Debris flow blocking structure and blocking method

A technology for debris flow and debris flow ditch, applied in dams, gravity dams, etc., can solve the problems of reduced debris flow destructive capacity, reduced debris flow carrying capacity, high engineering volume and cost, and achieves the effect of saving engineering costs, construction time, and resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

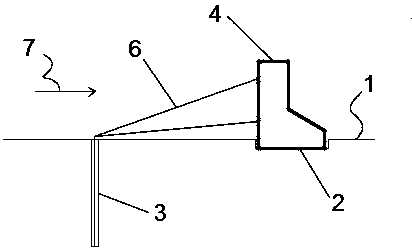

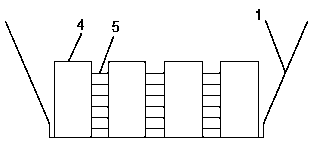

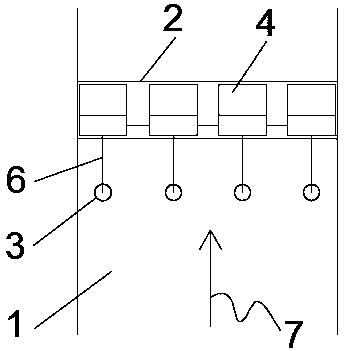

[0029] Such as Figure 1-3 The debris flow blocking structure shown includes an anchor rod 3, a cable 6, a groove 2, a gravity pier 4, and a connecting cable 5. The anchor rod 3 is installed in the debris flow ditch 1, and the diameter of the anchor rod 3 is 80mm-120mm. The anchoring section of the rod 3 extends into the bedrock, and the length of the anchoring section is not less than 400mm. One end of the drag cable 6 is connected to the anchor rod 3, and the other end of the drag cable 6 is connected to the gravity pier 4. The connection between the drag cable 6 and the anchor rod 3, the tension The connection between the cable 6 and the gravity pier 4 can be disassembled. A trench 2 is excavated in the debris flow ditch 1. Several gravity piers 4 are placed in the trench 2. The gravity piers 4 are placed side by side in the trench 2. Between the gravity piers 4 Connected by the cable 5, the diameter of the cable 6 and the cable 5 is not less than 50mm.

[0030] The stay c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com