Fabricated concrete gravity dam based on composite structure and construction method of fabricated concrete gravity dam

A concrete and prefabricated technology, applied in the direction of gravity dams, dams, water conservancy projects, etc., can solve the problems of long curing time of cast-in-place concrete, construction speed affected by the environment, high gravity dam temperature cracks, etc., to achieve easy quality control and construction Fast speed, reducing the effect of temperature cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

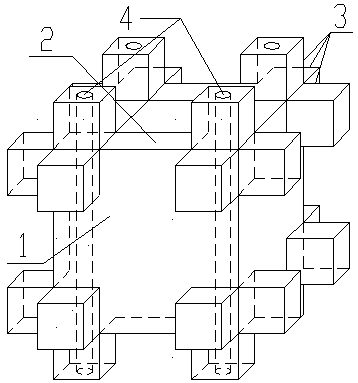

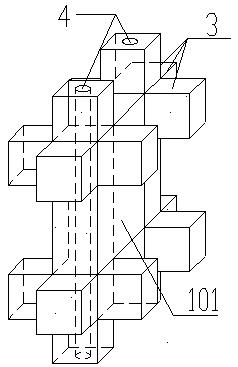

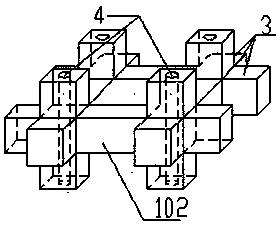

[0040] Embodiment 1: as Figure 1-8 As shown, a prefabricated concrete gravity dam based on a superimposed structure includes a superimposed structural concrete 11, an upstream concrete panel 12, a drainage grouting gallery 13, a downstream concrete panel 14, a plain concrete cushion 15, an anti-seepage curtain 16, Dam foundation drainage holes 17; the dam body is poured by superimposed structural concrete 11 except for the upstream concrete panel 12, drainage grouting corridor 13, downstream concrete panel 14, plain concrete cushion 15, anti-seepage curtain 16, and dam foundation drainage holes 17. (that is, the dam body is mainly composed of laminated structural concrete 11), the upstream concrete panel 12 and the downstream concrete panel 14 are poured on the upstream and downstream sides of the dam body;

[0041] The composite structural concrete 11 includes a precast concrete member 1 and post-cast concrete 5 poured inside the precast concrete member 1 and between two adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com