Patents

Literature

74 results about "Joint temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

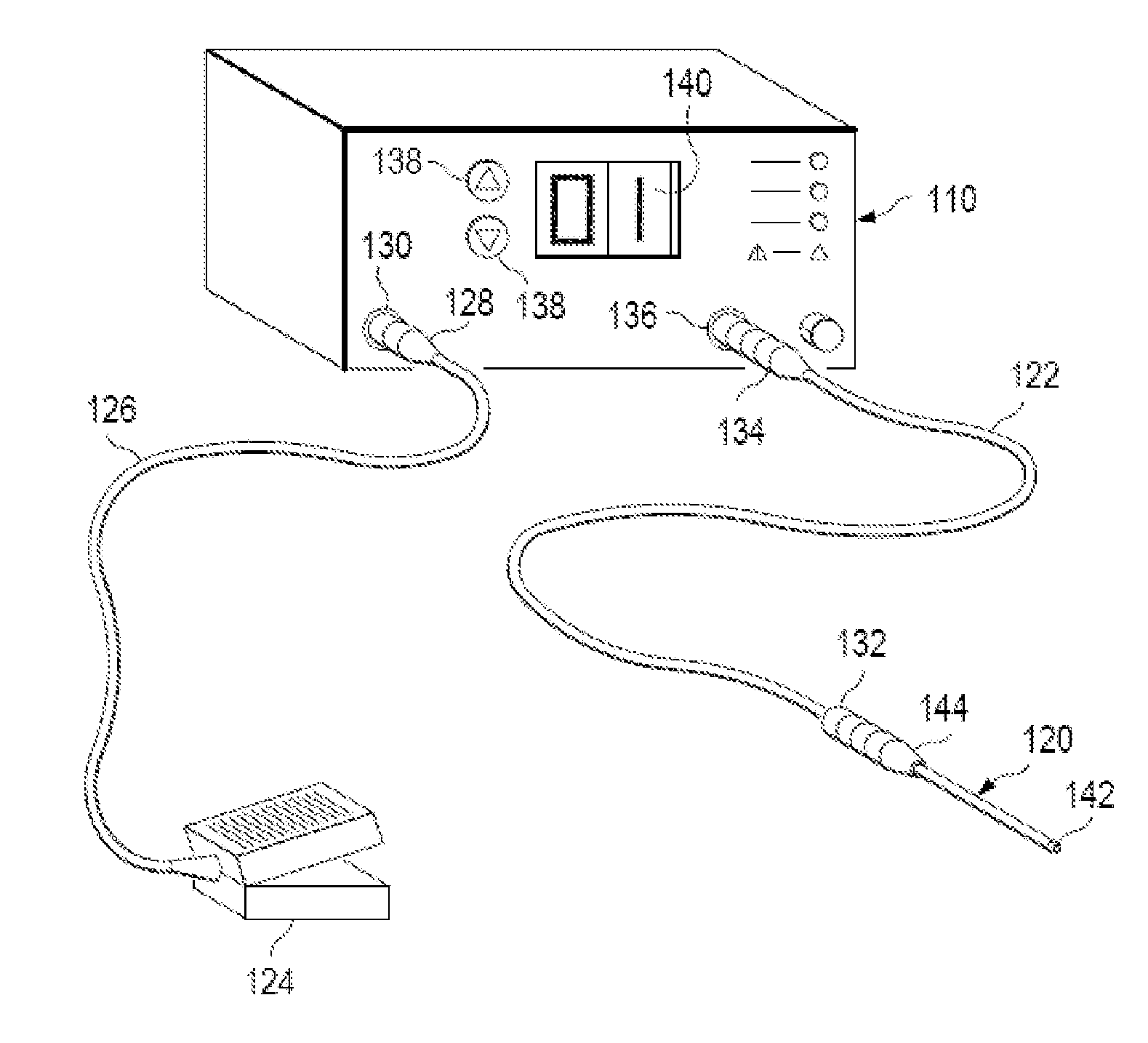

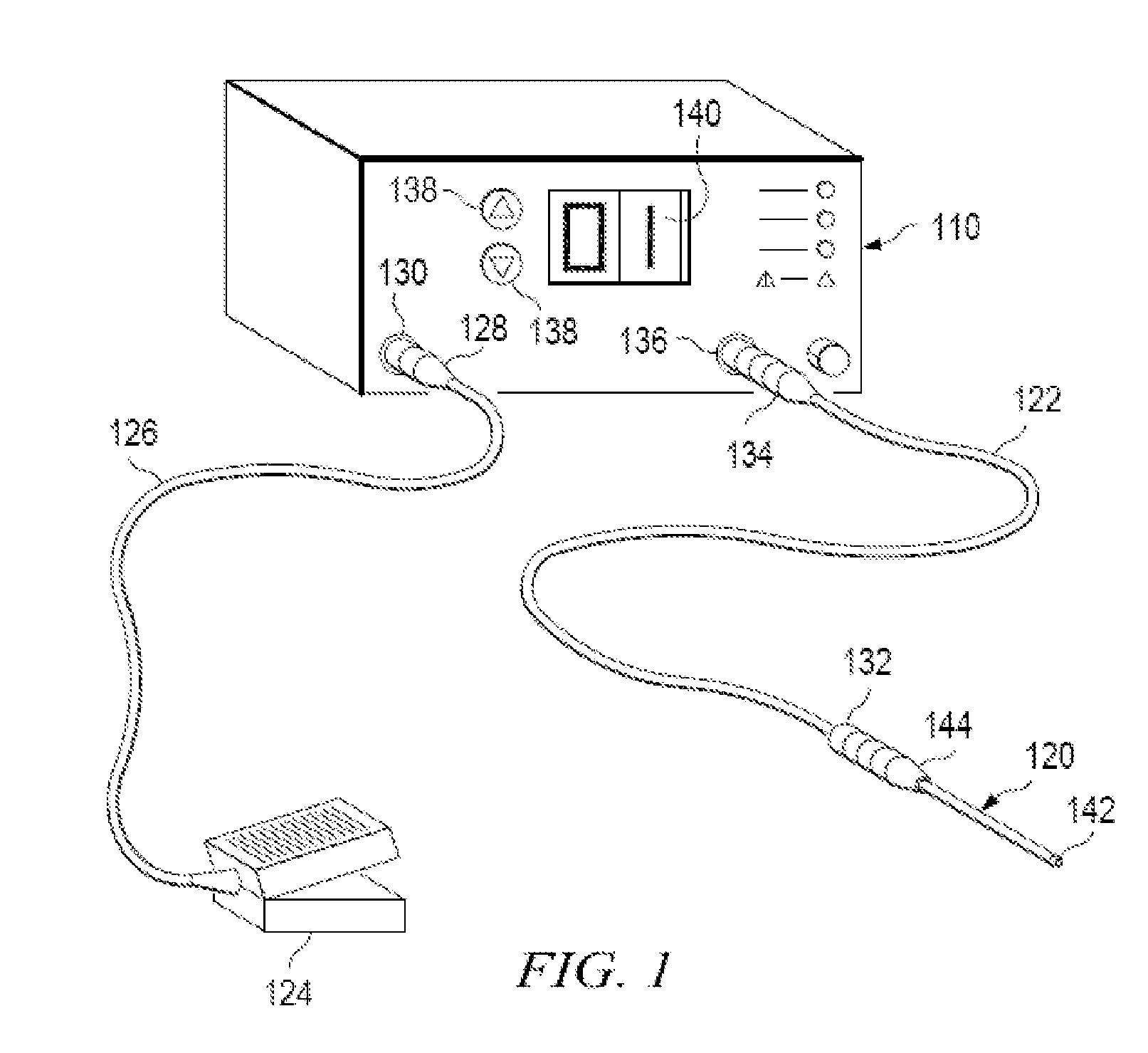

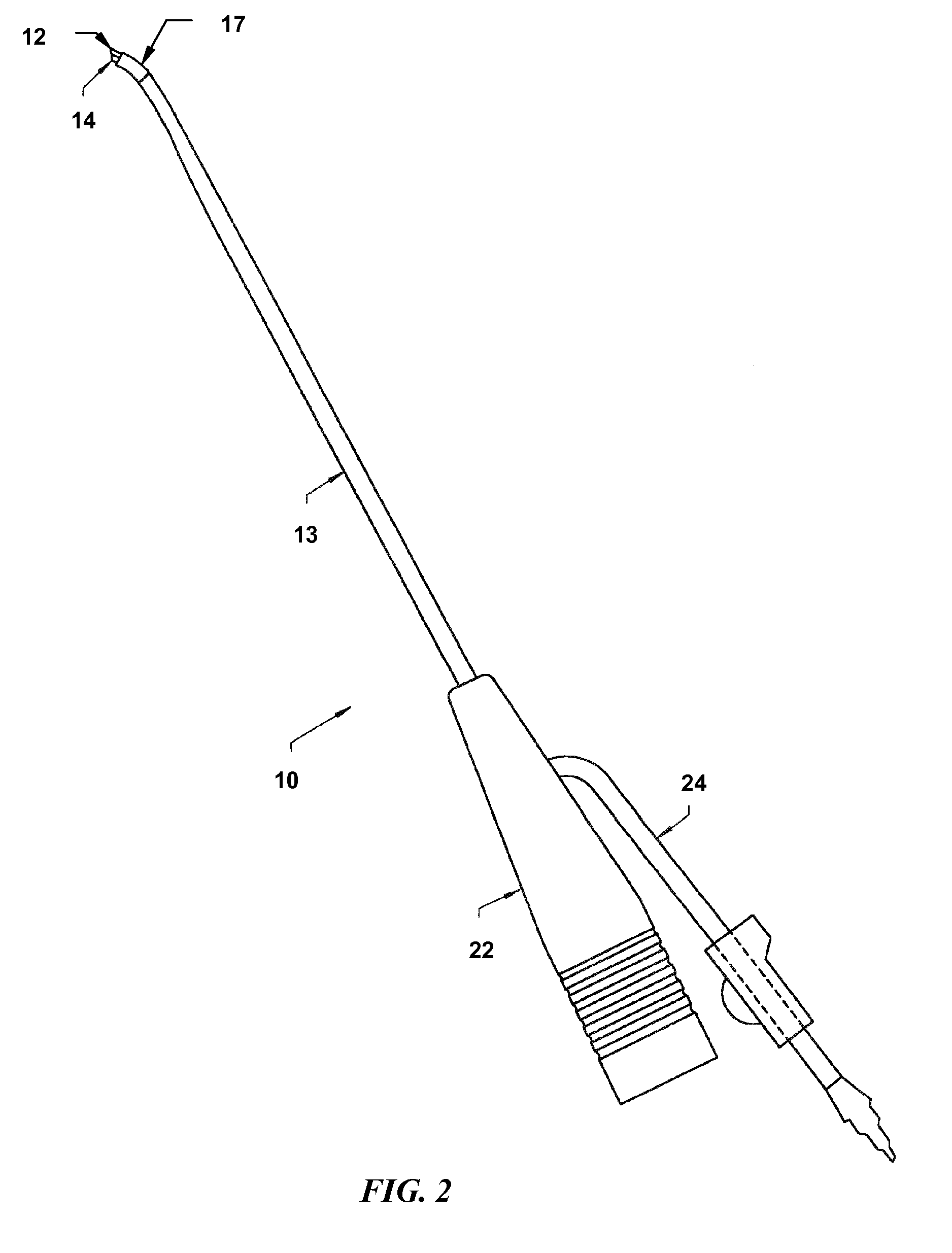

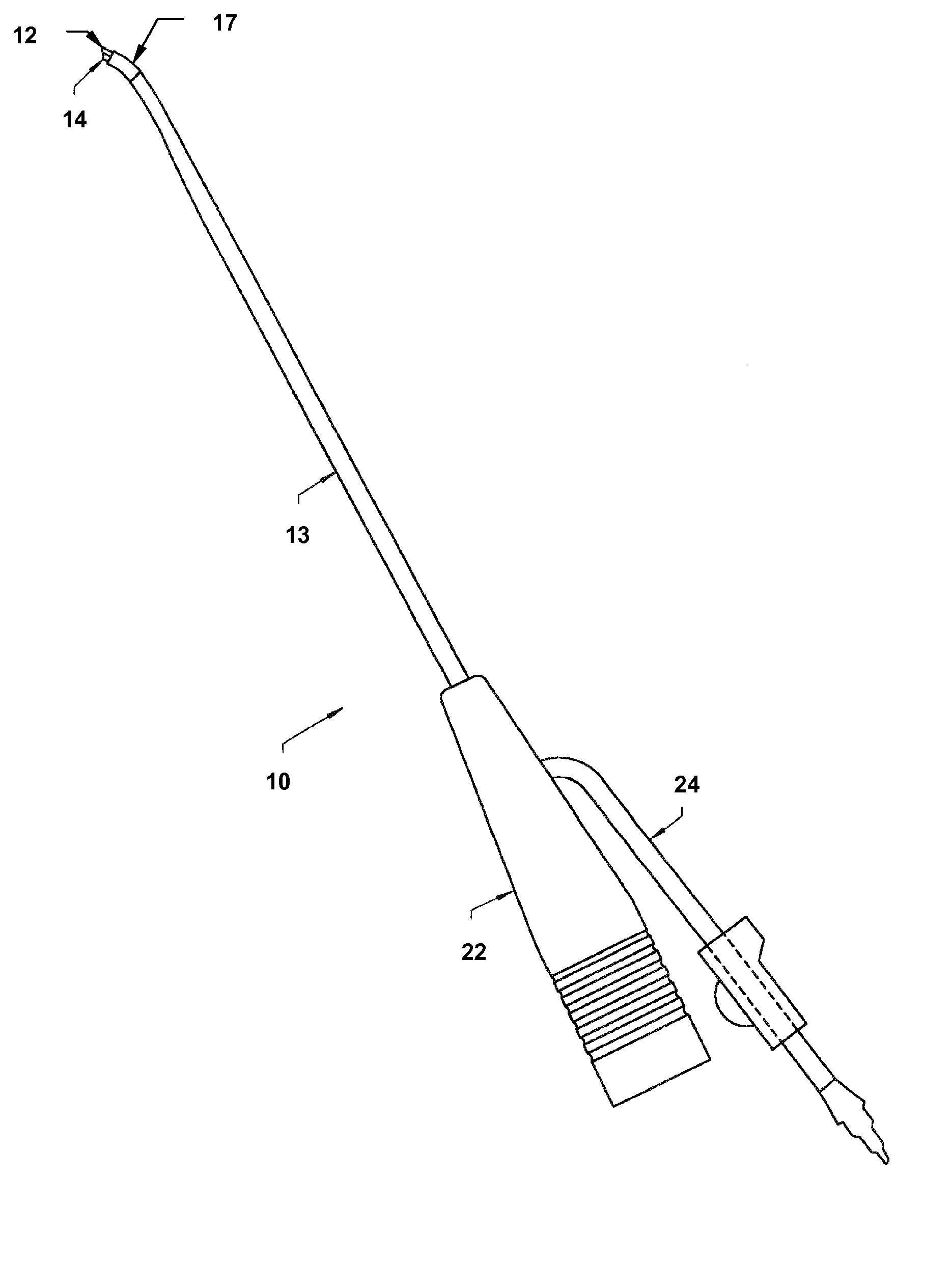

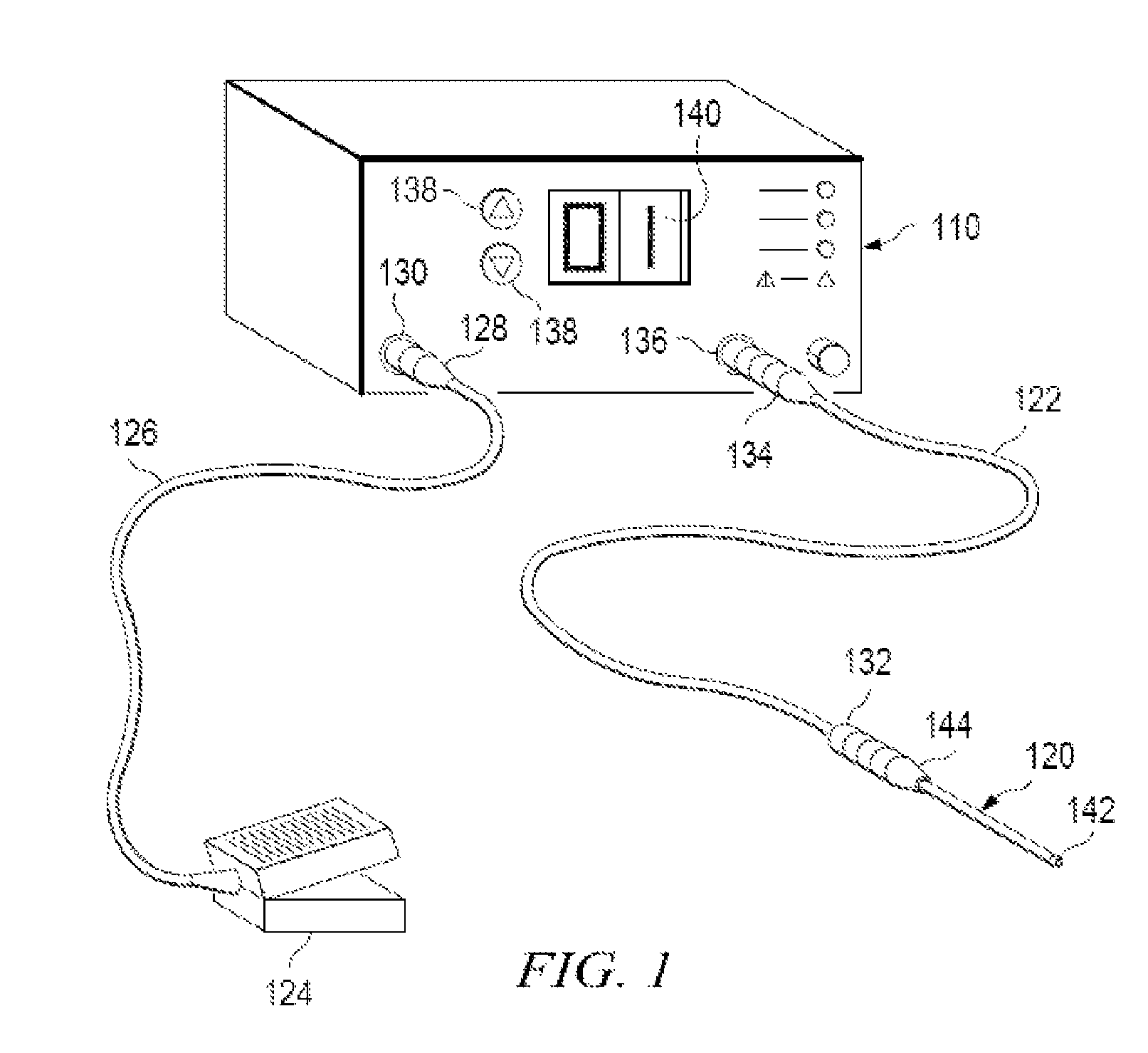

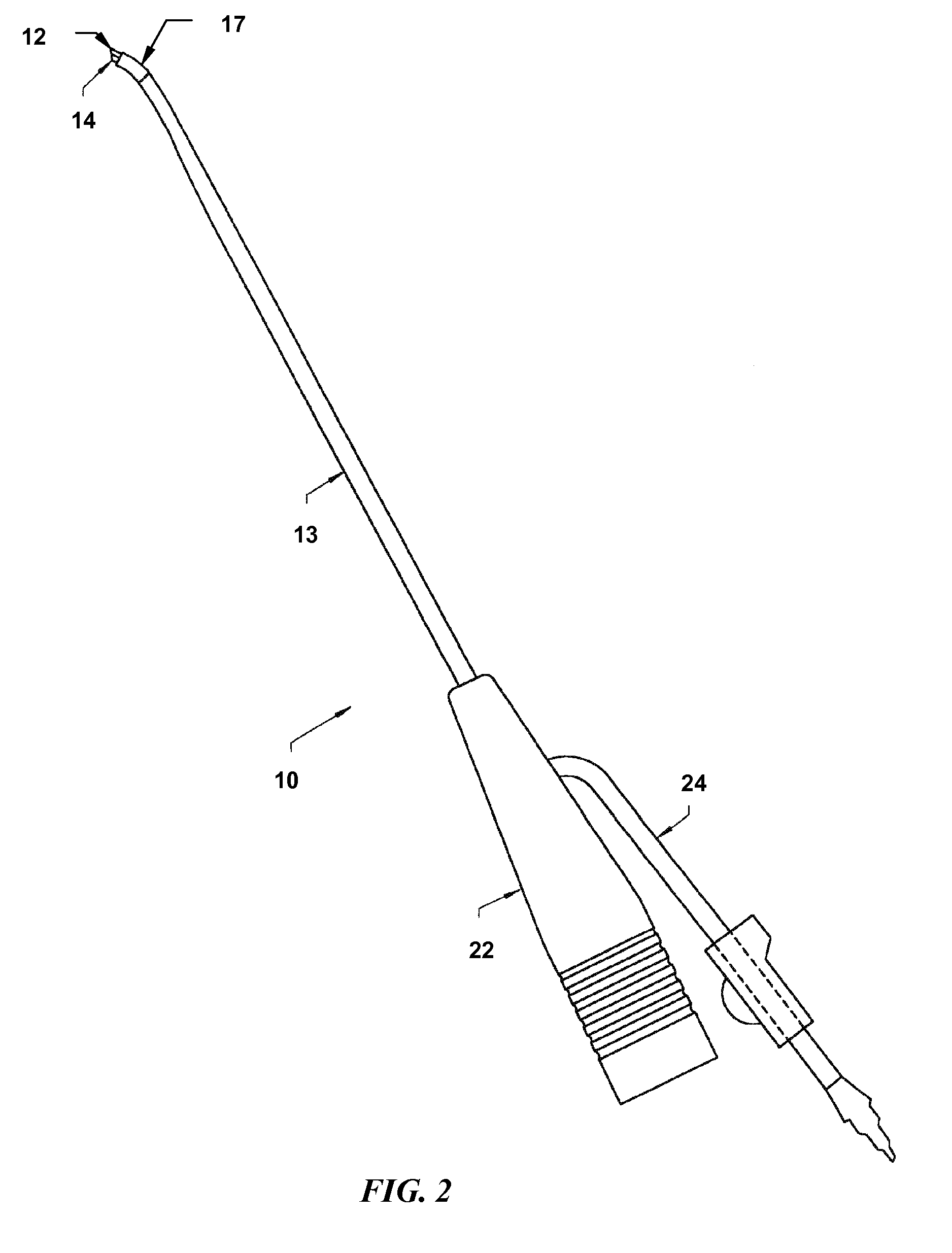

Systems and methods for limiting joint temperature

ActiveUS20100152724A1Reduce the risk of injuryReduce and eliminate temperature influenceDiagnostic recording/measuringSensorsTarsal JointFluid temperature

Joint temperature monitoring and control systems and methods are described herein in which the temperature of a fluid within a body or joint space is determined and / or monitored despite the energy generated during treatment by an ablation probe. One or more temperature sensors are positioned along the probe proximally of the electrode assembly and measure the temperature of an electrically conductive fluid without being overly influenced by the surgical effect occurring proximate the electrode assembly. The controller coupled to the probe can also be configured to set temperature limits and treatment times as well as moderating joint temperature by altering the electrically conductive fluid flow.

Owner:ARTHROCARE

Systems and methods for limiting joint temperature

ActiveUS8355799B2Reduce and eliminate temperature influenceReduce the risk of injuryDiagnostic recording/measuringSurgical instruments for heatingControl systemMonitoring and control

Joint temperature monitoring and control systems and methods are described herein in which the temperature of a fluid within a body or joint space is determined and / or monitored despite the energy generated during treatment by an ablation probe. One or more temperature sensors are positioned along the probe proximally of the electrode assembly and measure the temperature of an electrically conductive fluid without being overly influenced by the surgical effect occurring proximate the electrode assembly. The controller coupled to the probe can also be configured to set temperature limits and treatment times as well as moderating joint temperature by altering the electrically conductive fluid flow.

