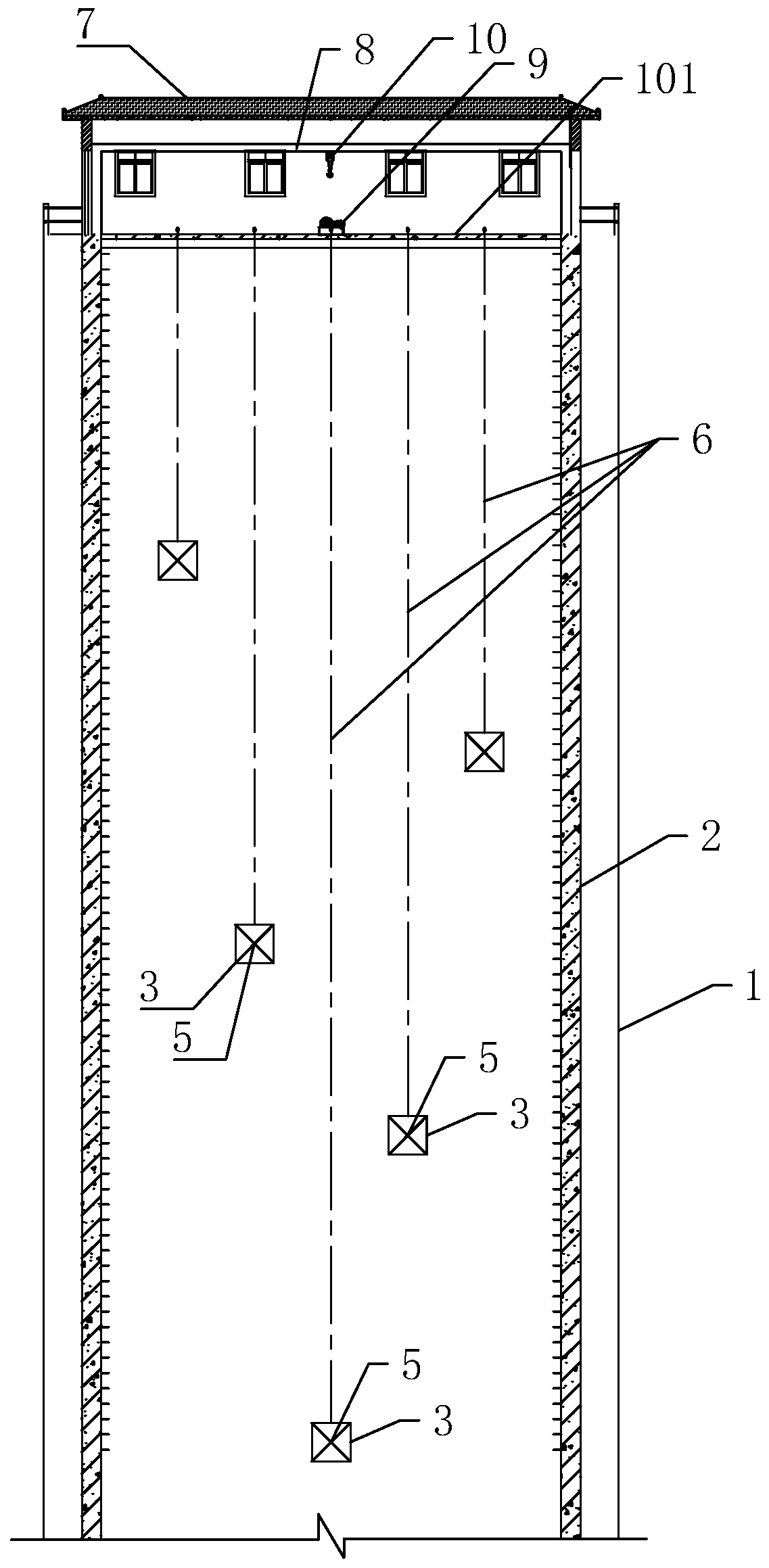

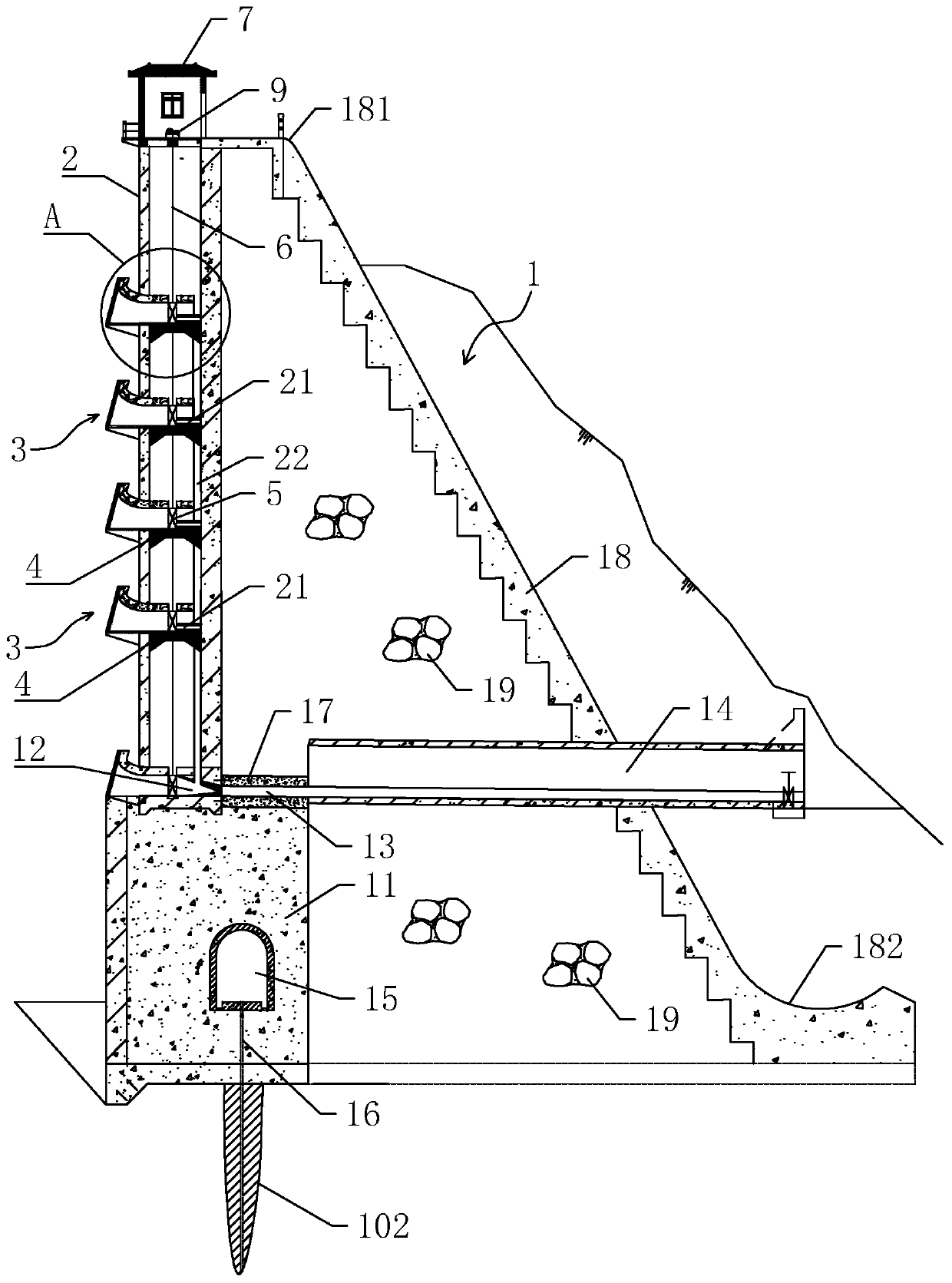

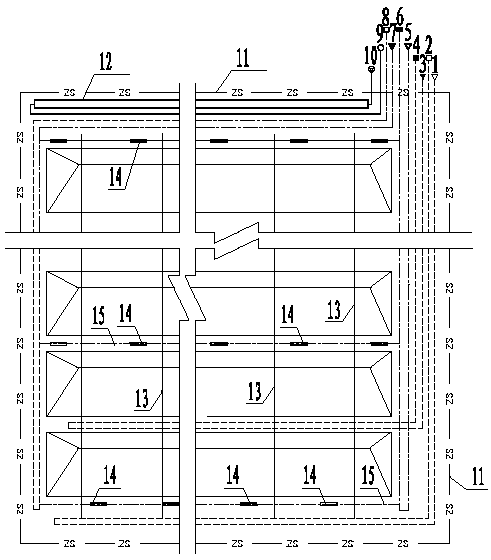

Layered water intake system for rockfill concrete gravity dam

ActiveCN110863471ANot easy to shakeFirmly connectedBarrages/weirsDrinking water installationWinchWater intake

The invention relates to a layered water intake system for a rockfill concrete gravity dam. The layered water intake system includes a dam body, a shaft, water intake opening structures, a support structure, opening and closing gates, a hoisting rope, a working room, a horizontal rail, an electric hoist, a winch and a bottom rail. The shaft is located on the inner side face of the dam body, the multiple water intake opening structures are arranged on the inner side of the shaft, water inlet pipe parts of the water intake opening structures extend into the shaft, the shaft is internally provided with the support structure, the opening and closing gates are assembled in water inlet pipes in a sliding manner, the hoisting rope is connected to the top of the opening and closing gates, the working room is arranged on the top of the dam body, and the top of the