Filling machine and method hereof

a filling machine and filling method technology, applied in the field of filling machines and methods, can solve the problems of troublesome and expensive process establishment, individual components getting, etc., and achieve the effect of simple and efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

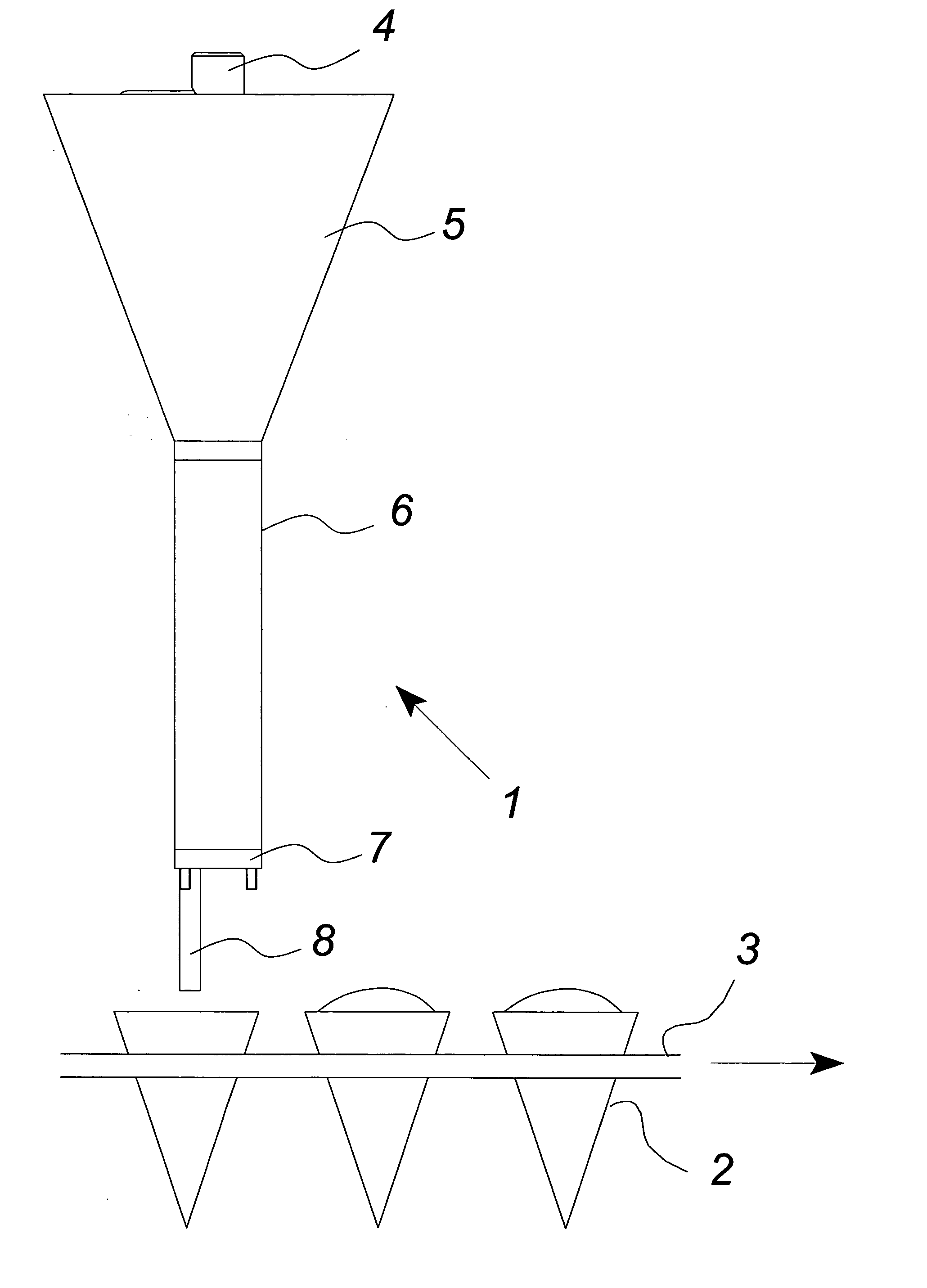

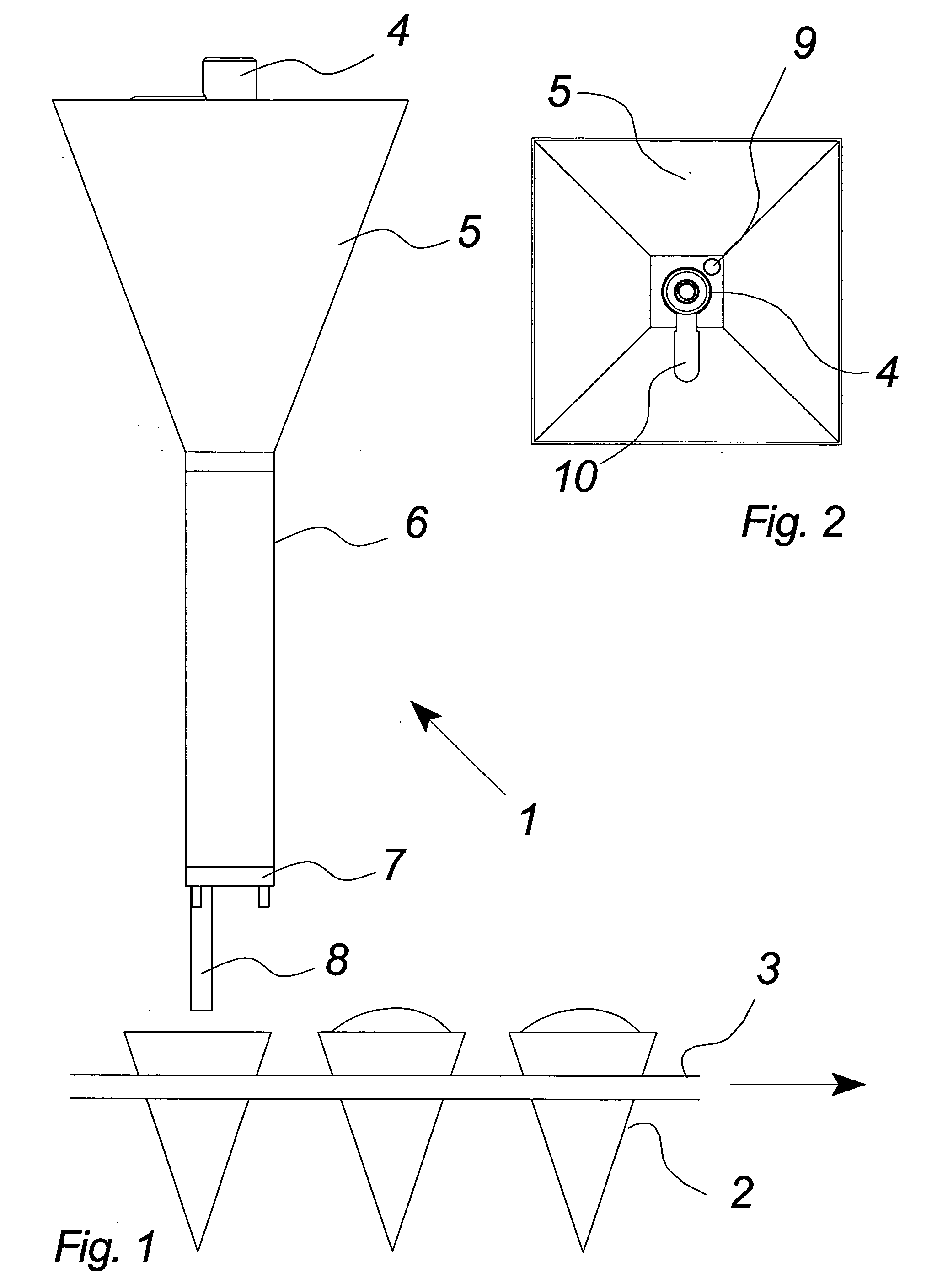

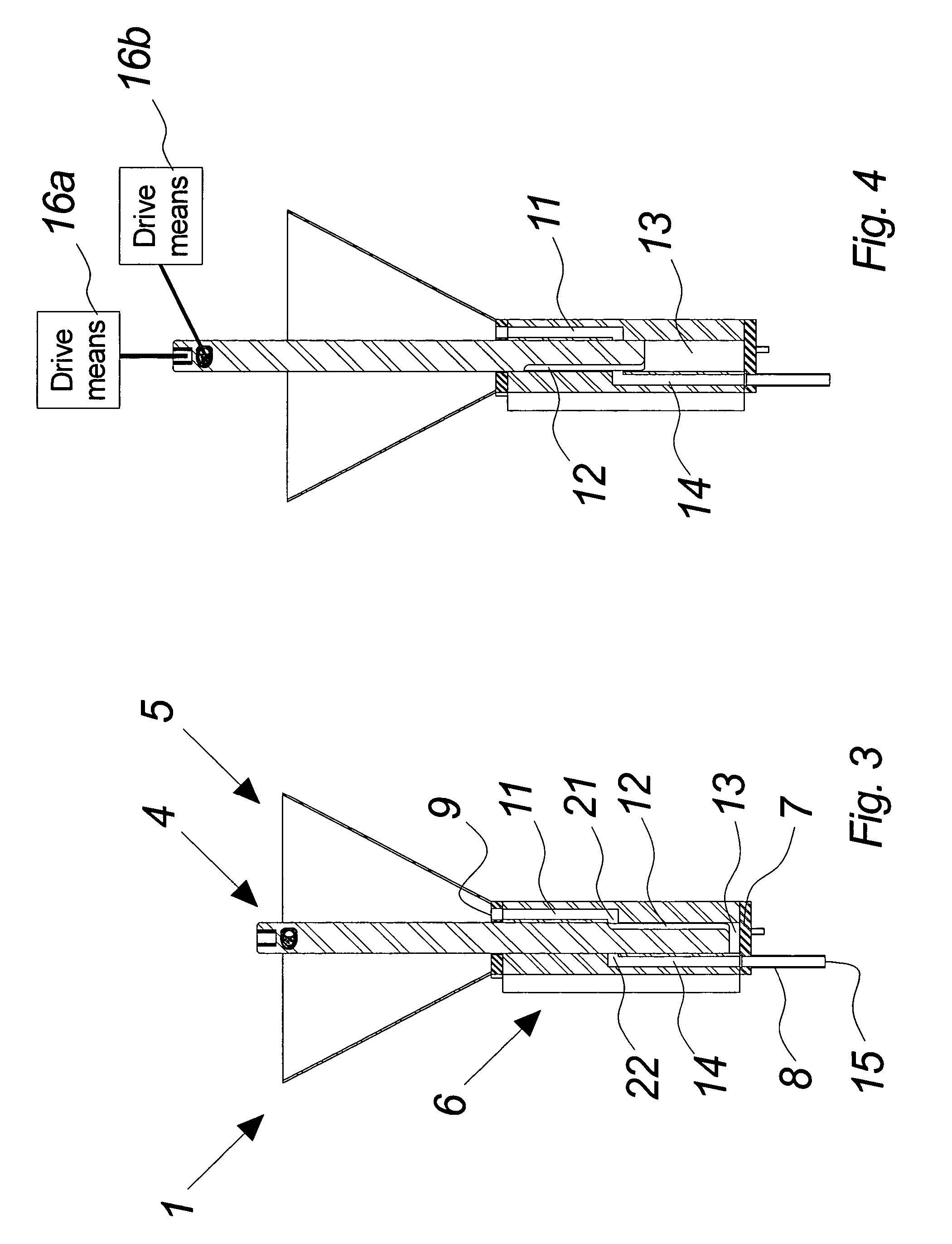

[0033]FIG. 1 shows a filling machine 1 for measuring-out and transfer of predetermined amounts of edible ice to containers 2 which pass under an outlet pipe 8 for the machine. In the figure, the containers are shown as cones which are fed successively under said outlet pipe by a conveyor belt 3. In addition to cones, the containers can also be other forms of containers for edible ice such as ice boats, ice cups or freezing pockets and paper or plastic packaging for edible ice.

[0034] A freezing pocket forms part of a mould unit for ice mass. The mould unit is hollow, where a coolant runs in the inside while a part of the surface consists of a number of moulds called freezing pockets. The freezing pockets are filled with edible ice, after which the coolant transfers cold through the material in which the freezing pockets are formed and herewith ensures a quick freezing-down of the edible ice. After the freezing-down, each edible ice items can be removed from their freezing pockets.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| side lengths | aaaaa | aaaaa |

| side lengths | aaaaa | aaaaa |

| side lengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com