Patents

Literature

51results about How to "Reduce temperature cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

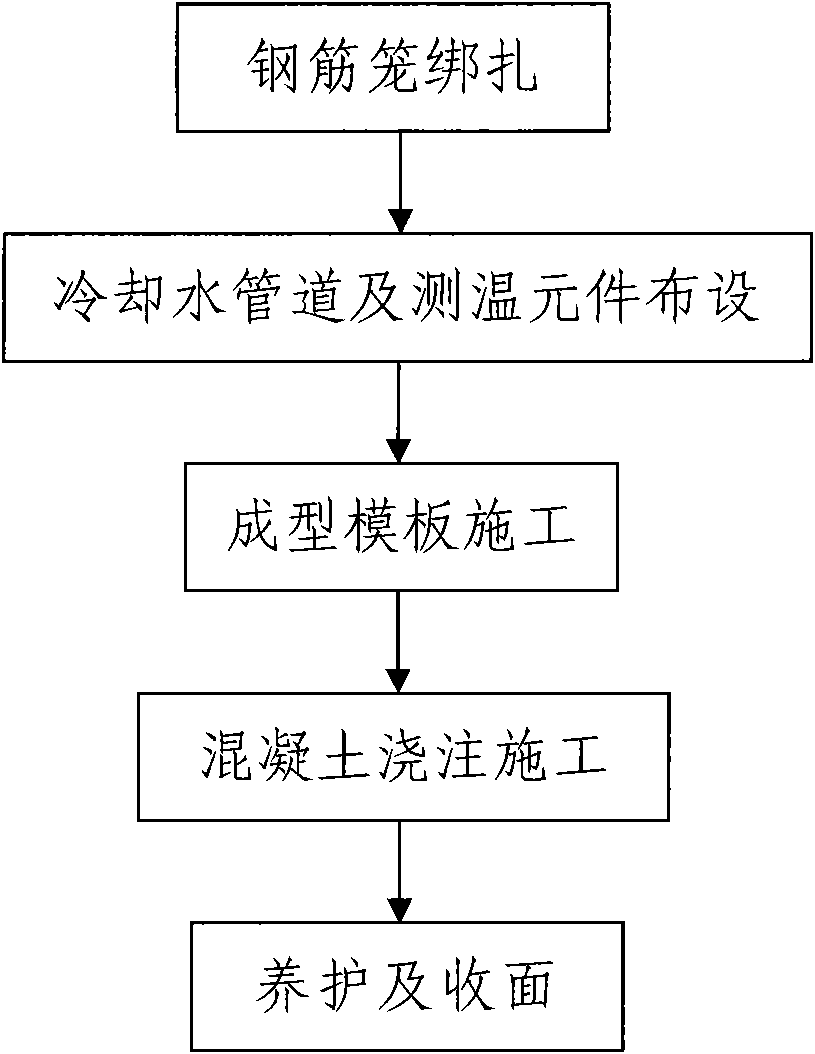

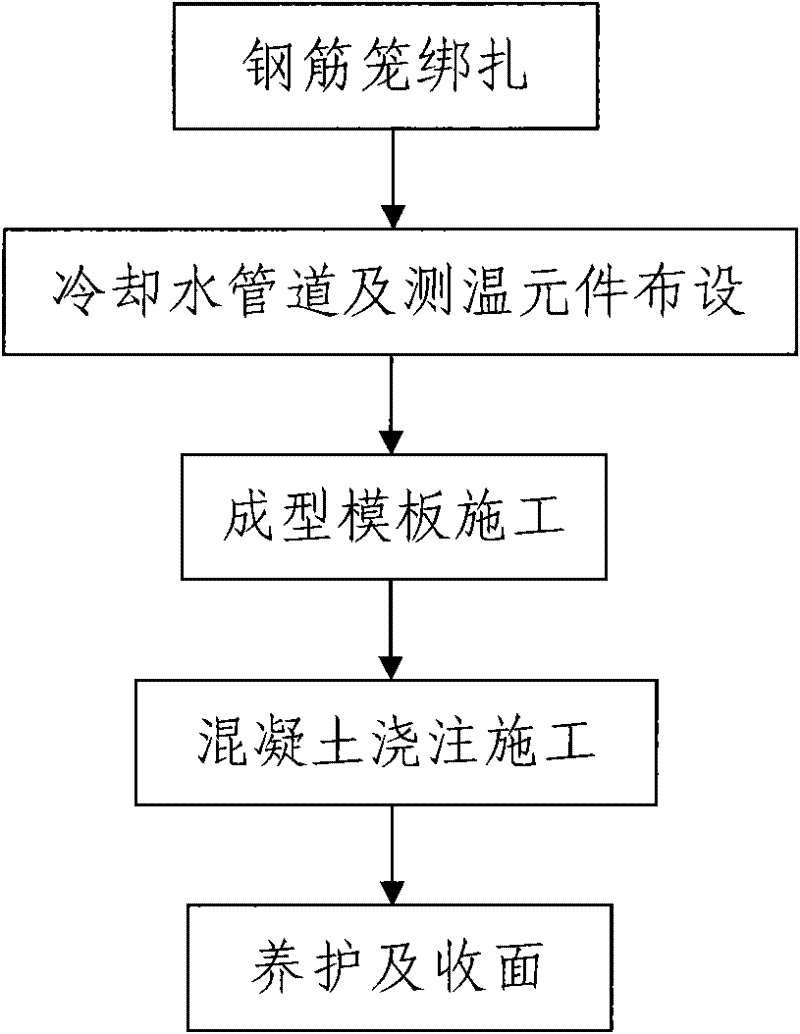

Construction method of large-volume concrete bearing platform with one-time pouring in winter

The invention discloses a construction method of a large-volume concrete bearing platform with one-time pouring in winter, comprising the following steps of: step 1, binding steel reinforcement cages; step 2, laying cooling water pipelines and temperature measuring elements; step 3, constructing formed templates, wherein the construction process comprises delimiting template lines and constructing formed brick dies; step 4, pouring concrete; and step 5, conserving and finishing surface: finishing surface in time when completing the pouring of the concrete, carrying out the surface finishing twice, carrying out the first surface finishing when pouring the concrete to the top, carrying out the second surface finishing when the concrete is initially congealed, and adopting a mode that external stores water for conserving when the concrete is initially congealed. The invention has the advantages of reasonable design, simple construction method step, convenient operation, short construction period, one-time pouring molding and strong maneuverability, the large-volume concrete bearing platform constructed for molding in winter has good quality, the poured concrete is not frozen, and the surface of the bearing platform can not have temperature cracks.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

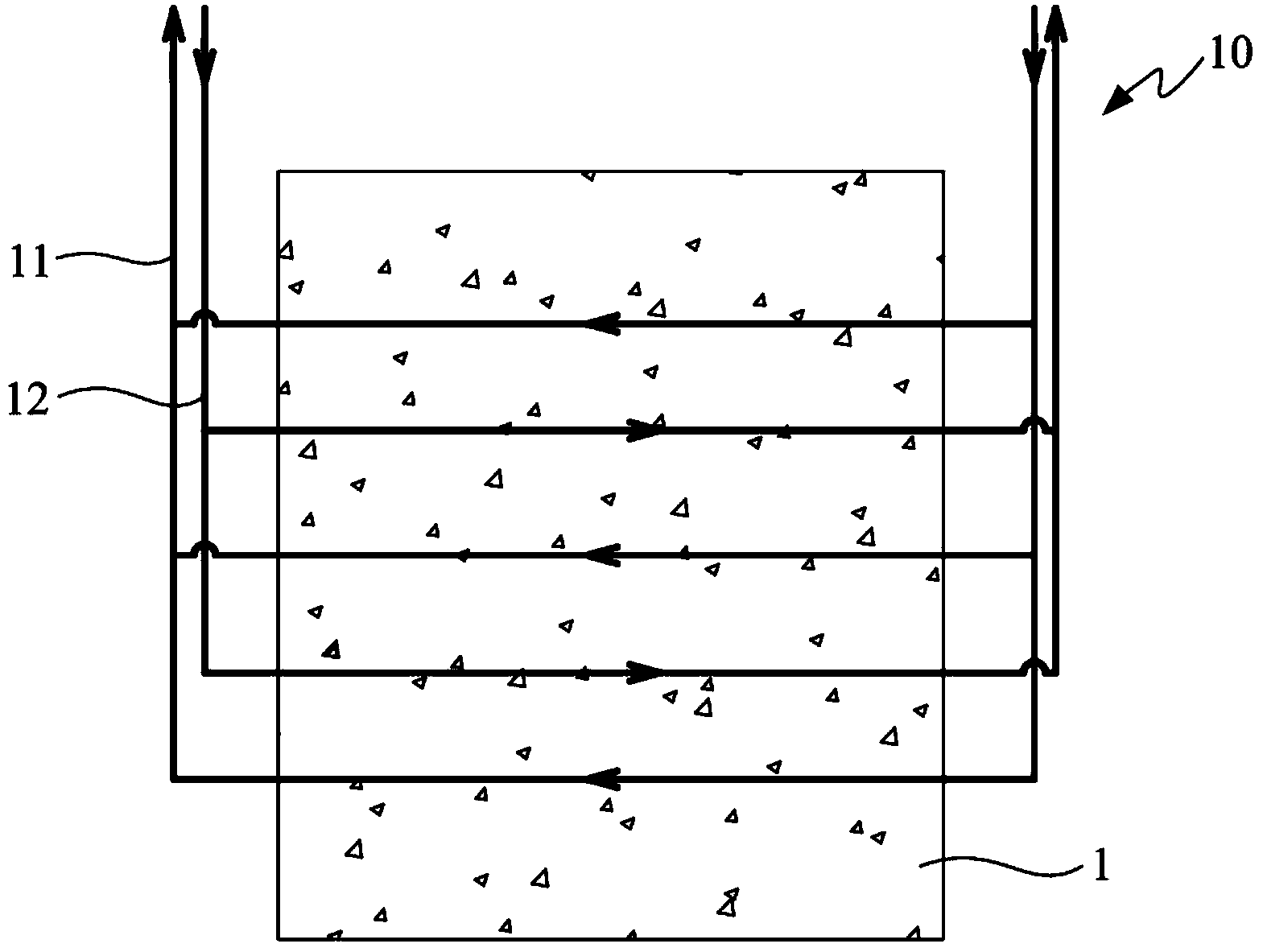

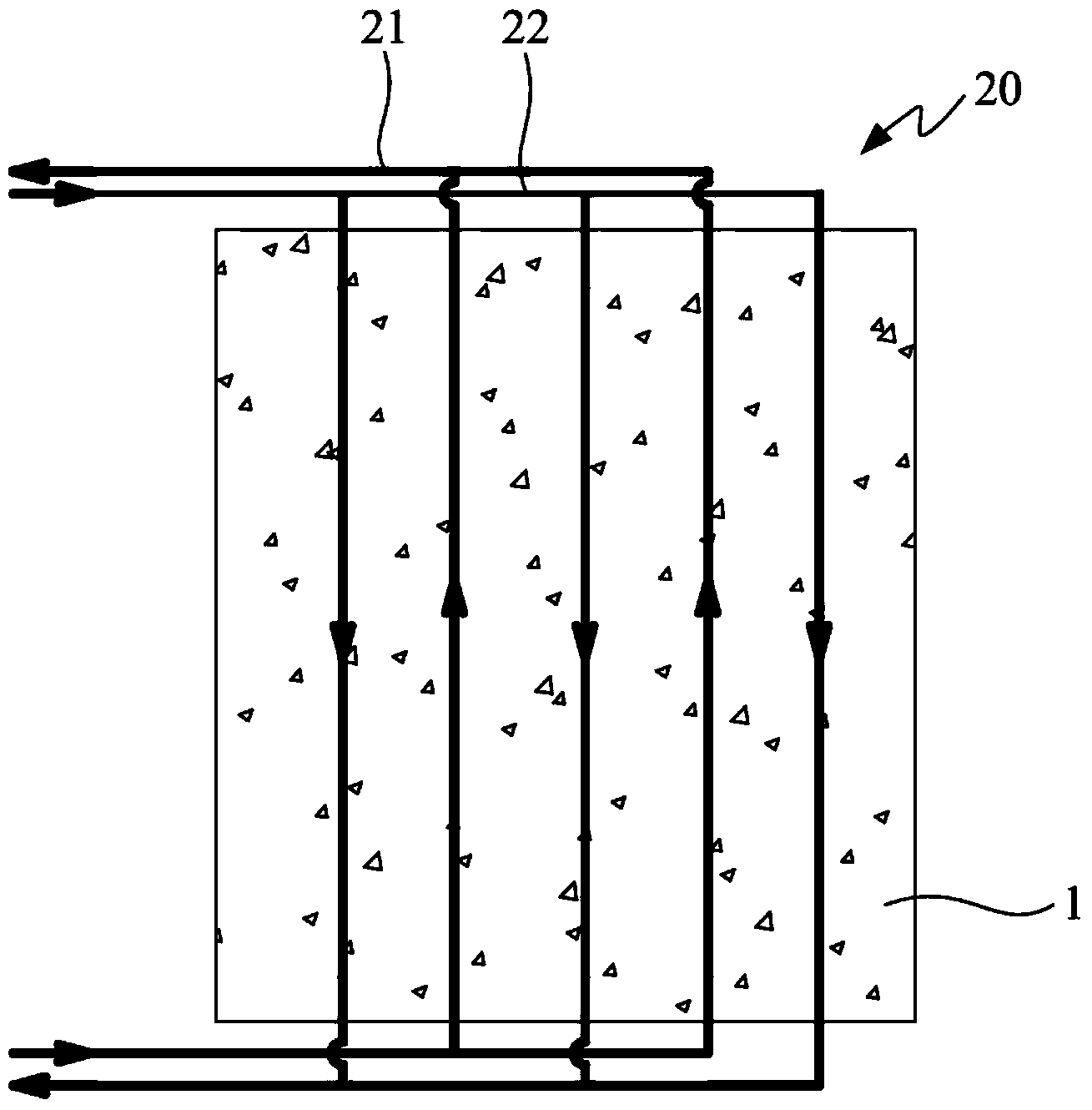

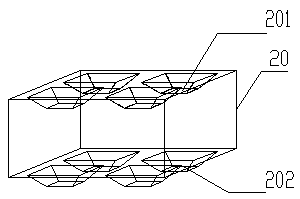

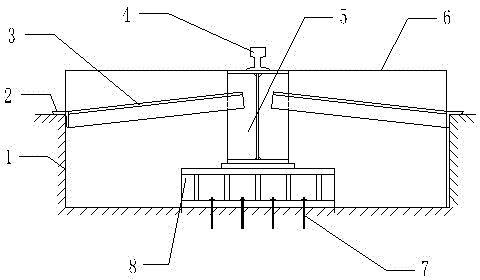

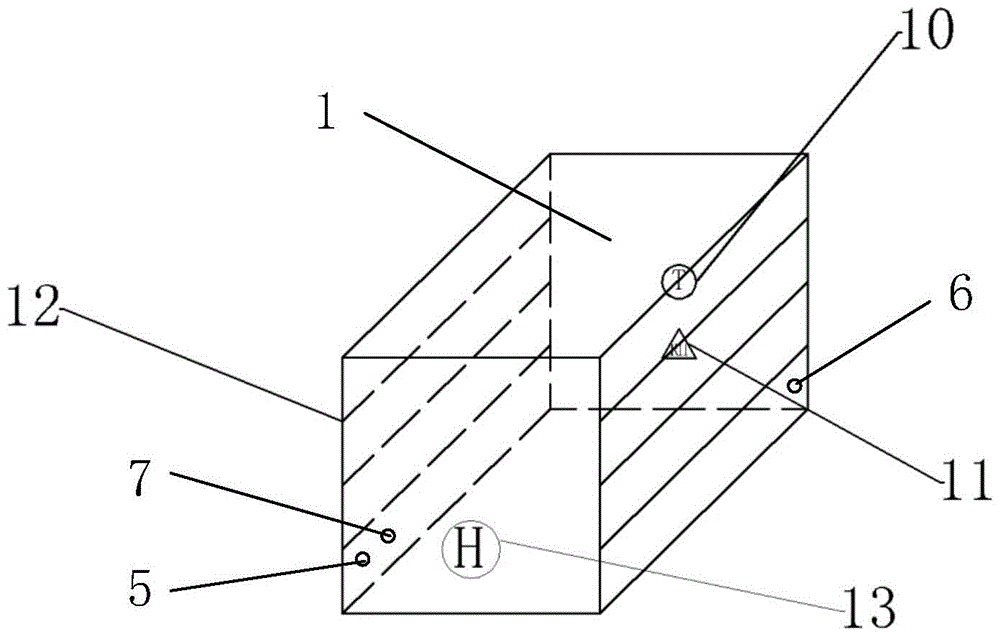

Temperature-control cooling system for large-size concrete structure and cooling control method of temperature-control cooling system

InactiveCN104234431AControl the phenomenon of uneven coolingChange asymmetryBuilding material handlingElement modelEngineering