hoisting rope extends out of the inner bottom wall of the working room; and the horizontal rail is arranged on the top of the working room, the electric hoist is assembled on the horizontal rail in a sliding manner, the bottom wall is arranged on the inner bottom wall of the working room, the winch is assembled on the bottom railin a sliding manner, the electric hoist is used for dragging the winch to slide, and the top of the hoisting rope and a winding drum of the winch are detachably assembled. By means of the layered water intake system, one winch is used for controlling the multiple opening and closing gates to achieve lifting opening and closing, and the effects of reducing the cost and being short in construction period are achieved.

Owner:湖北志宏水利水电设计有限公司

Detachable gravity dam and construction and dismounting method thereof

The invention relates to a detachable gravity dam and a construction and dismounting method thereof, and belongs to the technical field of water conservancy projects. The detachable gravity dam comprises a drainage grouting gallery, an anti-seepage curtain, a dam foundation drainage hole, a middle pier, a side pier and a transverse seam, and further comprises an upstream concrete panel, building block concrete, a downstream concrete panel, a plain concrete cushion layer and a dam foundation anchor bar; the building block concrete is formed by connecting prefabricated building blocks through bolts according to a certain sequence; the upstream concrete panel and the downstream concrete panel are correspondingly poured on the upper surface and the downstream side of a dam body, and the plainconcrete cushion layer is laid on the dam foundation, the detachable building block concrete is built on the plain concrete cushion layer, and the dam foundation anchor bar is arranged in each hoisting hole of the bottom-layer building block concrete. According to the detachable gravity dam and the construction and dismounting method thereof, the advantages of reliable quality and high construction efficiency of a prefabricated concrete component can be fully utilized, so that temperature cracks in the dam body are reduced, the safety of the gravity dam is ensured, meanwhile, the dam body is convenient to detach, and the economical and environment-friendly effects are realized.