Owner:ARTHROCARE

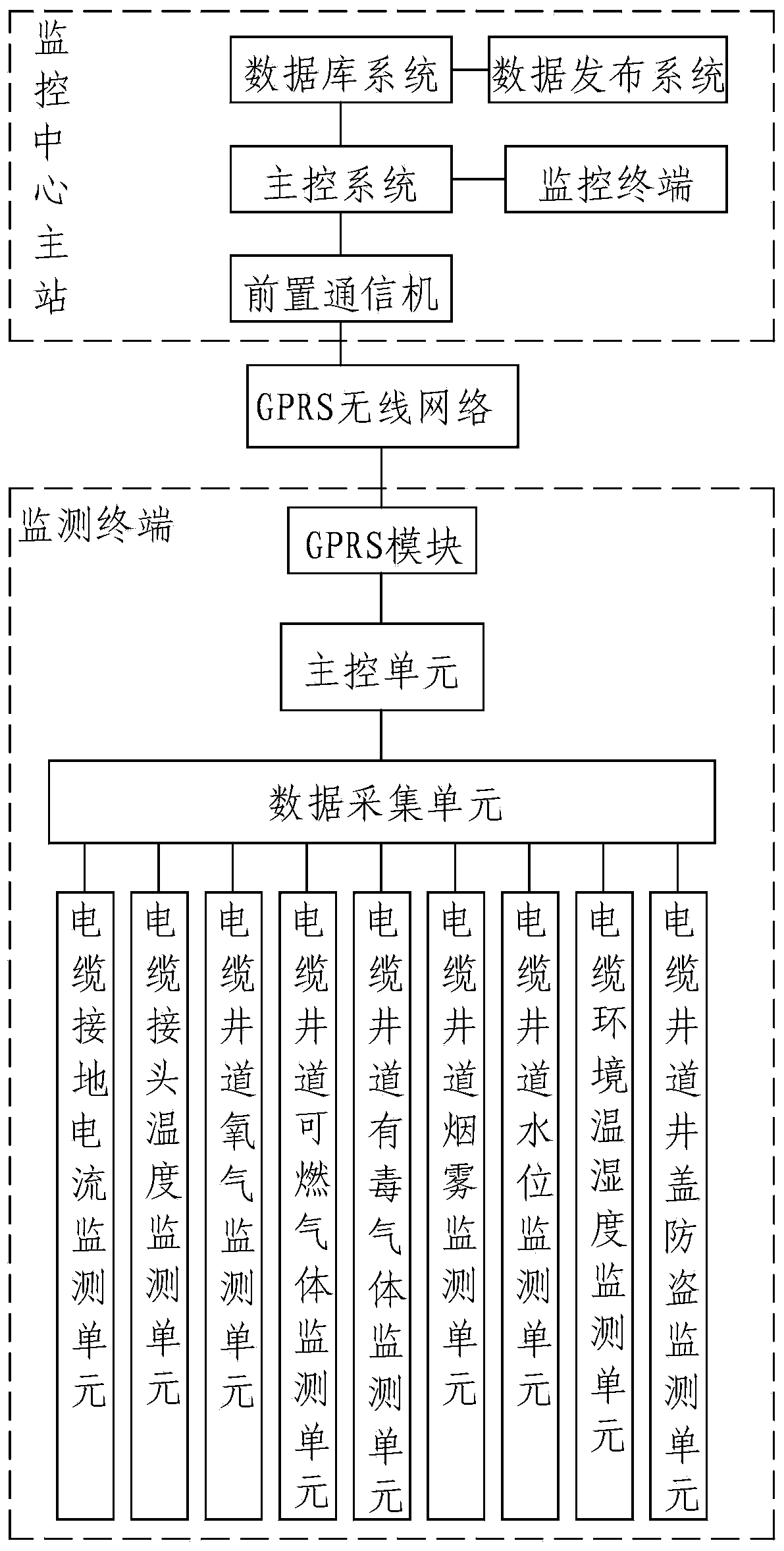

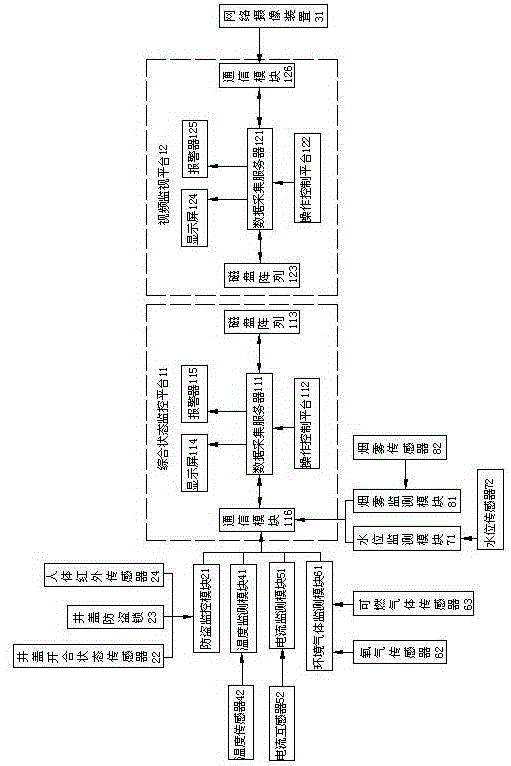

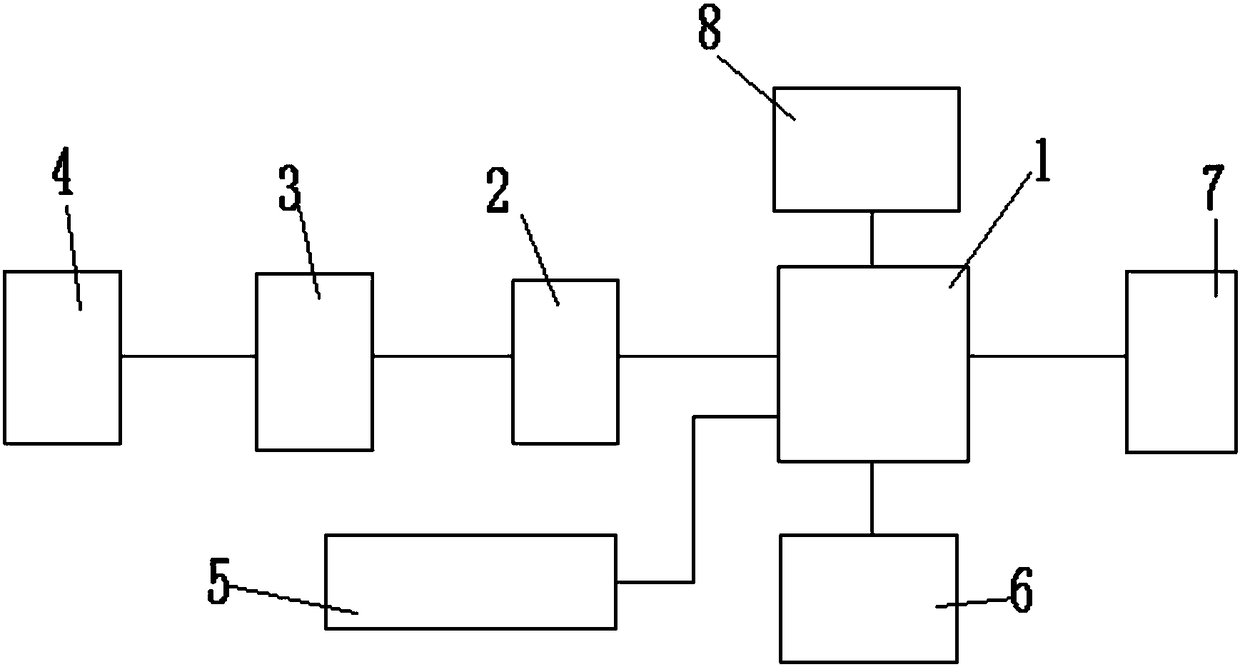

Intelligent online monitoring and pre-warning system for cable operation condition

InactiveCN104050793AEasy to handleAvoid major problemsMeasurement devicesTransmission systemsSynthetic dataEngineering

The invention relates to an intelligent online monitoring and pre-warning system for cable operation condition. The intelligent online monitoring and pre-warning system comprises a monitoring terminal and a monitoring center master station, wherein the monitoring terminal acquires monitoring parameters of the cable operation condition, such as the grounding current of the metal protective layer of the cable, cable joint temperature, combustible gas content, poisonous gas content, oxygen gas content, smoke, water level and manhole cover security, in real time and reports the acquisition data to the monitoring center master station in a timing manner through a wireless network; the monitoring center master station is used for timely carrying out storage, statistic, analysis, display and processing on the reported acquisition data and has functions of acquiring synthetic data of cable operation, monitoring the operation state in real time, displaying image data, pre-warning a fault and giving an alarm, carrying out statistic analysis of information data and the like. The intelligent online monitoring and pre-warning system can provide an effective monitoring method for ensuring the cable trench line security, ensure that the high-voltage cable line runs stably and reliably and greatly improve the power supplying reliability.

Owner:STATE GRID CORP OF CHINA +1

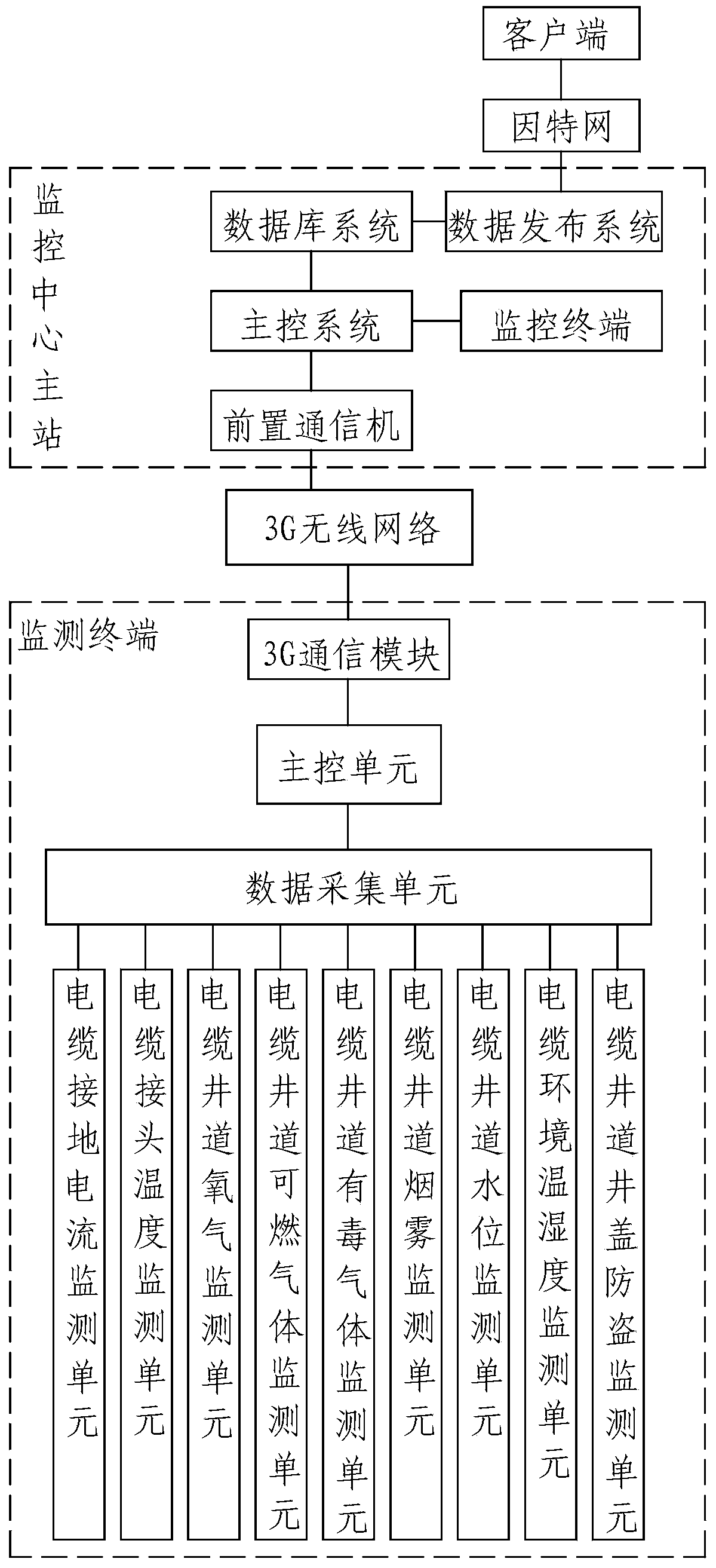

Intelligent integrated online monitoring system and method for underground cable operation

InactiveCN104954756APrevent theftMany reserved contactsNon-electrical signal transmission systemsMeasurement devicesVideo monitoringNormal conditions

The invention discloses an intelligent integrated online monitoring system and method for underground cable operation. The online monitoring system comprises a monitoring center as well as a cable anti-stealing detection unit, a cable video monitoring unit, a cable joint temperature monitoring unit, a cable metal sheath grounding current monitoring unit, an environment gas monitoring unit, a cable tunnel water level monitoring unit and a cable tunnel smoke monitoring unit which are connected with the monitoring center respectively. According to the system and the method, various sensors and mutual inductors are adopted to monitor cables and cable environments, the monitoring center masters the operation conditions of the cables in real time and gives an alarm when a normal condition happens, a worker is reminded to clear a fault in time, and large potential safety hazard is avoided; with the adoption of anti-stealing monitoring, the possibility of stealing of the cables is eliminated, in combination of video monitoring, the missing report caused by visual fatigue is prevented, one all-weather dead-zone-free monitoring platform is established, so that visual monitoring of important positions in cable tunnels is realized, manual inspection is replaced, the labor cost is reduced, the time is saved, further, videos can be stored and taken, and later maintenance is facilitated.

Owner:BENGBU POWER SUPPLY COMPANY STATE GRID ANHUI ELECTRIC POWER +1

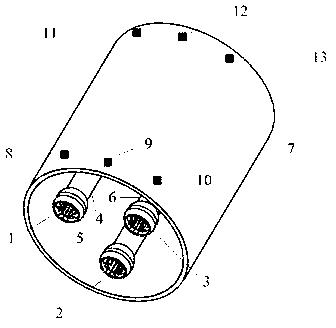

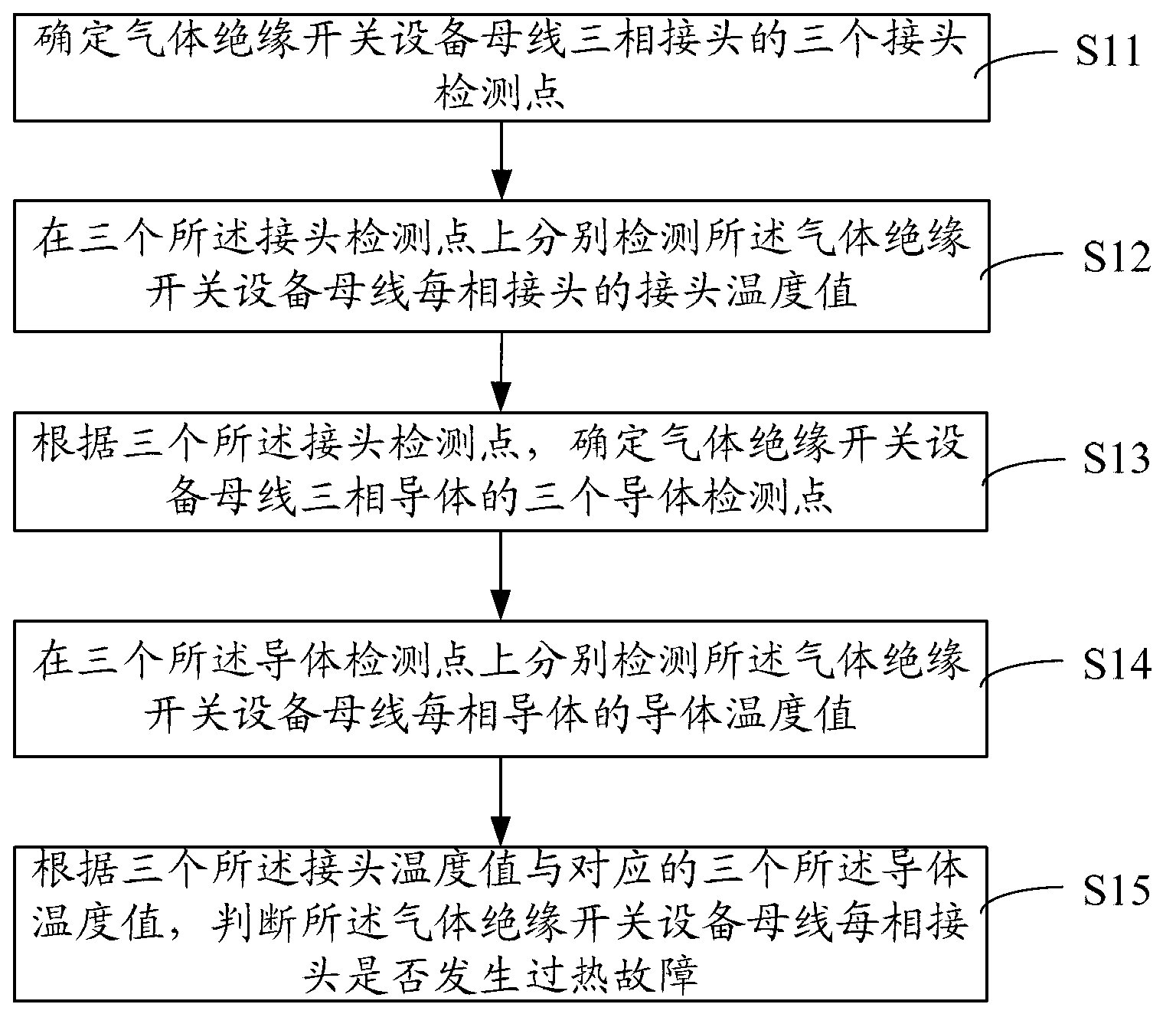

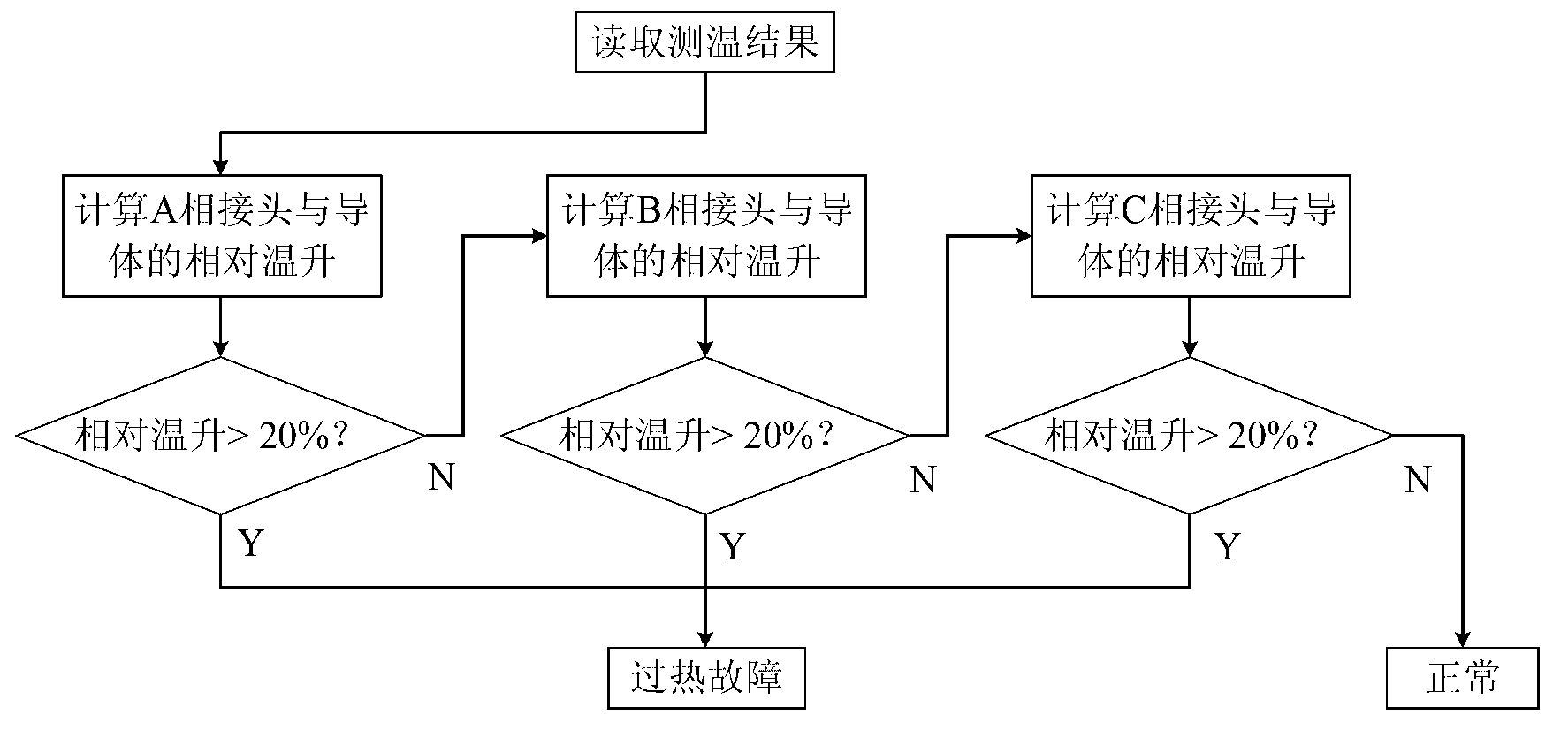

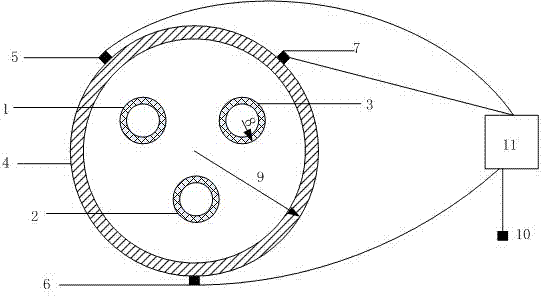

Method and system for diagnosing overheat fault of joints of gas insulated switch equipment bus

ActiveCN102798783AReal-time diagnosis of overheating faultElectrical testingThermometers using physical/chemical changesElectrical conductorThree-phase

The invention discloses a method for diagnosing overheat fault of joints of a gas insulated switch equipment bus. The method comprises the following steps: determining three joint detection points of three-phase joints of the gas insulated switch equipment bus and detecting the joint temperature value of each phase joint of the gas insulated switch equipment bus respectively; determining three conductor detection points of three-phase conductors of the gas insulated switch equipment bus according to the three joint detection points and detecting the conductor temperature value of each phase conductor of the gas insulated switch equipment bus respectively; and judging each phase joint of the gas insulated switch equipment bus is in overheat fault or not according to the temperature value of the three joints and the temperature value of the three corresponding conductors. Correspondingly, the invention also provides a system for diagnosing the overheat fault of the joints of the gas insulated switch equipment bus. By the method and the system, the overheat fault of the bus joints can be judged, the fault type of the three-phase joints can be determined and the diagnosis result is not influenced by the environmental factor.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID +1

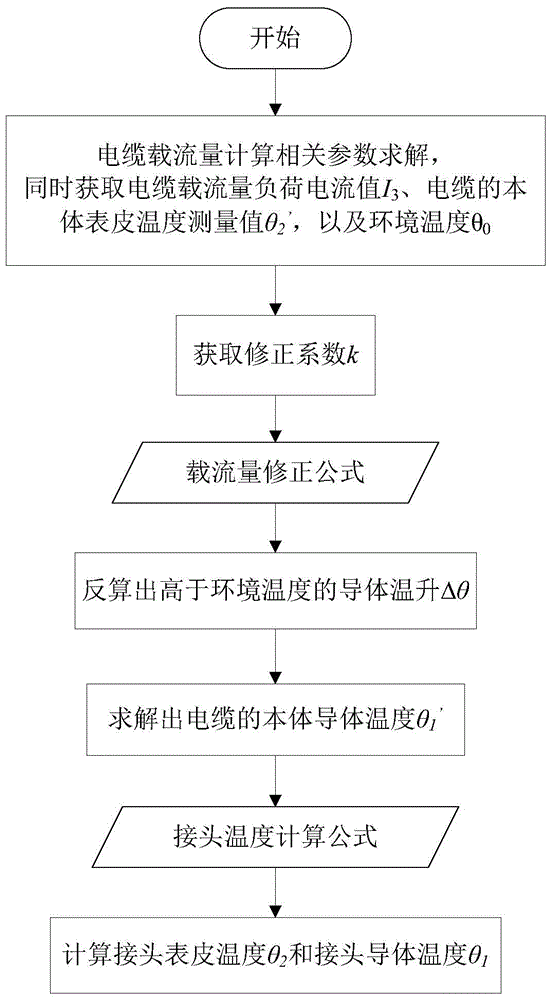

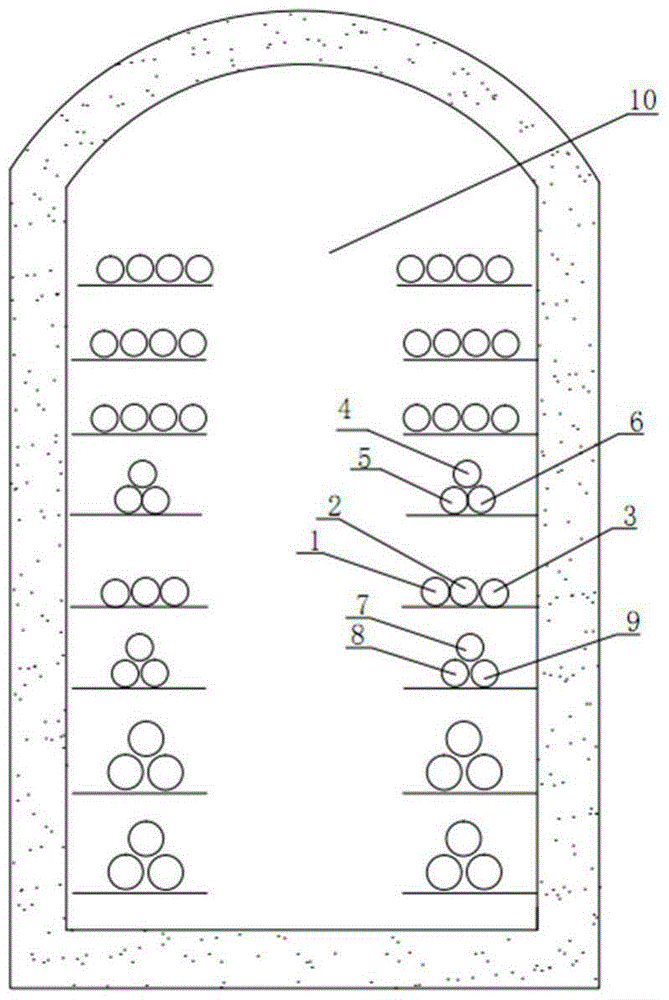

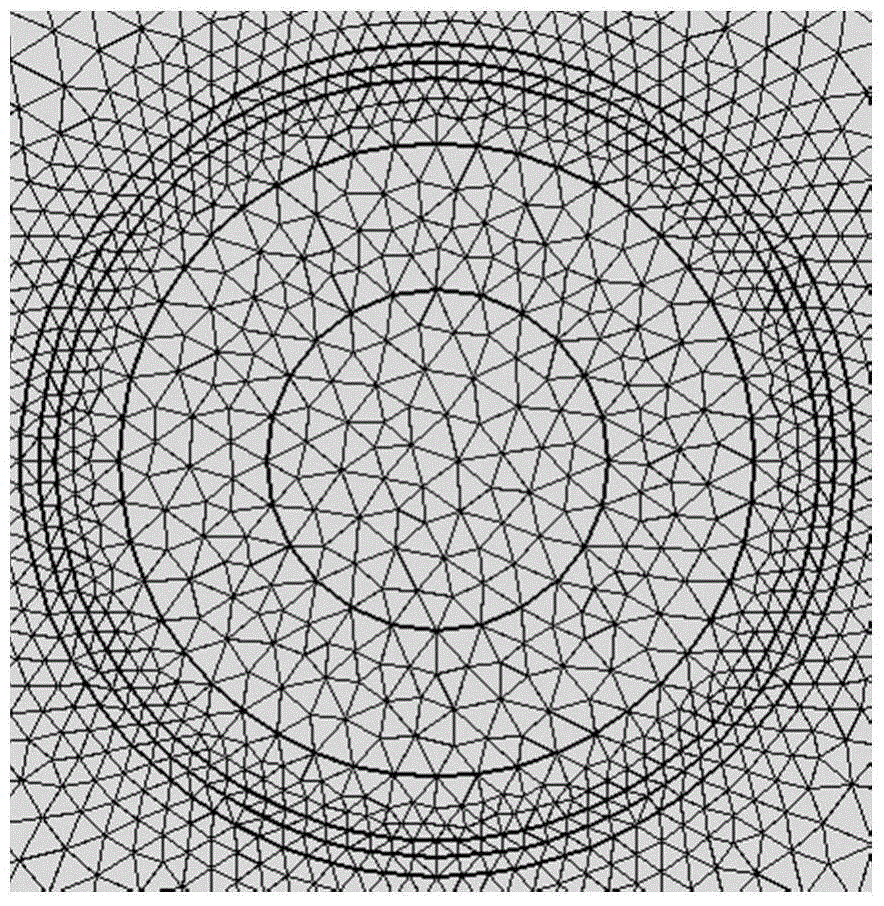

Power cable intermediate joint temperature calculating method

ActiveCN105222909AThe calculation result is accurateImprove calculation accuracyThermometers using electric/magnetic elementsUsing electrical meansPower cableElectrical conductor