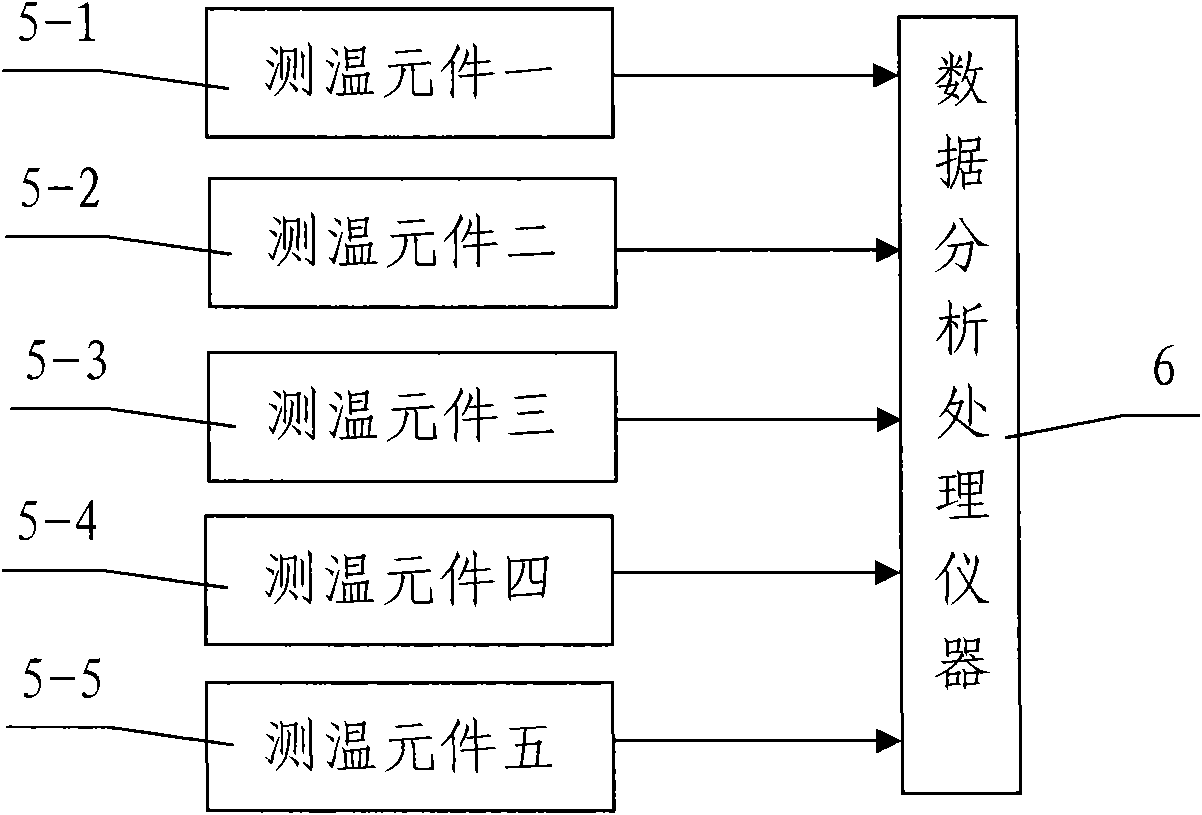

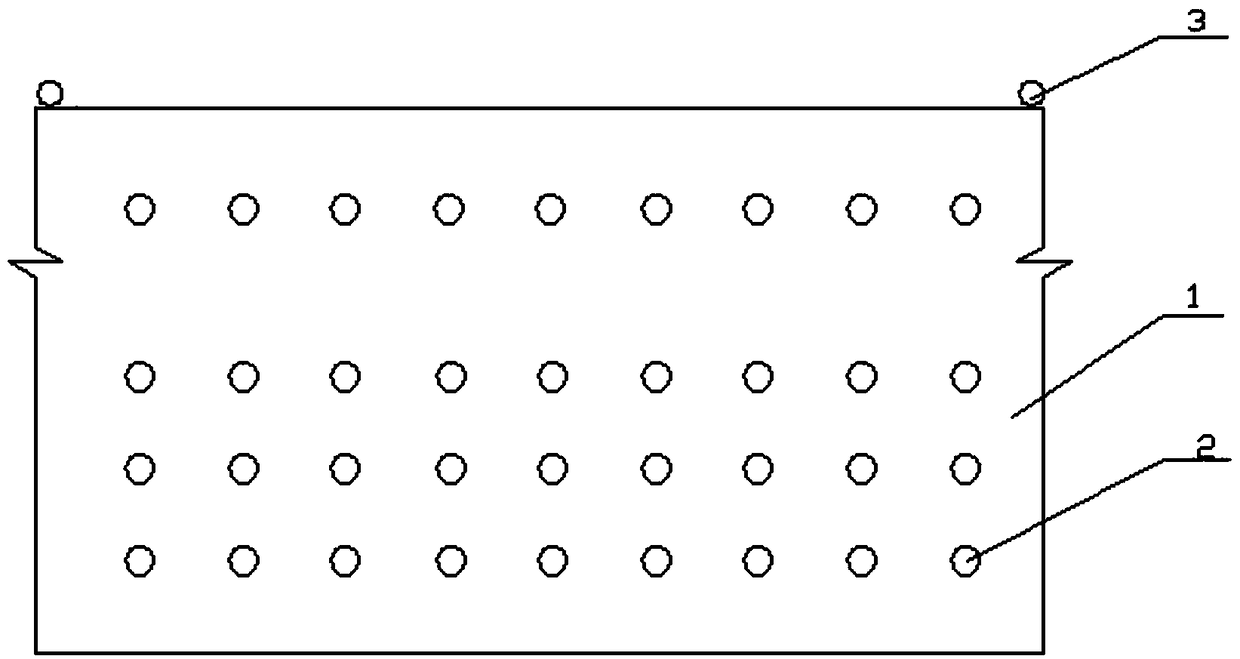

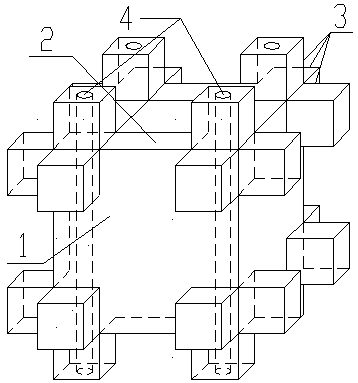

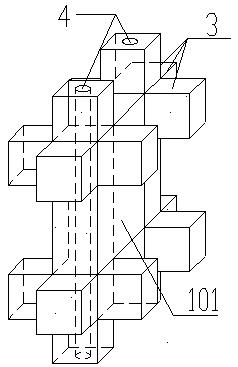

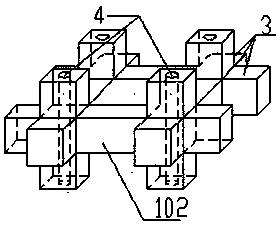

The invention provides a temperature-control cooling system for a large-size concrete structure and a cooling control method of the temperature-control cooling system, and relates to the technical field of large-size concrete construction by aiming at the problems that in the existing method, the arrangement blindness of cooling pipes is great, the inside temperature distribution rule of the concrete cannot be well combined, and the inside temperature reduction uniformity of the cooling pipes cannot be effectively controlled. Cooling water pipe units are horizontally arranged in a template, and comprise two cooling water pipe groups, the two cooling water pipe groups are staggered and overlapped, the cooling water pipes of the two cooling water pipe groups are parallel and are separately arranged, and the flowing directions of cooling circulation water in the adjacent cooling water pipes are opposite. The method comprises the following steps that 1, a finite element model is created, and in addition, the water thermalization analysis is carried out for judging the highest temperature difference and the temperature gradient; 2, the arrangement scheme of the cooling water pipe units is primarily determined; 3, the information of the arrangement scheme is substituted into the finite element model for analogue simulation, when the judging result is assertive, the construction is carried out according to the arrangement scheme, and when the judging result is negative, the arrangement and the flow rate of the cooling water pipe units are regulated until the requirements are met.

Owner:SHANGHAI CONSTRUCTION GROUP

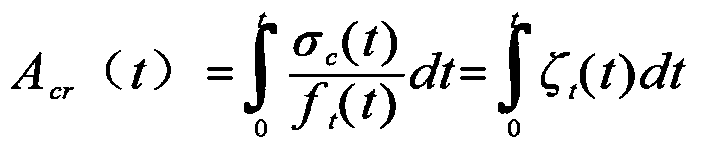

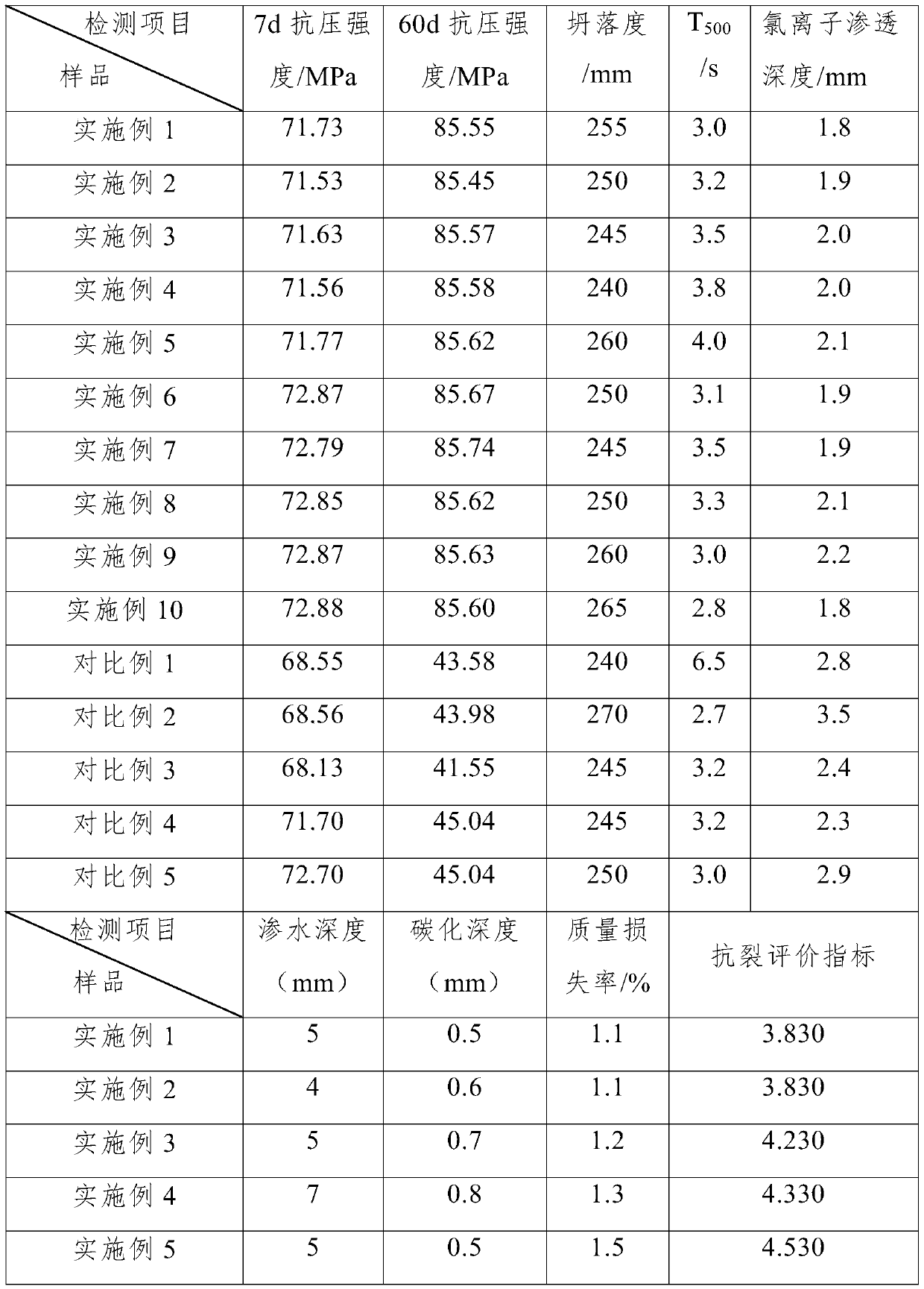

C70 mass concrete and preparation process thereof

The invention discloses C70 mass concrete. The C70 mass concrete is prepared from the following components by mass: 140 to 170 parts of water, 400 to 450 parts of cement, 1,000 to 1,200 parts of crushed stone, 550 to 650 parts of gravel, 70 to 110 parts of coal ash, 60 to 90 parts of mineral powder, 30 to 70 parts of silica fume, 8 to 10 parts of a pumping agent, 35 to 45 parts of an anti-crackingagent, and 0.3 to 0.4 part of an internal curing agent. The invention also discloses a preparation method for the C70 mass concrete. The method comprises a first step of uniformly mixing sand, graveland water and a second step of adding other components and carrying out uniform mixing under stirring. According to the composition of the mass concrete in the invention, mineral powder, silica fumeand fly ash are used as mineral admixtures and can delay the release rate of cement hydration heat and reduce the shrinkage and deformation of the concrete, and the mineral admixtures acts synergistically with the other components to inhibit the generation of cracks at the same time; and the preparation method of the invention is simple in process and easy to implement.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

Method for preparing carbon-fixation filling paste from waste concrete

InactiveCN109650805AAffect qualityIncrease carbon sequestrationGas treatmentDispersed particle separationCarbonizationToxic industrial waste

The invention discloses a method for preparing a carbon-fixation filling paste from waste concrete. The method comprises the following steps: industrial waste gas is dedusted, and then is mixed with normal temperature air, a waste concrete and a gangue mixture is crushed in the obtained industrial exhaust gas atmosphere, and coarse aggregates, fine aggregates and fine powder obtained after screening and carbon dioxide in the industrial exhaust gas undergo a carbonization reaction in a carbon fixation chamber; and the carbon-fixation coarse aggregates, the carbon-fixation fine aggregates, a filling paste additive, cement, phase change material microcapsules and water are stirred and mixed to form a filling body mixture, and the industrial exhaust gas is continuously injected in the stirring, mixing and conveying process of the filling paste to make the filling paste and the carbon dioxide in the industrial exhaust gas undergo the carbonization reaction in order to obtain the carbon-fixation filling paste. The carbonization reaction of the waste concrete and carbon dioxide is fully used, so the damages of the waste concrete to the environment are reduced, and the emission of greenhouse gases is reduced; and hydration heat is fully used in the carbonization reaction, so the filling effect of the carbon-fixation filling paste is good.

Owner:XUZHOU UNIV OF TECH

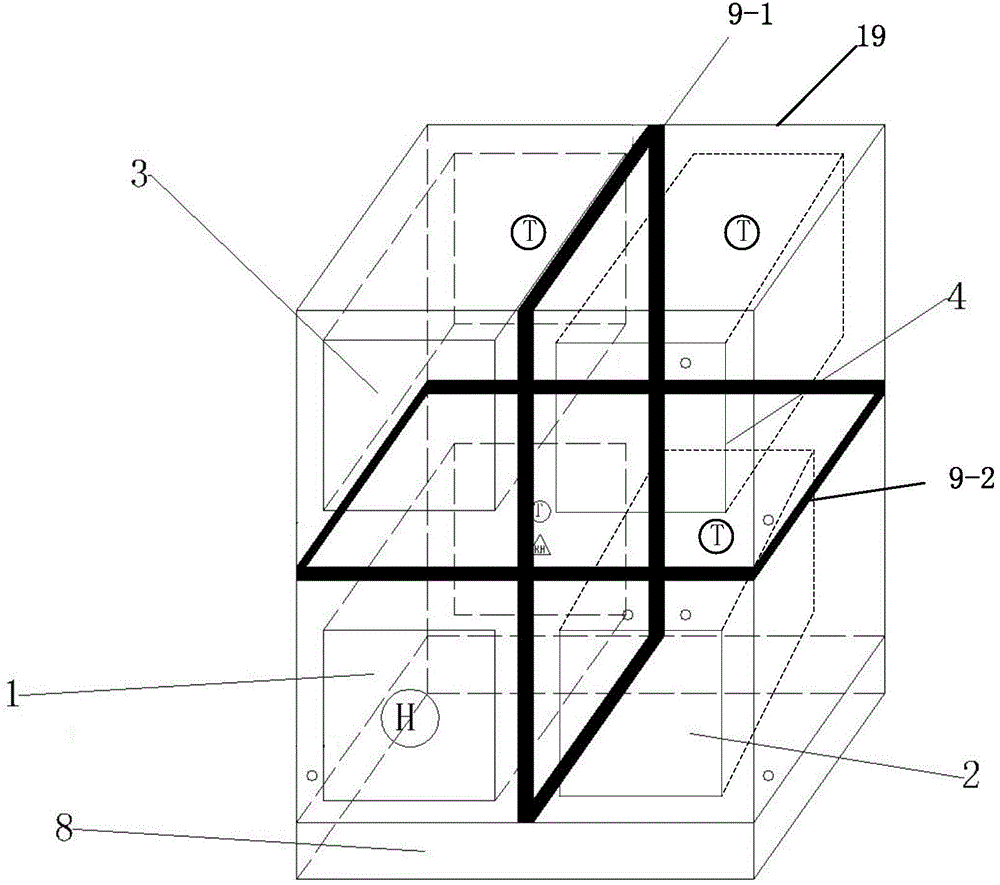

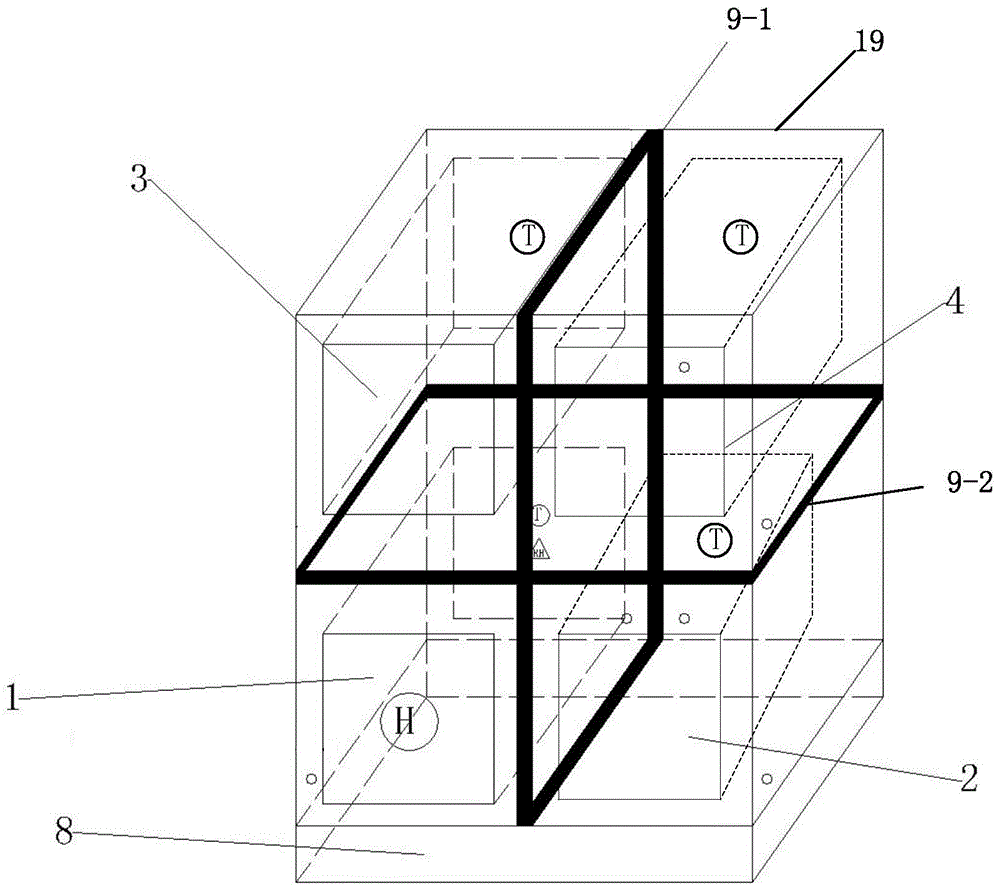

Multifunctional curing box for mass concrete

ActiveCN104690815AReasonable layoutShorten the construction periodCeramic shaping apparatusTemperature stressComplete data

The invention provides a multifunctional curing box for mass concrete. The multifunctional curing box comprises a box body with a door, four cavities and a refrigerating and heating device mounted at the bottom of the box body with the door, wherein the four cavities are defined by a horizontal thermal-insulating water-resisting layer and a vertical thermal-insulating water-resisting layer which are perpendicular to each other and mounted inside the box body with the door; a standard curing box is arranged in the first cavity; a curing box with the highest temperature of 30 DEG C is arranged in the second cavity; a curing box with the highest temperature of 60 DEG C is arranged in the third cavity; a curing box with the highest temperature of 80 DEG C is arranged in the fourth cavity; the refrigerating and heating device comprises a refrigerating device, a liquid collecting box and a heating device, which are mounted at the bottom of the box body with the door. The multifunctional curing box disclosed by the invention can be matched with mass concrete samples at the matched temperature, cannot limit the size of the sample, has the characteristics of being economic, safe, environment-friendly and energy-saving, can provide relatively complete data, and further provides experimental data and conditions for research about how to control temperature stress cracks of the mass concrete caused by hydration heat in the early stage and development of the concrete mechanical properties.