Owner:KUNMING UNIV OF SCI & TECH

Mixed constructing method of high concrete gravity dam and high concrete gravity dam

ActiveCN104060581AEliminates significant risk of longitudinal seam splayFoundation engineeringGravity damsRoller-compacted concreteMaterials science

The invention relates to a mixed constructing method of a high concrete gravity dam with the height exceeding 70 meters and the high concrete gravity dam. Normal concrete is adopted for conducting pouring on dam blocks which must be poured through normal concrete, however, roller compacted concrete is adopted for conducting pouring on other dam blocks which do not need to be poured through normal concrete and requires increasing of the construction progress. A conventional grouting system is used for conducting grouting on longitudinal joints between the dam blocks. A repeated grouting system is used for conducting grouting on the longitudinal joints multiple times, wherein the longitudinal joints are opened again. According to the high concrete gravity dam constructed through the constructing method, partial dam blocks are normal concrete dam blocks poured through the normal concrete, and the rest of the dam blocks are roller compacted concrete dam blocks poured through the roller compacted concrete. According to the high concrete gravity dam, partial dam blocks are adjusted to be the roller compacted concrete dam blocks, and therefore the field requirement for increasing the construction progress is met; the joint face grouting processing measure is adopted, and therefore the risk that the longitudinal joints between the dam blocks are opened due to the fact that hydration heat is not synchronous because the properties of the concrete adopted in all the dam blocks are different is eliminated.

Owner:POWERCHINA ZHONGNAN ENG

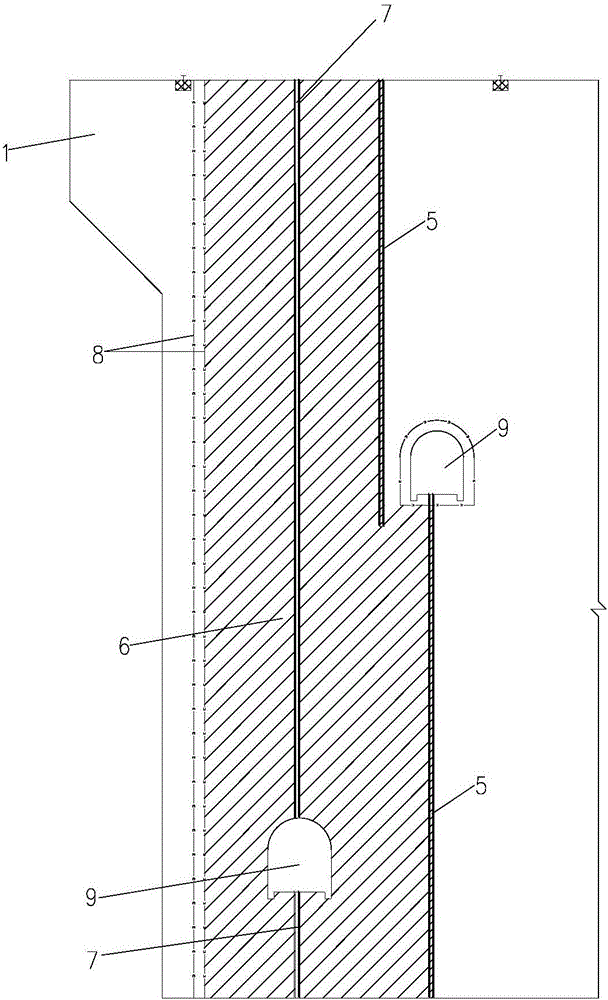

Repair structure and construction method of pathological concrete gravity dam in severe cold area

ActiveCN105735206ARealize anti-seepage repairImprove anti-seepage effectGravity damsEngineeringCold area

The invention relates to a repair structure and a construction method of a pathological concrete gravity dam in a severe cold area. The invention aims to provide the repair structure and the construction method of the pathological concrete gravity dam in the severe cold area, which have the advantages of simple structure, convenience in construction, safety and reliability. The repair structure of the pathological concrete gravity dam in the severe cold area adopts the technical scheme that the repair structure is used for repairing the part, of which the anti-seepage performance is poor, of the water attaining surface of a dam body of the concrete gravity dam, brackets are arranged on the water attaining surface of the dam body and below the part of which the anti-seepage performance is poor, concrete protection plates which are formed in a way that a plurality of concrete precast blocks are overlapped and spliced and cover the water attaining surface of the dam body are arranged above the brackets and at a certain distance away from the water attaining surface of the dam body, the lower ends of the concrete protection plates are supported on the brackets, bituminous concrete anti-seepage plates are arranged between the concrete protection plates and the dam body, and the lower ends of the bituminous concrete anti-seepage plates are supported on the brackets. The repair structure and the construction method are suitable for structure repairing and other similar projects of the pathological concrete gravity dam of which the dam height is below 50 m in the severe cold area.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Debris flow blocking structure and blocking method

