Assembled type debris flow silt dam and construction method thereof

A technology for sand control dams and debris flow, applied in the field of debris flow prevention and control, can solve problems such as being easily affected by construction seasons, large site environmental damage, and difficult transportation of construction materials, and achieve the effects of shortening the construction period, saving the construction period, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

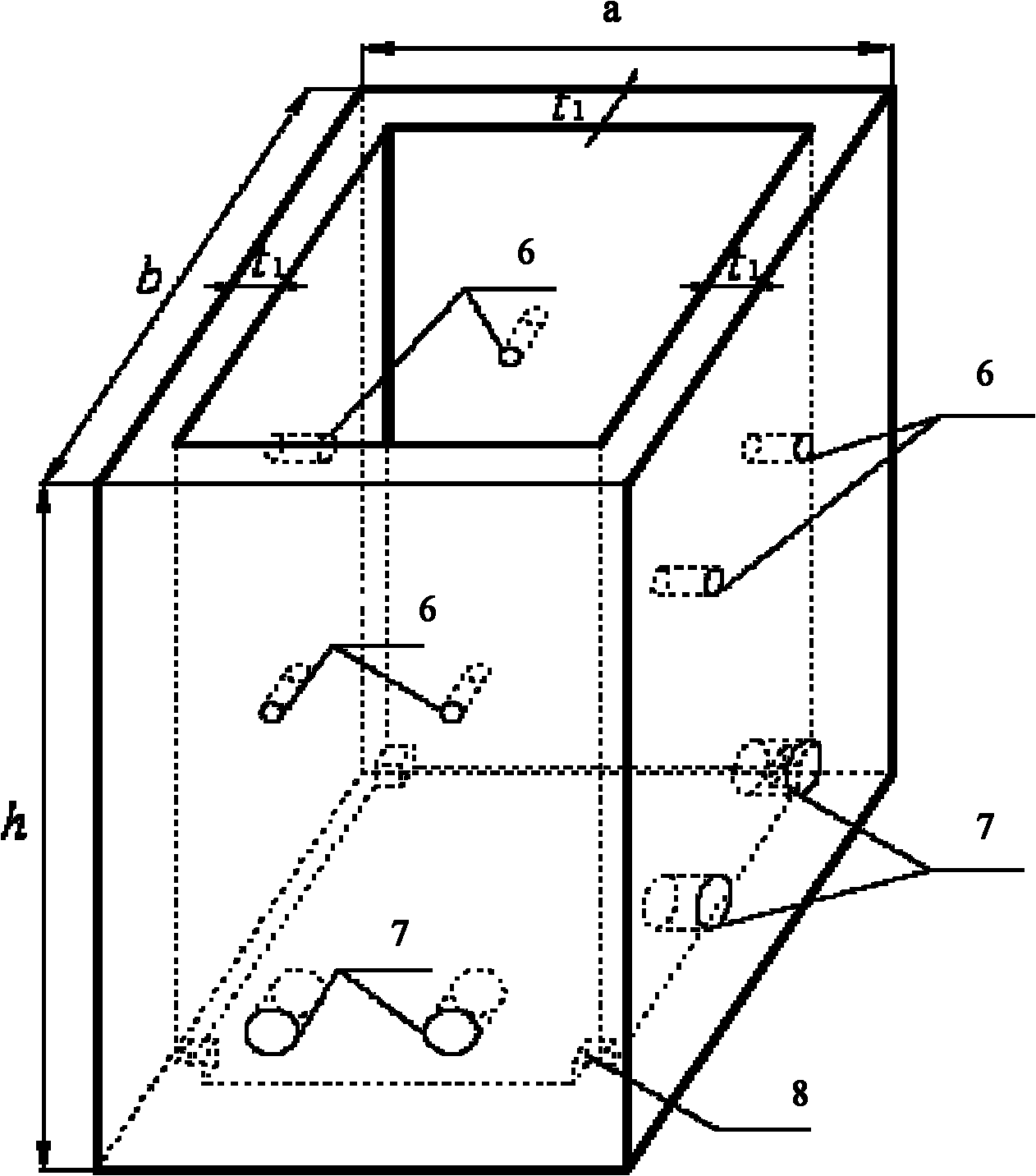

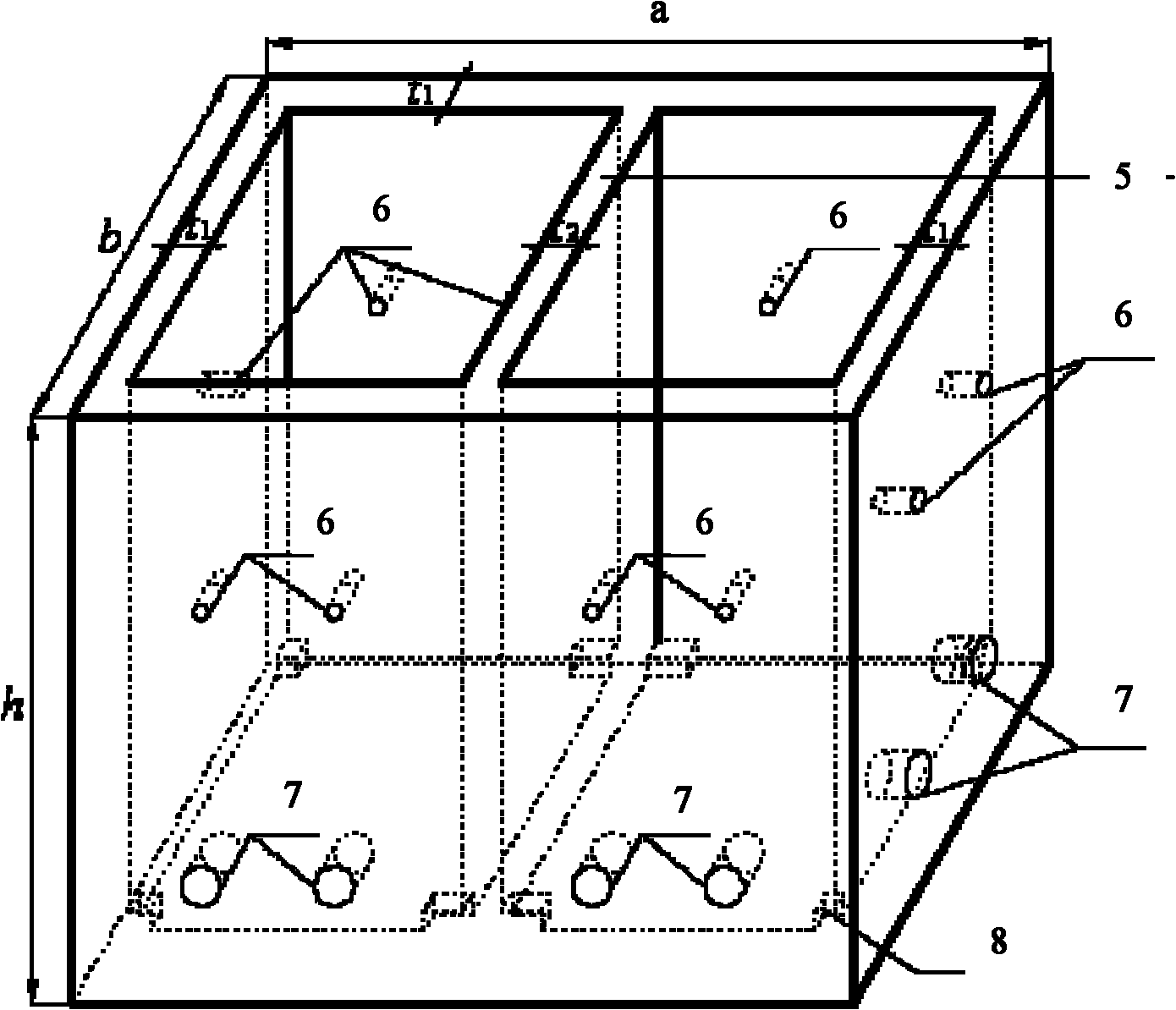

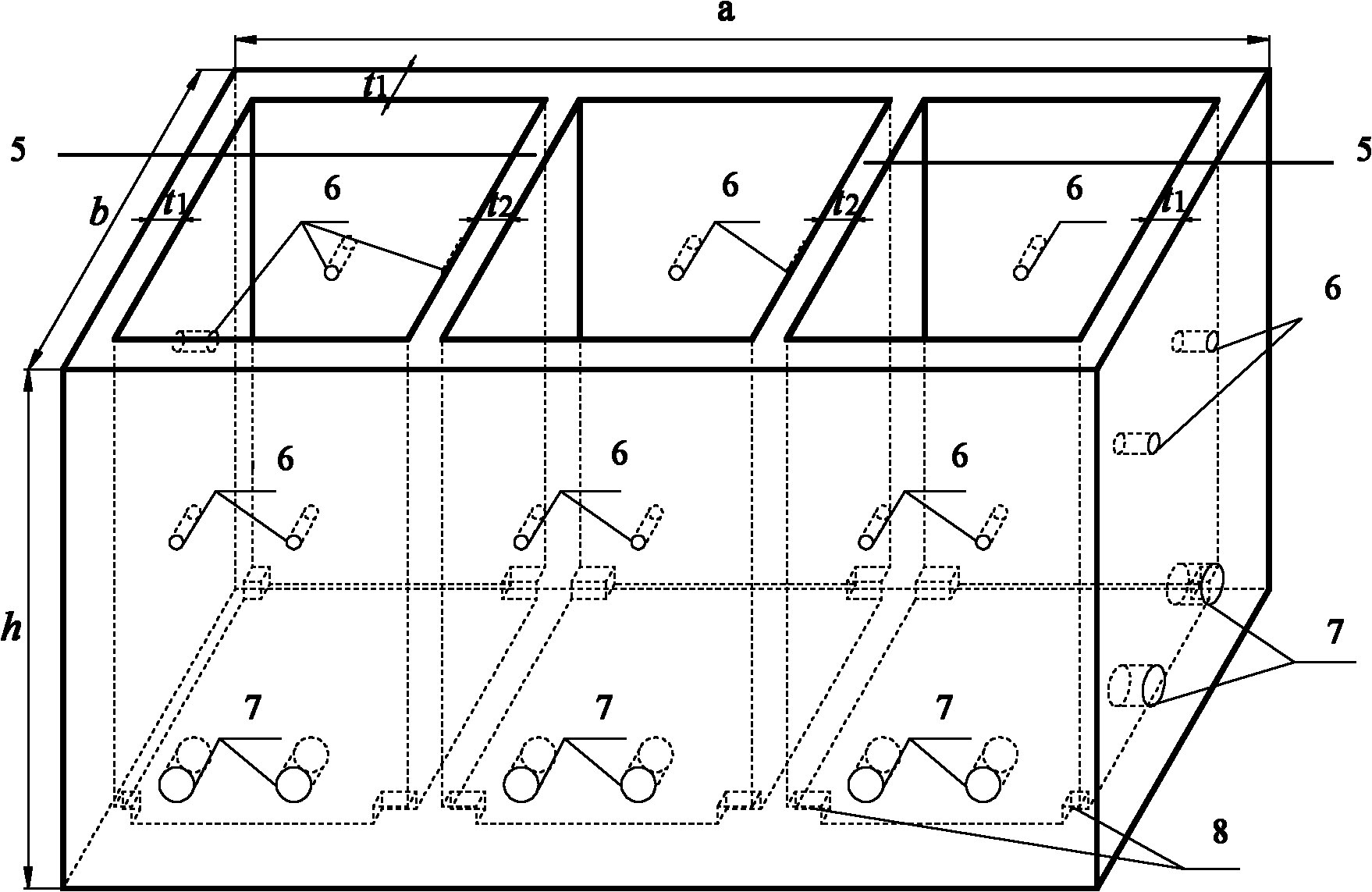

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 shown. The drainage area of a debris flow ditch is 5.6km 2 , in order to control debris flow disasters, it is planned to set up 5 Gufang, 1 sand dam and 700m drainage channel in the middle of the basin. For the sand retaining dam, the following construction methods are adopted:

[0038] In the first step, the net dam height H from the overflow of the sand dam to the dam foundation 2 is planned to be 6.0m, the width B of the dam crest 4 is 2.0m, and the slope gradient inside the dam body is 1∶m according to the situation of the debris flow ditch. 1:0.67. Since the net height H of the dam is less than or equal to 10.0m, it is planned to adopt the assembled debris flow sand retaining dam of the present invention. The assembled debris flow sand control dam includes several prefabricated reinforced concrete rectangular boxes 1 vertically and horizontally connected to form the main body of the dam body....

Embodiment 2

[0047] Such as figure 1 , figure 2 , Figure 4 , Figure 5 shown. The same as the first embodiment will not be repeated, the difference is:

[0048] The first step, for the debris flow ditch basin area of 10.0km 2 , the net dam height H from the overflow of the sand control dam to the foundation 2 of the dam body is planned to be 10.0m, the width B of the dam crest 4 is 3.0m, and the slope gradient 1:m inside the dam body is 1:0.7. Since the net height H of the dam is less than or equal to 10.0m, it is planned to adopt the assembled debris flow sand retaining dam of the present invention. According to the planned space size of the sand control dam, the geometric dimensions of the prefabricated rectangular box 1 are planned: ① According to the net dam height H from the overflow of the dam body to the dam body foundation 2 is an integer multiple n1 of the height h of the rectangular box body 1, It is preliminarily determined that n1 is taken as 10, and the height h of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Side wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com