Owner:HARBIN ENG UNIV

Recycled concrete and preparation method thereof

The invention discloses a recycled concrete, which is characterized in that the recycled concrete is prepared from the following components by weight: 60~95 parts of water, 40~64 parts of cement, 38~62 parts of ore powder, 22~34 parts of fly ash, 280~350 parts of natural sand, 210~260 parts of recycled coarse aggregate, 70~120 parts of recycled fine aggregate, 6~8 parts of silicon powder, and 1~2parts of modified polyacrylic acid high-efficiency water reducing agent. In conclusion, the recycled concrete has the advantages of improving the compressive property of concrete and improving the rheological property, mechanical property, volume stability and durability of concrete.

Owner:禹州市国泰建工科技有限公司

Light energy-saving heat-insulating wall material

The light energy-saving heat insulating wall material is produced with light aggregate in 1.2-2.6 wt%, gelating material in 72-76 wt% and sand in 22-26 wt%, as well as water in 35-88 wt% of gelating material, bulking agent in 13 wt% of gelating material and water reducing agent in 1 wt% of gelating material. The light energy-saving heat insulating wall material has the advantages of saving in land, low power consumption, light weight, easy construction, high heat insulating performance, etc. and may be used in network structure building system and non-bearing wall building system.

Owner:HARBIN ENG UNIV

Detachable gravity dam and construction and dismounting method thereof

The invention relates to a detachable gravity dam and a construction and dismounting method thereof, and belongs to the technical field of water conservancy projects. The detachable gravity dam comprises a drainage grouting gallery, an anti-seepage curtain, a dam foundation drainage hole, a middle pier, a side pier and a transverse seam, and further comprises an upstream concrete panel, building block concrete, a downstream concrete panel, a plain concrete cushion layer and a dam foundation anchor bar; the building block concrete is formed by connecting prefabricated building blocks through bolts according to a certain sequence; the upstream concrete panel and the downstream concrete panel are correspondingly poured on the upper surface and the downstream side of a dam body, and the plainconcrete cushion layer is laid on the dam foundation, the detachable building block concrete is built on the plain concrete cushion layer, and the dam foundation anchor bar is arranged in each hoisting hole of the bottom-layer building block concrete. According to the detachable gravity dam and the construction and dismounting method thereof, the advantages of reliable quality and high construction efficiency of a prefabricated concrete component can be fully utilized, so that temperature cracks in the dam body are reduced, the safety of the gravity dam is ensured, meanwhile, the dam body is convenient to detach, and the economical and environment-friendly effects are realized.

Owner:KUNMING UNIV OF SCI & TECH

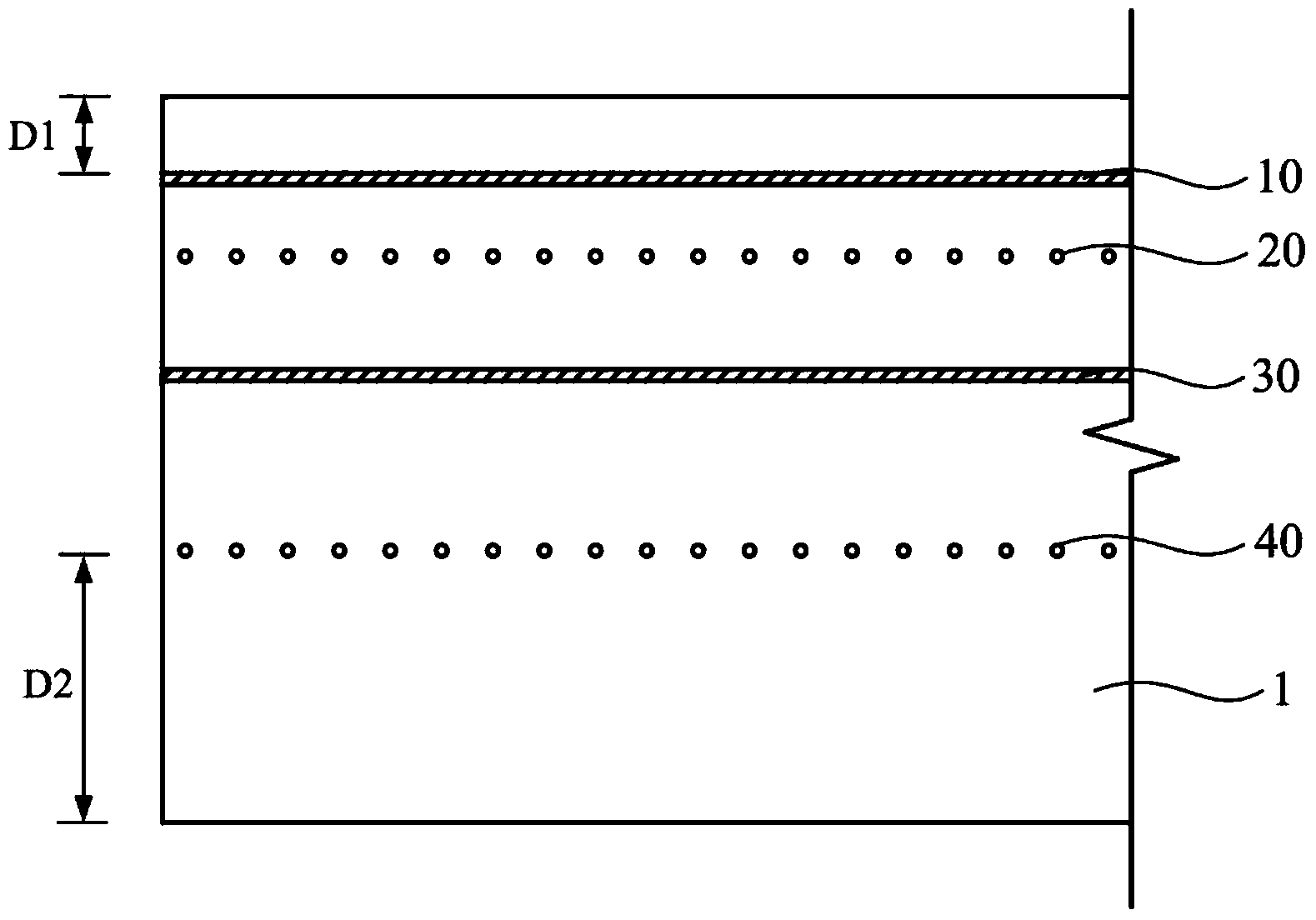

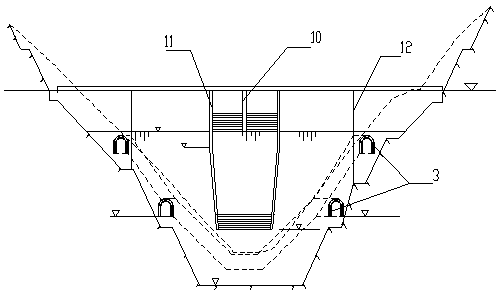

Anti-seam temperature control pouring method and structure for foundation mat mass concrete

PendingCN108104126AUniform temperatureReduce crackingFoundation engineeringTemperature controlEngineering

The invention discloses an anti-seam temperature control pouring method and structure for foundation mat mass concrete. The method is characterized by comprising the following steps that a water through cooling device is arranged in a space to be poured of mat concrete, and cooling water is used for water through cooling; concrete is poured into the space to be poured; a heat-storage humidity-preservation heat-preservation measure is adopted for the surface of the mat concrete finishing pouring; and die removal is carried out on the mat concrete.

