Water purification technology

A water purification and process technology, applied in the field of water treatment, can solve the problems of low removal capacity and toxicity of dissolved organic matter, achieve good removal effect, reduce membrane pollution, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

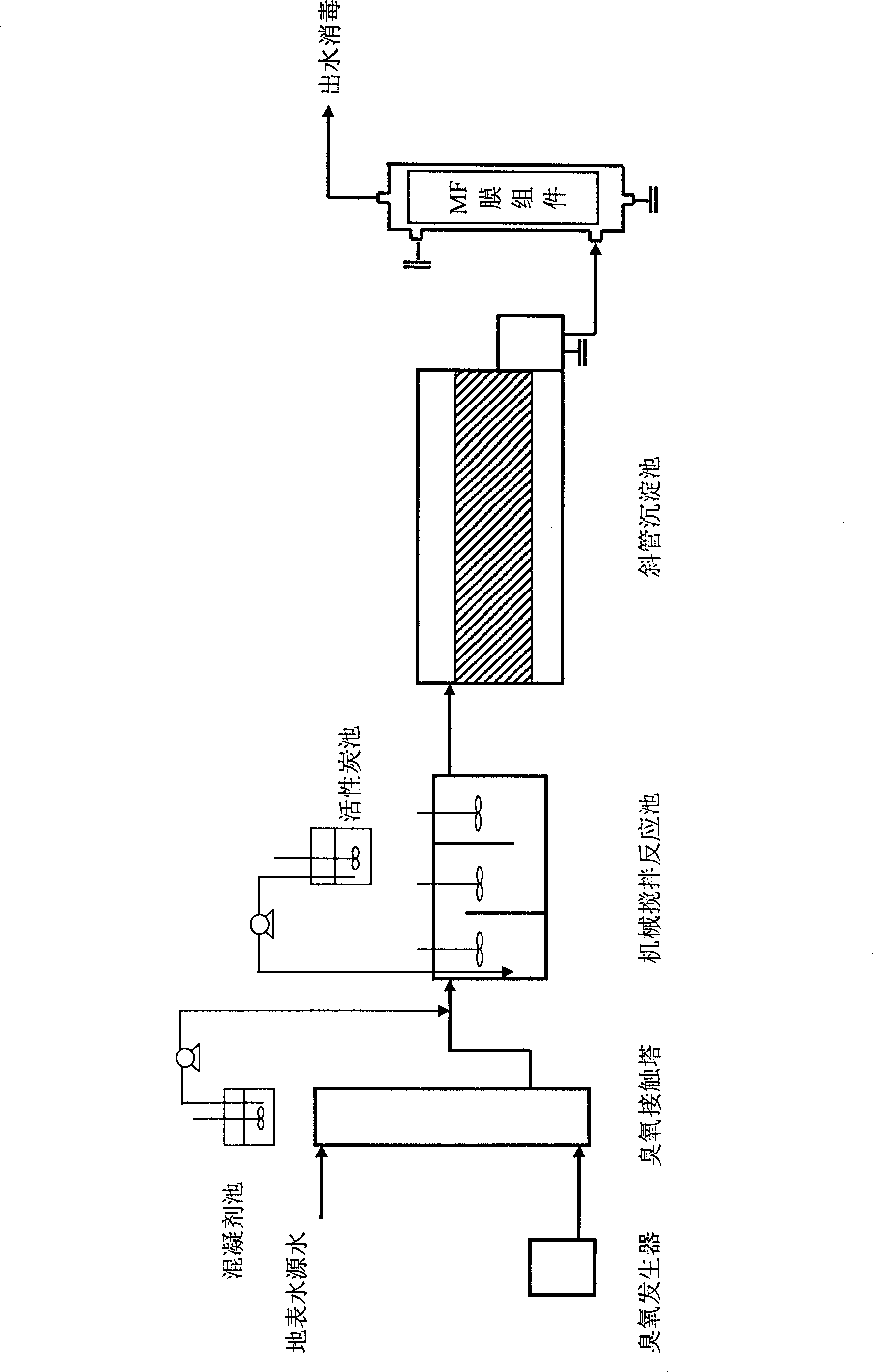

[0030] First build an ozone generating device, an ozone contact tower, a powdered activated carbon dosing device, a mechanical coagulation tank, an inclined tube sedimentation tank, and a PVDF hollow fiber microfiltration device.

[0031] COD of polluted source water Mn (Water pollution indicator COD Mn It refers to the consumption of oxidant (K 2 MnO 4 ), which is often used as a comprehensive indicator reflecting the degree of water pollution by reducing substances, is a routine monitoring indicator of water pollution and an important pollution control indicator) is around 6mg / L, turbidity is 20-80NTU, and iron in water High manganese content. After the source water is pre-oxidized by ozone (the concentration of ozone is 0.5-1.5mg / L) for 5 minutes, it enters the coagulation and sedimentation unit, and aluminum sulfate is used as the coagulant. The dosage of the coagulant is about 15-20mg / L ; After passing through the coagulation and sedimentation unit, the effluent water...

Embodiment 2

[0035] In addition to adding 20mg / L powdered activated carbon at the front of the coagulation tank, the ozone pre-oxidation time is 10 minutes (the concentration of ozone is 1.5-2.0mg / L), and polyaluminum chloride is used as the coagulant. The amount is about 5-10 mg / L, and the PVDF flat membrane with a pore size of 0.05 μm is used, and other conditions are basically the same as in Example 1. The test results showed that the final COD Mn The removal rate can be about 60%. Compared with Example 1, the removal rate of organic matter can be effectively improved, so it can be used as an emergency rescue process in the period of water quality deterioration. The final effluent can fully meet the national drinking water quality standards.

Embodiment 3

[0037] Except adding the powdered activated carbon of 10mg / L simultaneously at the front end of the coagulation tank, other conditions are basically the same as example 1. The test results are shown in Table 2. It can be seen that when the water quality of source water deteriorates, COD Mn When it is above 7mg / L, after adding 10mg / L powdered activated carbon, the final effluent COD Mn The removal rate can be more than 60%, which can fully meet the national drinking water standard. Compared with Example 1, the addition of powdered activated carbon can effectively improve the removal rate of organic matter, reduce the pollution load of the microfiltration membrane, and prolong the chemical cleaning cycle of the membrane. Therefore, it can be used as an emergency process when the water quality of the water source is deteriorating.

[0038]Table 2 Water purification effect of microfiltration membrane group and process after adding powdered activated carbon (water temperature 20°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com