The invention discloses a power cable intermediate joint temperature calculating method, and belongs to the technical field of cable monitoring. The method comprises the following steps: A, consulting an IEC60287 standard, obtaining correlation parameters needed for calculating the current-carrying capacity of a cable, a current-carrying capacity load current value I3 of the load, a body skin temperature measuring value theta 2' of the cable, and an ambient temperature theta 0; B, obtaining a correction coefficient k, and obtaining a correction formula; C, according to correlation parameters, introducing the I3 into the correction formula, and inversely calculating a conductor temperature rise delta theta higher than the ambient temperature; D, according to the theta 2' and the delta theta, solving a body conductor temperature theta1' of the cable; and E, according to the ambient temperature theta 0 and the body conductor temperature theta 1', solving a joint skin temperature theta 2 and a joint conductor temperature theta 1 by use of a joint temperature calculation formula. According to the invention, the correction coefficient k is introduced so that the precision of calculating the current-carrying capacity of the cable by means of the IEC 60287 standard is improved. The intermediate joint temperature calculation method is also brought forward, and the method can accurately calculate the joint conductor temperature and the joint skin temperature, facilitates real-time monitoring of the intermediate joint and well supplements the IEC 60287 standard.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

Temperature detection method for busbar joint of gas insulation switch equipment

ActiveCN104132746ARealize online accurate detectionImprove securityThermometer detailsThermometers using physical/chemical changesBusbarTransformer

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID +1

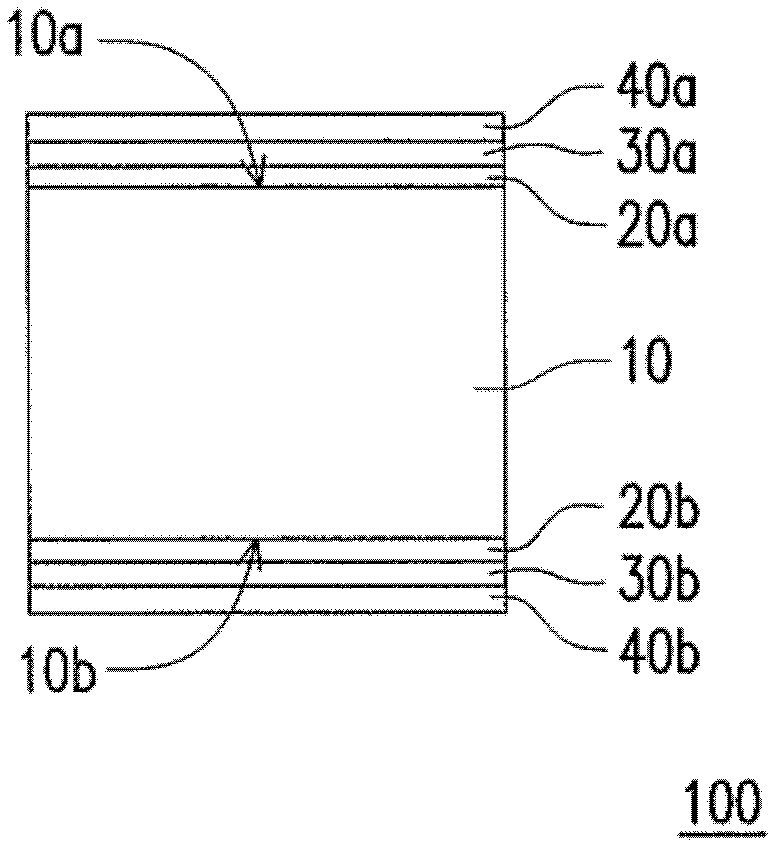

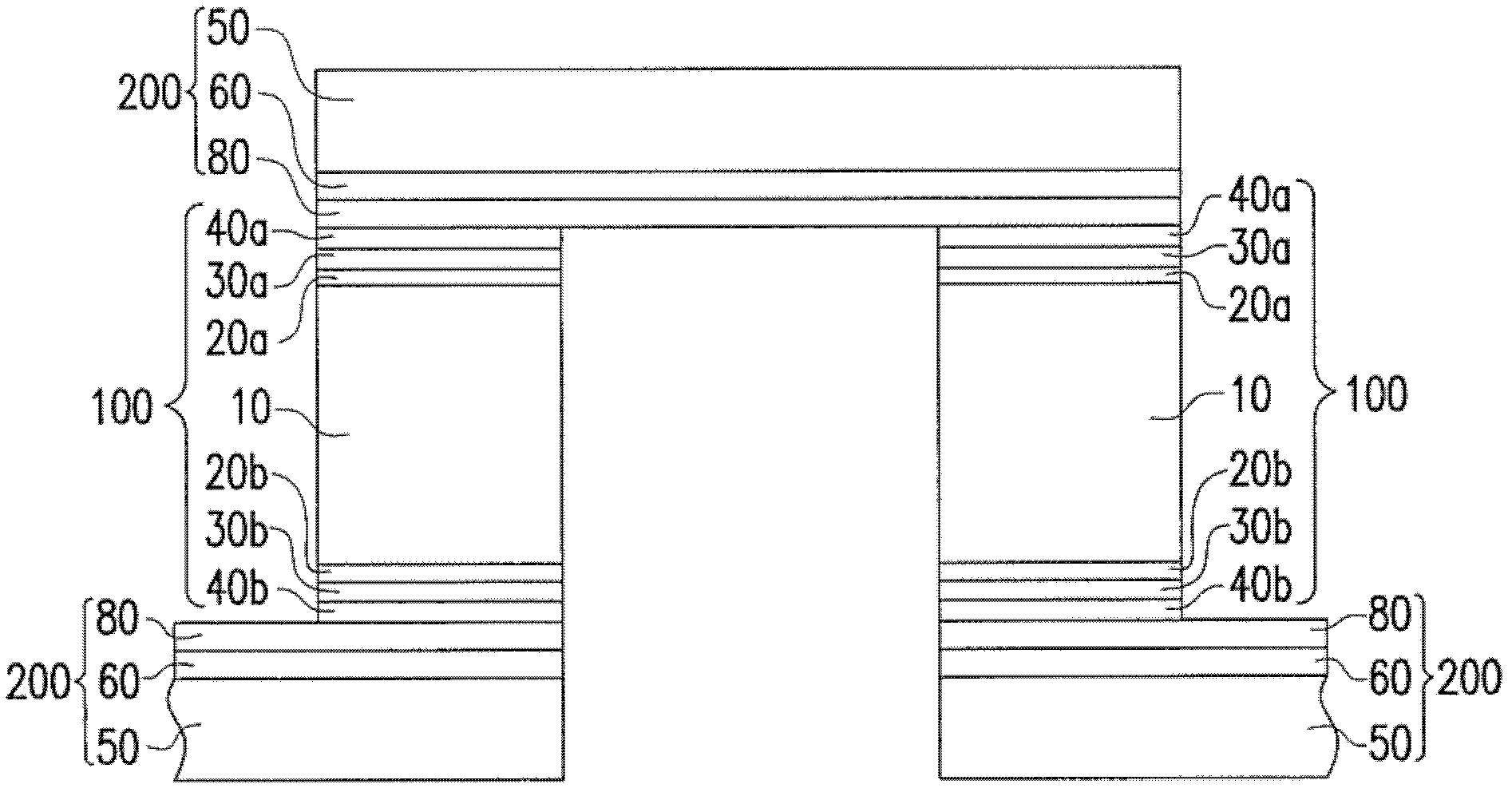

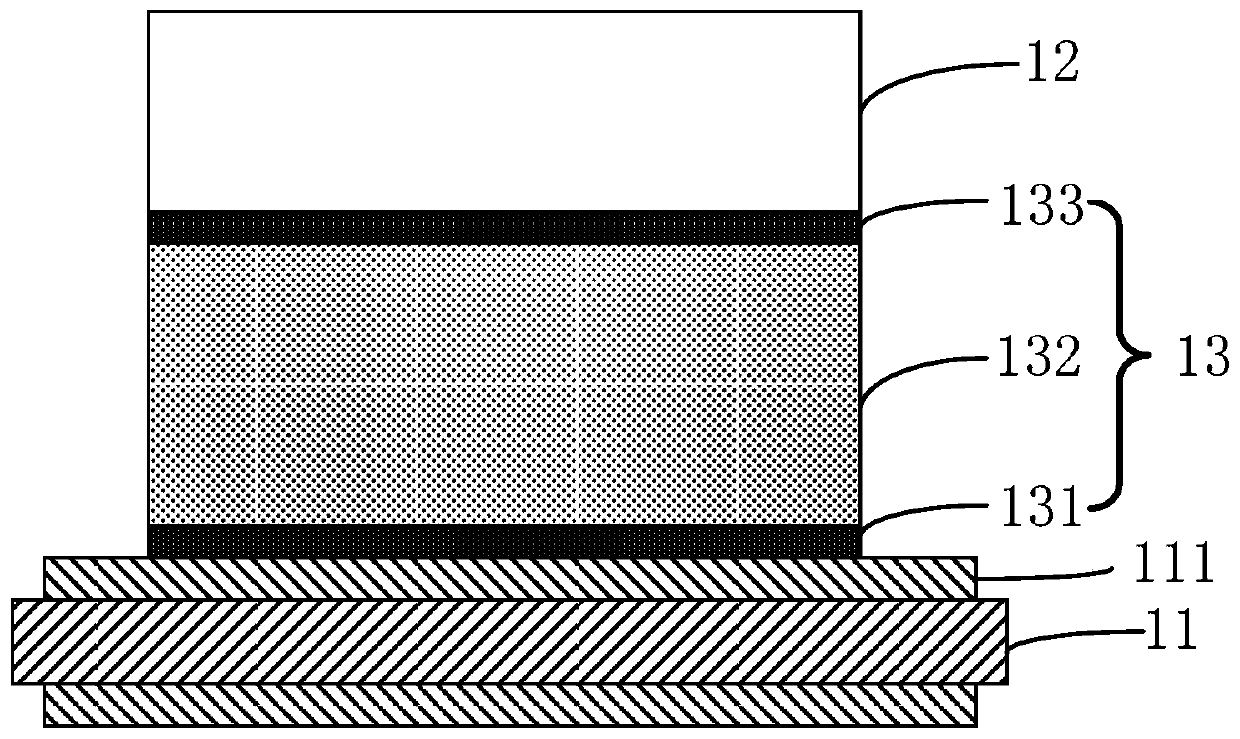

Solid-liquid interdiffusion bonding structure of thermoelectric module and fabricating method thereof

ActiveCN103178204AThermoelectric device manufacture/treatmentWelding/cutting media/materialsAlloyOptoelectronics

A solid-liquid interdiffusion bonding structure of a thermoelectric module and a fabricating method thereof are provided. The structure is characterized in that, at least one intermetallic compound is formed in the thermoelectric component and the electrode plate. The method includes coating a silver, nickel, or copper layer on surfaces of a thermoelectric component and an electrode plate, and then coating a low-melting-point tin layer. A thermocompression treatment is performed on the thermoelectric component and the electrode plate, such that the melted tin layer reacts with the silver, nickel, or copper layer to form a silver-tin intermetallic compound, a nickel-tin intermetallic compound, or a copper-tin intermetallic compound. After cooling, the thermoelectric component and the electrode plate are bonded together. The thermoelectric module forms a higher-melting-point intermetallic compound due to complete reaction of the low-melting-point tin layer and the silver, nickel, or copper layer is partially left, and therefore as a great characteristic, after joint, an application temperature of the thermoelectric module can be higher than a joint temperature.

Owner:IND TECH RES INST

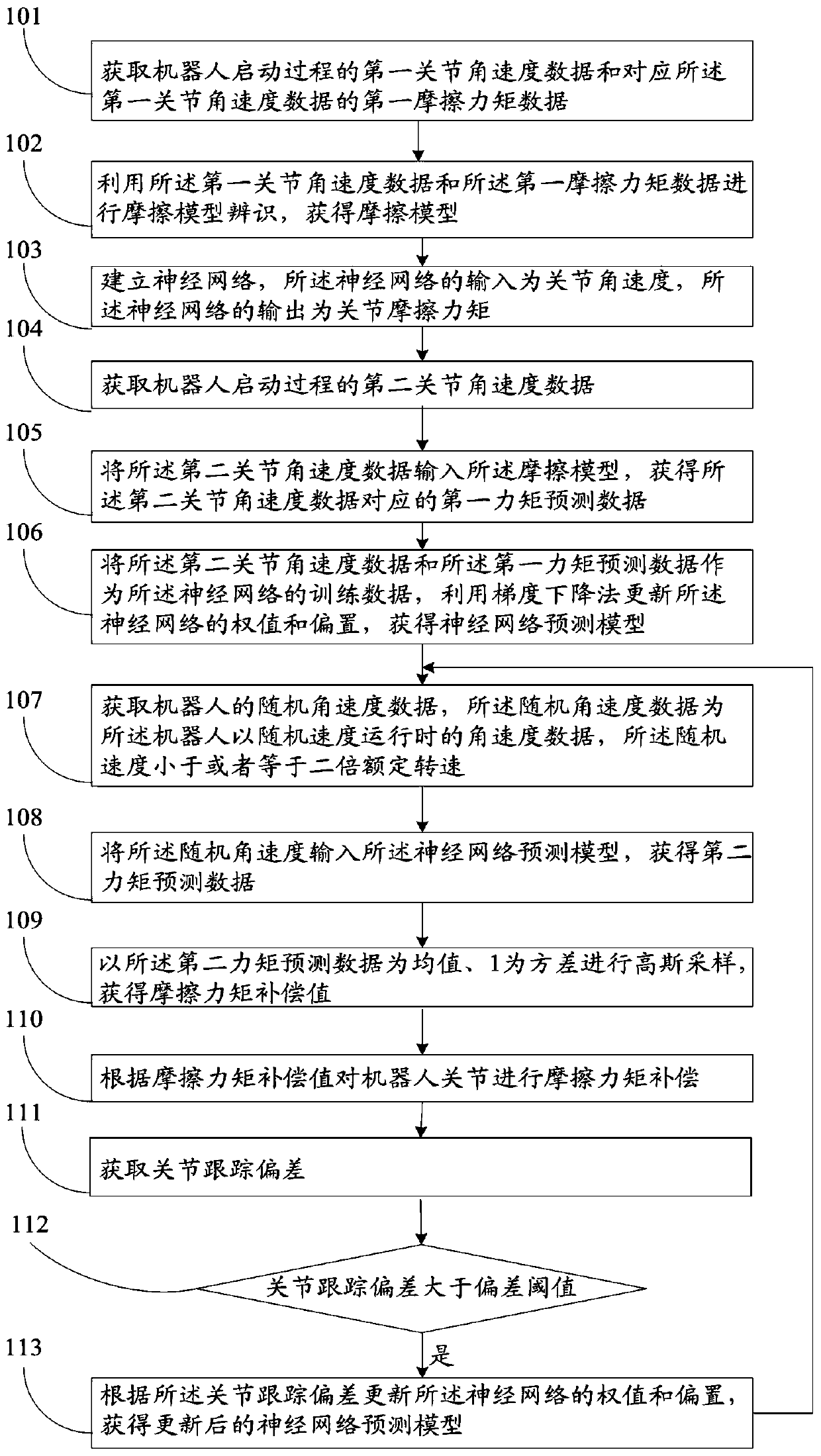

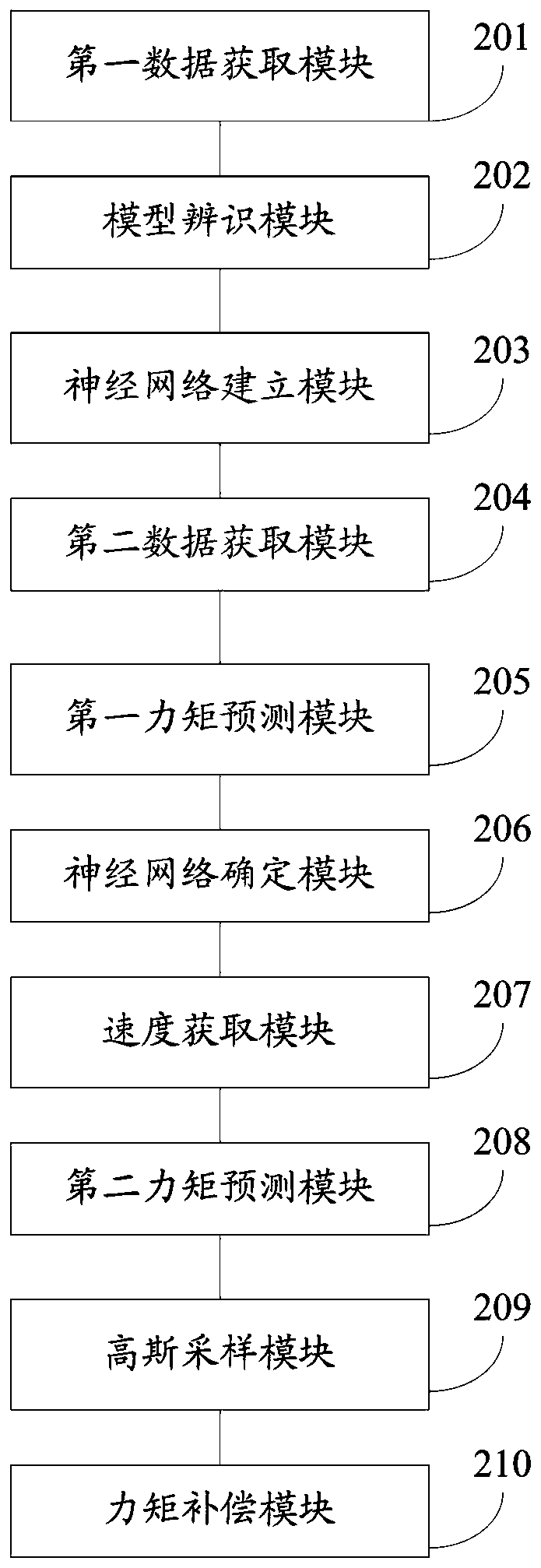

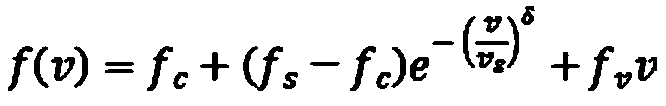

Robot joint friction torque compensation method and system

ActiveCN109732605AHigh training and learning process efficiencyImprove tracking speedProgramme-controlled manipulatorLocal optimumFriction torque

Owner:XIAMEN UNIV

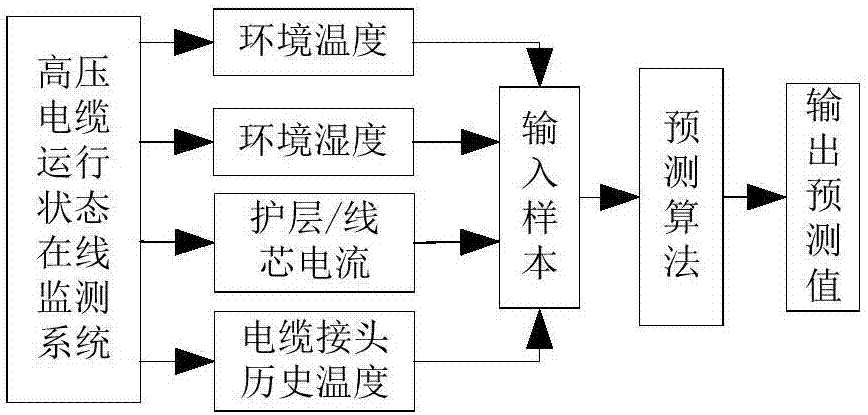

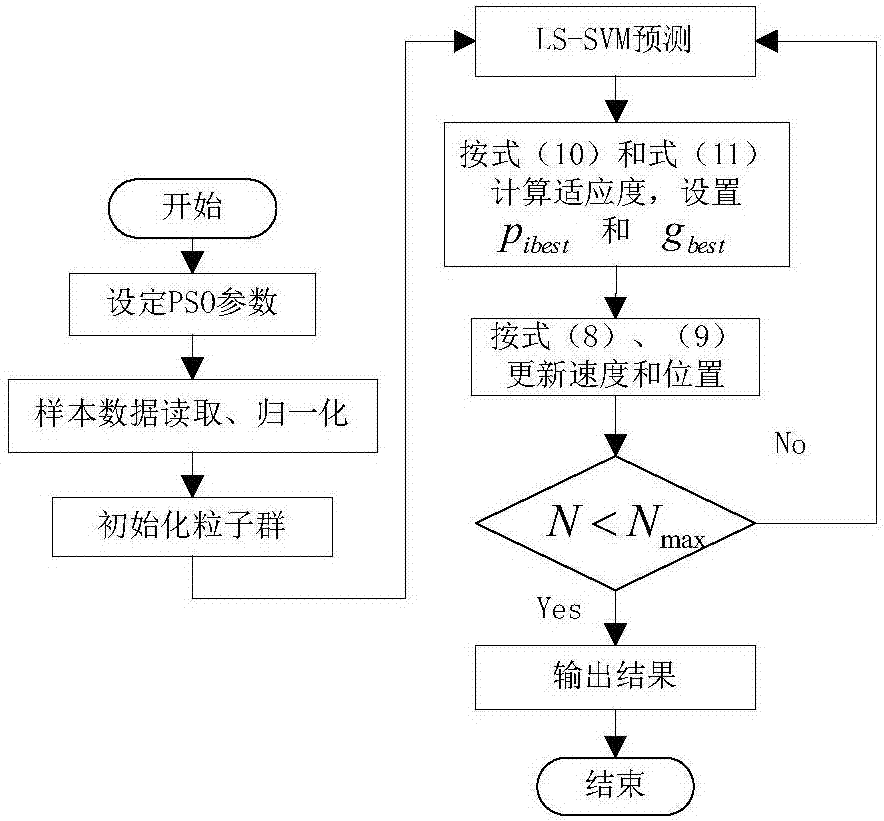

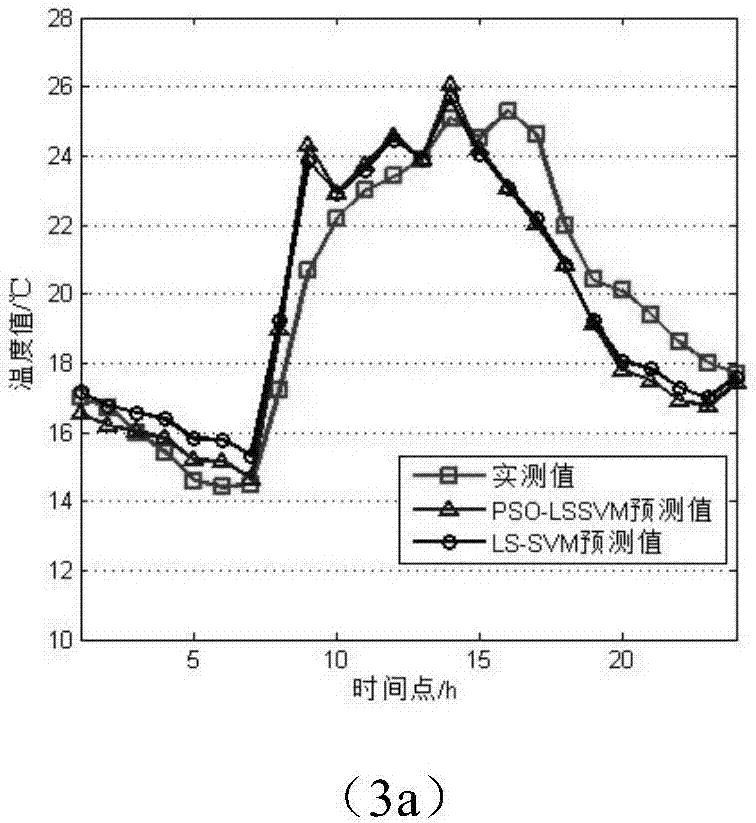

Temperature prediction method of high voltage cable joints

InactiveCN107103184AFast convergenceFast trainingCharacter and pattern recognitionArtificial lifeLeast squares support vector machineEngineering

The invention relates to a temperature prediction method of high voltage cable joints. The method comprises the steps of (1) adopting environmental temperature, environmental humidity, a current ratio of a cover layer and a cable core, and previous temperature values of a cable joint as an inputted training samples, and building a joint temperature prediction model based on a least squares support vector machine; (2) adopting particle swarm optimization to dynamically seek an optimum from a regularization parameter C and a standardized parameter sigma of the least squares support vector machine, and forming a joint temperature prediction model based on the particle swarm optimization and the least squares support vector machine; (3) conducting temperature prediction according to the joint temperature prediction model based on the particle swarm optimization and the least squares support vector machine, the real-time environmental temperature, the environmental humidity, the current ratio of the cover layer and the cable core, and the previous temperature values of the cable joint, and obtaining a predicted value of the high voltage cable temperature. Compared with the existing technology, the temperature prediction method of high voltage cable joints has the advantages of high flexibility, high prediction accuracy, pretty fast training speed and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