Owner:湖北宣鹤高速公路有限公司

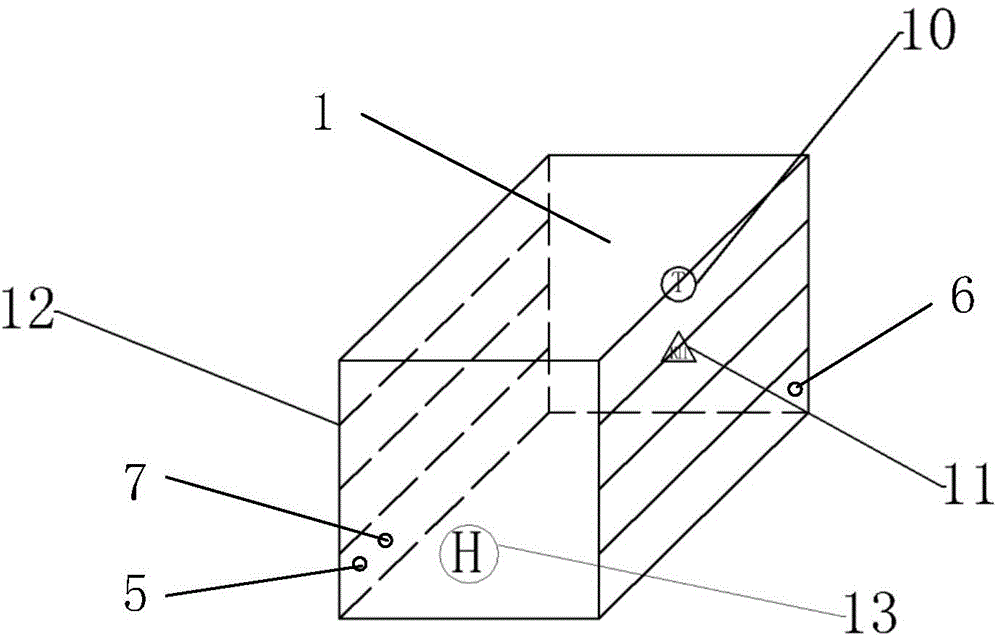

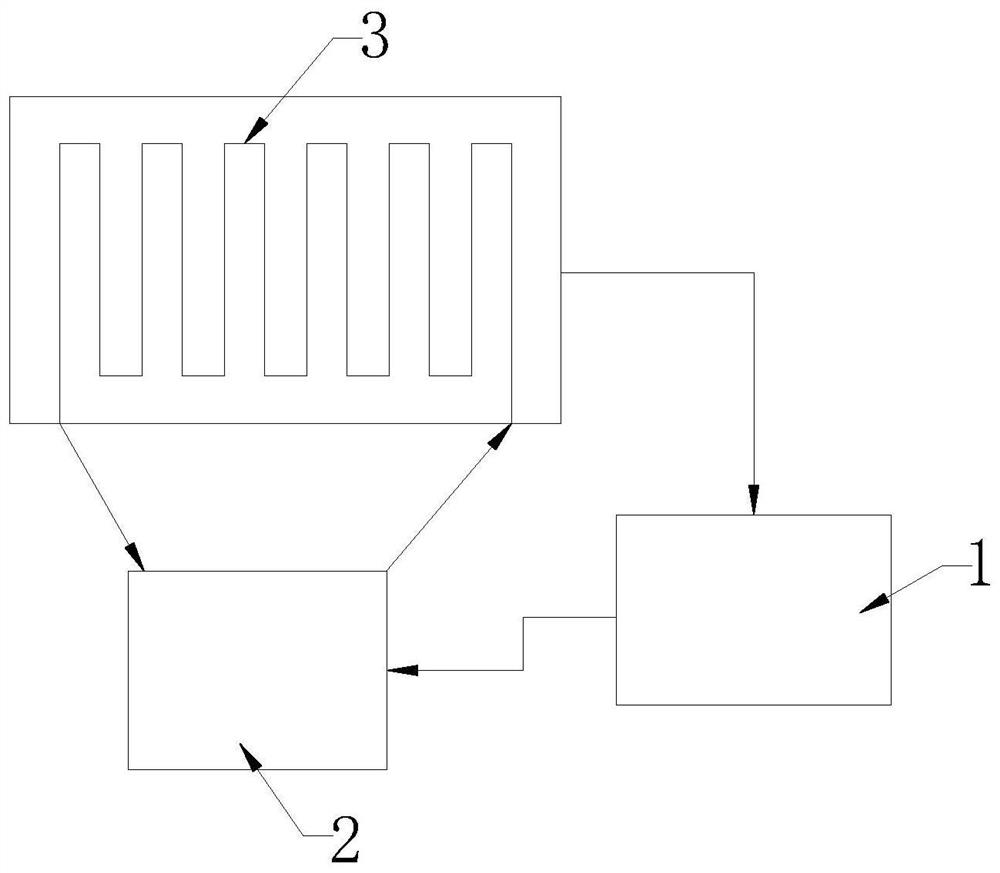

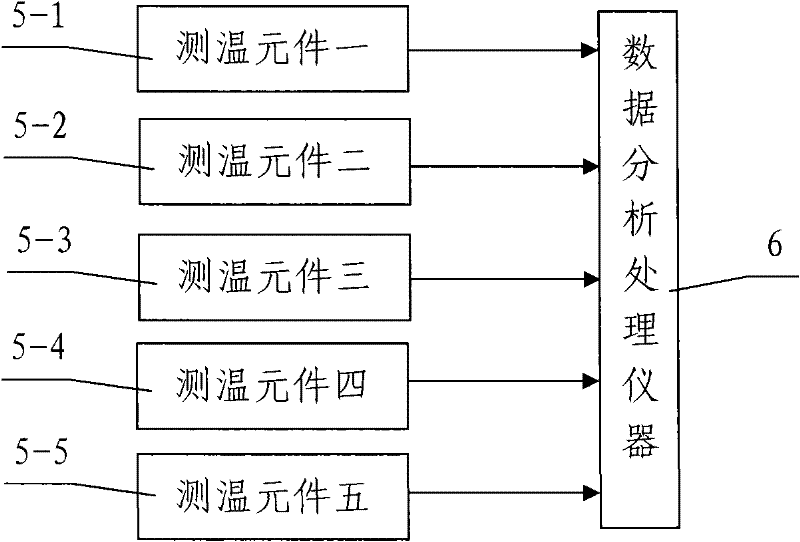

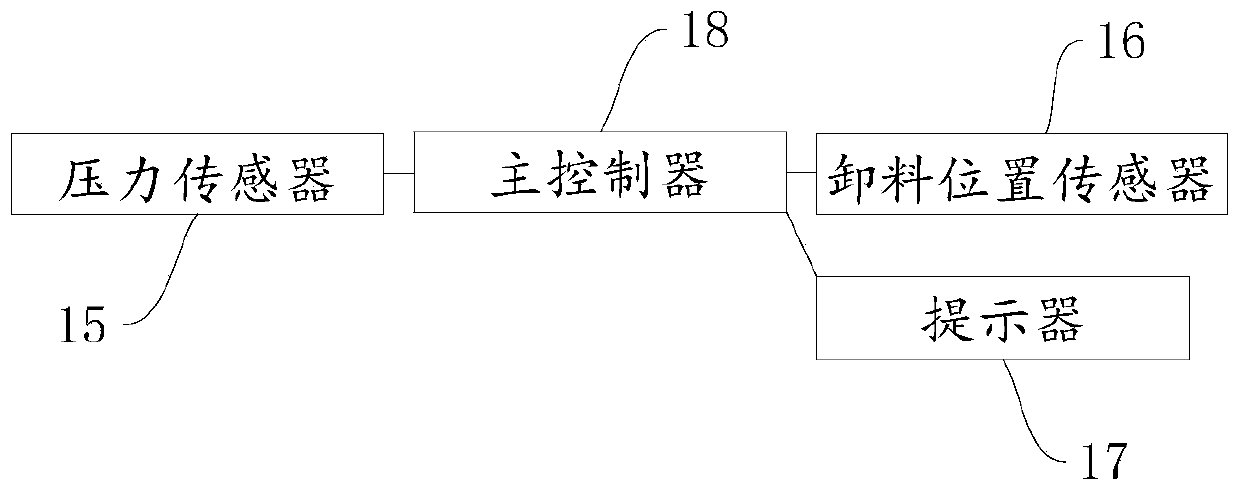

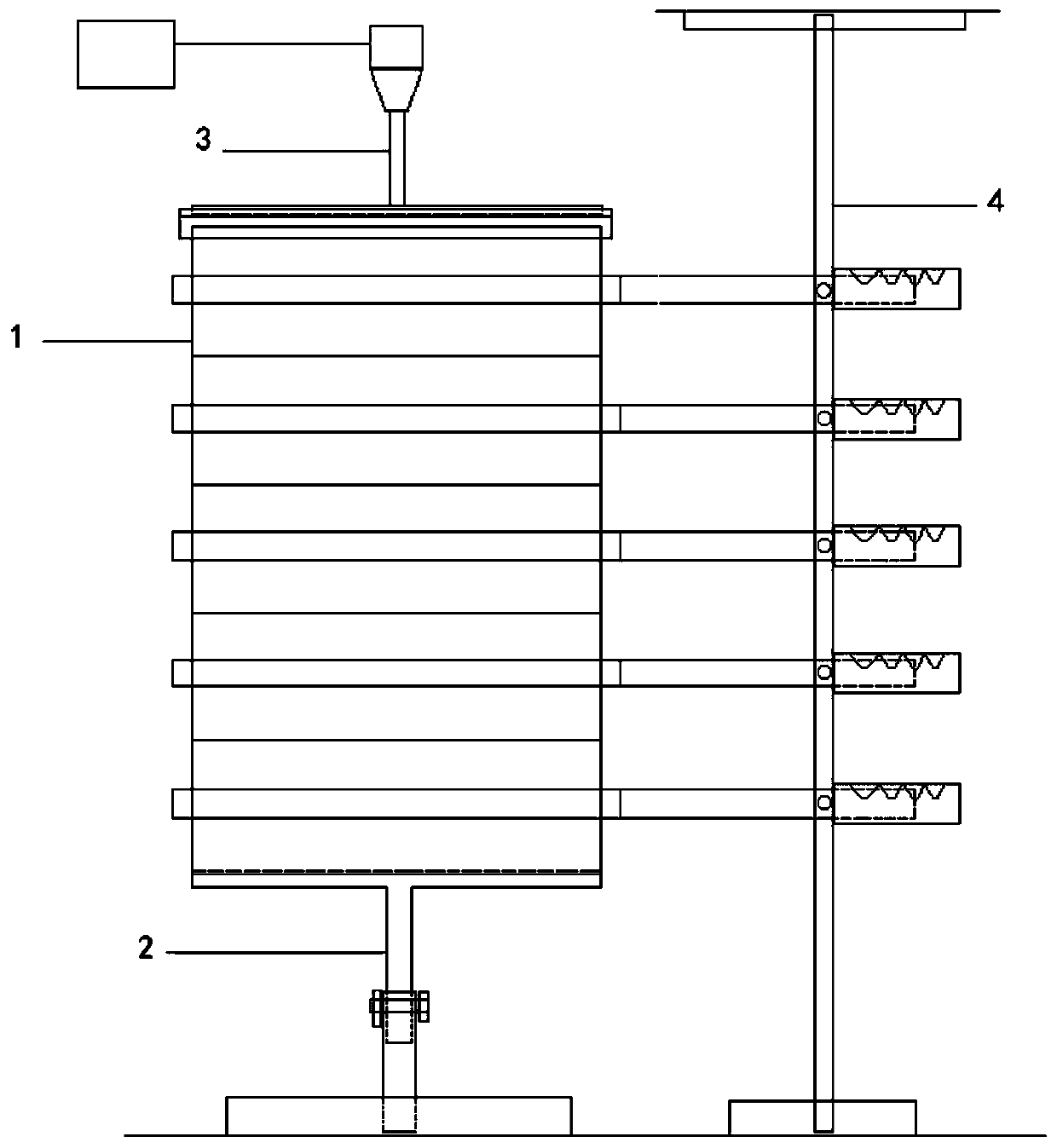

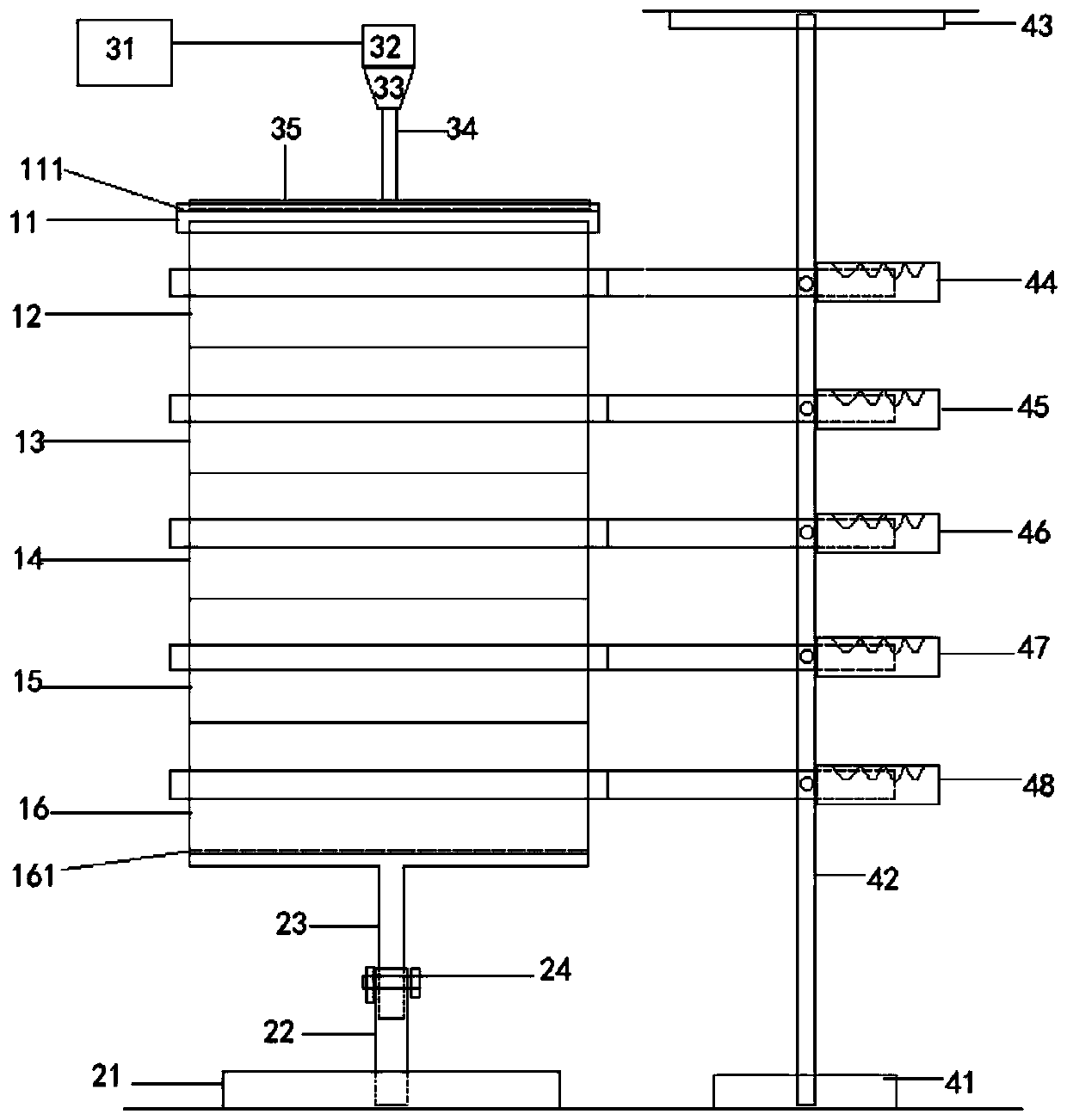

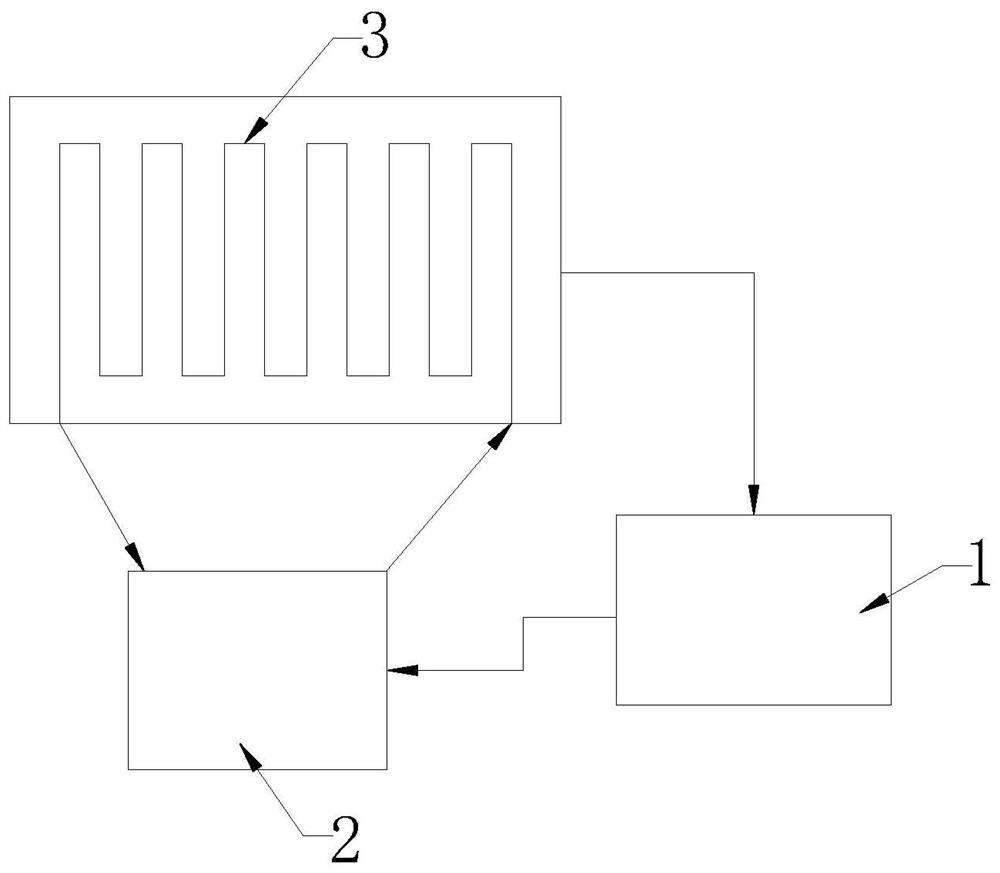

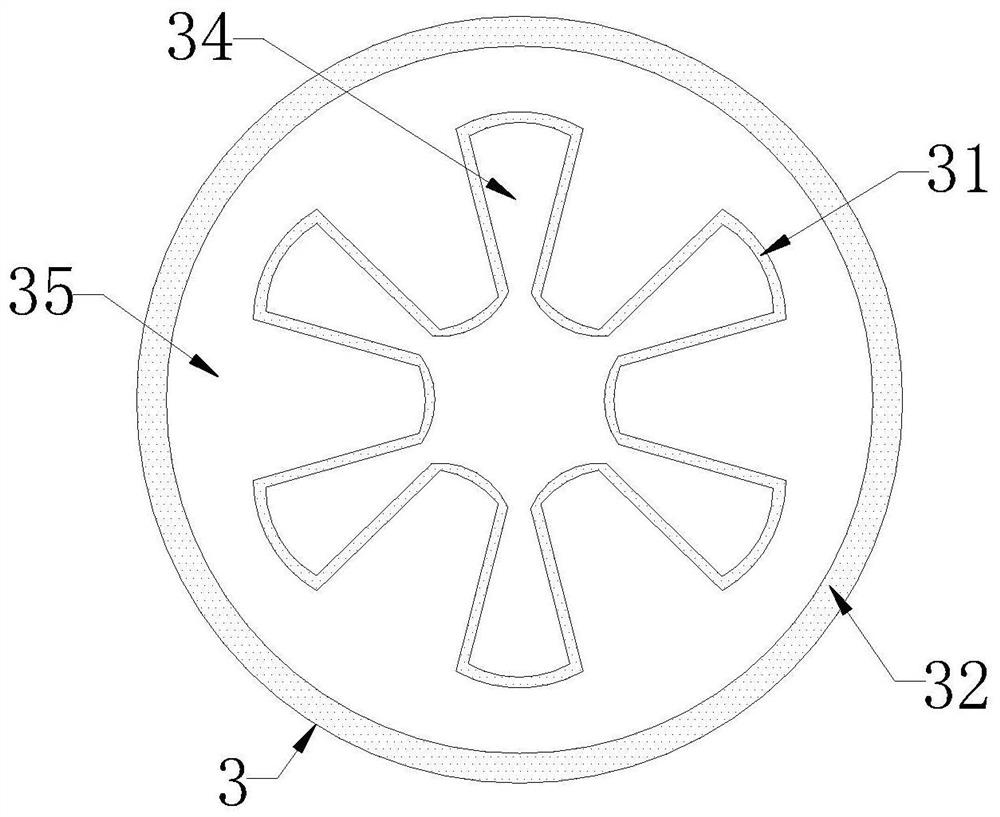

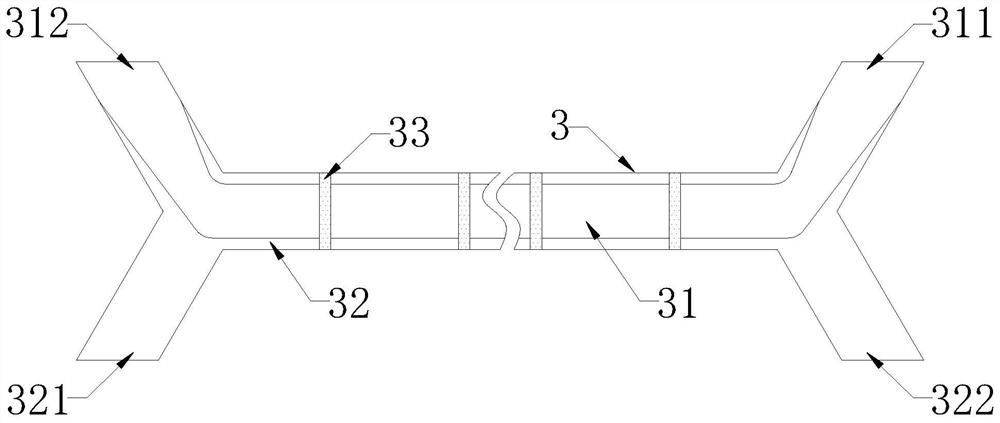

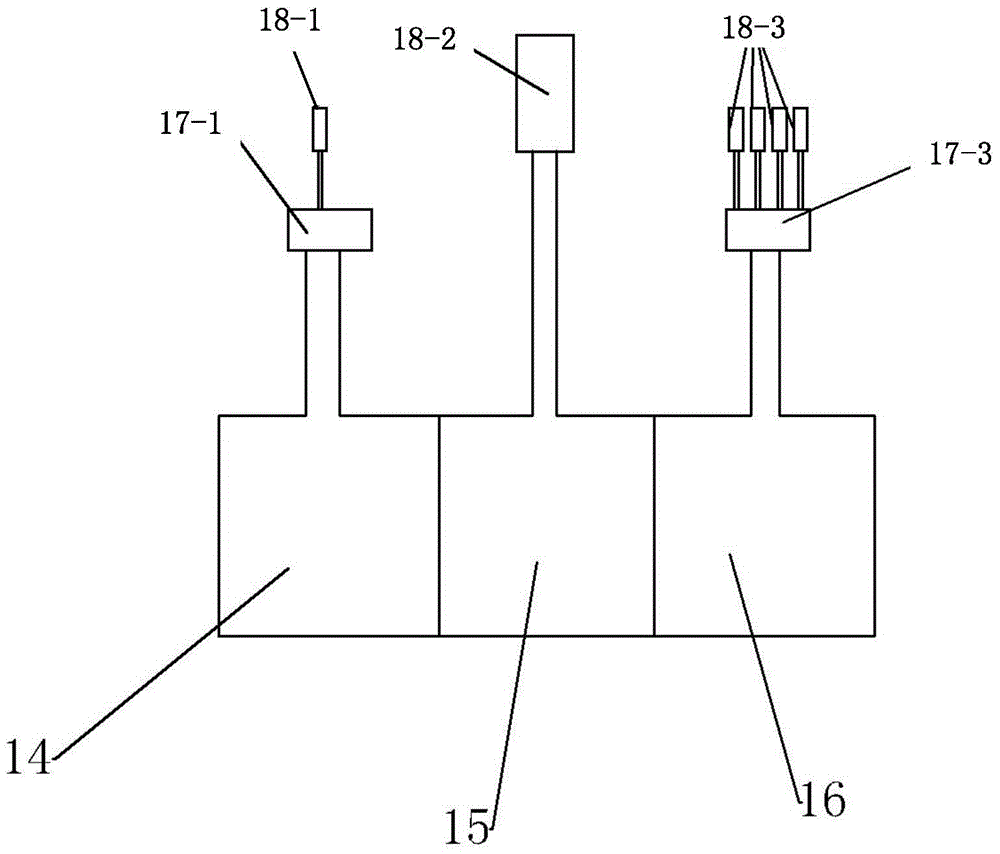

Mass concrete temperature control automatic integrated system

ActiveCN111734139AAvoid errorsHigh frequency of data collectionFoundation engineeringStationary tubular conduit assembliesPhysicsIntegrated systems

The invention provides a mass concrete temperature control automatic integrated system. The mass concrete temperature control automatic integrated system comprises master control equipment, a pipelineassembly, a temperature measuring assembly and a cooling assembly. The input end of the master control equipment is electrically connected with the temperature measuring assembly, the output end of the master control equipment is electrically connected with the cooling assembly, and the cooling assembly controls on-off and opening degree of the pipeline assembly. The pipeline assembly consists ofa plurality of cooling pipes, each cooling pipe comprises an air cooling pipe and a water cooling pipe, the flow directions of the air cooling pipes and the water cooling pipes are opposite, and theproblem that cooling in the same horizontal layer is not uniform and asymmetric is effectively avoided. The cooling assembly comprises air cooling equipment and a circulating cooling water system, andthe air cooling equipment communicates with the air cooling pipes. The circulating cooling water system comprises a circulating cooling water tank, a variable-frequency water pump and adjusting valves arranged on the air cooling pipes and the water cooling pipes, the variable-frequency water pump and the adjusting valves are electrically connected with the master control equipment, and the mastercontrol equipment adjusts the ventilation quantity and / or water flow of the air cooling pipes and the water cooling pipes according to the temperature of the temperature measuring assemblies and controls concrete circulating cooling.