The invention discloses a debris flow blocking structure and a blocking method. The debris flow blocking structure comprises an anchor rod, an inhaul cable, a groove, gravity piers and a connection cable, wherein the anchor rod is arranged in a debris flow ditch, an anchor section of the anchor rod extends into bedrock, one end of the inhaul cable is connected with the anchor rod, the other end ofthe inhaul cable is connected with the gravity piers, the inhaul cable and the anchor rod are detachably connected, the groove is dug in the debris flow ditch, a plurality of gravity piers are arranged in the groove, the gravity piers are arranged in the groove in parallel, and the gravity piers are connected through the connection cable. According to the debris flow blocking structure disclosedby the invention, the anchor rod can provide resistance, and a project amount is reduced; thus, project cost and construction time are saved. The blocking structure can stop large-particle stone in debris flow, so that flushing capacity of the debris flow is weakened, and debris flow disaster is prevented. In addition, the blocking structure disclosed by the invention can be freely disassembled and can be recycled for multiple times.

Owner:范云鹤

Process for constructing long intermittent layer in wind, dry, hot and high-evaporation environments

InactiveCN102155092ASimple construction processEasy to operateBuilding material handlingGravity damsEmulsionEvaporation

The invention provides a process for constructing a long intermittent layer in wind, dry, hot and high-evaporation environments. The process comprises the following steps of: cleaning a concrete surface; and paving a layer mix, wherein the cleaning treatment comprises flushing treatment with high-pressure water and soaking treatment; the layer mix is paved by the following steps of: paving a layer of cement paste with the thickness of 2-4 millimeters; and paving mortar of 1-2 centimeters. Mortar paved around a junction surface is preferably acrylic emulsion mortar. Preferably, the thickness of the cement paste is 3 millimeters, and the thickness of the mortar is 1.5 centimeters. The process for constructing the long intermittent layer in the wind, dry, hot and high-evaporation environments is simple, and is easy to operate. By adopting the process, negative influences of environmental factors such as wind, dryness, heat, high evaporation and the like can be restrained, and horizontal cracks on the long intermittent layer are avoided.

Owner:SINOHYDRO ENG BUREAU 15

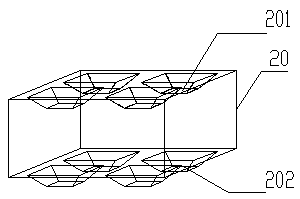

Fabricated concrete gravity dam based on composite structure and construction method of fabricated concrete gravity dam

ActiveCN110468795AFacilitate factory productionQuality controllableGravity damsStructure systemPrecast concrete

The invention relates to a fabricated concrete gravity dam based on a composite structure and a construction method of the fabricated concrete gravity dam, and belongs to the technical field of waterconservancy engineering. According to the fabricated concrete gravity dam, a dam body is mainly formed by pouring composite-structured concrete, and an upstream concrete panel and a downstream concrete panel are poured on the upstream side and the downstream side of the dam body; a plain concrete cushion is paved on a dam foundation, and the composite-structured concrete is laid on the plain concrete cushion; the composite-structured concrete is composed of precast concrete components and post-poured concrete in the precast concrete components, wherein the post-poured concrete is connected mutually to form a spatial frame structure system, and the stability of the dam body is enhanced; the advantages of the reliable quality of the precast concrete components, reduction of temperature cracks in the dam body and high construction efficiency can be fully used, meanwhile, due to the spatial frame structure system formed by the post-poured concrete, the integrity and stability of the dam body can be improved, and the safety of the dam body is ensured.