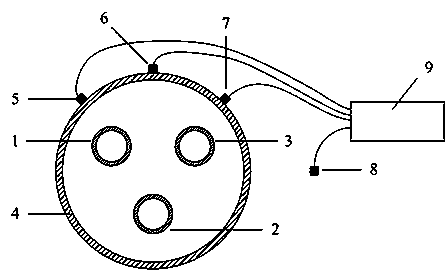

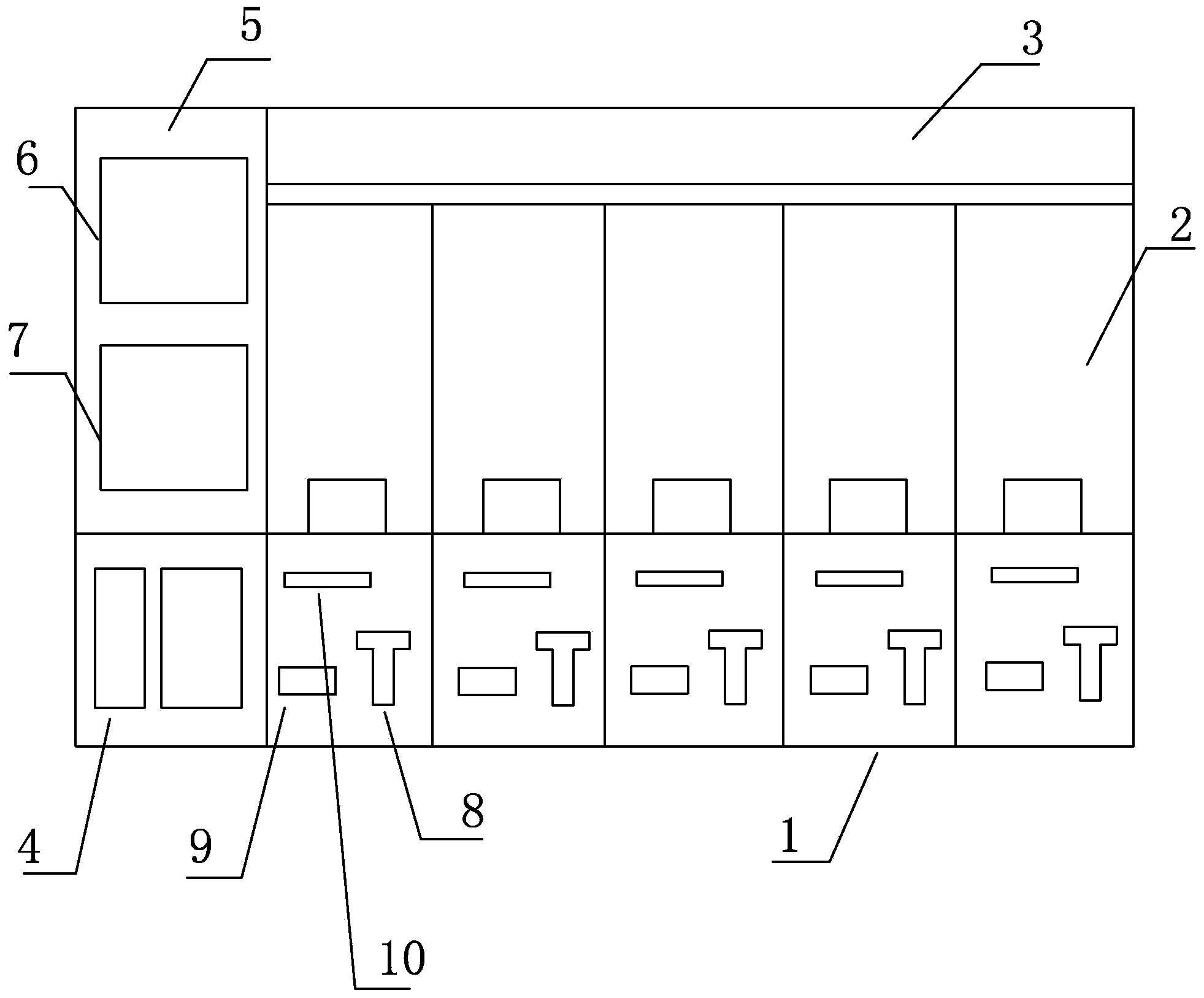

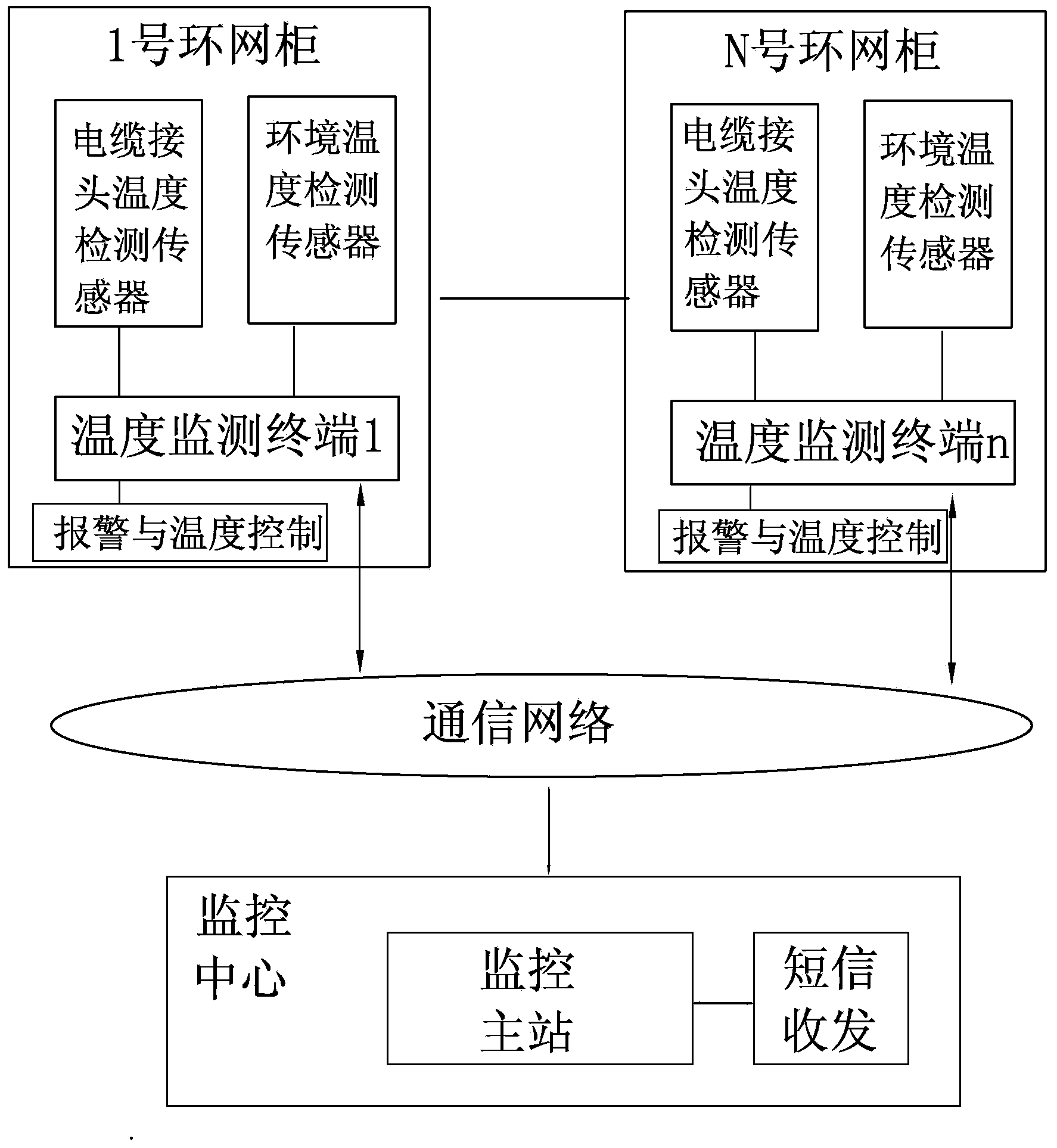

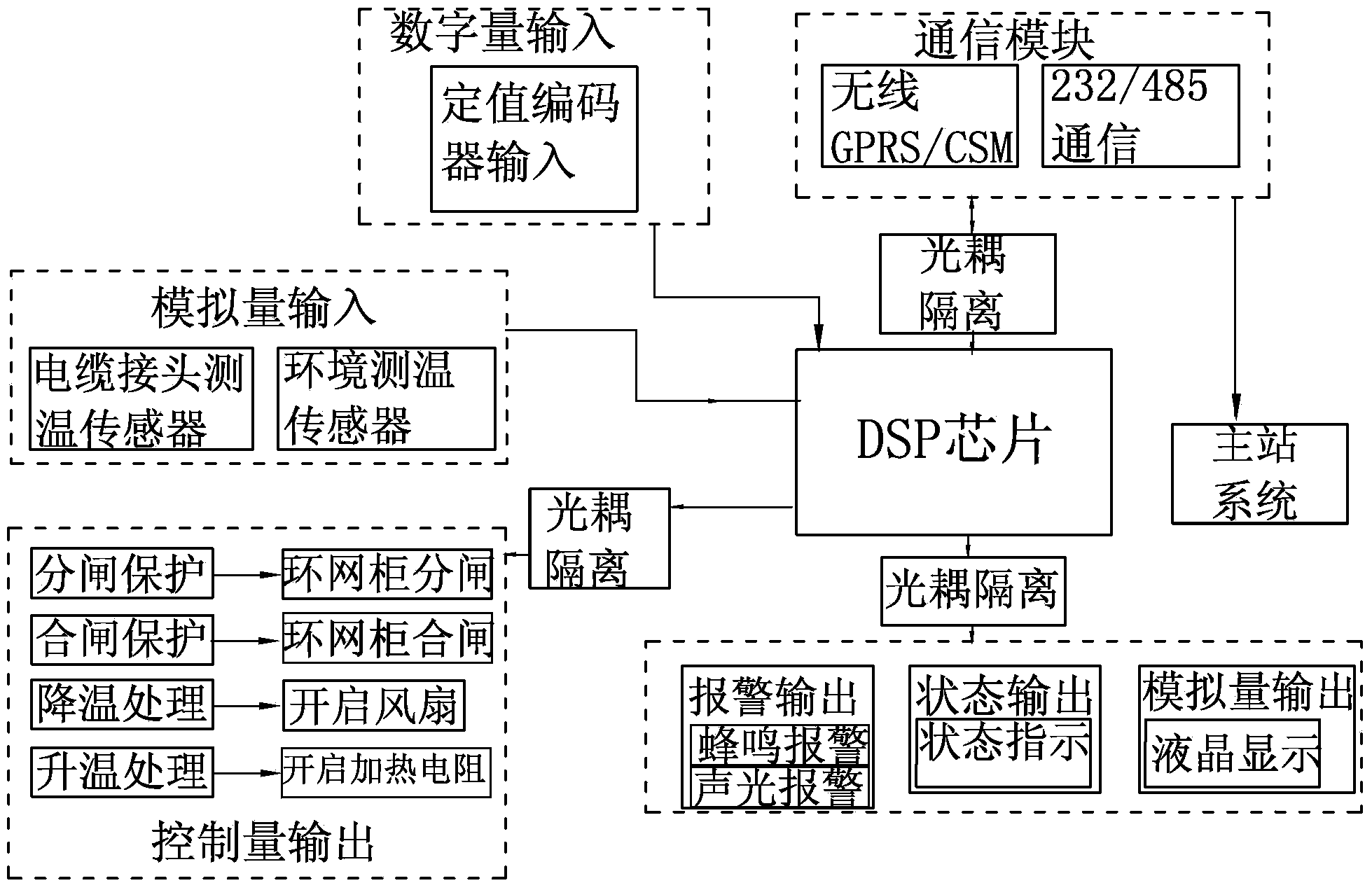

System and method for monitoring ring main unit cable joint temperature

ActiveCN103676888AReal-time and more reliable online monitoringReal-time more reliable early warningProgramme total factory controlMaster stationTemperature monitoring

The invention discloses a system and method for monitoring the ring main unit cable joint temperature. The system comprises a ring main unit which comprises a cable chamber, a switch chamber, a secondary wiring chamber, a PT cabinet chamber, a network distributing automation chamber, a ring main unit power distribution terminal, a temperature monitoring terminal and a temperature sensor. In the temperature monitoring process, the environment temperature inside the ring main unit and the temperature of a cable joint inside the ring main unit are respectively measured in real time and are transmitted to a digital signal processor inside the temperature monitoring terminal, the actual temperature rising rate of the cable joint is obtained by carrying out compensation and verification on data, and the actual temperature rising rate is compared with the pre-set actual temperature rising rate threshold value of the cable joint. When the actual temperature rising rate of the cable joint exceeds the threshold value, a digital signal controller produces an alerting signal and enables an alarming module to be started to give an alarm, the data and the state are sent to a long-distance master station, workers of the long-distance master station can respond to fire and other dangerous incidents inside the main ring unit fast, and losses are reduced.

Owner:BEIJING HEROSAIL POWER SCI & TECH

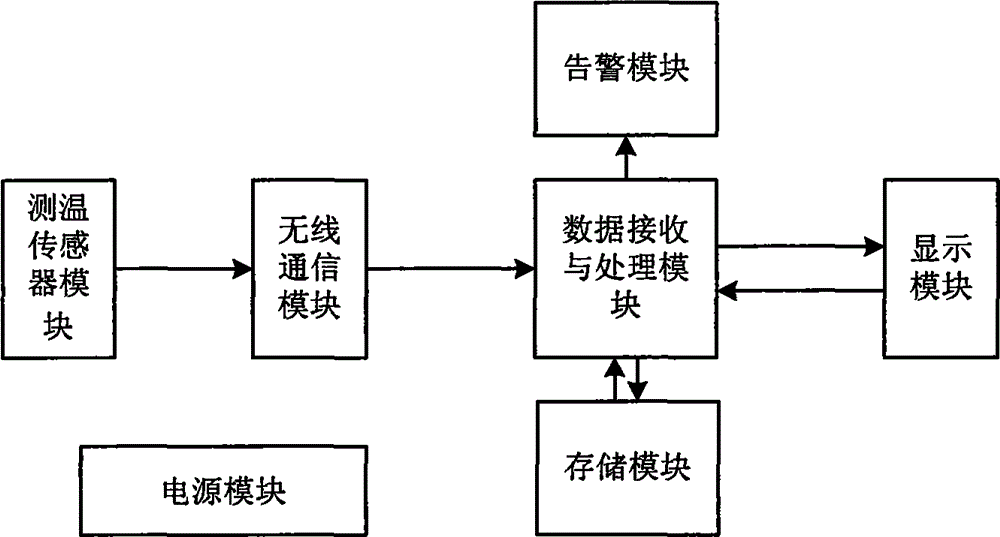

Power cable joint temperature measuring device

InactiveCN105371967AReal-time temperature monitoringThermometer detailsFault locationPower cableProcess module

The invention relates to a power cable joint temperature measuring device which comprises the components of a temperature measuring sensor module, a data receiving and processing module, a wireless communication module, a display module, a storage module, an alarm module and a power module. The temperature measuring sensor is arranged on the grounded part of the outer conductive layer of the power cable joint. Data which are measured by the temperature measuring sensor are transmitted to the data receiving and processing module through the wireless communication module for being processed. The storage module is used for storing failure information. The display module is a projection type capacitive touch screen and can display a cable joint temperature result which is obtained through monitoring. Furthermore the display module can set a temperature monitoring mode through a screen menu and inquires a historical record. The power module supplies electric power for the whole system. When overhigh temperature of the cable joint occurs, a monitoring result is displayed on the screen, and simultaneously the fault information is transmitted to the alarm module. Related personnel can understand the fault condition timely and accurately through the screen and the alarm information, thereby facilitating maintenance and emergency repair of the cable.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

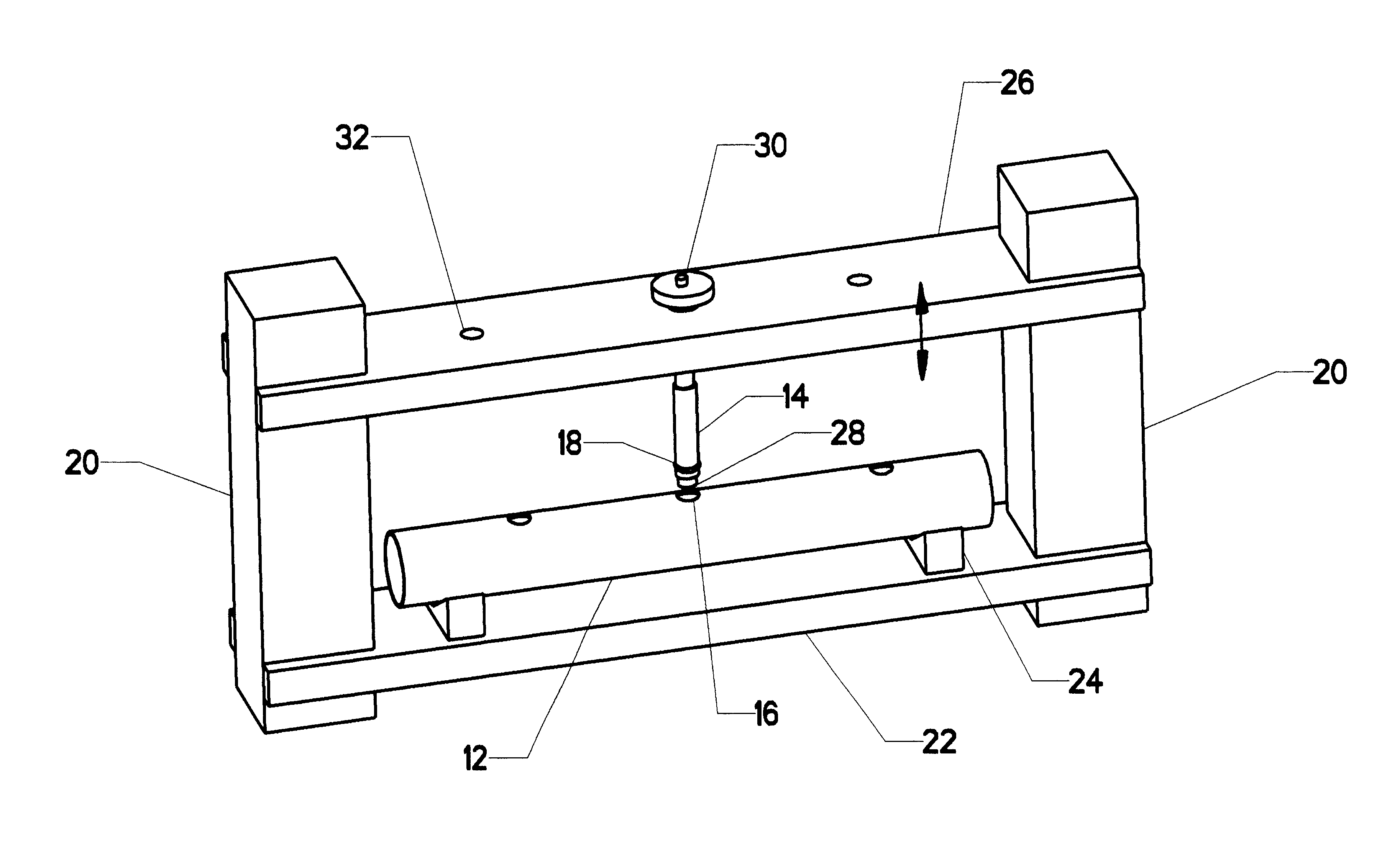

Automated header brazing machine

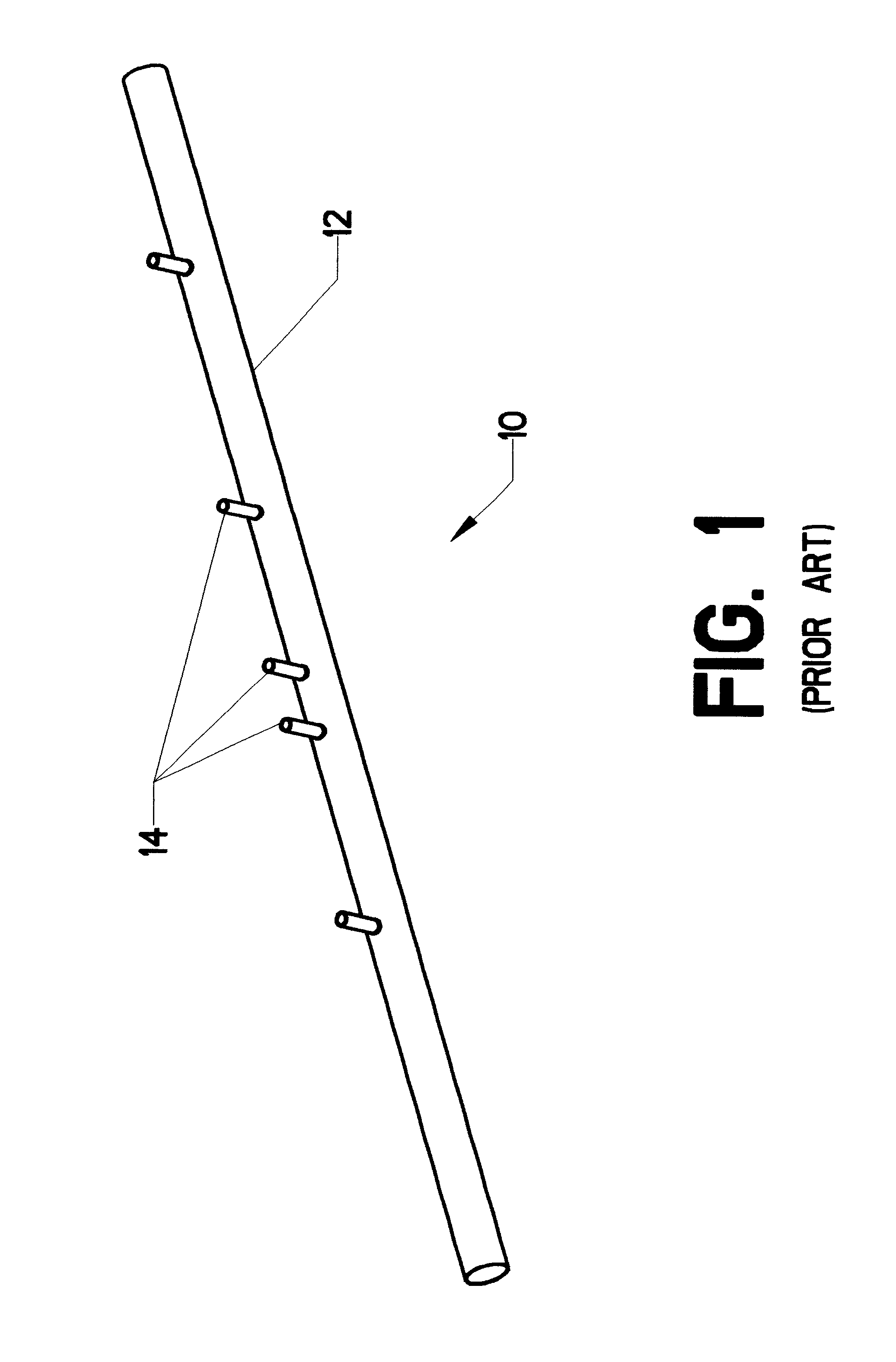

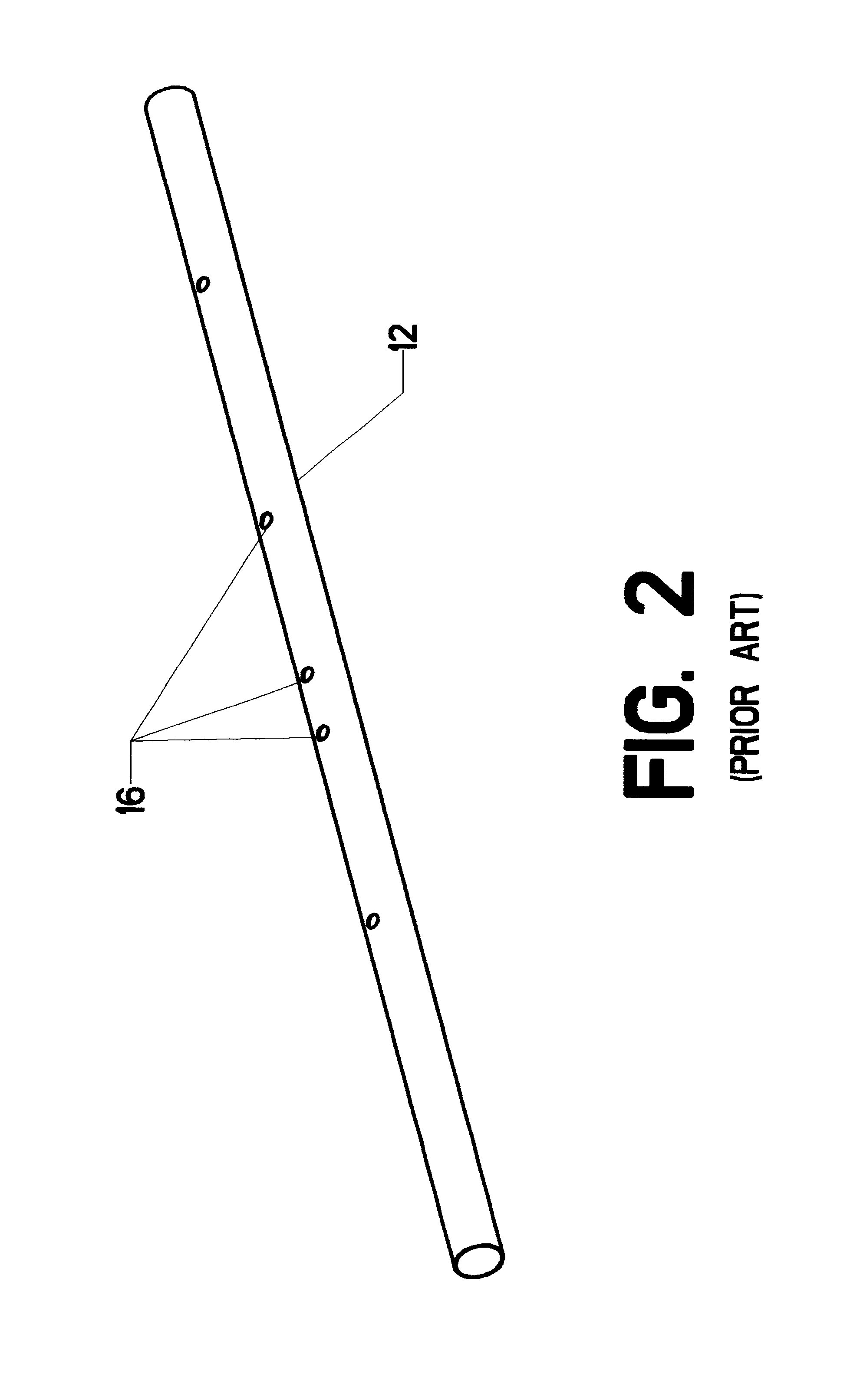

InactiveUS6871771B2Good repeatabilityWelding/cutting auxillary devicesFeeding apparatusCombustorReciprocating motion

A machine for determining the location of junction tubes along a header and automatically brazing them to the header. A chassis is employed to hold the junction tubes and header in the proper orientation. A carriage then travels along a line which is parallel to the central axis of the header. The carriage includes a sensor which is able to determine the exact position of the junction tubes. This positional information is stored in a controller. The carriage also includes a reciprocating pair of burners for heating the joint to be brazed. A pair of brazing wire feeders are included for feeding the brazing alloy alloy to the joint. A pyrometer is also included for measuring the temperature of the joint during the brazing process. In operation, the carriage slides along with the sensor measuring the position of each joint to be brazed. The burners and brazing alloy feeders are located in such a position on the carriage that the sensor precedes them in coming to each joint location. Thus, the joint location is determined, then the carriage is moved to bring the burners in contact with the joint. Once in position, the burners are moved through a reciprocating motion to evenly heat the joint. A pyrometer is used to monitor the joint temperature (through the operation of the controller). When the appropriate temperature is reached, the controller causes the brazing wire feeders to feed the appropriate amount of brazing alloy to the joint—thereby brazing the joint. The carriage then moves on to the next joint position. The process is repeated until every joint on the header has been brazed.