Owner:安徽贝慕物联科技有限公司

Fabricated concrete gravity dam based on composite structure and construction method of fabricated concrete gravity dam

ActiveCN110468795AFacilitate factory productionQuality controllableGravity damsStructure systemPrecast concrete

The invention relates to a fabricated concrete gravity dam based on a composite structure and a construction method of the fabricated concrete gravity dam, and belongs to the technical field of waterconservancy engineering. According to the fabricated concrete gravity dam, a dam body is mainly formed by pouring composite-structured concrete, and an upstream concrete panel and a downstream concrete panel are poured on the upstream side and the downstream side of the dam body; a plain concrete cushion is paved on a dam foundation, and the composite-structured concrete is laid on the plain concrete cushion; the composite-structured concrete is composed of precast concrete components and post-poured concrete in the precast concrete components, wherein the post-poured concrete is connected mutually to form a spatial frame structure system, and the stability of the dam body is enhanced; the advantages of the reliable quality of the precast concrete components, reduction of temperature cracks in the dam body and high construction efficiency can be fully used, meanwhile, due to the spatial frame structure system formed by the post-poured concrete, the integrity and stability of the dam body can be improved, and the safety of the dam body is ensured.

Owner:KUNMING UNIV OF SCI & TECH

Construction method of large-volume concrete bearing platform with one-time pouring in winter

The invention discloses a construction method of a large-volume concrete bearing platform with one-time pouring in winter, comprising the following steps of: step 1, binding steel reinforcement cages; step 2, laying cooling water pipelines and temperature measuring elements; step 3, constructing formed templates, wherein the construction process comprises delimiting template lines and constructing formed brick dies; step 4, pouring concrete; and step 5, conserving and finishing surface: finishing surface in time when completing the pouring of the concrete, carrying out the surface finishing twice, carrying out the first surface finishing when pouring the concrete to the top, carrying out the second surface finishing when the concrete is initially congealed, and adopting a mode that external stores water for conserving when the concrete is initially congealed. The invention has the advantages of reasonable design, simple construction method step, convenient operation, short construction period, one-time pouring molding and strong maneuverability, the large-volume concrete bearing platform constructed for molding in winter has good quality, the poured concrete is not frozen, and thesurface of the bearing platform can not have temperature cracks.

Owner:CHINA RAILWAY 20 BUREAU GRP CORP LTD +3

Buried water supply steel pipe liner mortar

InactiveCN109592945AReduce heat of hydrationReduce temperature cracksHigh pressure waterCement mortar

The invention discloses buried water supply steel pipe liner mortar and belongs to the technical field of polymer cement mortar. According to the buried water supply steel pipe liner mortar provided by the invention, raw materials comprise a gel material, fine aggregate, calcium triple superphosphate, hydroxyethyl cellulose ether, a water reducing agent, dispersible adhesive powder, a de-foaming agent, an expanding agent and basalt fibers, wherein the water-material ratio of the mortar is 0.3 to 0.4, the 28d strength of the mortar is 40 to 60MPa, the breaking strength is 10MPa or more, the bonding strength is greater than 1.0MPa and the shrinkage rate is -0.2 to +0.05 percent. The mortar disclosed by the invention has micro-expansion and flexible properties so that the mortar has an adhesion force on a steel pipe and can bear stress generated by the deformation of the steel pipe under high-pressure water flow.

Owner:JIAHUA SPECIAL CEMENT

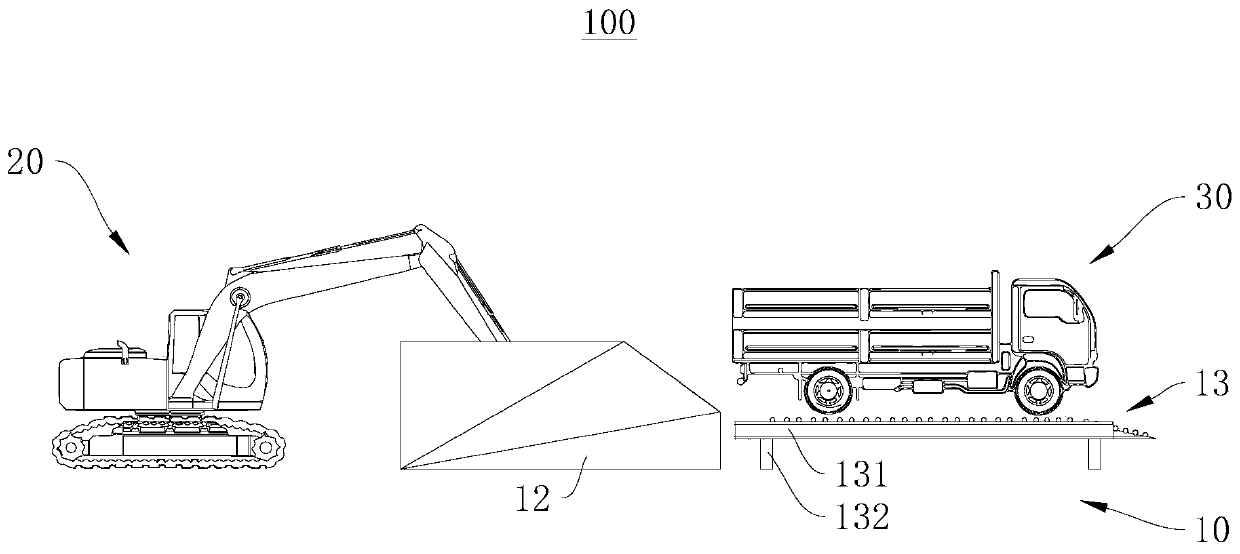

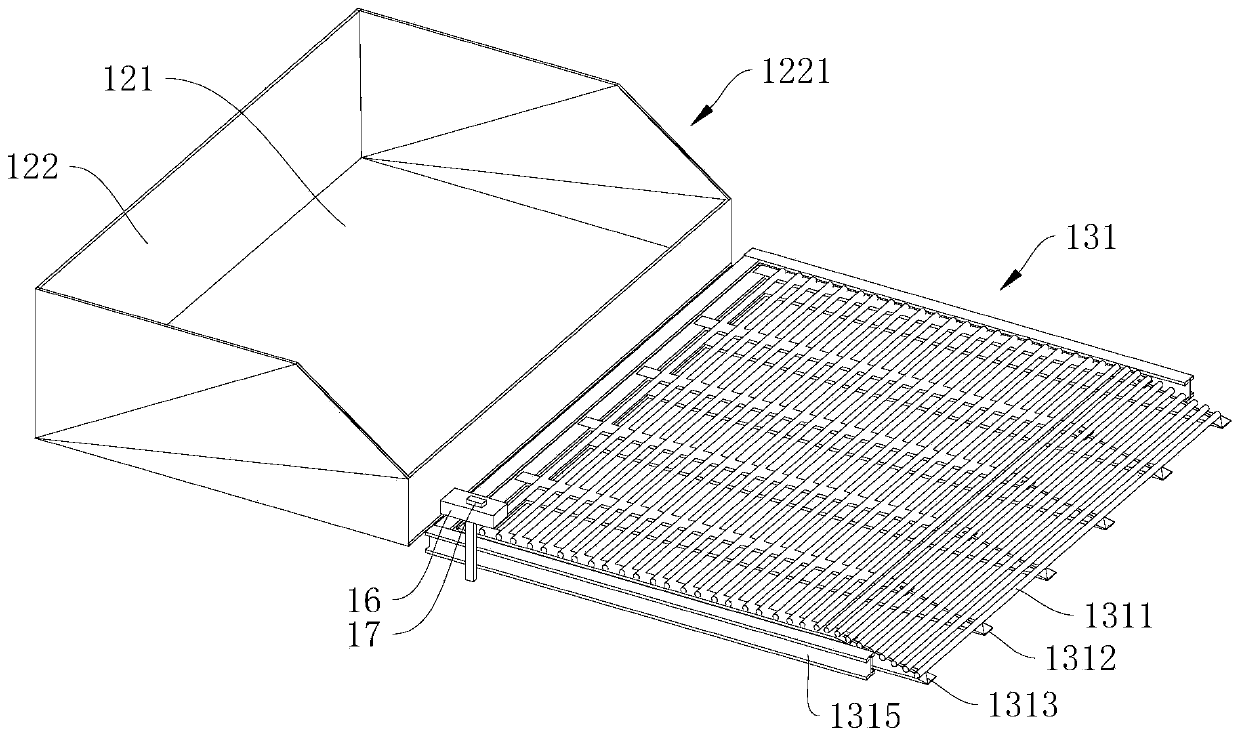

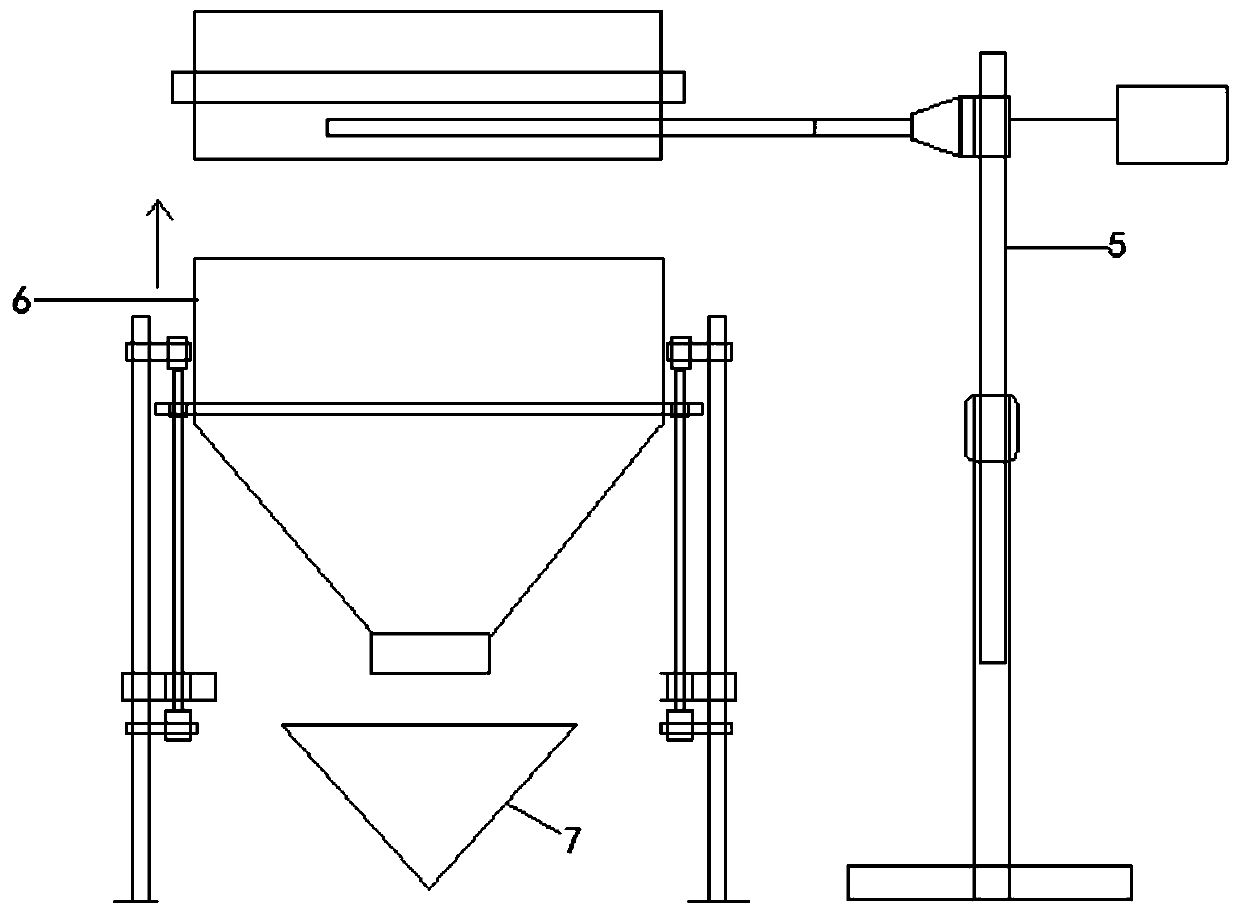

Unloading device and concrete warehousing method

PendingCN111196513AEasy to slant downEasy to retreatLoading/unloadingTemperature controlArchitectural engineering

The invention discloses an unloading device and a concrete warehousing method, and relates to the technical field of concrete unloading and warehousing. The unloading device comprises a collection hopper and an unloading platform, the collection hopper is used for being installed on the ground and used for containing concrete for excavation of an excavator, the unloading platform comprises an unloading support and a lifting driving piece which are mutually connected, the unloading support is located on one side of the collection hopper and used for bearing a concrete transport vehicle, the lifting driving piece is connected to the ground and used for lifting the unloading support, and therefore the concrete transport vehicle on the unloading support can unload concrete to the collection hopper. The unloading device and the concrete warehousing method can warehouse concrete with the low collapsbillity, and are beneficial to controlling temperature of the concrete.

Owner:SINOHYDRO BUREAU 9

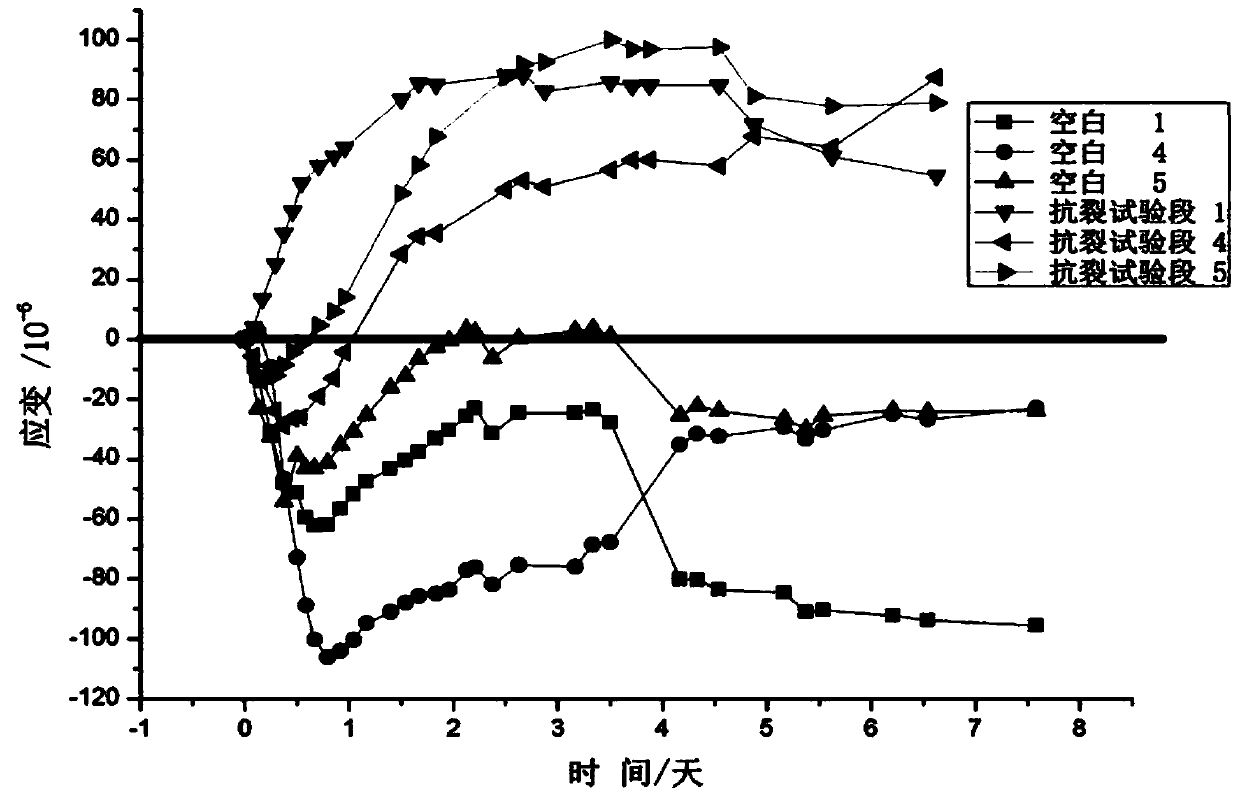

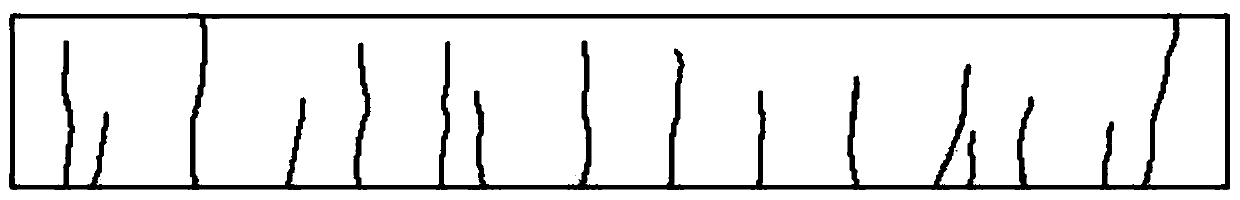

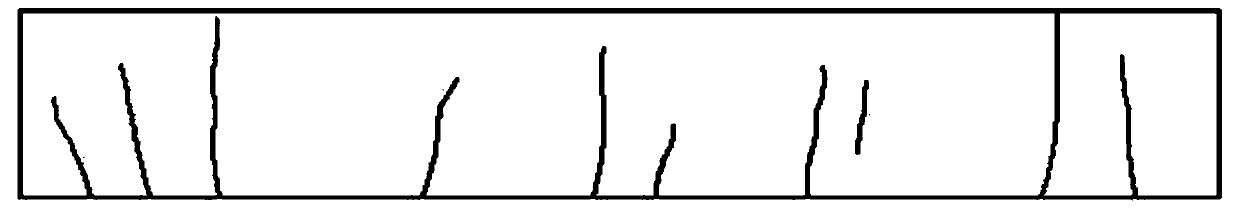

Anti-crack concrete suitable for large stations and construction method

InactiveCN110683810AReduce heat of hydrationReduce the water-binder ratioArtificial islandsPublic buildingsWater storageArchitectural engineering

The invention discloses anti-crack concrete suitable for large stations and a construction method. The anti-crack concrete is prepared from the following raw materials in parts by weight: 167 parts ofwater, 296 parts of cement, 636 parts of river sand, 1039 parts of gravels, 7.42 parts of a delayed coagulation type water reducing agent, 40 parts of a magnesium anti-crack agent, 66 parts of fly ash, 88 parts of slag powder and 0.9 part of polypropylene fiber. The construction method comprises the following steps: embedding an embedded-type strain-temperature sensor, and preparing a concrete byadopting a double-doping technology; installing a form board, and carrying out concrete pouring; disassembling a side wall form board, curing with plastic film and double-layer thermal-insulation cotton, after top plate pouring, covering the plastic film for moisture preservation, and carrying out water storage maintenance. According to the anti-crack concrete suitable for large stations and theconstruction method, through optimization of concrete raw materials and the mix proportion and control over the internal and external temperature and stress of the concrete, damages to large-size concrete structures caused by crack development are prevented, and the stability and construction safety of the concrete structures are guaranteed.

