A large-volume concrete temperature control automatic integrated system

A large-volume concrete and automatic technology, which is applied in the direction of electrical program control, sequence/logic controller program control, roads, etc., can solve problems such as large impact on construction quality, deviation of design status, waste of water resources, etc., to achieve Avoid uneven cooling, reduce horizontal temperature gradient, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

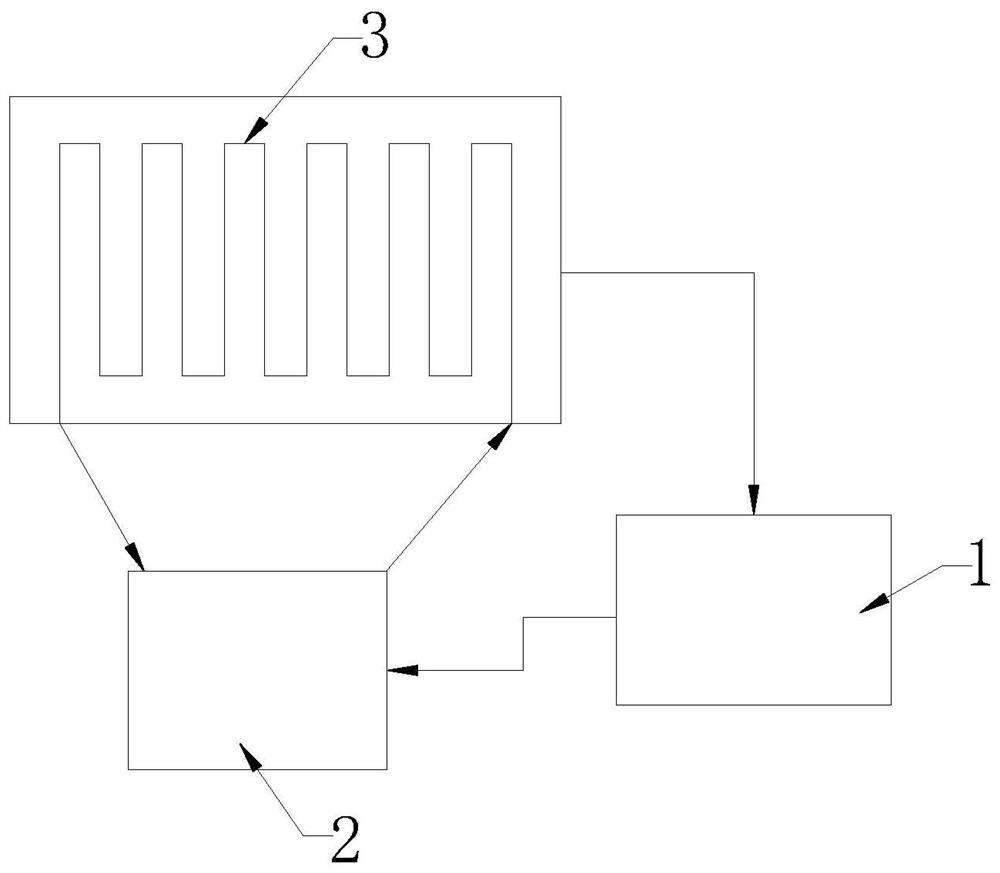

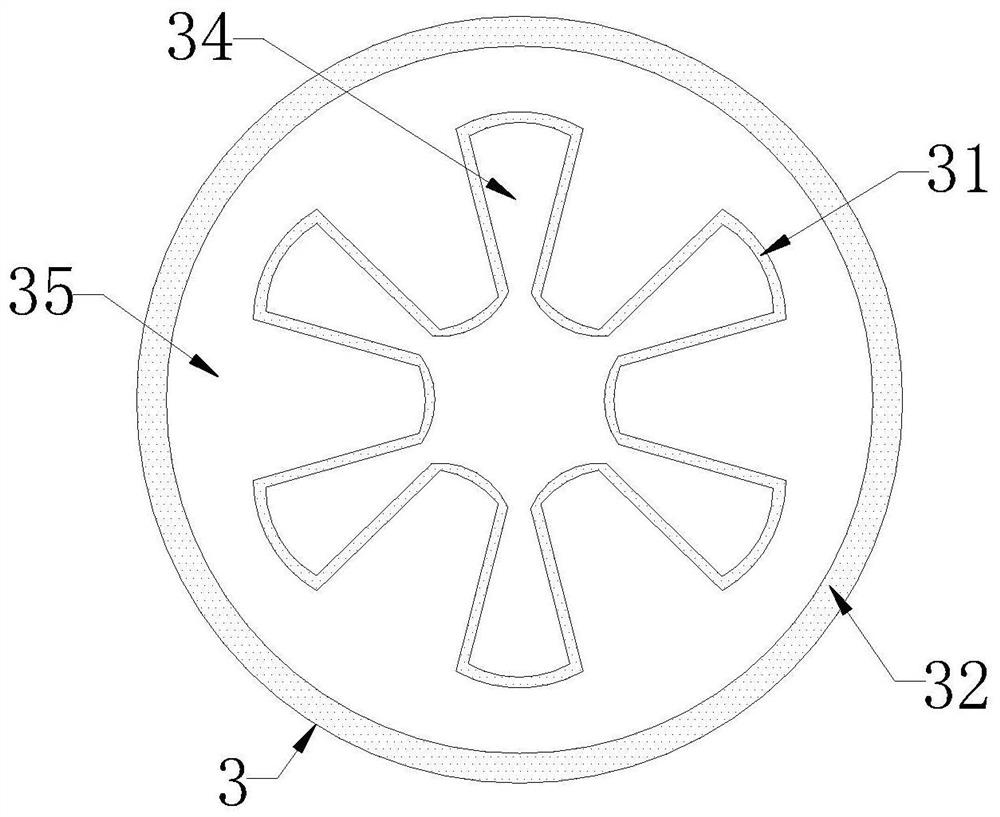

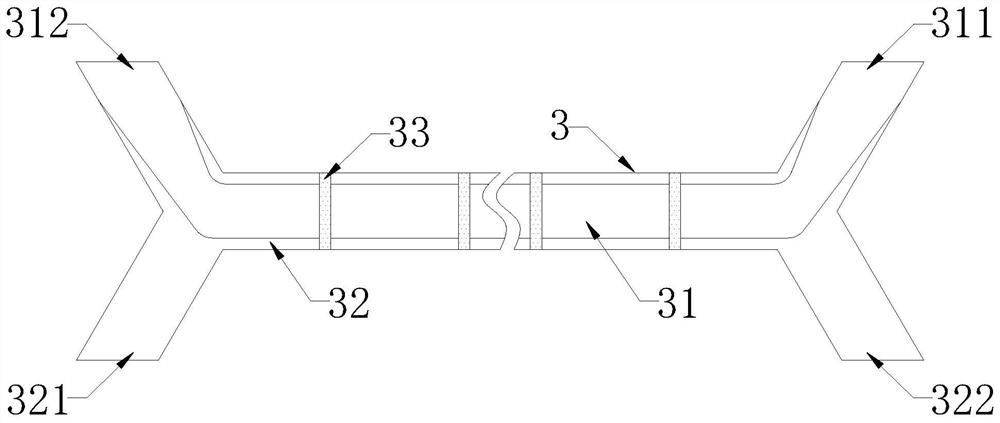

[0045] Example: such as Figure 1-3 As shown, a large-volume concrete temperature control automatic integrated system provided by the present invention includes a general control device 1, a pipeline assembly, a temperature measurement assembly and a cooling assembly 2, and the pipeline assembly is composed of several cooling pipes 3, The temperature measuring component is a plurality of temperature sensors pre-embedded in mass concrete, the cooling component includes air cooling equipment and a circulating cooling water system, the input end of the general control device 1 is electrically connected to the temperature sensor, and the temperature sensor The model is JMT-36, its output end is electrically connected with the cooling component 2, and the cooling component 2 controls the on-off and opening of the cooling pipe 3. When the temperature detected by the temperature sensor is greater than 13 degrees but less than 15 degrees, the master control device 1 Turn on the water-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com