Owner:PRECISION ENGINEERED SYST

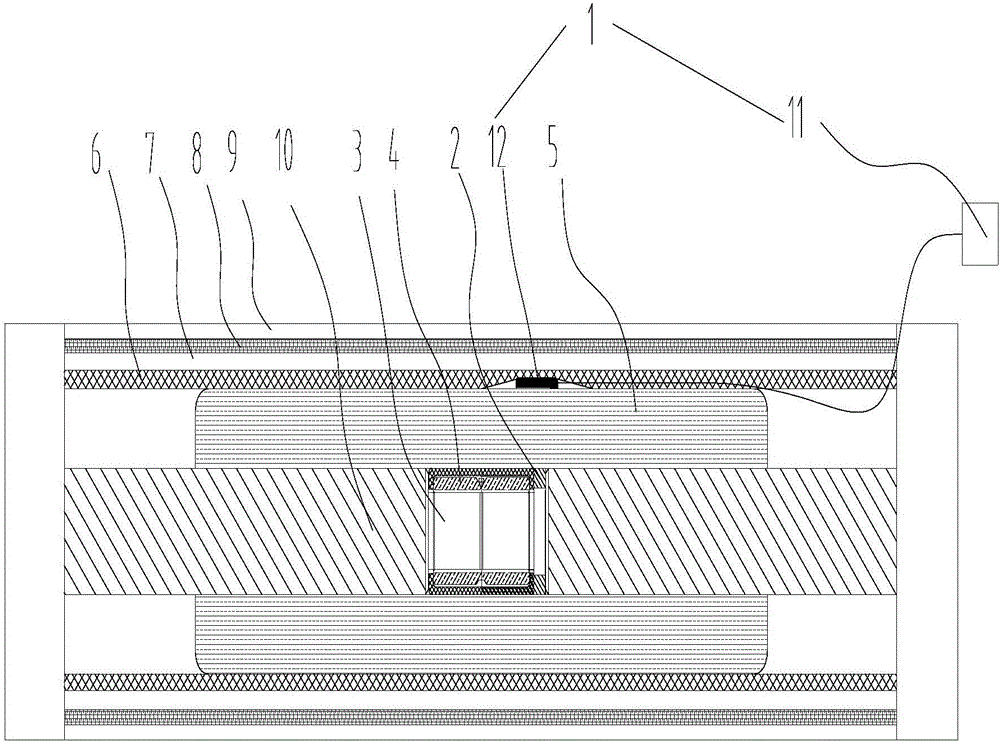

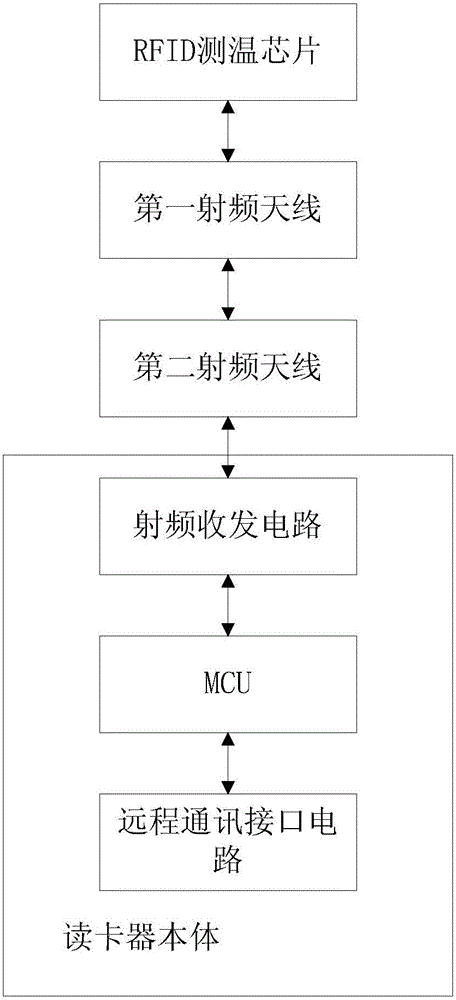

High voltage cable joint temperature measuring device

InactiveCN106197707AAccurate measurementThermometers using electric/magnetic elementsUsing electrical meansRadio frequency signalCore temperature

The invention discloses a high voltage cable joint temperature measuring device, comprising a card reader and at least one temperature measurement mechanism. The temperature measuring mechanism comprises a circuit board; the circuit board is provided with an RFID temperature measurement chip, a metal block and a first radio frequency antenna; the card reader comprises a card reader main body and a second radio frequency antenna; the RFID temperature measurement chip is connected to a first radio frequency antenna; the card reader main body is connected to the second radio frequency antenna; the RFID temperature measurement chip is connected to the metal block; the metal block is in contact with a cable core; the RFID temperature measurement chip is used for detecting a temperature value of the metal block and transmits the temperature value and an ID code corresponding to the RFID temperature measurement chip to the card reader main body through the first radio frequency antenna and the second radio frequency antenna. The RFID temperature measurement core chip converts the radio frequency signal emitted by the card reader to energy to supply power, does not need other driving sources and can accurately measure high voltage cable core temperature.

Owner:ZHUHAI YADO MONITORING TECH CO LTD

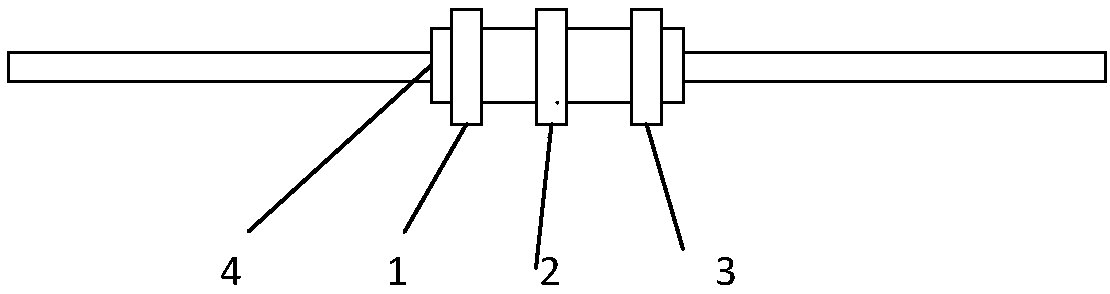

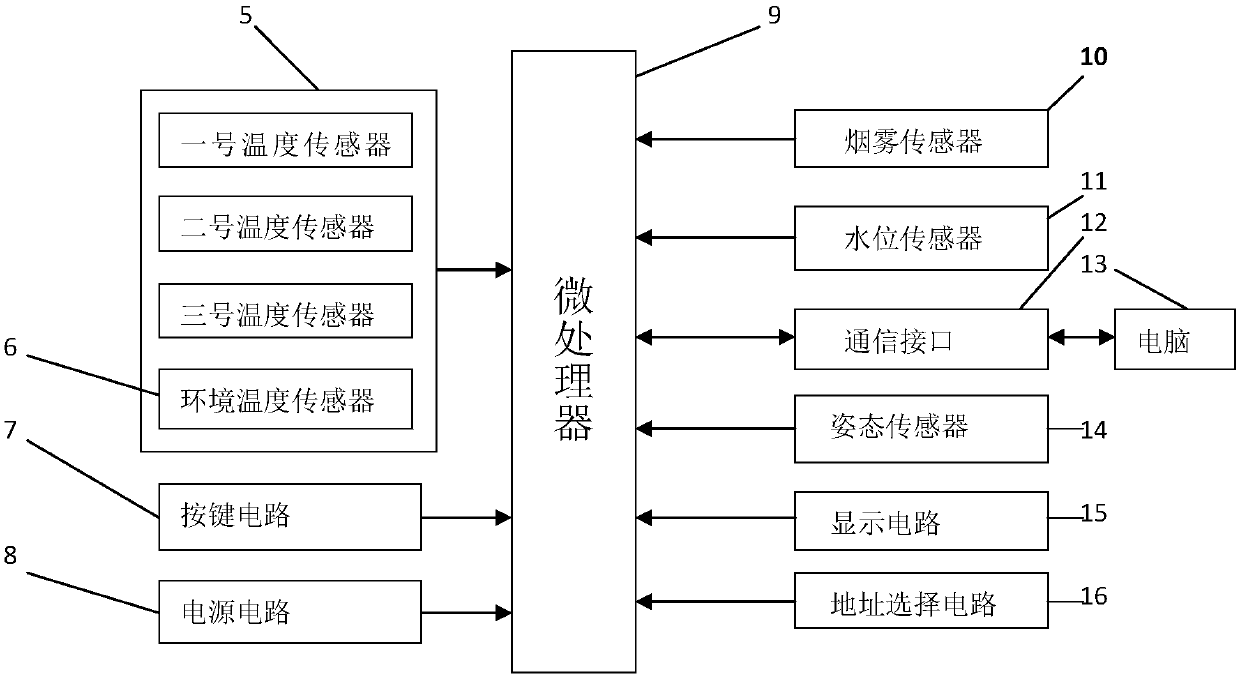

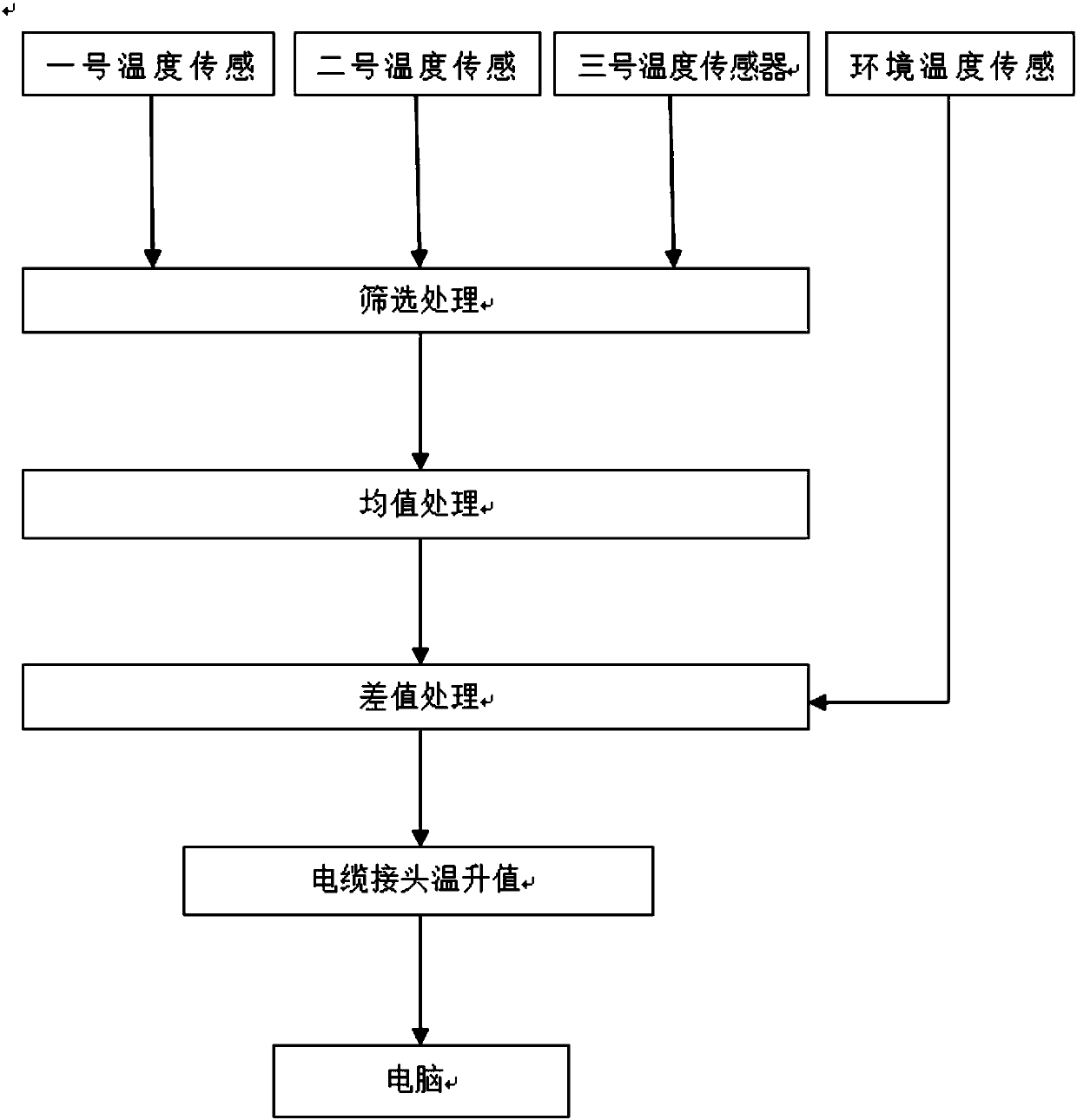

Cable intermediate joint temperature rise on-line monitoring device and method based on temperature difference method

InactiveCN107764424APrecise positioningTimely repairThermometer detailsThermometers using electric/magnetic elementsTemperature differenceMaterial resources

The invention relates to a cable intermediate joint temperature rise on-line monitoring device and method, and mainly solves the problems of waste of manpower, material resources and financial resources, low monitoring reliability, poor real-time performance, and being difficult to find equipment safety hazards of a conventional cable joint manual inspection method in the prior art. The device comprises a temperature sensing module, a microprocessor and a power supply circuit. The method is characterized by carrying out screening on the detected temperature and calculating the difference valuebetween the temperature value and environmental temperature value to judge whether the temperature rise is normal. The method and device can accurately obtain the cable joint temperature and can carry out real-time monitoring on the cable joint temperature, thereby ensuring health and safe operation of a cable.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD +3

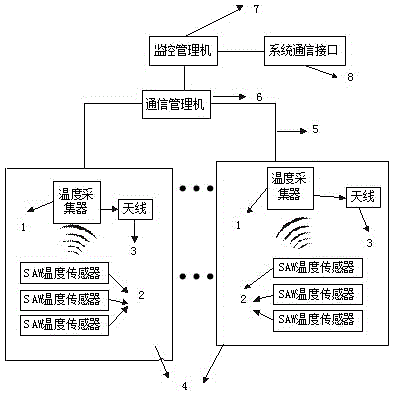

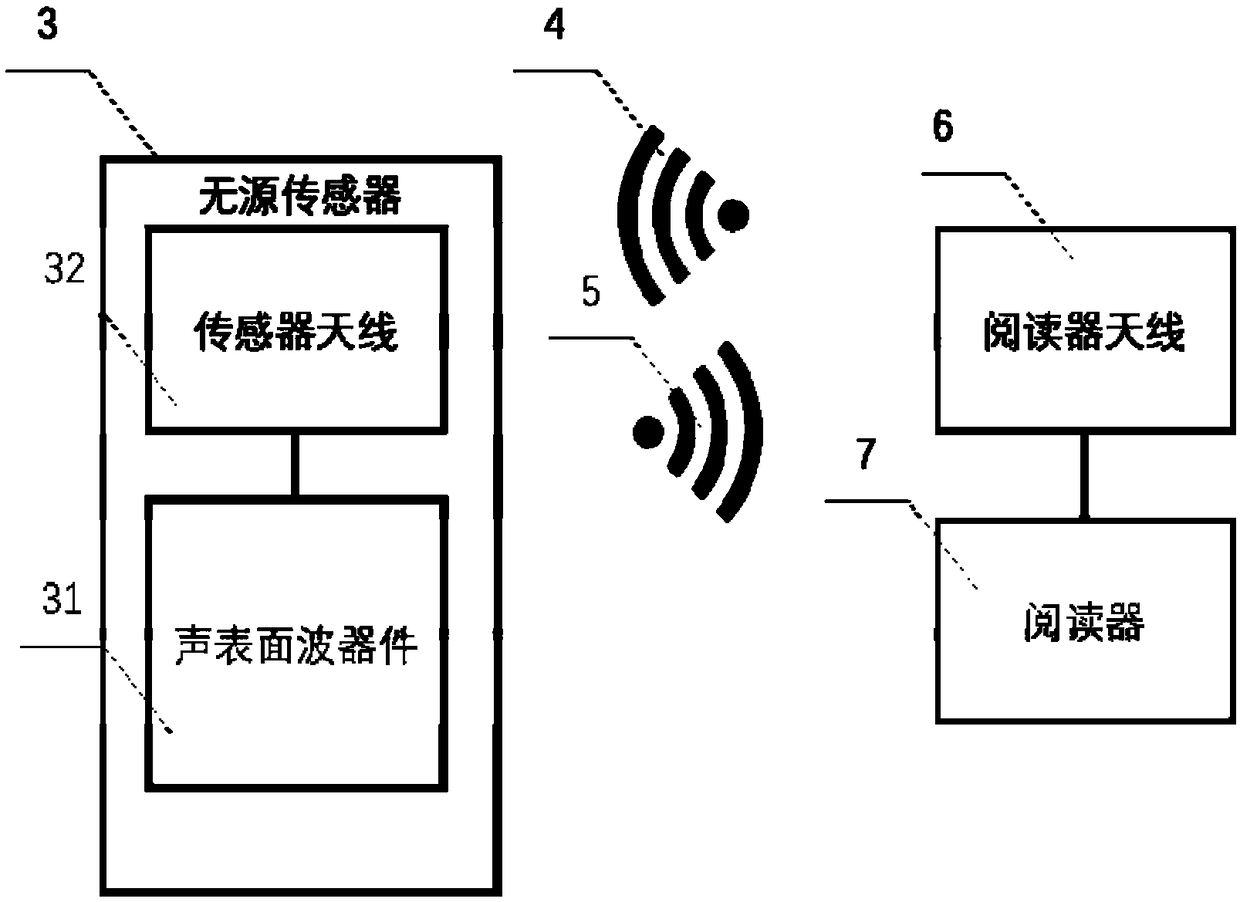

Wireless and passive power cable joint temperature monitoring system

InactiveCN105004432AAcquisition period is shortSolution to short lifeThermometer detailsTransmission systemsCommunication interfacePower cable

The present invention relates to a wireless and passive power cable joint temperature monitoring system. The wireless and passive power cable joint temperature monitoring system is characterized in that a temperature collector is communicated with a SAW temperature sensor in a wireless communication manner and is connected with a bus communication management machine, the communication management machine is connected with a monitoring management machine via a bus, and the monitoring management machine is connected with an external monitoring center via a system communication interface. The wireless and passive power cable joint temperature monitoring system can realize the real-time on-line temperature measurement, provides the electric energy with the help of a power grid, is longer in service life, and guarantees the system and device safety and reliability better.

Owner:邢永安

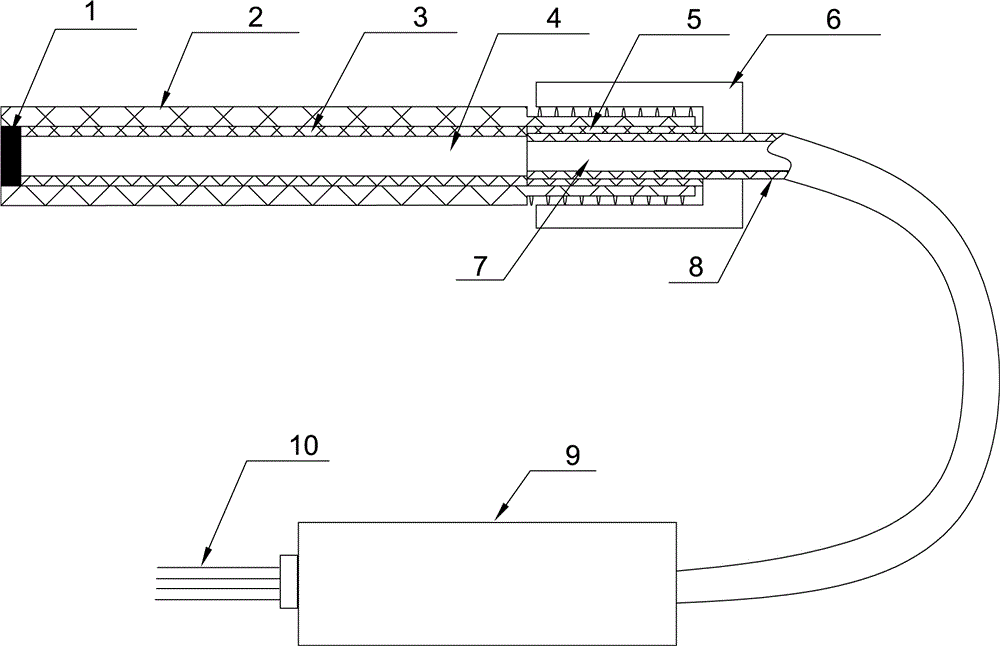

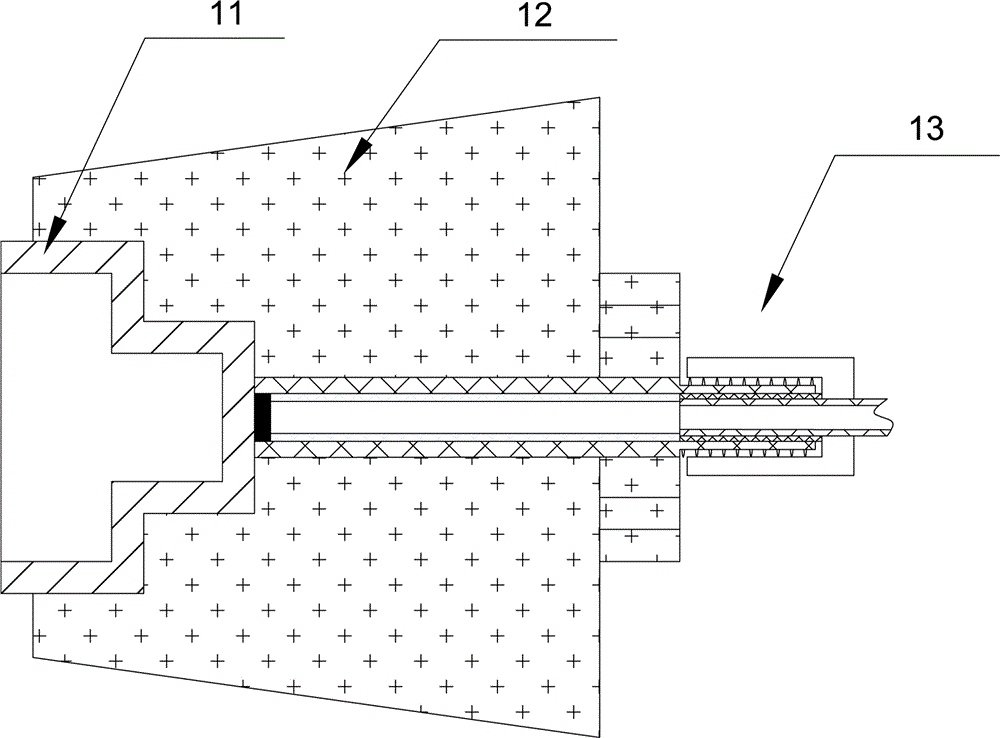

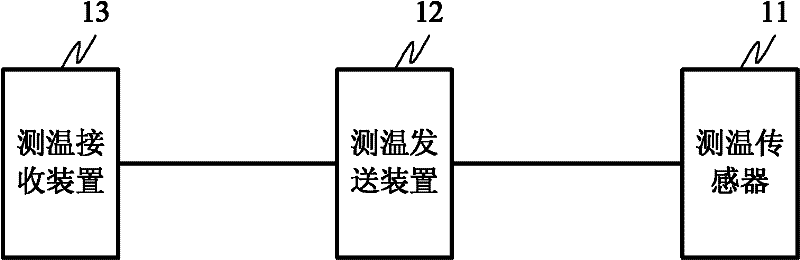

Built-in cable joint temperature fiber on-line monitoring sensor

ActiveCN106124088ALow costSimplify the installation processThermometers using physical/chemical changesEpoxyFiber

The invention discloses a built-in cable joint temperature fiber on-line monitoring sensor, and the sensor comprises a quartz rod or a quartz optical fiber, a fluorescent material which is pasted at the front end of the quartz rod or the quartz optical fiber and is closely attached to a tested cable joint metal nut, a teflon casing pipe and an insulating ceramic tube which are disposed at the exterior of the quartz rod or the quartz optical fiber from the inside to the outside, a plastic optical fiber with a plastic clamping sleeve, an optical processing module connected with the other end of the plastic optical fiber, and a 485 output end disposed at the other end of the optical processing module, wherein the plastic optical fiber with the plastic clamping sleeve is closely attached to an end face of the quartz rod or the quartz optical fiber through a nut. The exterior of the insulating ceramic tube and a metal nut is provided with an epoxy resin layer which is formed through high-temperature and high-pressure casting. The sensor is low in cost and is simple in installation process. When the sensor is in use, the fluorescent material can directly measure the contact temperature, and can improve the temperature measurement accuracy and precision of a cable joint.