Owner:SUBWAY ENG CO LTD OF CHINA RAILWAY 16TH CONSTR BUREAU +1

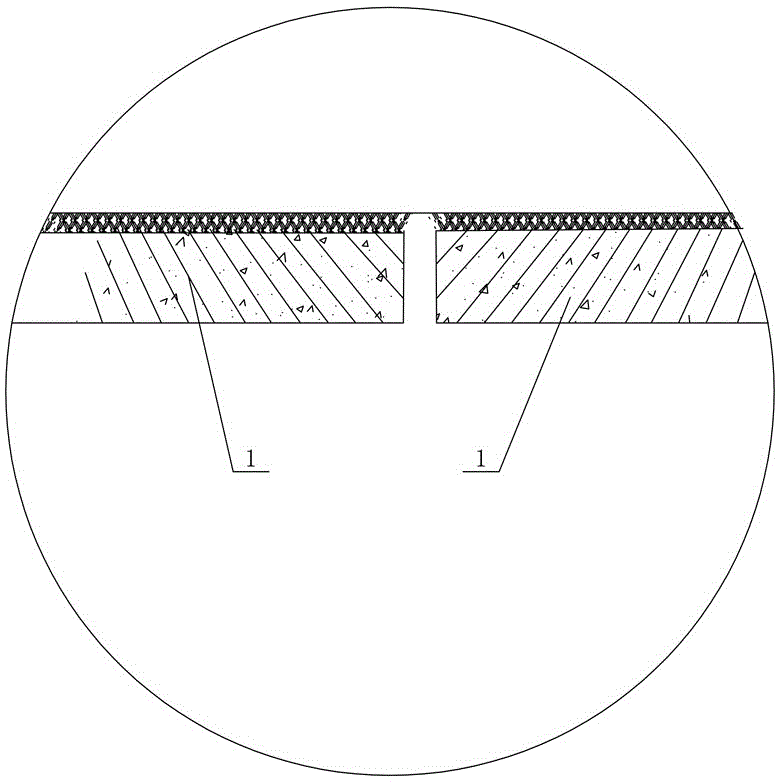

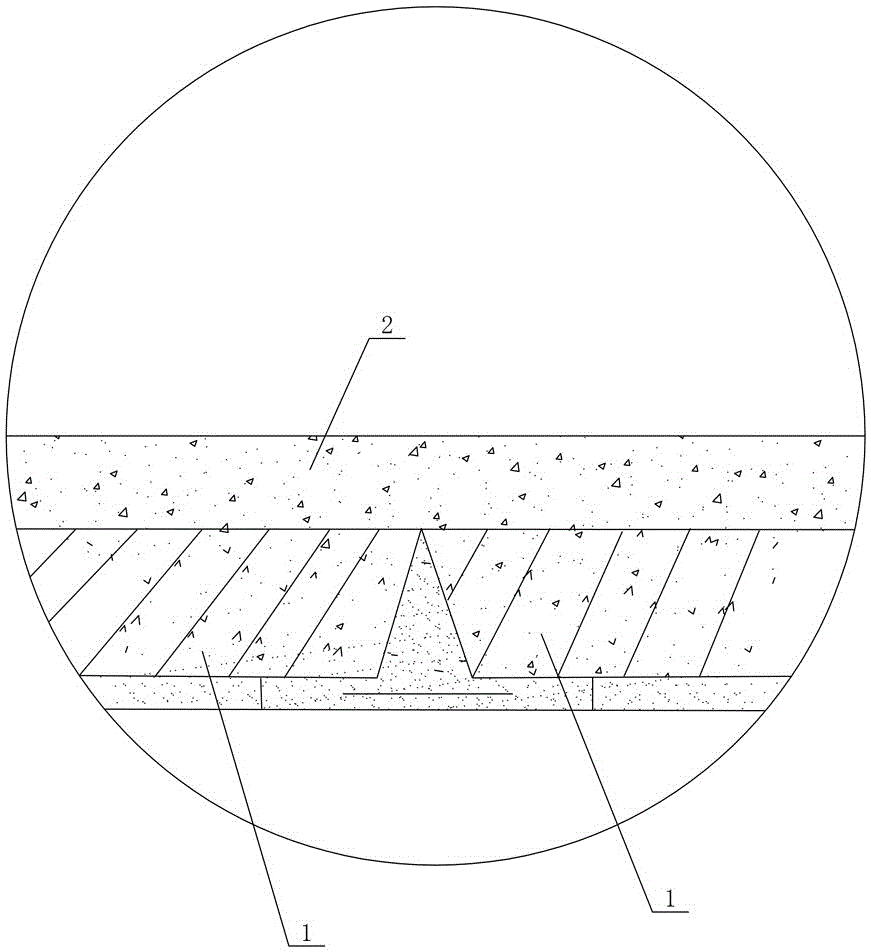

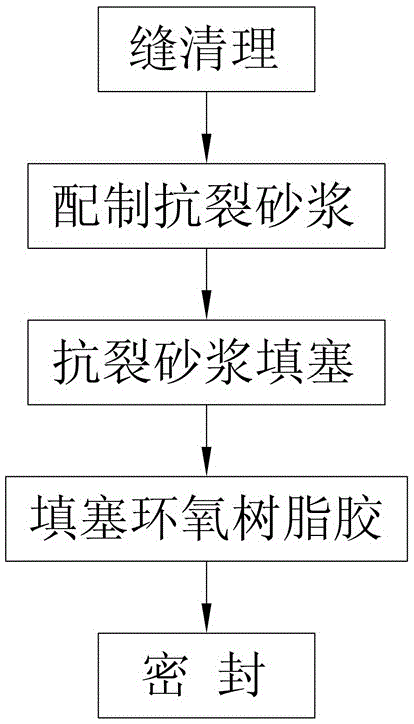

Treatment method of assembled-type prefabricated component wallboard joints

InactiveCN106759968AReduce creep shrinkage cracksReduce temperature cracksBuilding insulationsWall platePetroleum engineering

The invention discloses a treatment method of assembled-type prefabricated component wallboard joints. When being used for treating vertical splicing joints and top horizontal plate joints among prefabricated components, the treatment method includes following steps: S1, cleaning the joints; S2, preparing anti-cracking mortar; S3, filling with the anti-cracking mortar; S4, filling with epoxy resin glue; S5, sealing. When being used for treating connecting joints formed by connecting the prefabricated components with a cast-in-place wall, the treatment method includes following steps: S1, expanding the joints; S2, filling with epoxy resin glue; S3, sealing. The treatment method has the advantages of simple process, easiness in operation and high economic value.

Owner:SINOHYDRO BUREAU 8 CO LTD

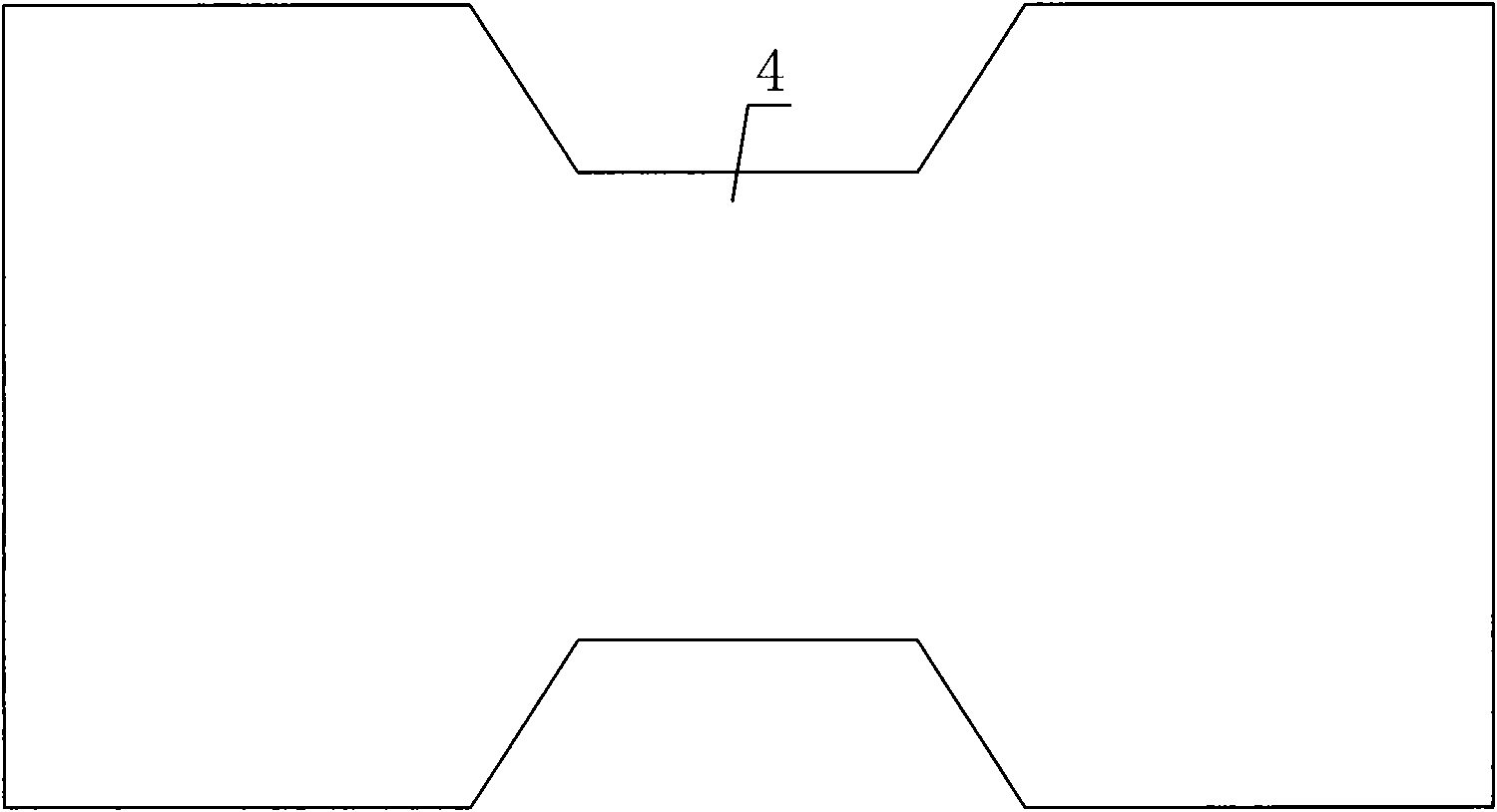

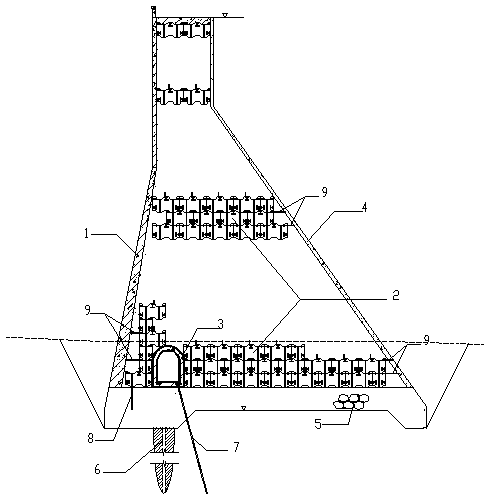

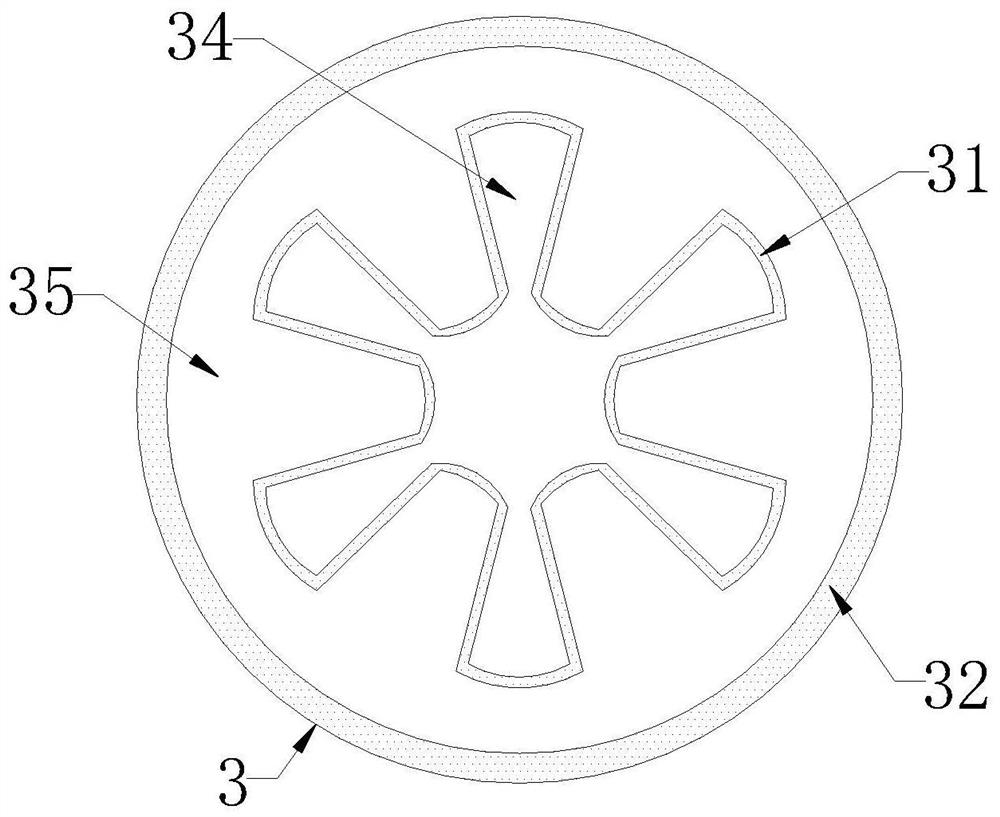

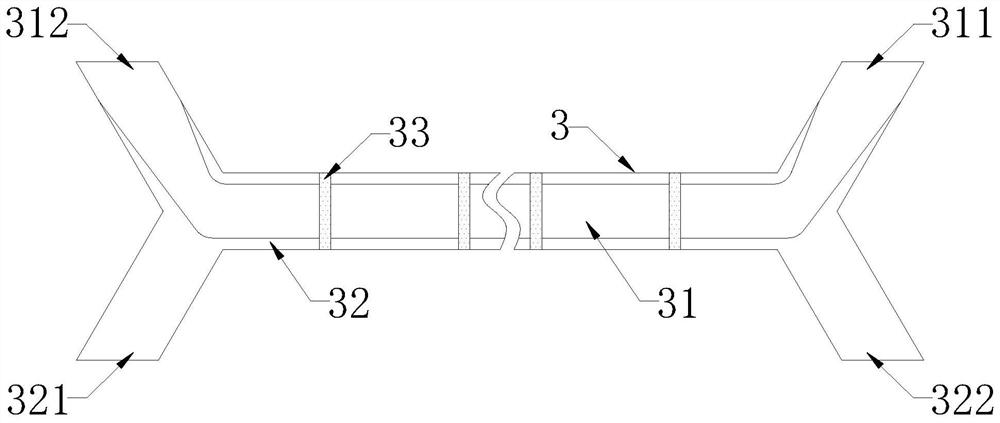

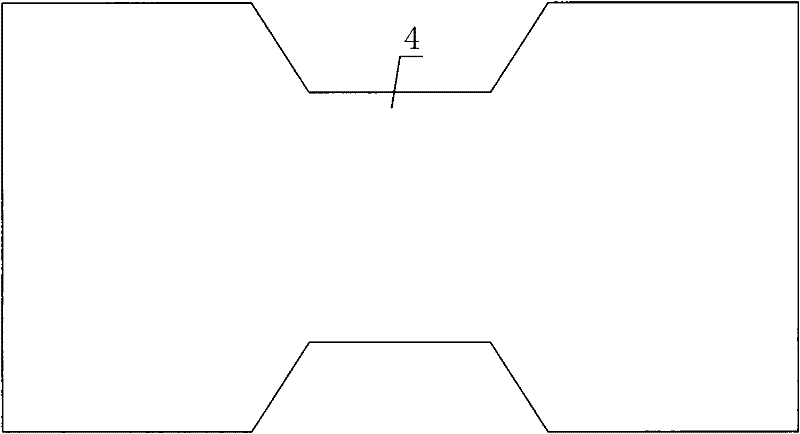

Construction method and device for water cooling of gate pier large volume concrete of tide gate

The invention discloses a construction method and device for water cooling of gate pier large volume concrete of a tide gate. The construction method for water cooling of the gate pier large volume concrete of the tide gate comprises the following steps that S1, a water cooling device is arranged; S2, steel bars are arranged; and S3, a tide gate is cast according to the principle that cooling water is introduced and then concrete is poured. In different time periods, the time interval of changing the direction of water introducing is different. The concrete temperature rise can be reduced during the casting and curing process of the gate pier, so that occurrence of cracks is avoided.

