Water leakage treatment structure for transverse seam of concrete gravity dam

A gravity dam and concrete technology, which is applied in gravity dams, dams, water conservancy projects, etc., can solve the problems of high processing cost and large economic loss of power generation, and achieve the effect of convenient and efficient construction and good water blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

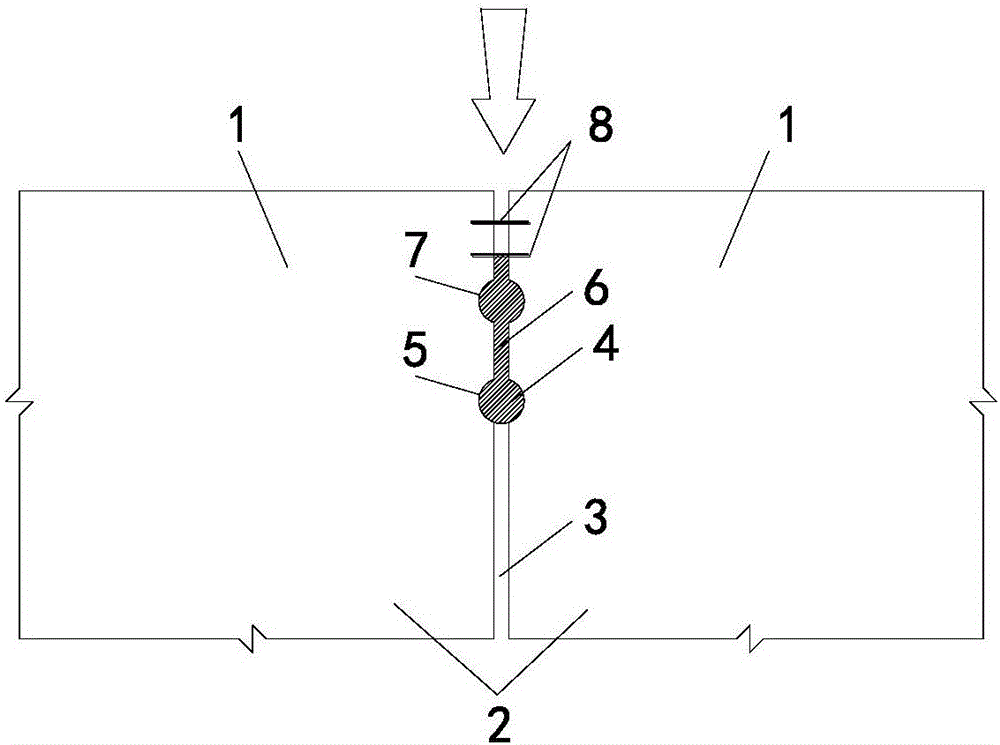

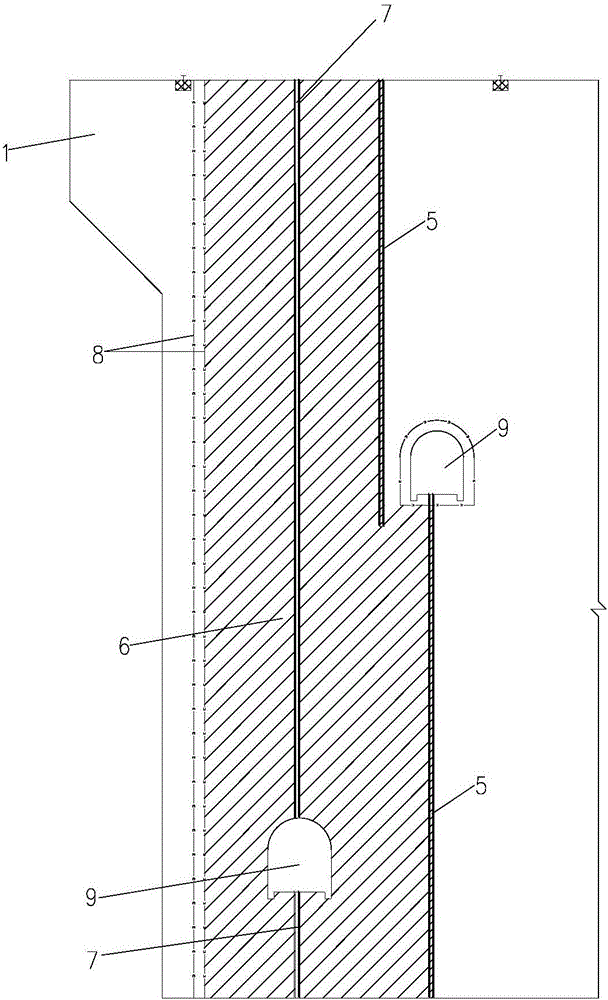

[0042] A concrete gravity dam transverse joint water leakage treatment structure includes a gravity dam 2 with a plurality of dam sections 1, transverse joints 3 are arranged between two adjacent dam sections 1, and a stopper for preventing water leakage from the transverse joints 3 is arranged in the gravity dam 2 The water belt 8; the gravity dam 2 is provided with a cement grouting hole 7 and a water blocking plug grouting hole 5, and the water blocking plug grouting hole 5 and the cement grouting hole 7 are arranged on the transverse joint 3 and extend from the top of the gravity dam 2 to the bottom of the dam , waterstop 8, cement grouting hole 7 and water blocking plug grouting hole 5 are arranged sequentially from upstream to downstream along the water flow direction; water blocking plug grouting hole 5 is provided with a water blocking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com