Owner:BEIJING BODA HUADIAN MEASUREMENT & CONTROL TECH

A cable joint temperature measuring device

Owner:BEIJING HEZONG SCI & TECH CO LTD

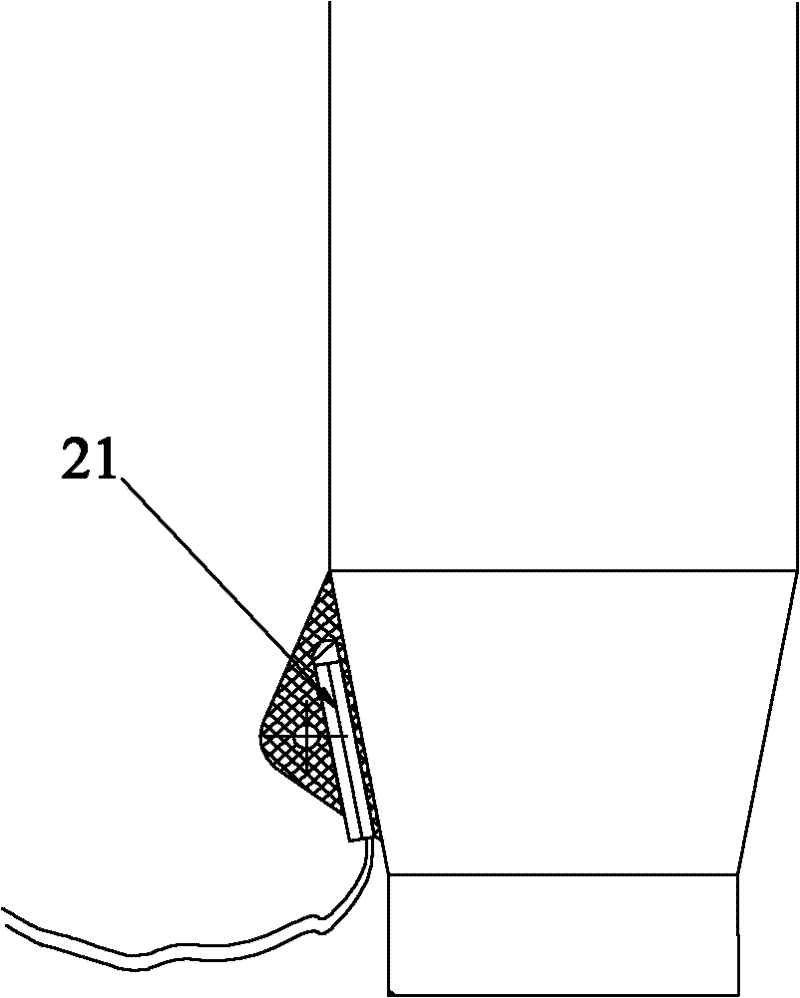

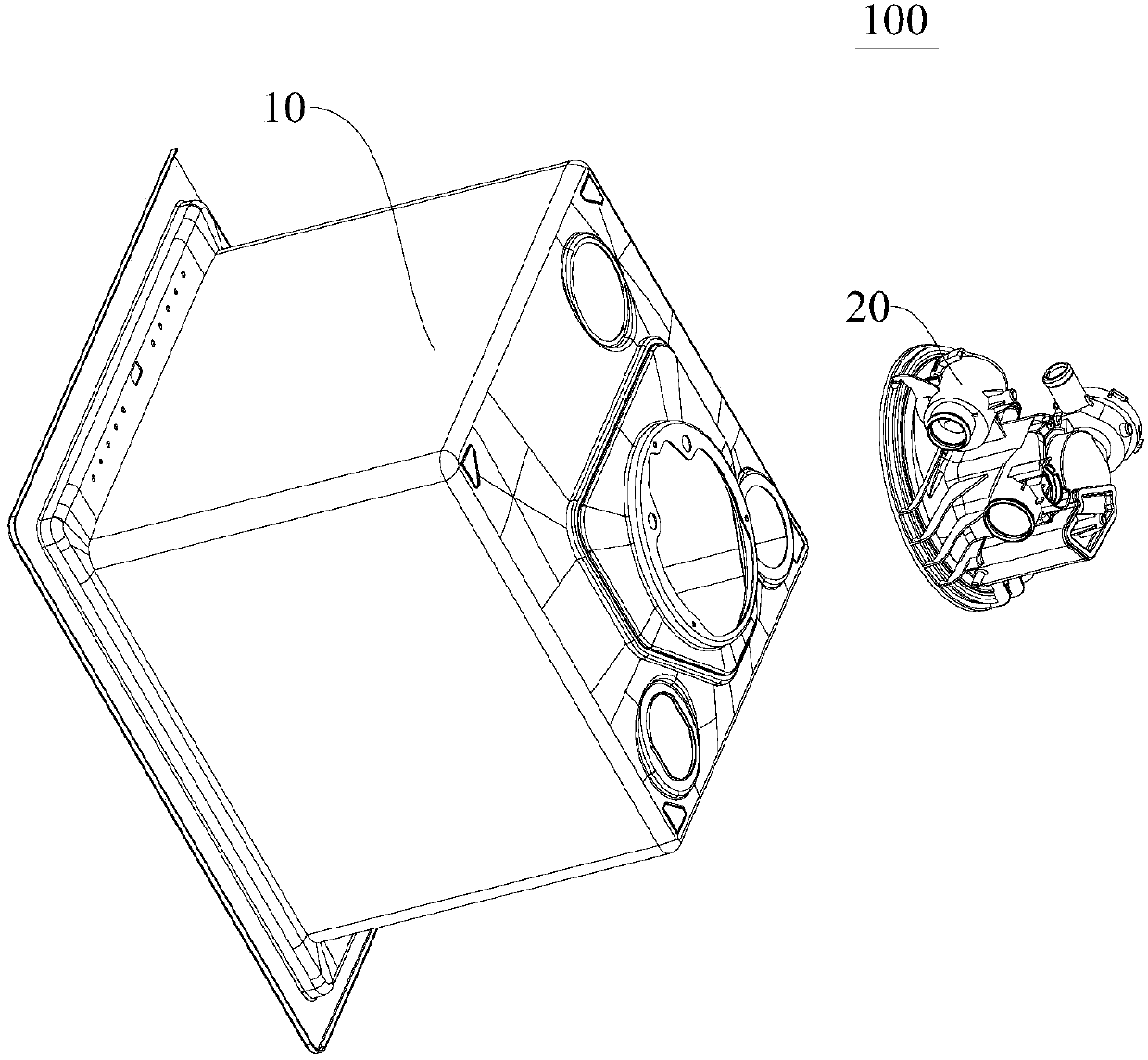

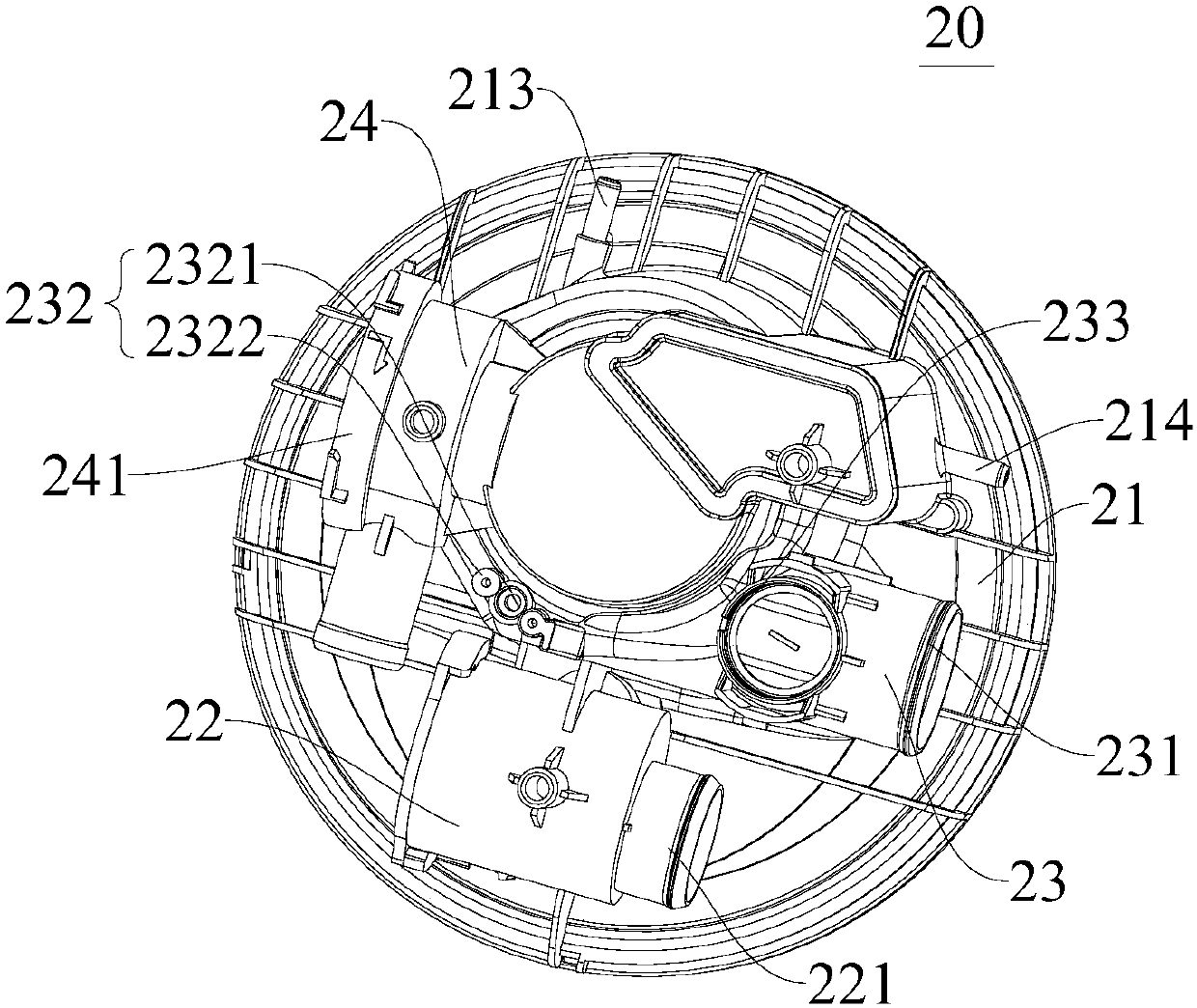

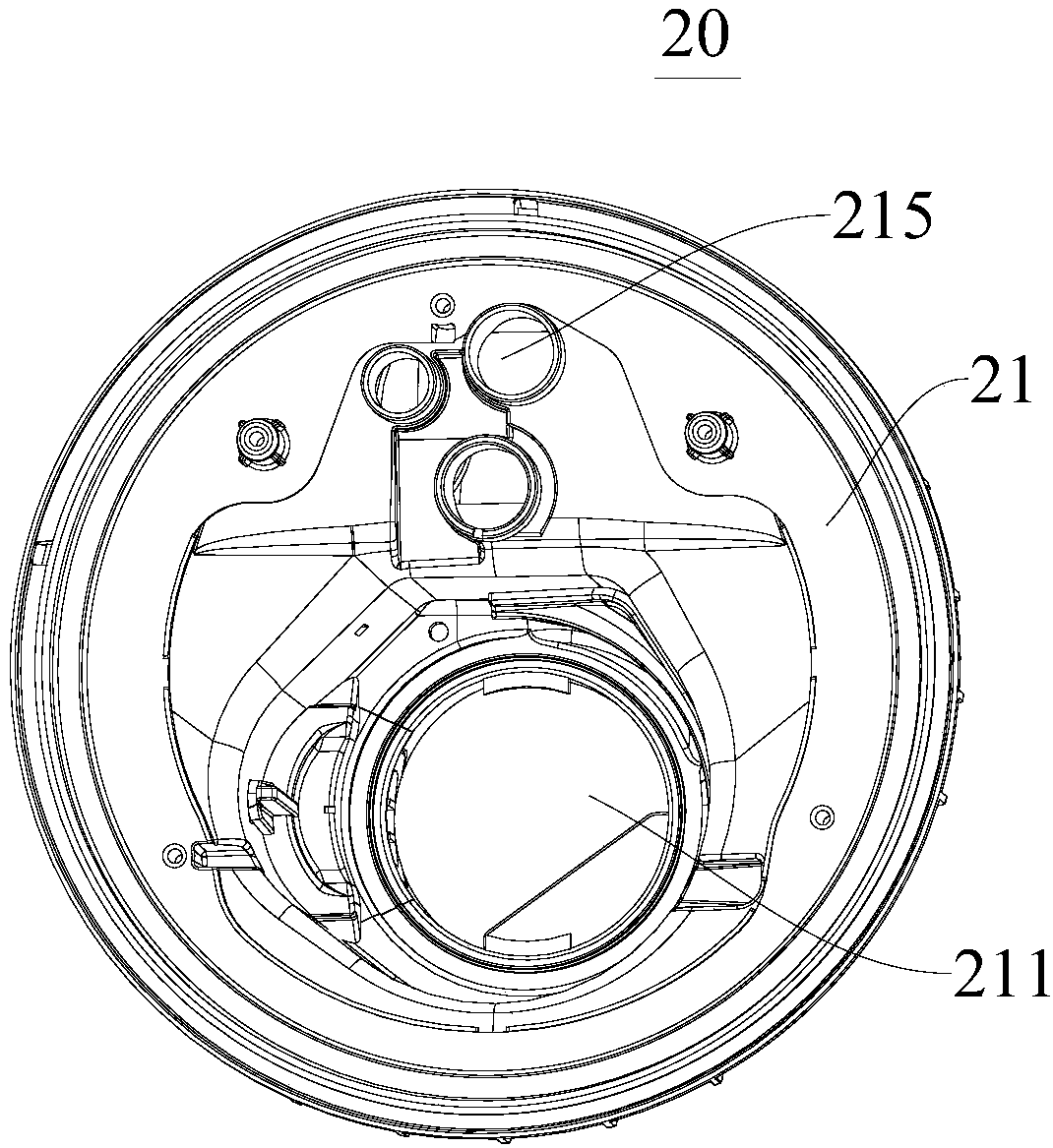

Integrated water cup of dishwasher and sink assembly and dishwasher with integrated water cup

PendingCN107854086AImprove assembly efficiencyHigh strengthTableware washing/rinsing machine detailsCleaning equipmentTurbidityEngineering

The invention discloses an integrated water cup of a dishwasher, a sink assembly with the integrated water cup and the dishwasher with the integrated water cup. A water chamber and an air chamber communicated with each other are defined in the integrated water cup, the integrated water cup is integrated with a circulating water inlet connector, a circulating water outlet connector, a water drain connector, a water inlet connector, a temperature sensor connector, a turbidity sensor connector, a pressure sensor connector and a spray arm connector, and the integrated water cup and the connectorsabove are molded in one piece. According to the integrated water cup of the dishwasher, as various connectors are integrated with the integrated water cup, not only can the assembly efficiency of thedishwasher be improved, but also the connection stability and connection tightness between the integrated water cup and various components can be improved; besides, as each connector is integrated with the integrated water cup, the strength is high and the service life is long.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

Power cable temperature measuring device and temperature measuring method

InactiveCN108225580AReal-time temperature monitoringDetailed and accurate understandingThermometer detailsThermometer applicationsCapacitancePower cable

The invention discloses a power cable temperature measuring device. The power cable temperature measuring device comprises an embedded processing unit, a temperature measuring sensor unit, a data receiving and processing unit, a communication module, a display module, a storage unit, an alarm device and a supercapacitor power supply group; data measured by the temperature measuring sensor unit arefed into the data receiving and processing unit through the communication module to process; the data receiving and processing unit feeds the processed data into the embedded type processing unit; when monitoring that the temperature is abnormal, the embedded type processing unit sends out alarm information to the alarm device and stores failure information into the storage unit; and the displaymodule is a projection type capacitive touch screen, can display a monitored cable joint temperature value and a processing result, and can set the temperature monitoring condition through a screen menu and inquire historic record. The invention also provides a temperature measuring method of the power cable temperature measuring device. The power cable temperature measuring device and the temperature measuring method have the beneficial effects of high reliability, full functions and capabilities of effectively reducing failure occurrence times and reducing failure loss.

Owner:STATE GRID CORP OF CHINA +1

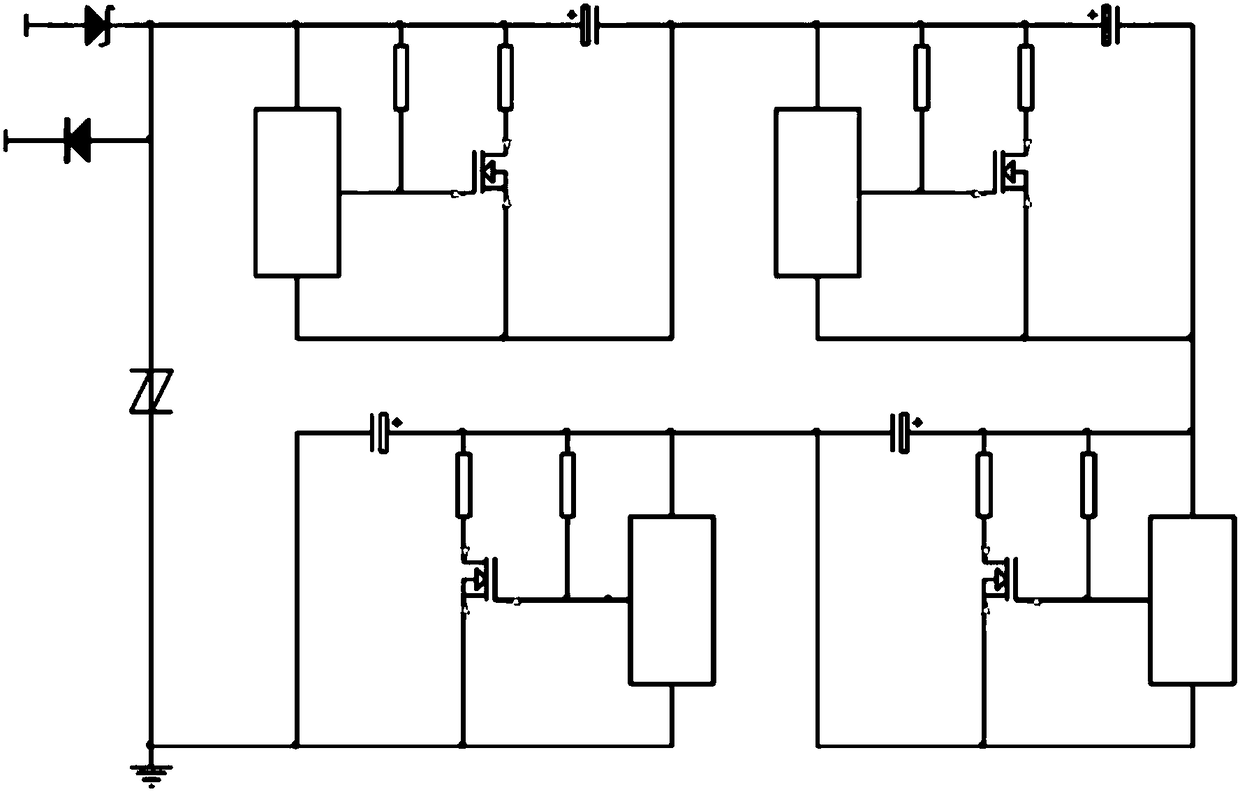

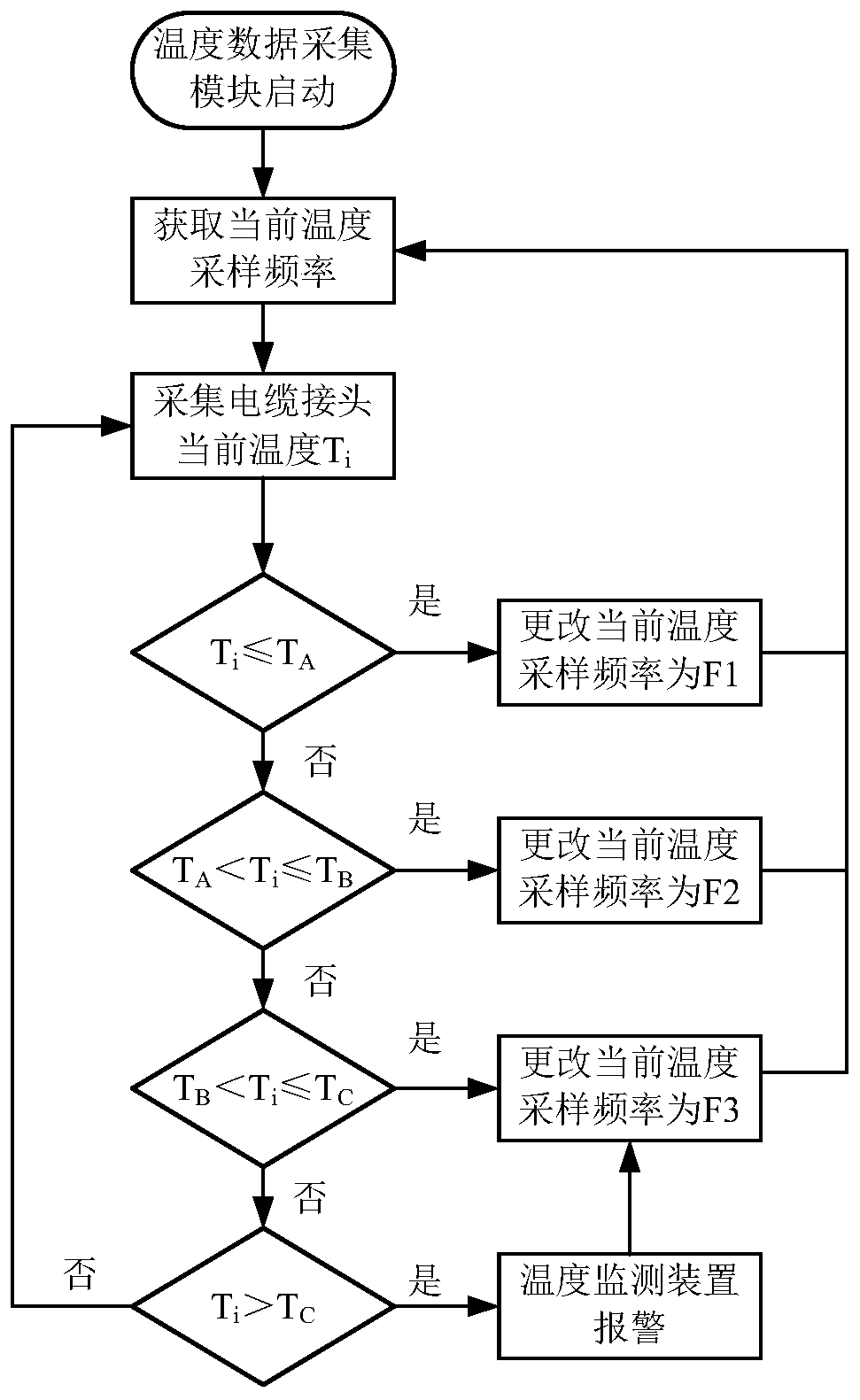

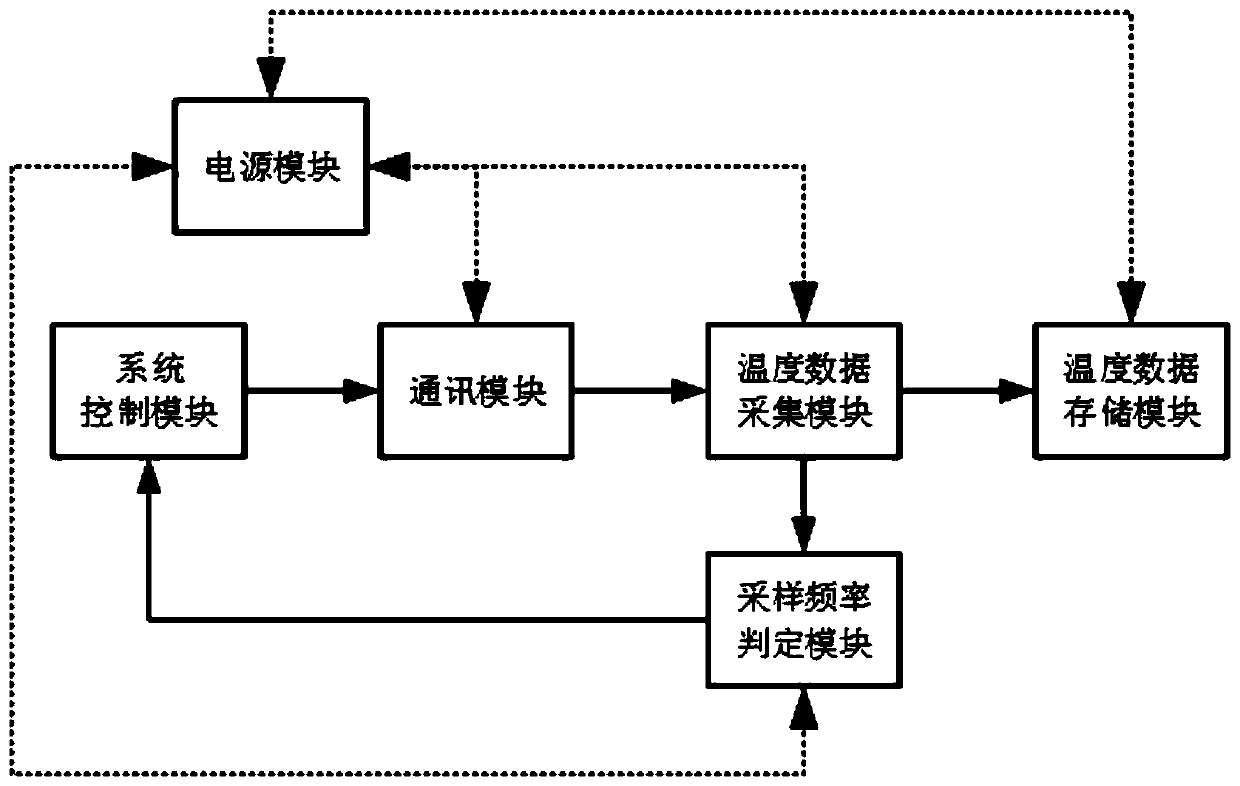

Cable joint temperature data acquisition method, monitoring device and storage medium

InactiveCN110879109AReal-time grasp of operating temperatureReasonable useThermometer detailsThermometer applicationsData acquisitionTemperature monitoring

The invention discloses a cable joint temperature data acquisition method, a monitoring device and a storage medium. The method comprises the following steps: S1, acquiring the current temperature ofa cable joint at an initial temperature sampling frequency; S2, comparing the current temperature with a preset cable joint temperature threshold, and changing a temperature sampling frequency according to a comparison result; S3, obtaining the temperature of the cable joint at the changed temperature sampling frequency, and repeating the steps S2 to S3. A cable joint temperature threshold value is preset, the acquired current temperature of the cable joint is compared with the preset cable joint temperature threshold, and the temperature sampling frequency is changed according to the comparison result, so that the intelligent dynamic adjustment of the cable joint temperature acquisition frequency is realized, the system resources can be reasonably utilized, and the service life of the cable joint temperature monitoring device is prolonged; and meanwhile, the operation temperature of the cable joint can be mastered in real time, potential safety hazards can be found in time, the line fault probability is reduced, and the line operation and maintenance cost is reduced.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

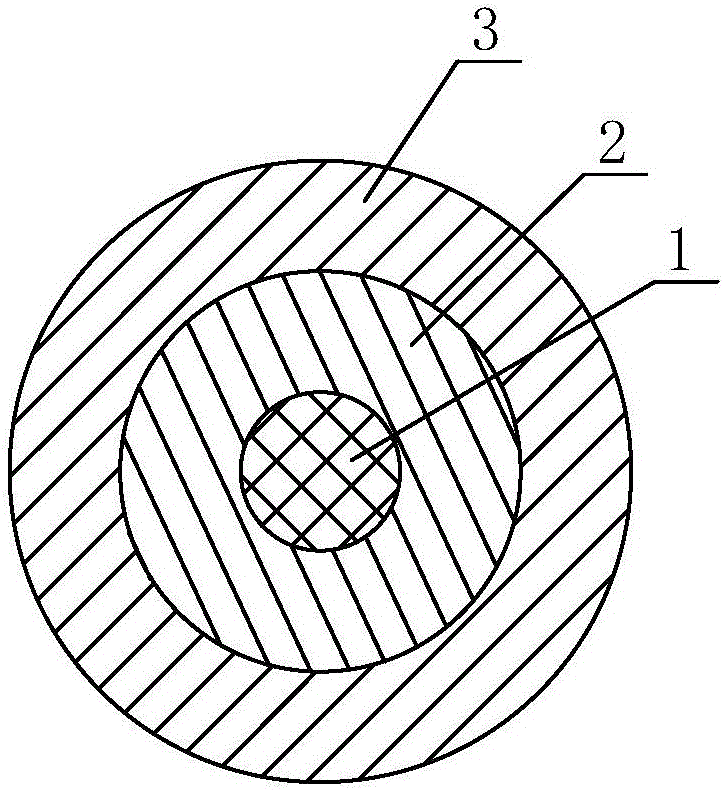

Carbon fiber wire and method of processing and connecting the carbon fiber wire and metal line joint

ActiveCN105120542AChange the situation of being too thinAvoid destructionHeater elementsHeating element shapesYarnFiber

A carbon fiber wire comprises carbon fiber yarns. A first high temperature resistance protecting layer is arranged on the outer side of the carbon fiber yarns. A second high temperature resistance protecting layer is arranged on the outer side of the first high temperature resistance protecting layer. The wall thickness of the first high temperature resistance protecting layer ranges from 2 mm to 3 mm. The carbon fiber wire with a reasonable structure is simple to operate. The internal carbon fiber yarns are prevented from being damaged during a carbon fiber wire rotary-cut peeling process. The basic design power of a product is unchanged. The power and heat can be easily controlled during later-stage using processes. Furthermore, the carbon fiber yarns and metal line joints are tightly and firmly connected. Reliable performance is achieved. No special joint temperature rise emerges. High-temperature or even ablation phenomena caused by virtual connection can be prevented. The carbon fiber wire is safe and reliable.

