Power cable joint temperature measuring device

A technology for power cables and temperature measuring devices, applied in measuring devices, thermometers, measuring heat, etc., can solve problems such as the working temperature of the cable core is exceeded, the copper or aluminum material of the wire core cannot be fully utilized, and the life of the cable insulation is shortened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments of the specification.

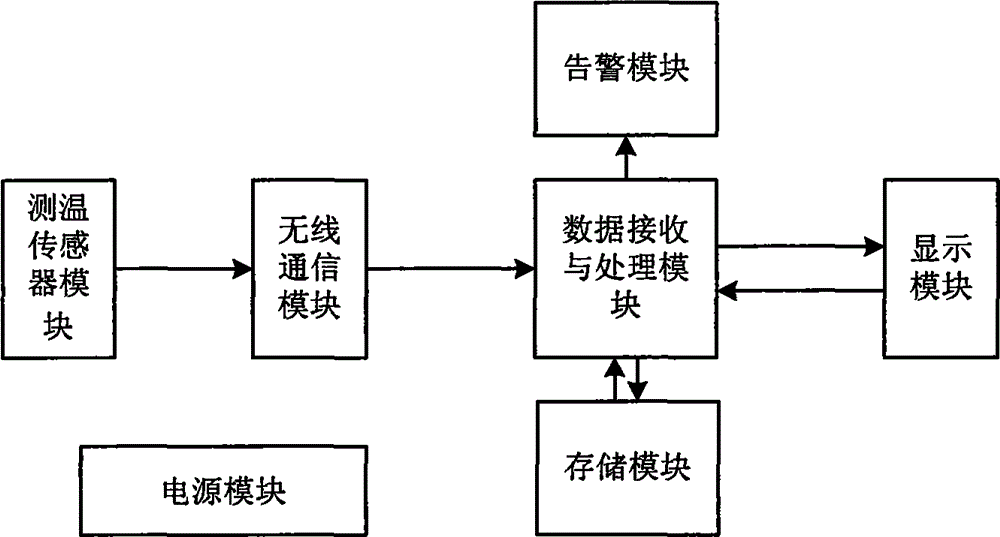

[0015] An embodiment of the present invention provides a temperature measuring device for a power cable joint, which can effectively monitor the temperature change of the power cable joint and improve the working efficiency of cable joint maintenance. Such as figure 1 As shown, it consists of a temperature measurement sensor module, a data receiving and processing module, a wireless communication module, a display module, a storage module, an alarm module and a power supply module; The data is sent to the data receiving and processing module; if an alarm indication is obtained through calculation and processing, the data receiving and processing module sends the alarm information to the alarm module, and sends the processing result to the display module for display, and stores the fault information into the storage module at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com