Owner:KUNMING UNIV OF SCI & TECH

Gravity reverse-supporting debris flow protective retaining wall and construction method thereof

InactiveCN108755604AOffset the shockImprove impact resistanceBarrages/weirsGravity damsButt jointEngineering

The invention discloses a gravity reverse-supporting debris flow protective retaining wall which comprises a substrate, and a dam body, a gravity plate and an angular position fixing seat arranged onthe substrate, wherein a groove is formed in the substrate, the dam body is arranged on one side of the groove, and a positioning body is arranged on one side, close to the groove, of the dam body ina semi-embedded manner; the angular position fixing seat is arranged on the other side of the groove, and an oblique supporting rod facing the dam body obliquely upward is arranged on the angular position fixing seat; a side edge of the gravity plate is a round sliding side, the round sliding side of the gravity plate is matched with and is in butt joint to the groove of the substrate, and the gravity plate leans against the tail end of the oblique supporting rod. By taking self weight of the gravity plate as a buffering force, when the debris flow impact comes, the debris flow straightens thegravity plate to counteract a considerable part of debris flow impact by leaning the gravity plate against the angular positioning fixing seat, so that the gravity reverse-supporting debris flow protective retaining wall has a better anti-impact effect.

Owner:励春亚

Seepage-proofing method for deep cover layer

InactiveCN107044131AShort construction periodEasy constructionFoundation engineeringGravity damsEngineeringGeological exploration

The invention relates to a seepage-proofing method for a deep cover layer. The seepage-proofing method comprises the following steps of: 1) dividing formation complex and determining seepage parameters; 2) performing construction by taking seepage slope as a main role and taking permeability as a subsidiary role; and 3) arranging seepage-proofing walls by adopting a seepage-proofing mode of short connecting plates and the seepage-proofing walls. According to the seepage-proofing method, the formation complex is divided and the seepage parameters of the cover layer are determined for judging and analyzing which form of piping erosion and flowing soil of rock-soil belongs to, construction is performed by taking seepage slope as the main role and taking permeability as the subsidiary role according to the seepage parameters of the cover layer, and the seepage-proofing walls are arranged by adopting the seepage-proofing mode of short connecting plates and the seepage-proofing walls, so that the seepage-proofing method has the characteristics of a short construction period, convenient construction and a good seepage-proofing effect. The seepage-proofing method performs seepage-proofing treatment on the deep cover layer in aspects of early-stage geological exploration and test, parameter determination, seepage-proofing scheme determination, construction scheme selection and the like, and therefore, the seepage-proofing method is obvious in seepage-proofing effect, and is especially suitable for seepage-proofing of the deep cover layer.