Owner:SHANDONG YINGHAO ELECTRONICS TECH CO LTD

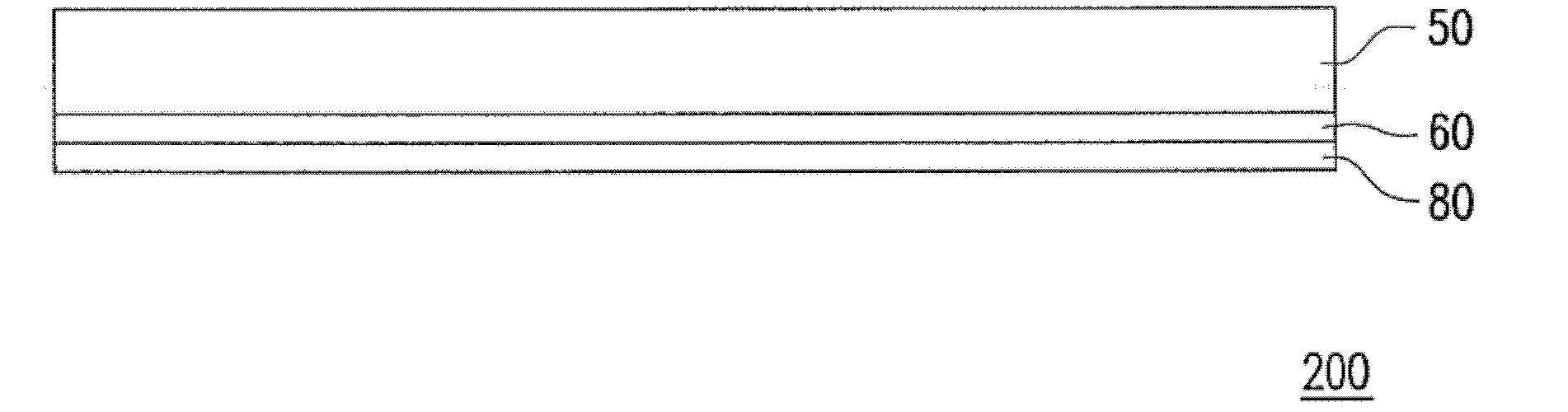

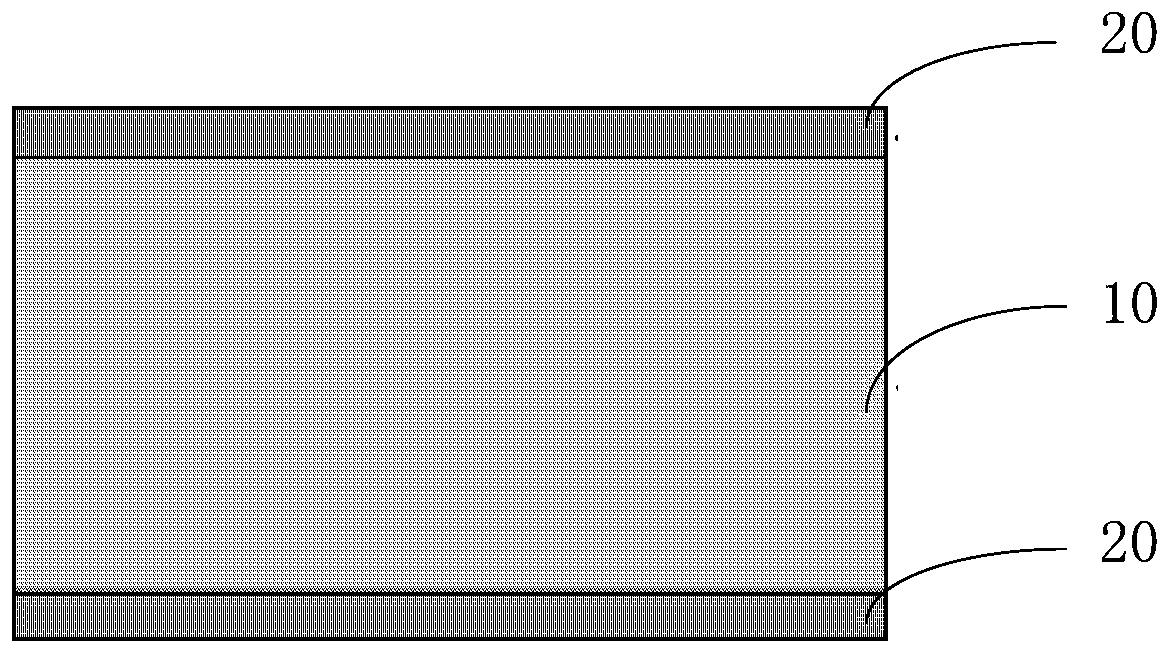

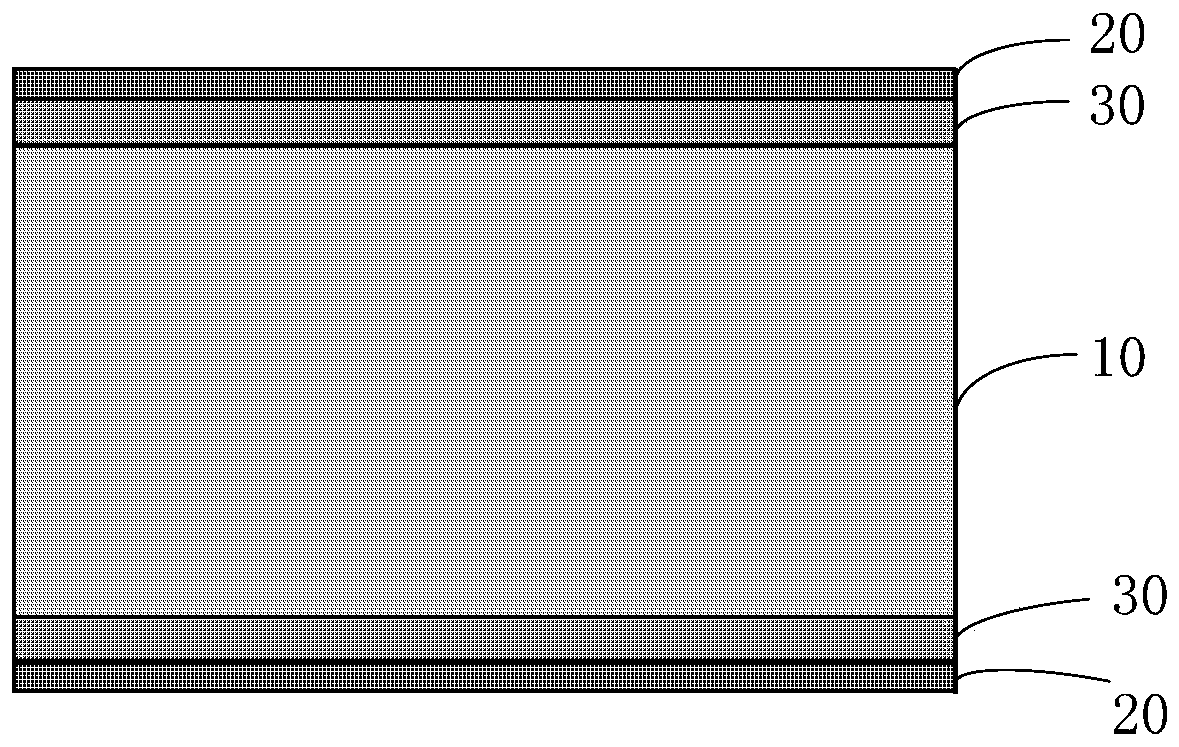

Joint material, semiconductor device and manufacturing method of semiconductor device

ActiveCN109755208AReduce internal stressImprove joint reliabilitySemiconductor/solid-state device detailsSolid-state devicesIndiumAlloy

The embodiment of the invention provides a joint material. The joint material comprises a supporting layer and solder layers arranged on the opposite side surfaces of the supporting layer. The supporting layer comprises at least one of Cu metal, Ni metal, Ag metal, Ti metal, Zn metal and alloys of the Cu metal, the Ni metal, the Ag metal, the Ti metal, the Zn metal, the supporting layer is provided with a porous structure, and the solder layers comprise at least one of tin-based solder and indium-based solder. According to the joint material, solder of the solder layers and the metal or alloysof the supporting layer can react at the joint temperature to form a high melting point intermetallic compound with a melting point higher than the joint temperature, so that a high temperature resistant joint layer is obtained through lower joint temperature, and multiple reflux can be resisted; and the supporting structure is provided with the porous structure, and the porous structure of the supporting layer is retained in a joint layer to effectively buffer the internal stress and improve the joint reliability. The embodiment of the invention further provides a semiconductor device usingthe joint material to joint and a manufacturing method of the semiconductor device.

Owner:XIAN RUIXIN TECH CO LTD

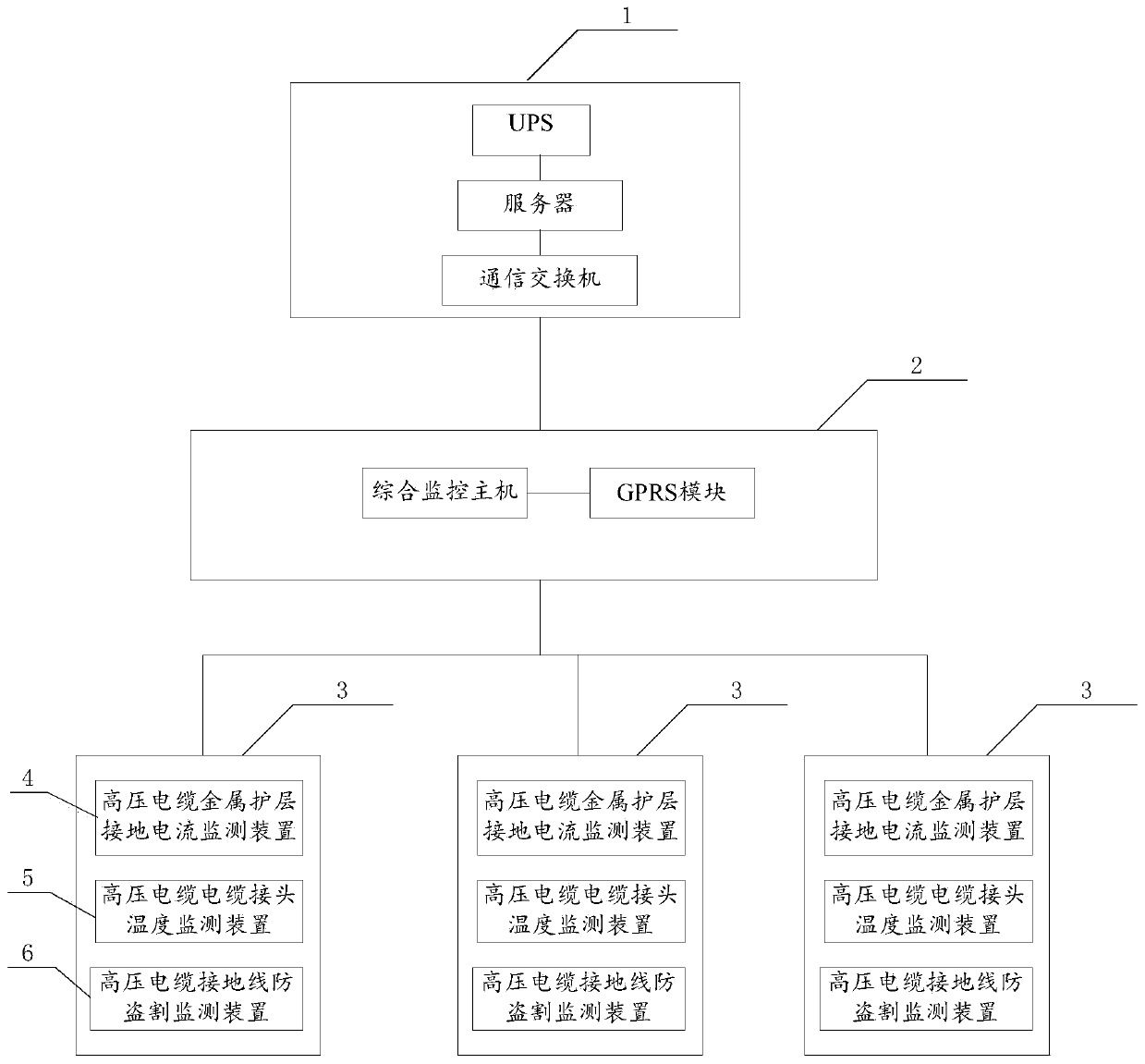

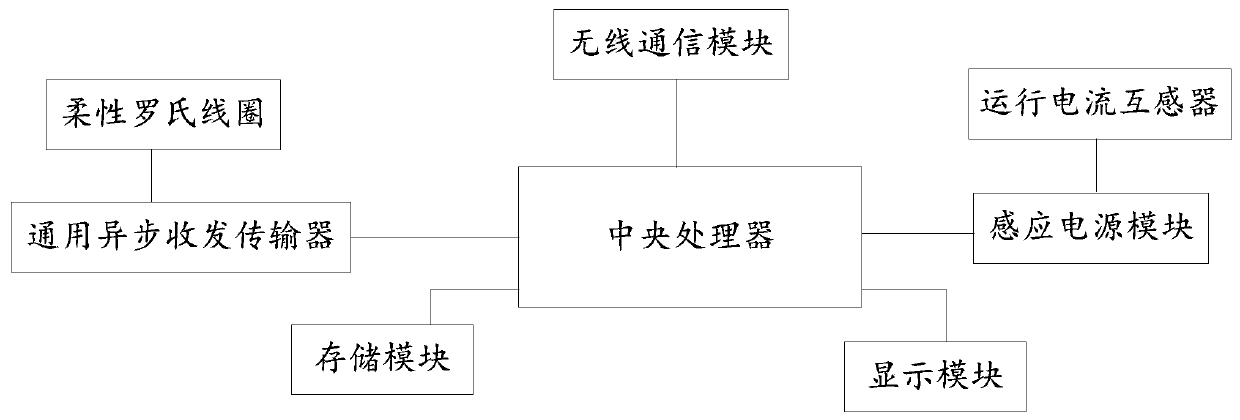

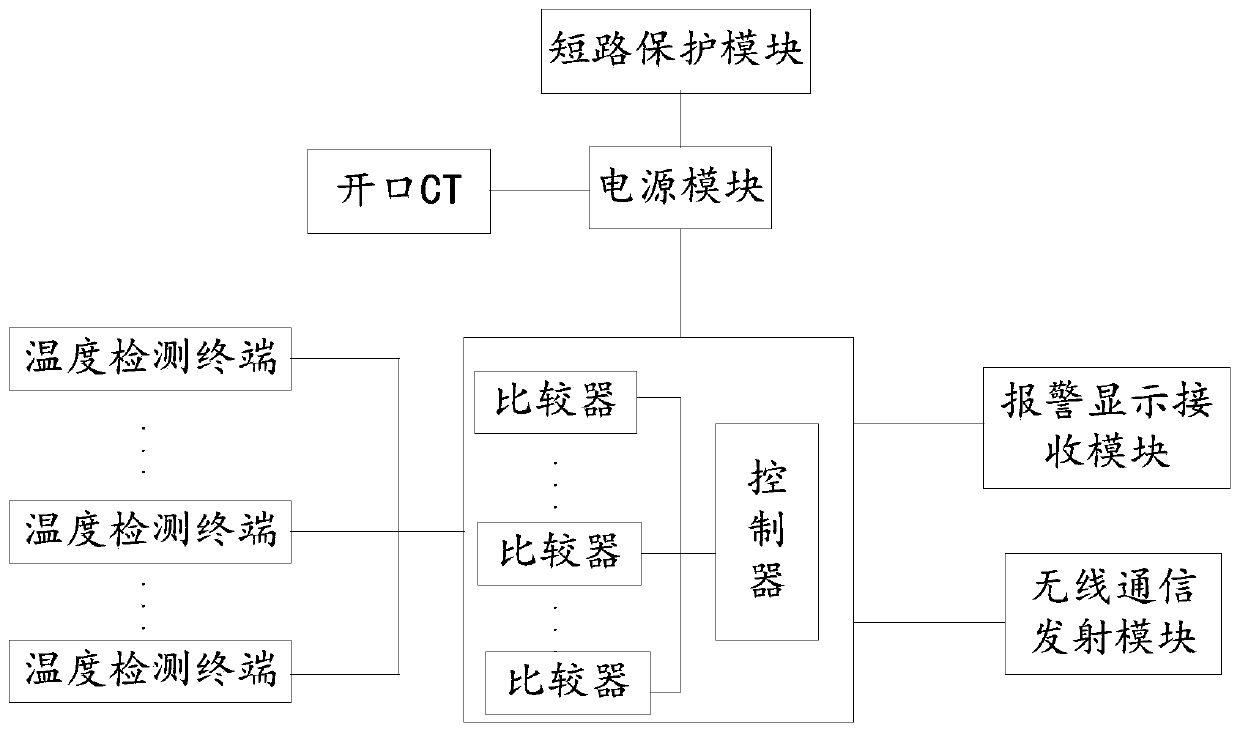

Multifunctional external-force-damage-resistant monitoring system and method for high voltage cable fixation construction site

ActiveCN110244101APrevent and reduce external damage accidentsReduce inspection workloadThermometer detailsOptical detectionMonitoring systemMaster station

The invention discloses a multifunctional external-force-damage-resistant monitoring system and method for a high voltage cable fixation construction site. The system and the method realize real-time monitoring on a grounding current of a metal sheath of a high voltage cable, a cable joint temperature of the high voltage cable and a fact that whether a ground wire of the high voltage cable is stolen and cut. The system comprises a master station, a transmission device and a plurality of terminal monitoring devices; the terminal monitoring devices respectively comprise a high voltage cable metal sheath grounding current monitoring device used for monitoring grounding current data of the metal sheath of the high voltage cable, a high voltage cable joint temperature monitoring device used for monitoring the cable joint temperature of the high voltage cable and a high voltage cable ground wire stealing-resistant and cut-resistant monitoring device used for monitoring whether the ground wire of the high voltage cable is stolen and cut; and the transmission device is used for receiving the grounding current of the metal sheath of the high voltage cable, the cable joint temperature of the high voltage cable and state data of the ground wire of the high voltage cable, summarizing and then uploading to the master station.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

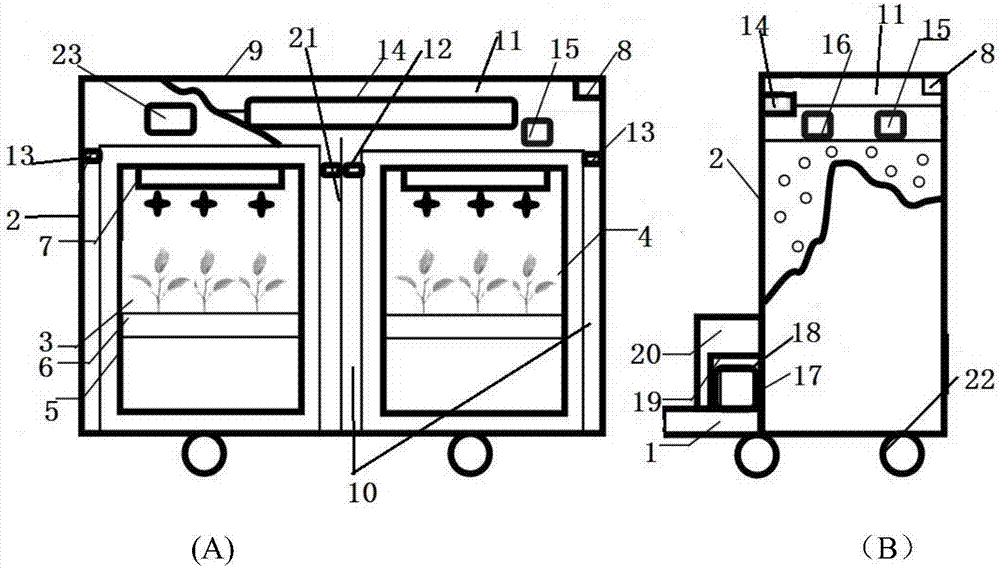

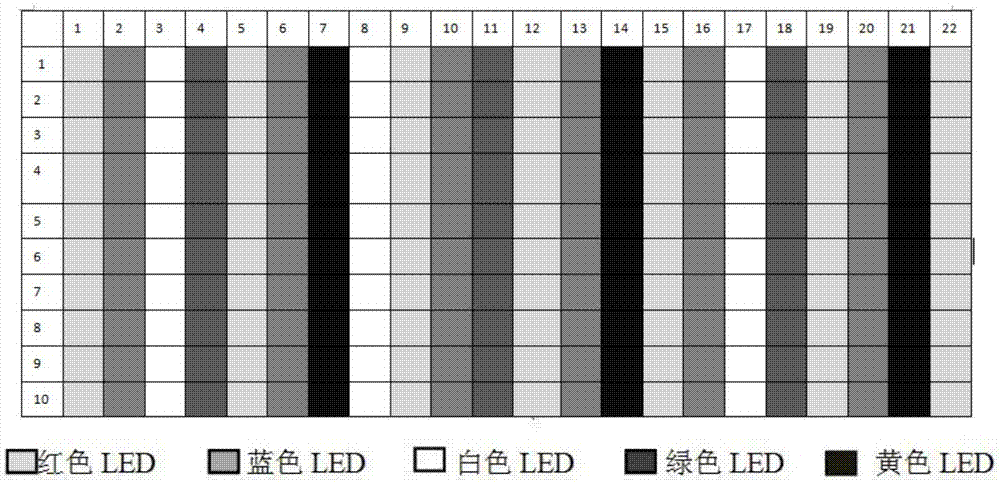

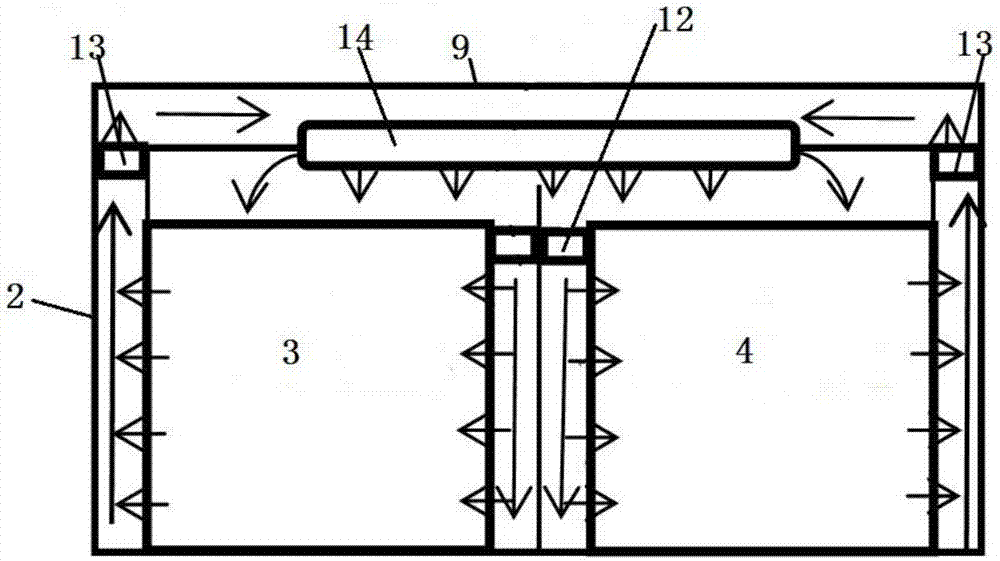

Intelligent plant growth experiment device and temperature adjusting and controlling method thereof

ActiveCN107258394AReduce temperature emergency responseRealize managementClimate change adaptationAuxillary controllers with auxillary heating devicesGrowth plantControl system

The invention discloses an intelligent plant growth experiment device which comprises a first growing room, a second growing room, a water-cooled type LED area light source, a control system, a cover plate, a public air adjusting room and a CO2 fertilizer applying device, a compressor, a fertilizer bucket, a water tank and the like. The experiment device is cooled by the compressor and heated by a PTC, recycles the heat generated by an LED light source and controls the joint temperature control module of the public air adjusting room. The temperatures of the two growing rooms are adjusted and controlled by controlling the temperature of an air supply room of the public air adjusting room and the flow and rotating speed of draught fans of the growing rooms, and the independent management of the temperatures of the growing rooms can be achieved. The invention further discloses a temperature adjusting and controlling method of the intelligent plant growth experiment device. The intelligent plant growth experiment device is reasonable in design and convenient to use, and the temperature adjustment and control of the device are effectively achieved.

