High voltage cable joint temperature measuring device

A technology of high-voltage cables and temperature measuring devices, which is applied in the direction of measuring devices, electrical devices, thermometers, etc., can solve the problems of easy breakage of optical fibers, inability to fundamentally achieve accurate temperature measurement, and limitations, and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

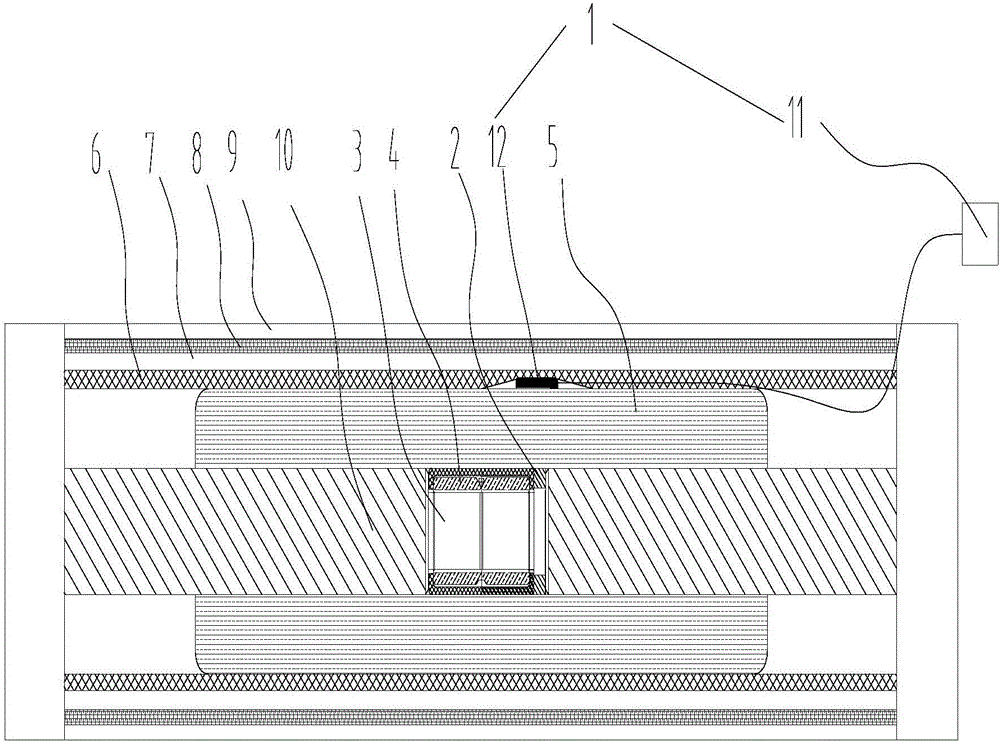

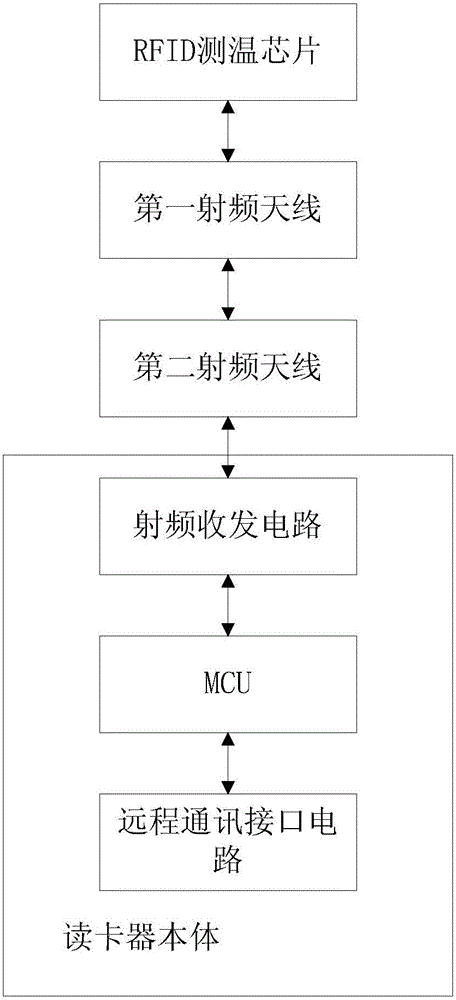

[0019] see figure 1 and figure 2 , the present invention provides a high-voltage cable joint temperature measurement device, which is applied at the joint of high-voltage cables, including a card reader 1 and at least one temperature measurement mechanism 2, and the temperature measurement mechanism 2 is installed on the high-voltage cable insulation layer and wire core 3; the temperature measuring mechanism 2 includes a circuit board, and the circuit board is provided with an RFID temperature measuring chip, a metal block and a first radio frequency antenna, and the card reader 1 includes a card reader body 11 and a second radio frequency antenna 12, and the RFID temperature measurement The chip is connected to the first radio frequency antenna, the card reader body 11 is connected to the second radio frequency antenna 12, the RFID temperature measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com