Owner:POWERCHINA XIBEI ENG +1

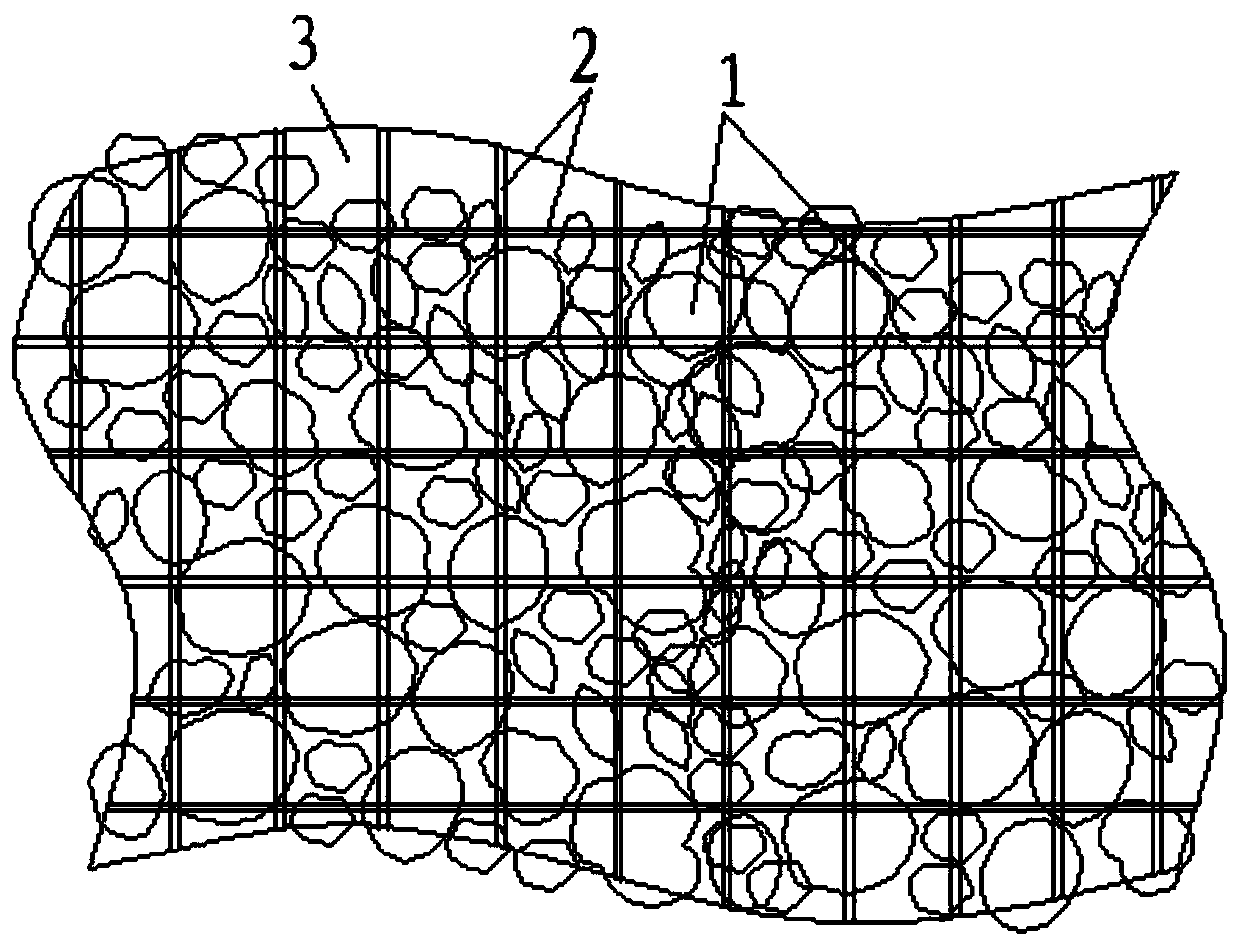

Self-compaction enrockment concrete gravity dam structure and construction method thereof

PendingCN110886274AReduce dosageReduce adiabatic temperature riseFoundation engineeringGravity damsRockfill materialArchitectural engineering

The invention discloses a self-compaction enrockment concrete gravity dam structure and a construction method thereof. The self-compaction enrockment concrete gravity dam structure comprises a steel bar layer, an enrockment material layer and a concrete material. The enrockment material layer is located in the middle of a dam body and is vertically arranged. The vertically-arranged steel bar layeris arranged on the two side edges of the enrockment material layer. The concrete material wraps the enrockment material layer and the steel bar layer inside. The construction method comprises the first step of bin face cleaning, the second step of template installing and steel bar bundling, the third step of rock block stacking, the fourth step of high-self-compaction performance concrete mixing,the fifth step of concrete transportation, the sixth step of high-self-compaction performance concrete pouring and the seventh step of curing. By adoption of the enrockment concrete structure, the concrete pouring amount of the dam body can be greatly reduced, the construction cost is greatly reduced, and the construction efficiency is improved; and meanwhile, due to the heat dissipation functionof enrockment, the concrete hydration heat can be greatly reduced, and a very good field construction effect is achieved.

Owner:贵州水务建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com