Lightweight autoclaved foam concrete block and production method thereof

A foam concrete and autoclaved technology, which is applied in the field of light-weight and energy-saving building wall materials, can solve the problems of poor performance such as waterproof and heat insulation, large amount of cement, and high production costs, and achieve excellent anti-permeability performance, reduce raw material costs, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

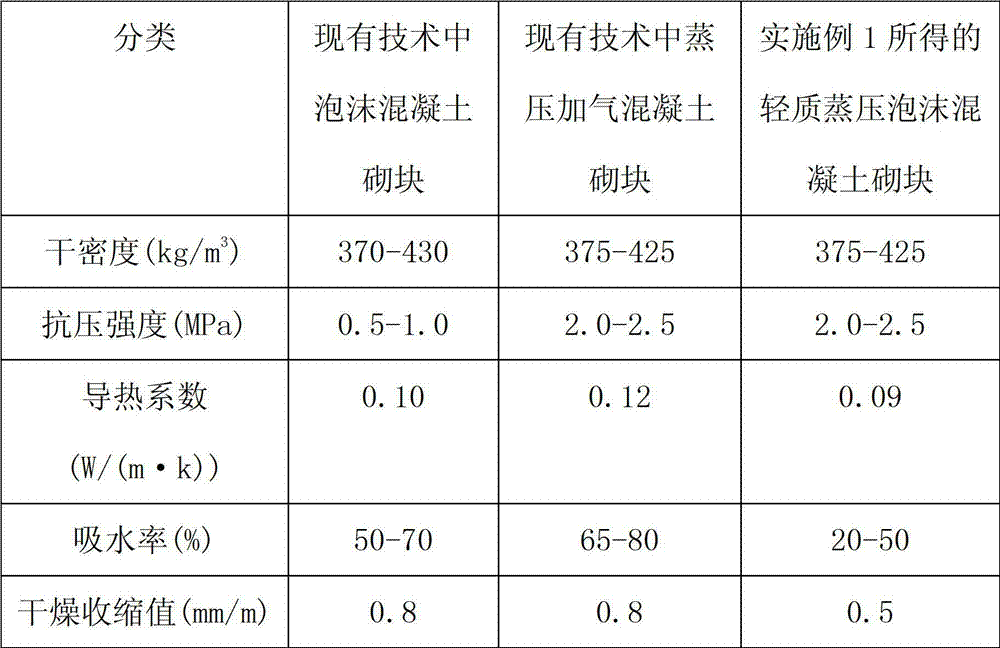

Embodiment 1

[0035] A lightweight autoclaved foam concrete block is obtained by the following steps:

[0036] (1) Configure the production raw materials and mix and stir.

[0037] The composition of raw materials per cubic meter is: 57.75kg of ordinary Portland cement with a strength grade of 42.5, and a specific surface area of 380-420m 2 96.25kg of blast furnace slag powder per kg, 57.75kg of quartz sand, 115.5kg of marble chips, 57.75kg of power plant slag, 0.8kg of coagulation accelerator thickener, 192.5kg of water, microbial protein foaming agent (Tianjin Yuchuan Microbial Products Co., Ltd. YCM20 type) 1.2kg. Among them, the fineness of marble chips, quartz sand and power plant slag is 0.080mm after being ground by a ball mill; Accounting for 50% of the total mass of coagulation accelerator thickener;

[0038] (2) Pump the slurry mixed and stirred in step (1) into the mold for molding;

[0039] (3) Steam curing for 3 hours at a temperature of 65°C;

[0040] (4) cutting;

[0...

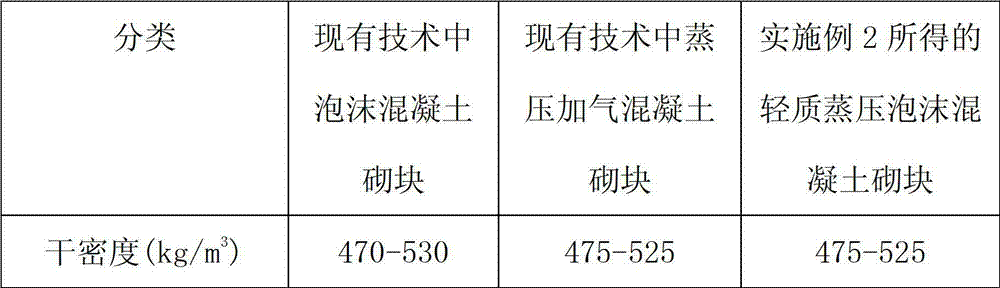

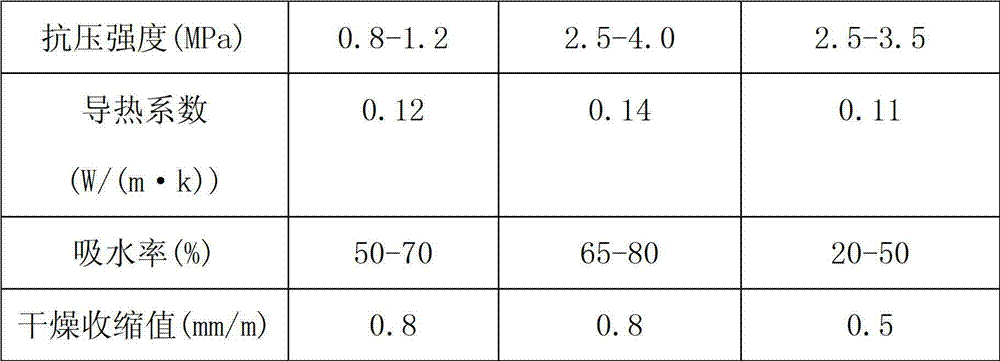

Embodiment 2

[0047] A lightweight autoclaved foam concrete block is obtained by the following steps:

[0048] (1) Configure the raw materials for production and mix and stir.

[0049] The composition of raw materials per cubic meter is: 72kg of ordinary Portland cement with a strength grade of 42.5, and a specific surface area of 380-420m 2 120kg of blast furnace slag micropowder per kg, 288kg of grade II fly ash, 1.2kg of accelerator thickener, 240kg of water, 1.0kg of microbial protein foaming agent (YCM20 type of Tianjin Yuchuan Microbial Products Co., Ltd.); The thickener is composed of aluminum sulfate and soda ash, the percentage of aluminum sulfate accounting for the total mass of the coagulation accelerator thickener is 50%, and the percentage of soda ash accounting for the total mass of the coagulation accelerator thickener is 50%;

[0050] (2) Pump the slurry mixed and stirred in step (1) into the mold for molding;

[0051] (3) Steam curing for 3 hours at a temperature of 65°...

Embodiment 3

[0060] A lightweight autoclaved foam concrete block is obtained by the following steps:

[0061] (1) Configure the raw materials for production and mix and stir.

[0062] The composition of raw materials per cubic meter is: 87kg of ordinary Portland cement with a strength grade of 42.5, and a specific surface area of 380-420m 2 145kg of blast furnace slag micropowder per kg, 348kg of grade II fly ash, 1.6kg of coagulation accelerator thickener, 290kg of water, and 0.8kg of microbial protein foaming agent (YCM20 type of Tianjin Yuchuan Microbial Products Co., Ltd.); among them, coagulation accelerator The thickener is composed of aluminum sulfate and soda ash, the percentage of aluminum sulfate accounting for the total mass of the coagulation accelerator thickener is 50%, and the percentage of soda ash accounting for the total mass of the coagulation accelerator thickener is 50%;

[0063] (2) Pump the slurry mixed and stirred in step (1) into the mold for molding;

[0064] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com