Carbon fiber wire and method of processing and connecting the carbon fiber wire and metal line joint

A technology of carbon fiber wire and connection method, applied in the direction of heating element, heating element material, heating element shape, etc., can solve the problems of uncontrollable power and heat, poor connection, performance impact, etc., and achieve easy control of power and heat, joints There is no special increase in temperature, and the effect of avoiding high temperature and even ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

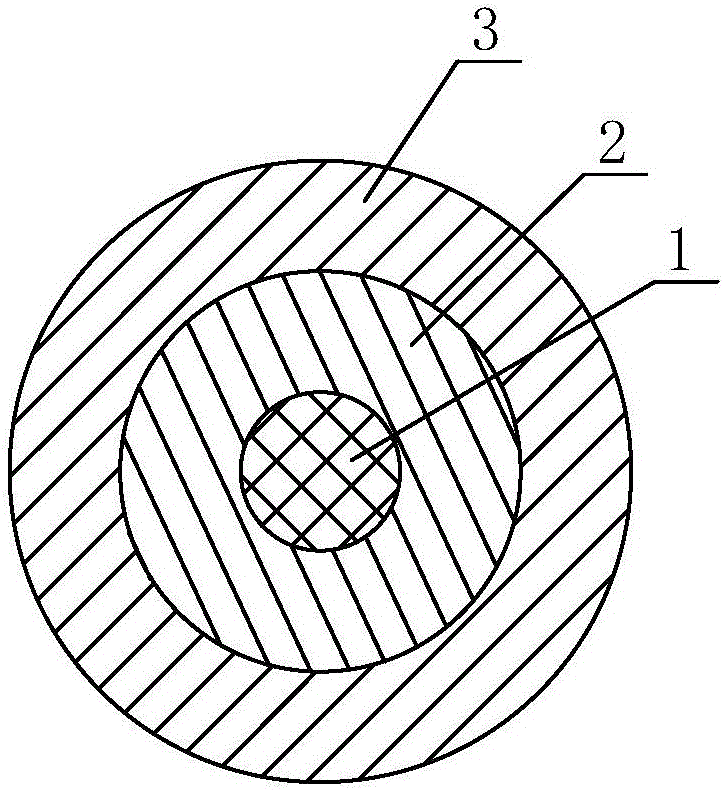

[0027] Such as figure 1 As shown, a carbon fiber thread includes a carbon fiber filament 1, a first high temperature resistant protective layer 2 is provided outside the carbon fiber filament 1, a second high temperature resistant protective layer 3 is provided outside the first high temperature resistant protective layer 2, and the first high temperature resistant protective layer 3 is provided outside the first high temperature resistant protective layer 2. The wall thickness of the first high temperature resistant protective layer 2 is 2-3 mm, which changes the situation that the first high temperature resistant protective layer of the existing carbon fiber wire is too thin, avoids the damage to the internal carbon fiber wire when the carbon fiber wire is rotary cut and peeled, and ensures The basic design power of the product remains unchanged, and it is easy to control power and heat during later use.

[0028] Both the first high temperature resistant protective layer 2 a...

Embodiment 2

[0039] Such as figure 1 As shown, a carbon fiber thread includes a carbon fiber filament 1, a first high temperature resistant protective layer 2 is provided outside the carbon fiber filament 1, a second high temperature resistant protective layer 3 is provided outside the first high temperature resistant protective layer 2, and the first high temperature resistant protective layer 3 is provided outside the first high temperature resistant protective layer 2. The wall thickness of the first high temperature resistant protective layer 2 is 2-3 mm, which changes the situation that the first high temperature resistant protective layer of the existing carbon fiber wire is too thin, avoids the damage to the internal carbon fiber wire when the carbon fiber wire is rotary cut and peeled, and ensures The basic design power of the product remains unchanged, and it is easy to control power and heat during later use.

[0040] Both the first high temperature resistant protective layer 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com