Owner:NANJING AGRICULTURAL UNIVERSITY

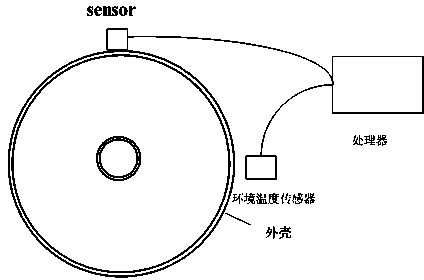

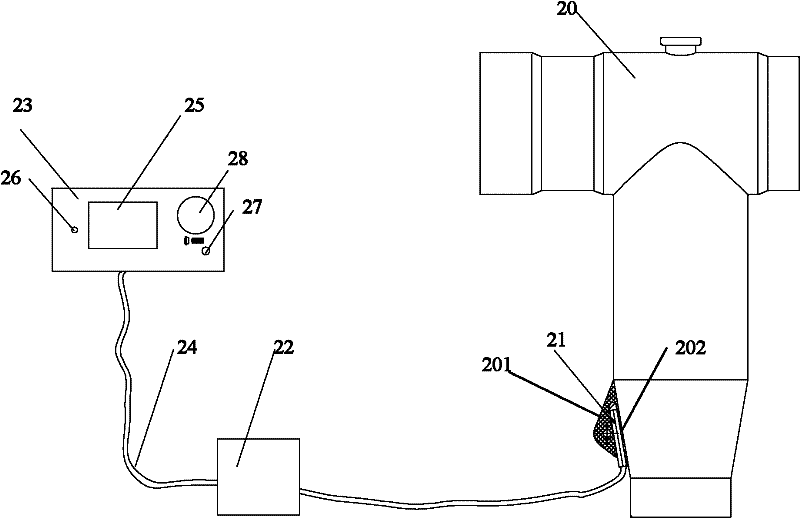

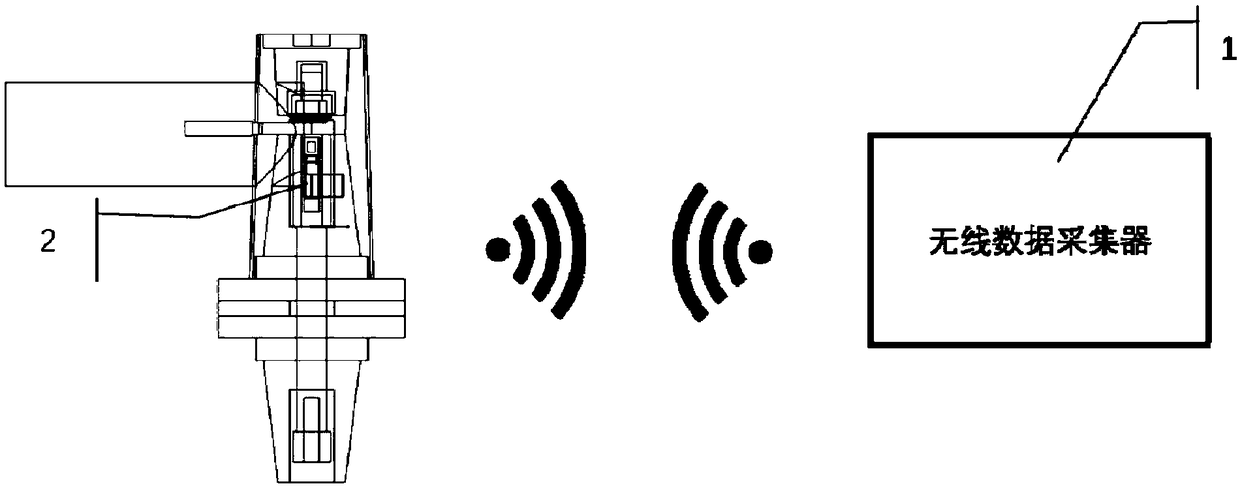

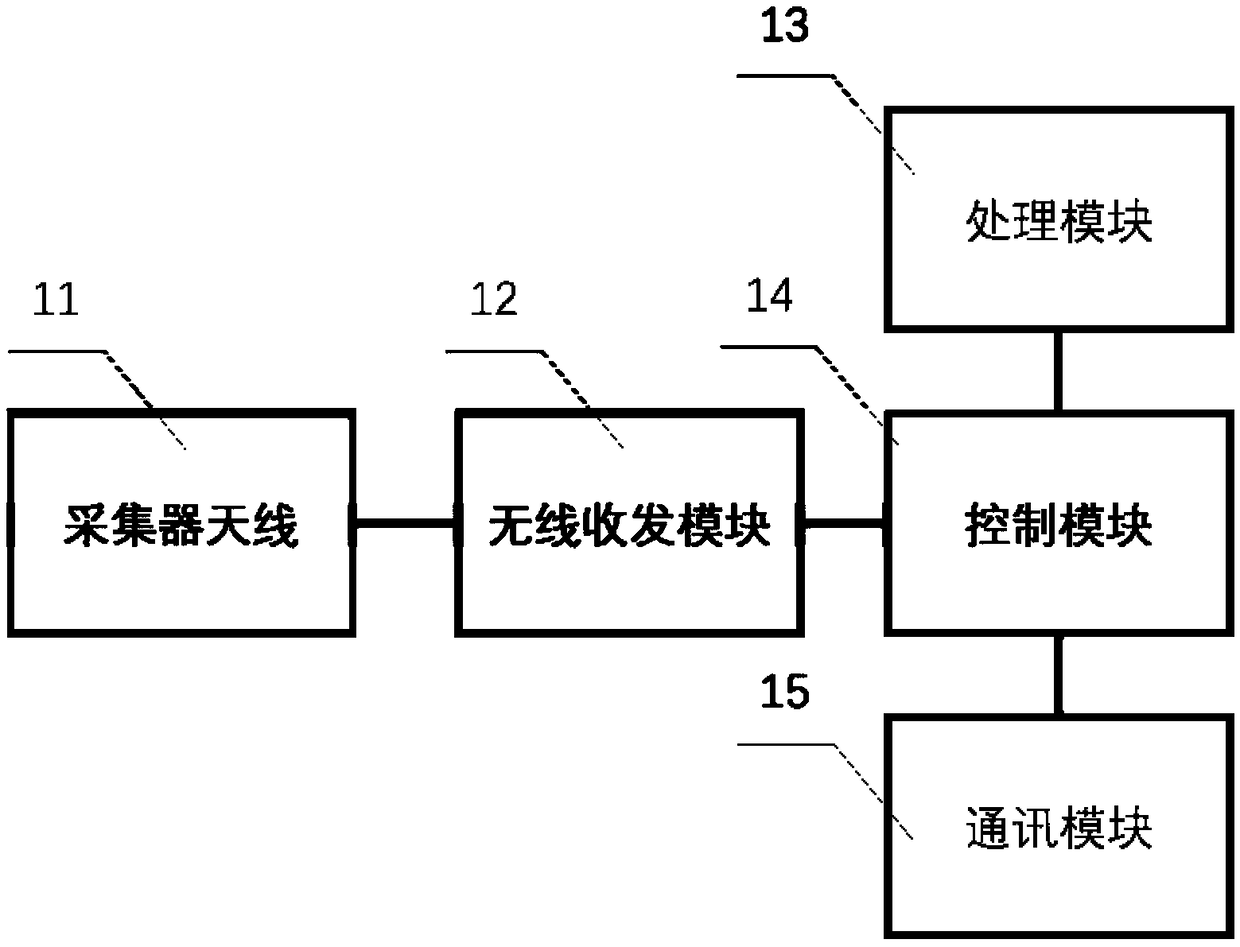

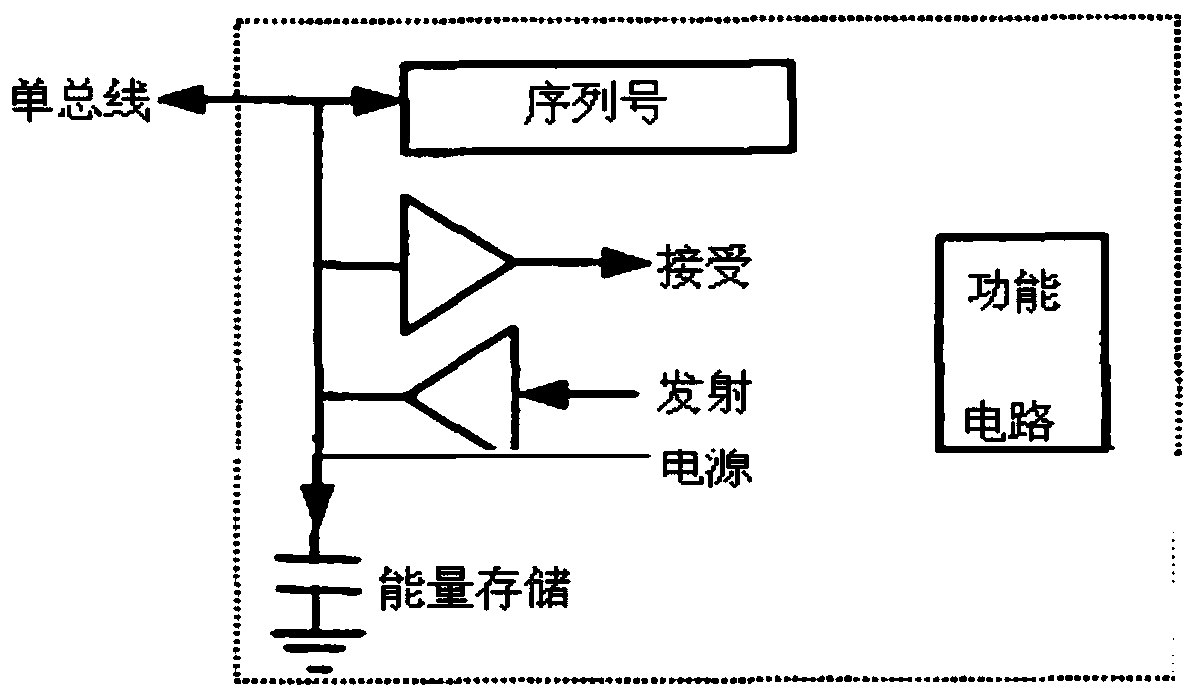

Ring main unit cable joint temperature sensing system

PendingCN109141680AImprove the safety of useImprove securityThermometer detailsThermometers using physical/chemical changesElectrical batteryData acquisition

The present invention provides a ring main unit cable joint temperature sensing system. The system comprises a data collector module (1) and a temperature sensor module (2); the data collector module(1) communicates with the temperature sensor module (2) through a mode; the temperature sensor module (2) comprises a temperature sensor (20), an antenna PCB (21) and an antenna metal radiation fin (23); and the temperature sensor (20) and the antenna metal radiation fin (23) are arranged on the antenna PCB (21). The ring main unit cable joint temperature sensing system provided by the invention achieves the temperature online sensing and monitoring function and changes the manual temperature measurement to automatic online monitoring so as to improve the usage safety of the ring main unit; and the temperature sensor employs a wireless mode for operation and can supply power without usage of batteries or other external power sources so as to further improve the safety of the monitoring system, and the ring main unit cable joint temperature sensing system is compact and reasonable in whole structure and easy to install and maintain.

Owner:OFWELT SUZHOU TECH CO LTD

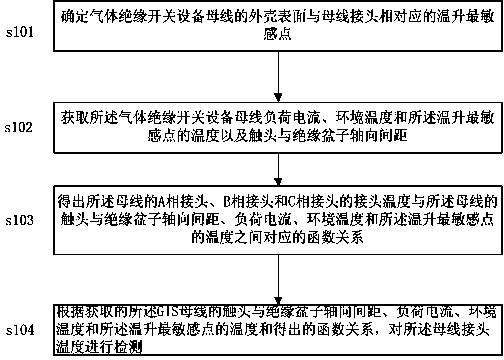

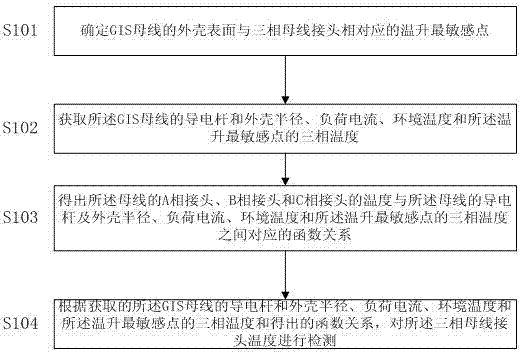

Online temperature detection method for three-phase box-sharing GIS (Gas Insulated Switchgear) bus joint

InactiveCN104122006ARealize online accurate detectionOperation without power downSwitchgear arrangementsThermometers using physical/chemical changesThermodynamicsTransformer

The invention discloses an online temperature detection method for a three-phase box-sharing GIS (Gas Insulated Switchgear) bus joint. The online temperature detection method comprises the following steps: determining a temperature rise most sensitive point corresponding to the three-phase bus joint on the surface of a shell of a GIS bus; acquiring the radiuses of a conducting rod and the shell of the GIS bus, load current, ambient temperature and the three-phase temperature of the temperature rise most sensitive point; acquiring corresponding function relations among the joint temperature of an equipment bus, the radiuses of the conducting rod and the shell of the equipment bus, the load current, the ambient temperature and the three-phase temperature of the temperature rise most sensitive point; detecting the joint temperature of the three-phase bus joint. By adopting the online temperature detection method, the temperature of the GIS bus joint can be detected accurately on line without cutting off, and detection results are not influenced by the external environmental factors. The equipment structure does not need to be changed, and high safety and high practicability are realized. Moreover, the temperatures of a plurality of GIS bus joints in a transformer substation can be detected at the same time, and convenience is brought to detection automation.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID +1

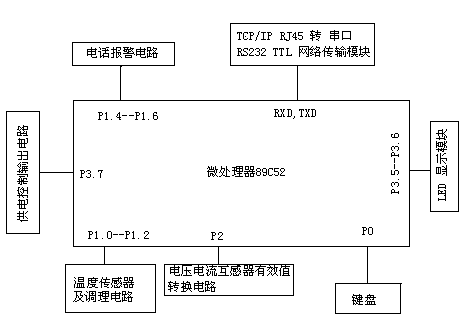

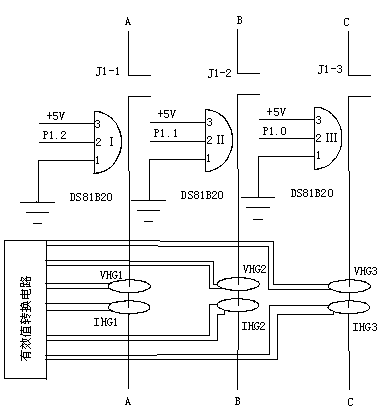

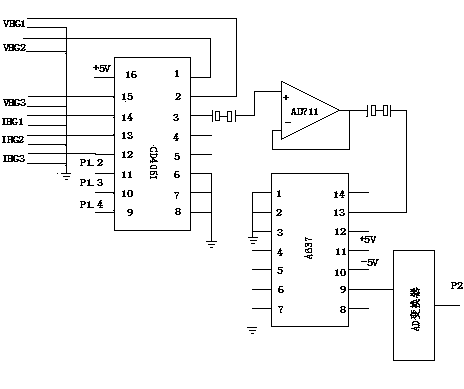

Intelligent monitoring system of low-voltage electric cabinet

InactiveCN103401313ARealize remote centralized measurement and controlReal-time monitoring of safe operationCircuit arrangementsSustainable buildingsAutomatic controlLow voltage

The invention relates to an intelligent monitoring system of a low-voltage electric cabinet, and belongs to the field of low-voltage power supply regulation and automatic control. The signal acquisition circuit of the intelligent monitoring system comprises a temperature sensor, a voltage transformer and a current transformer, wherein the temperature sensor is attached to a main power supply cable joint; digital voltage signals of the temperature sensor are output to a single-chip microcomputer; the voltage transformer and the current transformer are arranged on the main power supply cable; the digital voltage signals of the voltage transformer and the current transformer are output to the single-chip microcomputer; a power supply controlling output circuit receives the control signal of the single-chip microcomputer; the circuit breaker of the power supply controlling output circuit is used for controlling the make-and-break of a main power supply circuit; a network transmission module for converting serial port logic standards of a single-chip microcomputer into Ethernet interface logic standards is connected to the communication interface of the single-chip microcomputer. A microprocessor is adopted to serve as a data acquisition and control execution terminal, and is used for acquiring and processing power supply operation signals and cable joint temperature signals, conveying the acquired signals to a central control room through the Internet, and receiving control instructions sent by the central control room, so as to realize remote centralized measure and control.

Owner:TANGSHAN NORMAL UNIV

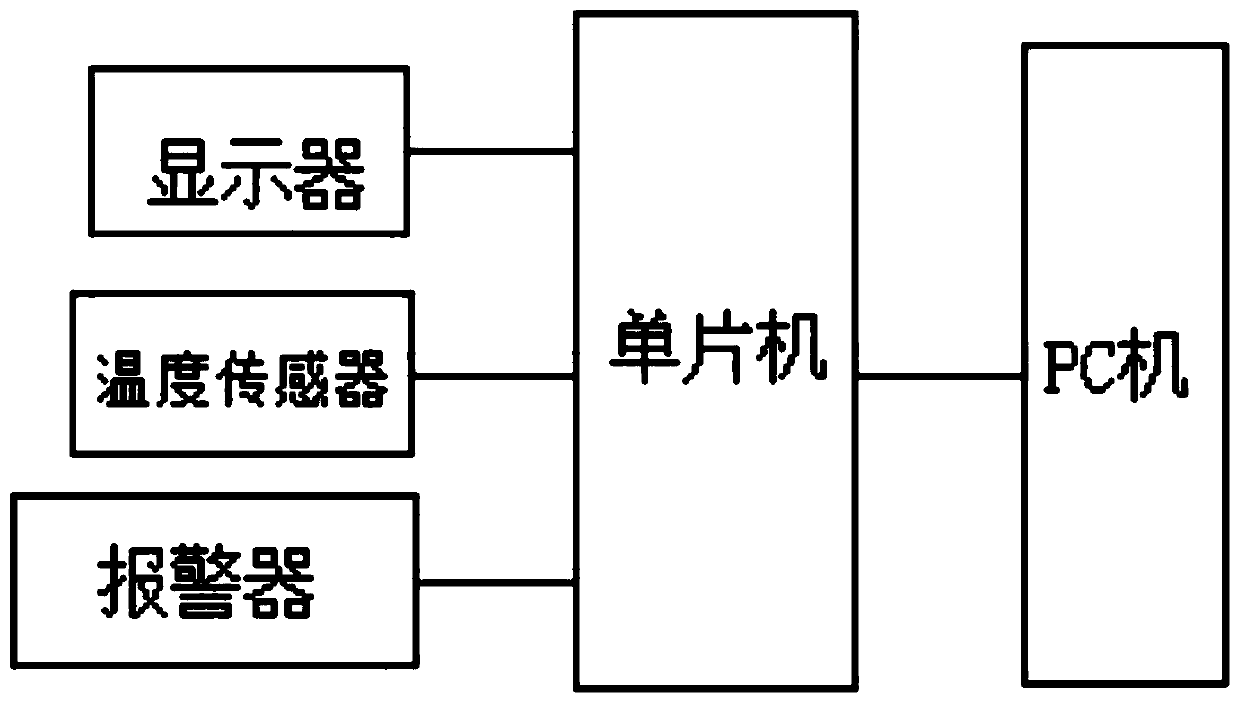

Centralized-distributed power cable joint temperature monitoring system

InactiveCN110595640ALow costImprove sensing accuracyThermometer detailsThermometers using electric/magnetic elementsMicrocontrollerDisplay device

The invention relates to the technical field of safety monitoring, in particular to a centralized-distributed power cable joint temperature monitoring system. The centralized-distributed power cable joint temperature monitoring system comprises a temperature sensor, a single chip microcomputer, an alarm, a display and a power supply unit, wherein the temperature sensor is arranged at a cable jointfor continuously monitoring a temperature change of the cable joint and forming a signal; the single chip microcomputer is electrically connected with the temperature sensor for receiving a signal output by the temperature sensor, and comparing the signal with a preset threshold to judge whether to output an alarm signal; the alarm is electrically connected with the single chip microcomputer forexecuting an alarm action after receiving the alarm signal of the single chip microcomputer; the display is electrically connected with the single chip microcomputer for displaying temperature data output by the single chip microcomputer; and the power supply unit is electrically connected with the single chip microcomputer for supplying power to the single chip microcomputer. The monitoring system can monitor the temperature change of a power cable in real time, and can promptly give an alarm when the temperature exceeds the limit or the temperature rise speed exceeds the limit to ensure theoperation safety.

Owner:DONGYING POWER SUPPLY COMPANY STATE GRID SHANDONG ELECTRIC POWER

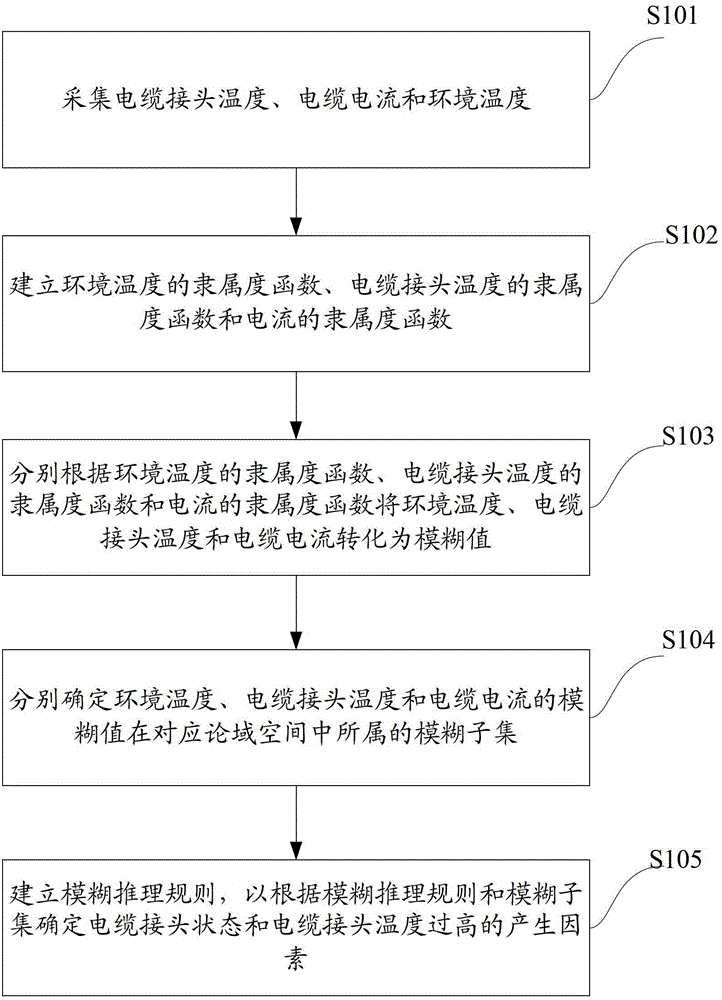

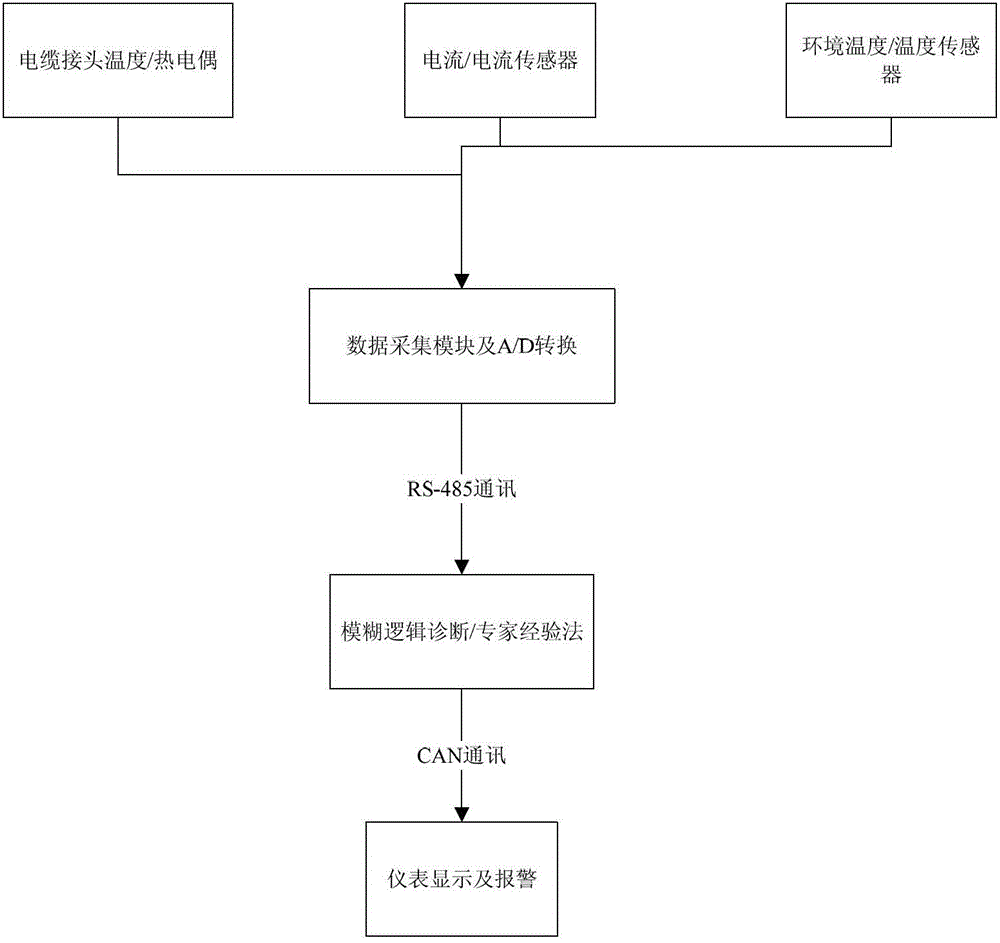

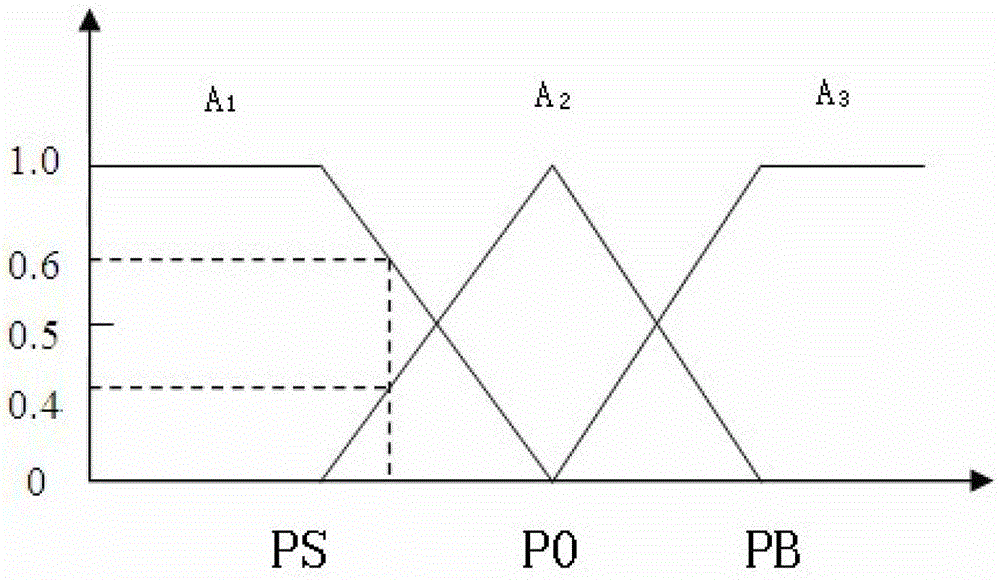

Automobile high-voltage cable joint state detection method and system

The invention brings forward a high-voltage cable joint state detection method. The method comprises the following steps: acquiring a cable joint temperature, a cable current and an environment temperature; respectively establishing membership functions; converting the environment temperature, the cable joint temperature and the cable current into fuzzy values respectively according to the membership functions; determining fuzzy subclasses which the fuzzy values of the environment temperature, the cable joint temperature and the cable current belong to in corresponding domain spaces; and establishing fuzzy inference rules so as to determine cable joint states and generation factors for the over-high cable joint temperature. According to the detection method provided by the embodiment of the invention, whether cable joints are abnormal and reasons why problems occur can be accurately and reliably analyzed, and alarms can be given timely, such that risks caused by abnormities of the cable joints can be avoided, and life and property safety of passengers are guaranteed. The invention also brings forward an automobile high-voltage cable joint state detection system.

Owner:BEIQI FOTON MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com