Owner:SHANDONG WATER GENERAL CO LTD +1

Activate micro powder prepared through wind quenching method steel slag and directly-discharged pulverized fuel ash and method

The invention discloses activate micro powder prepared through wind quenching method steel slag and directly-discharged pulverized fuel ash and a method. A raw material comprises 60 to 70% of steel slag, 20 to 30% of pulverized fuel ash, 16 to 20% of lime mixture and 0.1 to 0.3% of polycarboxylate superplasticizer powder by mass percent, the raw material is added into a weightless mixing stirrer,stirring is carried out to enable the material to be sufficiently mixed to be uniform, through a wind quenching method, the amorphous mineral phase on the surface of the steel slag is obviously increased, potential activity is increased, through a grinding aid, reinforced fibers, the polycarboxylate superplasticizer powder and monox, the activity is higher, compatibility with cement is good, the pulverized fuel ash delays the hydration speed, the temperature rise caused by heat transmission by water of the concrete can be reduced, temperature cracks generated by the concrete can be prevented,binding force of the concrete can be obviously improved, durability is improved, and for solving the problem that the grinding effect is affected due to the inconsistent steel slag sizes, and a screening auxiliary device for smashing of the steel slag is specially made

Owner:国宏联绿(北京)科技发展有限公司

Limestone flour mineral composite agent

The invention provides a limestone flour mineral composite agent. The limestone flour mineral composite agent is prepared from the following raw materials in parts by weight: 30 to 80 parts of limestone flour, 10 to 30 parts of slag powder, 5 to 10 parts of magnesia powder, 3 to 8 parts of nitrate, 20 to 50 parts of gypsum powder and 5 to 15 parts of triethanolamine. According to the composite agent, the early strength and long-term strength of concrete can be improved, the early hydration of cement is promoted due to the limestone flour, and moreover, the triethanolamine is also beneficial for the development on the early strength of concrete; the durability of concrete is improved, the porosity of concrete can be effectively reduced due to combined addition of the limestone flour and mineral powder, so that the pore structure is refined, the pore structure is improved, the chloride ion diffusion coefficient of concrete can be effectively reduced, and moreover, the triethanolamine enables a cement hydration product to be compact in structure. The composite agent is simple in preparation technology and low in cost, and is applicable for large-scale industrial production.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

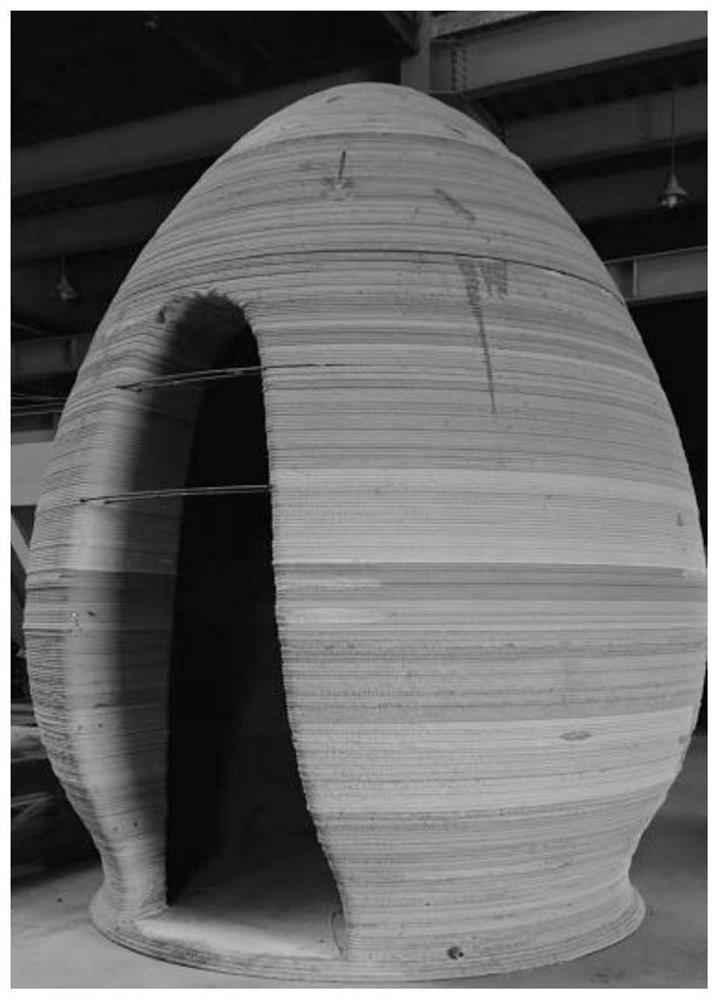

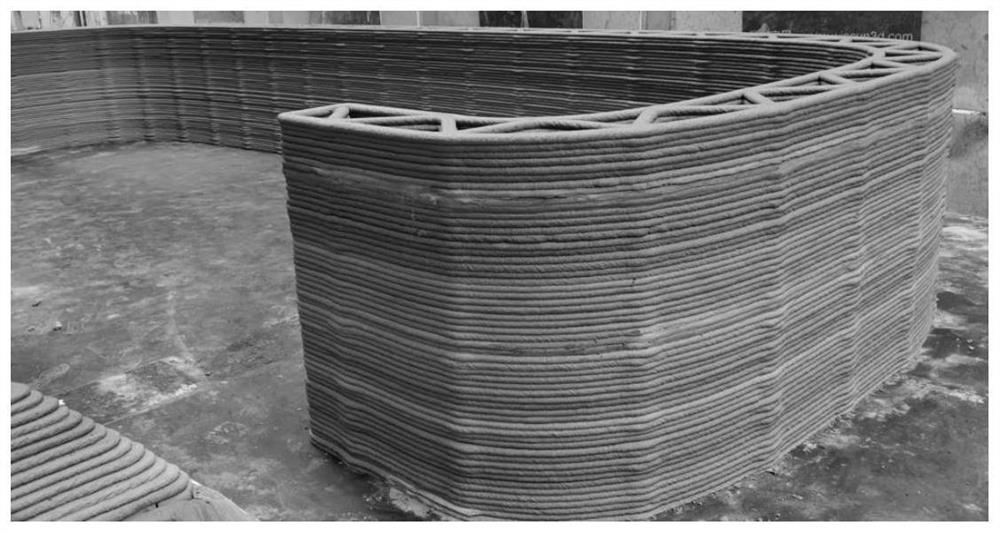

Steel slag composite material for 3D printing as well as preparation method and application of steel slag composite material

The invention discloses a steel slag composite material for 3D printing as well as a preparation method and application thereof, and relates to the technical field of civil engineering materials. The steel slag composite material for 3D printing comprises a solid component and a liquid component, and the solid component comprises steel slag and the like. The steel slag and the steel slag powder are added into the 3D printing building material in a large mixing amount for building printing, the steel slag powder replaces a cement binding material, and the steel slag replaces fine aggregate, so that on one hand, comprehensive resource utilization of solid waste is guaranteed, the building cost is greatly reduced, exploitation of river sand is reduced, and damage to the environment is reduced; and on the other hand, domestic steel slag inventory can be greatly consumed, the maintenance cost and the like of enterprises on the steel slag are reduced, waste is turned into wealth, the cost is turned into value-added benefits, and profits and values can be created for the enterprises.

Owner:盈创新材料(苏州)有限公司

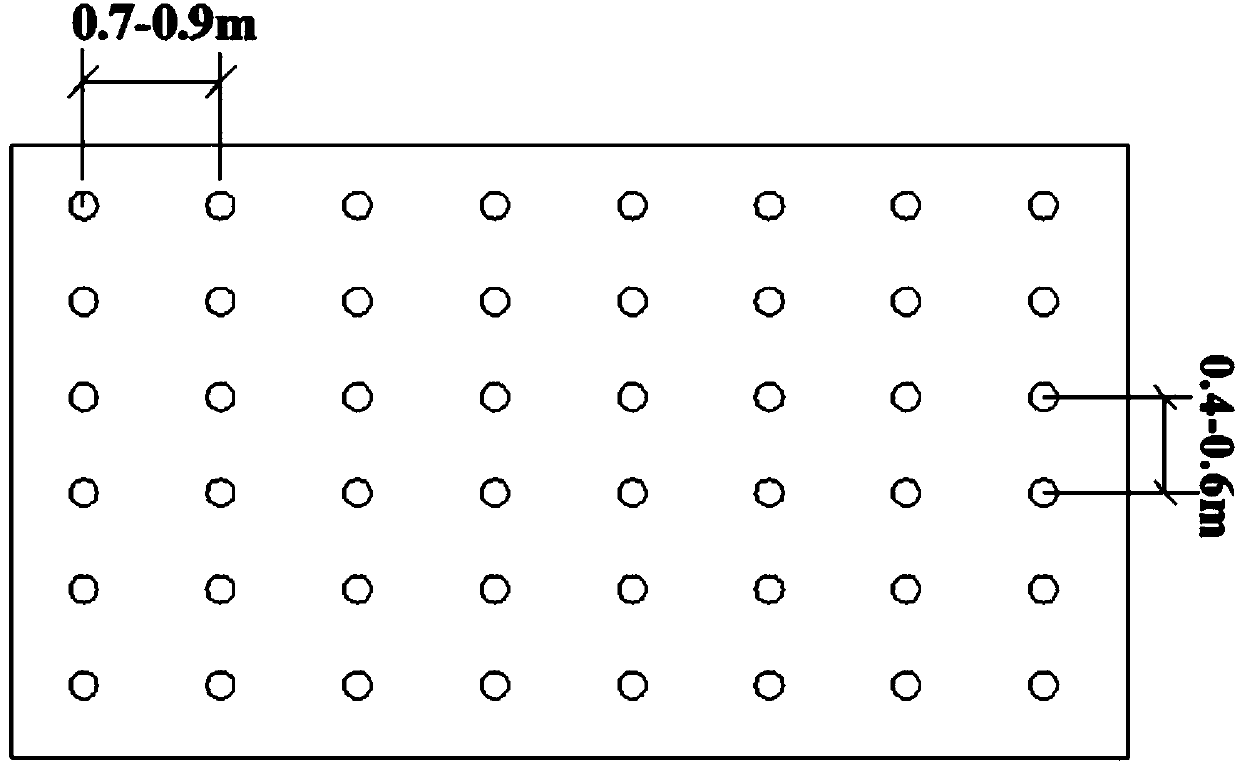

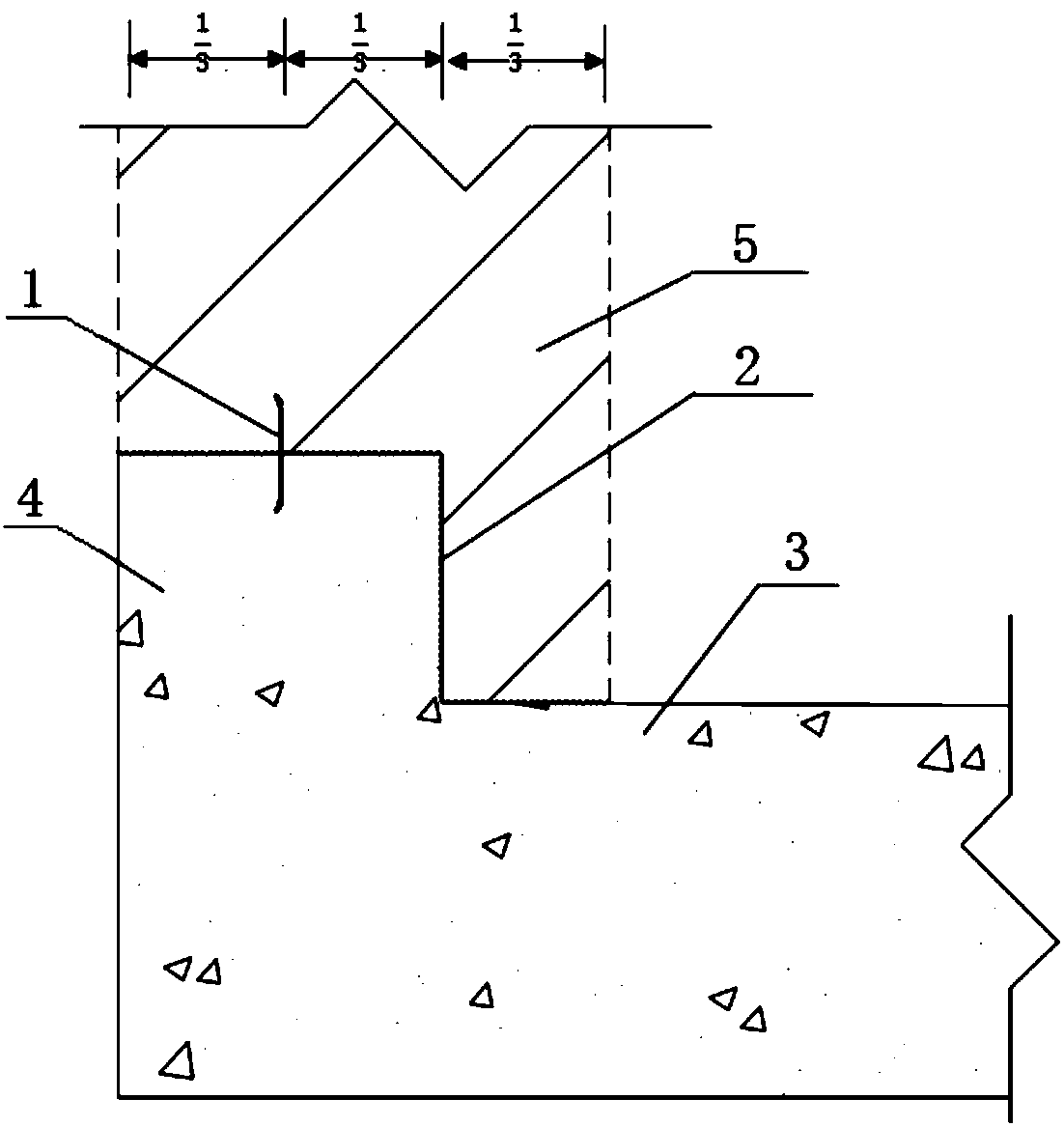

Preparation method for baseboard of main pipe and sluice and step-style construction joint for side wall of flow channel layer

ActiveCN108130889AReduce the difficulty of engineering constructionReduce construction difficultyHydraulic engineering apparatusMarine site engineeringBaseboardEngineering

The invention discloses a preparation method for baseboard of main pipe and sluice and step-style construction joint for side wall of flow channel layer. Under the circumstance that the flow channel layer is the special-shaped structure of gradient section and with the adoption of floor pouring technique, the height of the side wall of flow channel layer within two thirds of the width of the outboard of side wall is about 0.5m. The improved section of the side wall of flow channel layer is segmented by adopting overhanging model. By means of welding, a sealing plate is connected with a reticulate frame. After the floor pouring process is finished, the formed faulting is used as the stress release channel for the side wall of flow channel layer. The preparation method for baseboard of mainpipe and sluice and step-style construction joint for side wall of flow channel layer can reduce the difficulty in constructing baseboard, enlarge the pouring space of concrete base slab and improve the managing and controlling level and quality of the floor pouring of concrete base slab. The preparation method for baseboard of main pipe and sluice and step-style construction joint for side wall of flow channel layer can use the formed faulting in the floor pouring section as the release channel for the side wall of flow channel layer to reduce the restriction of the baseboard on the flow channel layer, which is beneficial to control the cracks caused by the temperature of concrete on the side wall of flow channel layer. The sealing plate, together with the floor pouring section, has a good water proofing effect. In one word, the preparation method for baseboard of main pipe and sluice and step-style construction joint for side wall of flow channel layer can obviously save the time forconstruction and accelerate the process of construction.

Owner:上海市水利工程集团有限公司

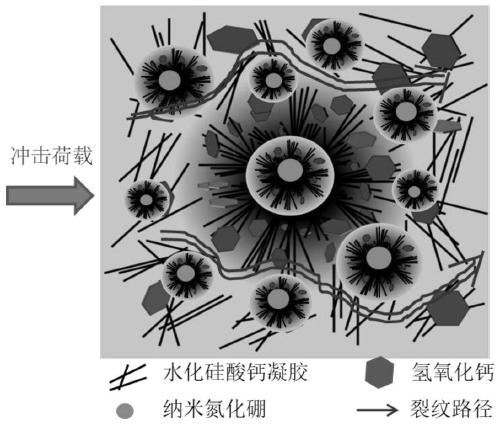

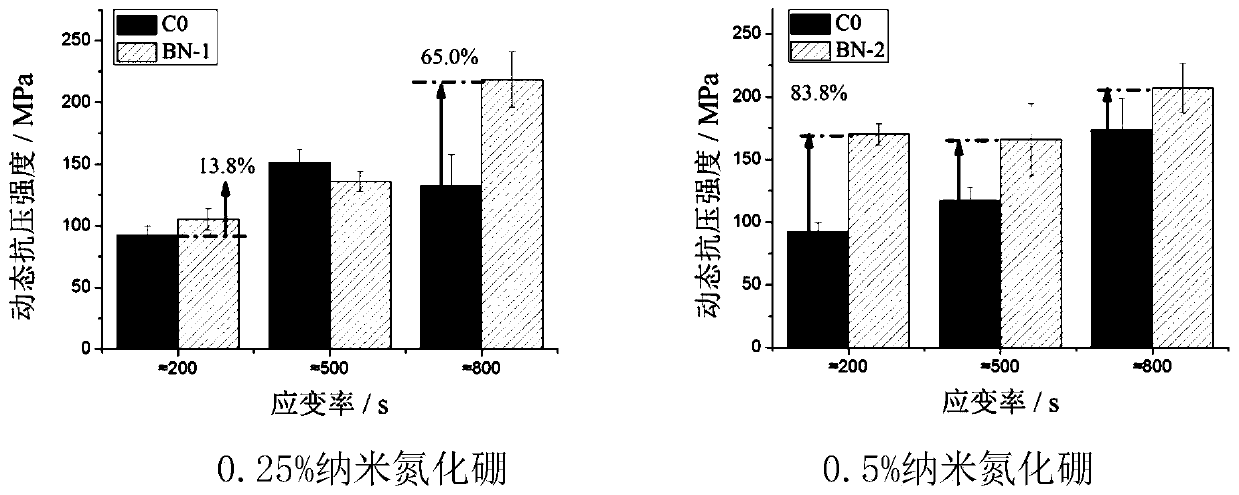

Impact-resistant nanometer boron nitride-modified concrete

The invention discloses an impact-resistant nanometer boron nitride-modified reactive powder concrete. Raw materials of the impact-resistant nanometer boron nitride-modified reactive powder concrete include cement, nanometer boron nitride, silica fume, fly ash, sands, a water reducer and water. The nanometer boron nitride can significantly enhance the dynamic compressive strength, dynamic peak strain and impact toughness of the reactive powder concrete. When the strain rate is in a range of 200-800 / s and the dosage of the nanometer boron nitride is 0.25-0.5%, the dynamic compressive strength of concrete can be increased by 83.8%, the dynamic peak strain can be increased by 30.5%, and the impact toughness can be increased by 94.6%.

Owner:DALIAN UNIV OF TECH

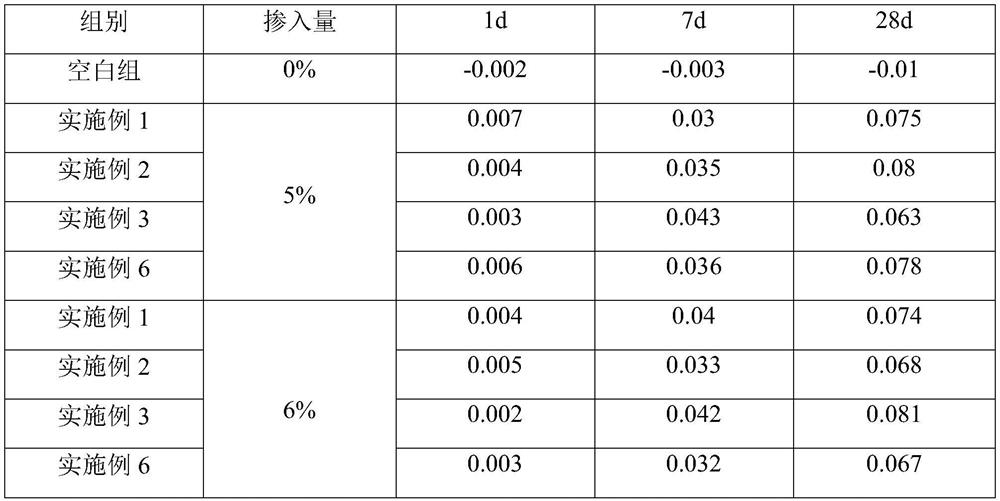

Magnesium high-performance anti-cracking agent for concrete as well as preparation method and application thereof

ActiveCN113563003AImprove compactnessImprove crack resistanceOrganic chemistrySolid waste managementSodium thiocyanateSlag

The invention discloses a magnesium high-performance anti-cracking agent for concrete as well as a preparation method and application thereof. The magnesium high-performance anti-cracking agent is prepared from the following raw materials of: 50 to 63 weight percent of light calcined magnesia clinker, 21 to 34 weight percent of phosphorus slag, 5 to 10 weight percent of coal slag, 1 to 3 weight percent of quartz sand, 1 to 2 weight percent of early strength agent and 0.5 to 1.3 weight percent of novel hydration heat absorbent. The light calcined magnesia clinker is formed by calcining magnesite, an iron material and bauxite at high temperature. The preparation method of the novel hydration heat absorbent comprises the following steps of: mixing maleic anhydride and sodium thiocyanate in a molar ratio of (7-9): 1; adding water to form a solution; dropwise adding a sodium benzenesulfonate solution in a nitrogen atmosphere; heating to 55-65 DEG C, carrying out heat preservation reaction for 2 hours; and cooling and drying to obtain the novel hydration heat absorbent. The anti-cracking agent disclosed by the invention has the functions of compensating concrete shrinkage, enhancing the mechanical property of concrete and absorbing cement hydration heat, and fundamentally improves the anti-cracking performance of the concrete material.

Owner:武汉三源特种建材有限责任公司 +1

Anti-cracking large-size early-strength, high-strength and micro-expansion M grouting material and construction method thereof

The invention discloses an anti-cracking large-size early-strength, high-strength and micro-expansion M grouting material which comprises cement, sand, an early strength agent, a water reducing agent and an expanding agent, and is characterized in that the cement refers to P.II 52.5R, has the amount of 440kg in each tonnage of the M grouting material and has a mix proportion of 1; the sand refers to medium sand, has the amount of 492kg in each tonnage of the M grouting material and has a mix proportion of 1.12; the early strength agent refers to calcium formate, has the amount of 10kg in each tonnage of the M grouting material and has a mix proportion of 0.02; the water reducing agent refers to poly-acid, has the amount of 5kg in each tonnage of the M grouting material and has a mix proportion of 0.01; and the expanding agent refers to a calcium sulphoaluminate expanding agent, has the amount of 53kg in each tonnage of the M grouting material and has a mix proportion of 0.12. The anti-cracking large-size early-strength, high-strength and micro-expansion M grouting material and the construction method thereof disclosed by the invention have the advantages that the M grouting material is simple and practical in preparation, high in operability and obvious in anti-cracking effect and is especially suitable for short-construction-period high-strength large-size grouting material engineering projects for on-line transformation, maintenance and rush repair.

Owner:MCC5 GROUP CORP SHANGHAI

Expansion fiber anti-crack waterproof concrete and preparation method thereof

The invention relates to expansive fiber anti-crack waterproof concrete, which is prepared from the following components in parts by mass: 880 to 950 parts of sand, 970 to 1020 parts of gravel, 45 to 55 parts of fly ash, 280 to 320 parts of cement, 150 to 170 parts of water, 30 to 40 parts of stone powder, 35 to 50 parts of expansive fiber and 6.6 to 7.8 parts of additives. The preparation method comprises the following steps: pouring 970-1020 parts of broken stone, 880-950 parts of sand, 45-55 parts of fly ash and 280-320 parts of cement into a concrete mixer, uniformly mixing, adding 30-40 parts of stone powder and 35-50 parts of expansion fiber, continuously uniformly mixing, uniformly mixing 6.6-7.8 parts of admixture and 150-170 parts of water, adding into the mixer, and continuously uniformly mixing to obtain the concrete mixture. The concrete is good in impermeability and early-stage crack resistance, and is suitable for underground engineering, large-scale pools and other concrete engineering with high waterproof requirements.

Owner:ROAD & BRIDGE INT +2

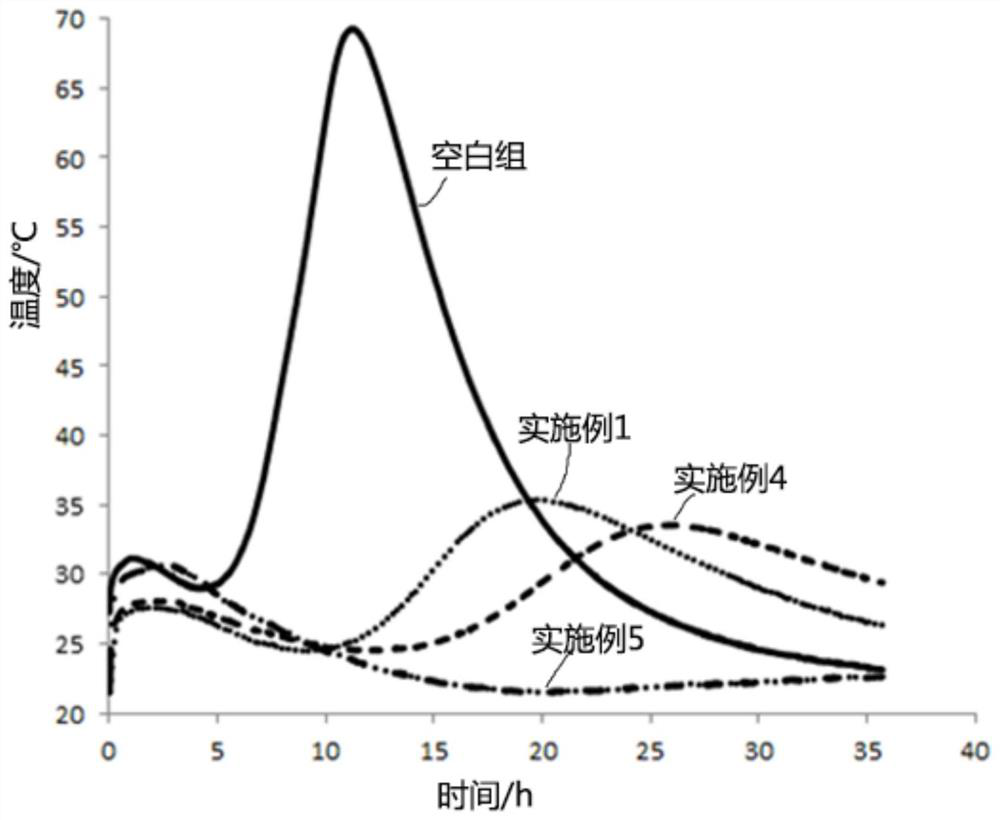

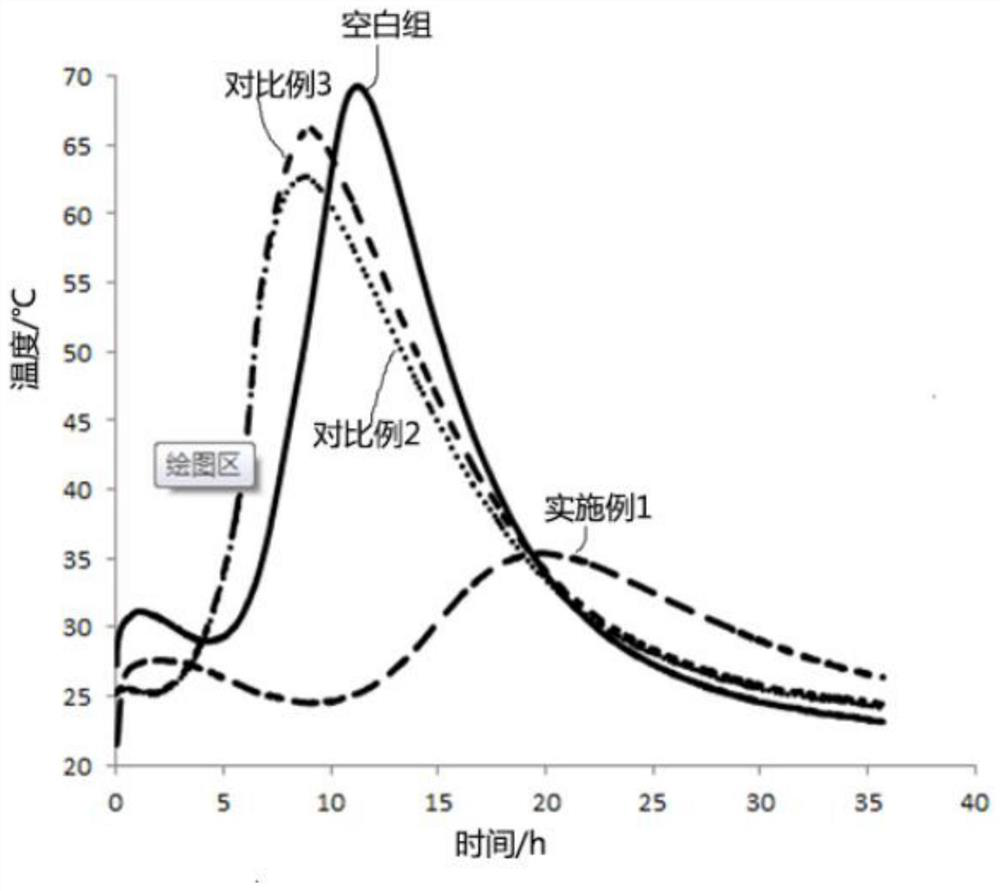

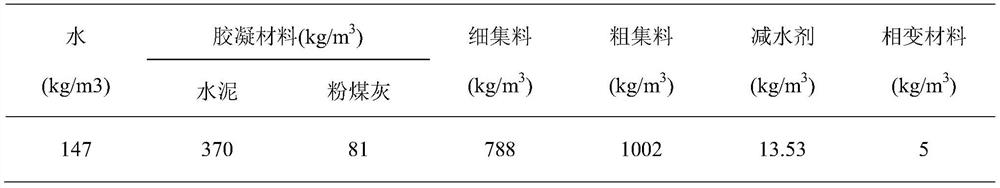

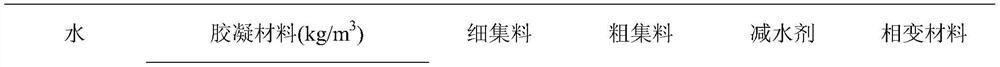

Phase-change mass concrete and preparation method thereof

The invention discloses phase-change mass concrete which comprises the following components: 140-170kg / m < 3 > of water; 300-400 kg / m < 3 > of cement; 50-150 kg / m < 3 > of coal ash; 650-850 kg / m < 3 > of fine aggregate; 1000-1200 kg / m < 3 > of coarse aggregate; 9.0-13.6 kg / m < 3 > of water reducing agent; 1-5 kg / m < 3 > of a phase change material; the phase-change material is a high-thermal-conductivity nanoscale microcapsule phase-change material, and the phase-change temperature is 49 DEG C; the phase-change mass concrete prepared based on the phase-change material can effectively slow down the internal temperature rise of the mass concrete, reduce the temperature gradient and reduce the probability of temperature cracks of the mass concrete; and compared with a traditional mass concrete cooling method, the construction cost is greatly reduced, the process is simple, the performance is stable, a traditional cooling water pipe cooling method can be replaced, and the construction period is greatly shortened.

Owner:CHINA FIRST METALLURGICAL GROUP

A large-volume concrete temperature control automatic integrated system

ActiveCN111734139BReal-time temperature monitoringReduced risk of crackingFoundation engineeringStationary tubular conduit assembliesTemperature controlWater flow

Owner:安徽贝慕物联科技有限公司

A multifunctional curing box for mass concrete

ActiveCN104690815BReasonable layoutShorten the construction periodCeramic shaping apparatusTemperature stressComplete data

The invention provides a multifunctional curing box for mass concrete. The multifunctional curing box comprises a box body with a door, four cavities and a refrigerating and heating device mounted at the bottom of the box body with the door, wherein the four cavities are defined by a horizontal thermal-insulating water-resisting layer and a vertical thermal-insulating water-resisting layer which are perpendicular to each other and mounted inside the box body with the door; a standard curing box is arranged in the first cavity; a curing box with the highest temperature of 30 DEG C is arranged in the second cavity; a curing box with the highest temperature of 60 DEG C is arranged in the third cavity; a curing box with the highest temperature of 80 DEG C is arranged in the fourth cavity; the refrigerating and heating device comprises a refrigerating device, a liquid collecting box and a heating device, which are mounted at the bottom of the box body with the door. The multifunctional curing box disclosed by the invention can be matched with mass concrete samples at the matched temperature, cannot limit the size of the sample, has the characteristics of being economic, safe, environment-friendly and energy-saving, can provide relatively complete data, and further provides experimental data and conditions for research about how to control temperature stress cracks of the mass concrete caused by hydration heat in the early stage and development of the concrete mechanical properties.

Owner:HARBIN ENG UNIV

A New Type of Building Thermal Insulation Mortar

The invention relates to a novel thermal insulation mortar for buildings. The novel thermal insulation mortar is prepared from the following raw materials in parts by weight: 25-32 parts of cement, 40-45 parts of fly ash, 35-40 parts of yellow sand, 8-10 parts of polyurethane particles, 10-15 parts of expanded vermiculite and 6-10 parts of a short fiber mixture. The novel thermal insulation mortarhas the advantages that a large amount of the fly ash is added into the raw materials, therefore, the cost of the mortar is obviously reduced; moreover, the fly ash is treated and then added into themortar, so that the comprehensive performance of the mortar can be obviously improved; the polyurethane particles and the expanded vermiculite are added into the raw materials, so that a thermal insulation effect of the mortar is enhanced; and synthetic fabric formed by mixing glass fiber and nylon fiber is added, so that not only is the combining strength of the fiber and the mortar ensured, butalso the fluidity and the plasticity of the mortar during a spraying process are guaranteed, and the construction performance of the mortar is improved.

Owner:常州市美高特建材科技有限公司

Double-doped biomass ash concrete and manufacturing method thereof

PendingCN113651578AImprove performanceReduce manufacturing costSolid waste managementProcess engineeringEnvironmental engineering

According to the double-doped biomass ash concrete and the manufacturing method thereof, industrial waste fly ash and CMA are doped in the concrete to replace part of cement, heat released by hydration heat of the fly ash is little, hydration heat reaction is reduced, temperature cracks are reduced, the CMA can reduce the heat conductivity coefficient of a base material, the self-heat-preservation function is achieved, and the strength meets the requirement; and the double-doped biomass ash concrete is low in cost, green and environment-friendly, can be applied to concrete with various requirements due to the specific performance, and improves the performance of the concrete.

Owner:XIJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com