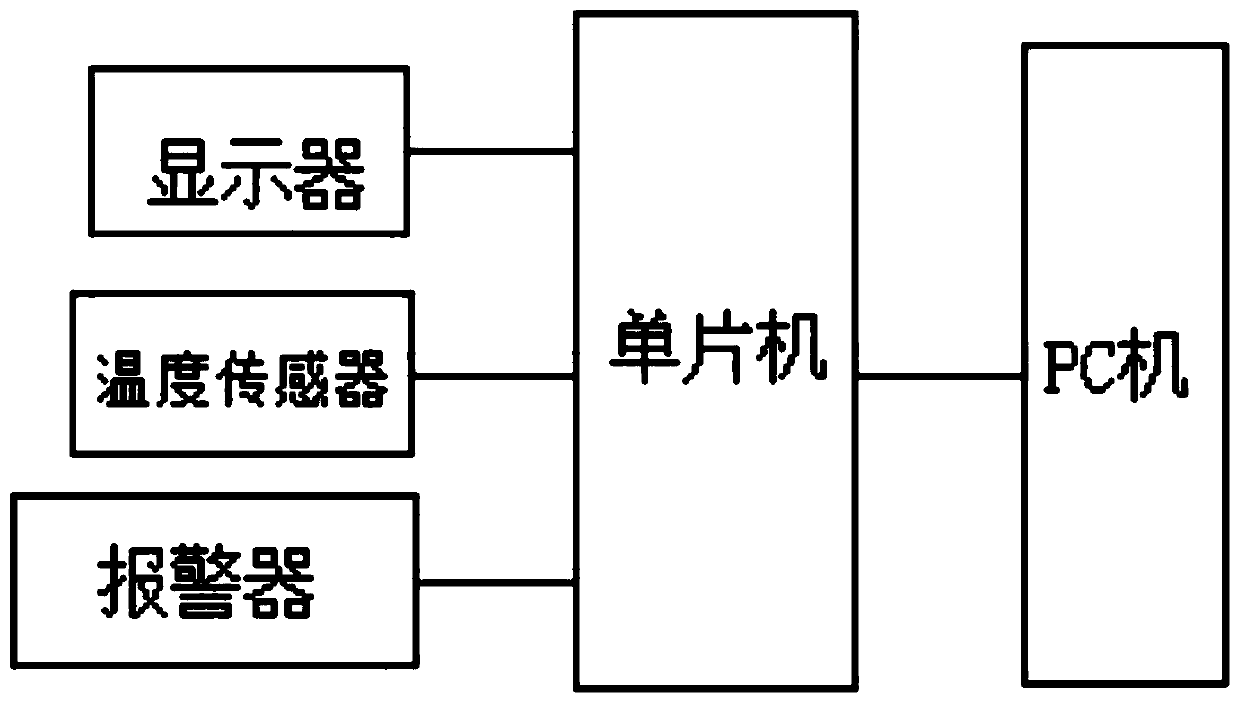

Centralized-distributed power cable joint temperature monitoring system

A power cable and monitoring system technology, applied to thermometers, applications of thermometers, and parts of thermometers, etc., can solve the problems of long laying distance of power cables, fewer personnel, and complicated directions, and achieve more temperature measurement points, easy management, The effect of simple interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

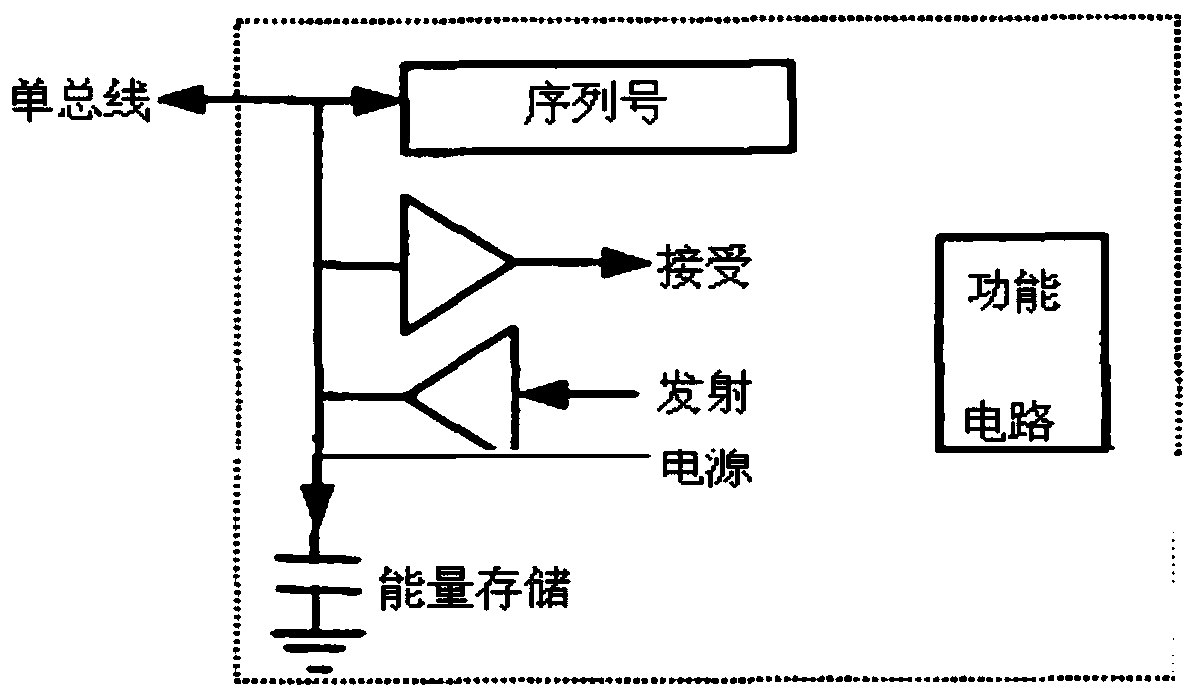

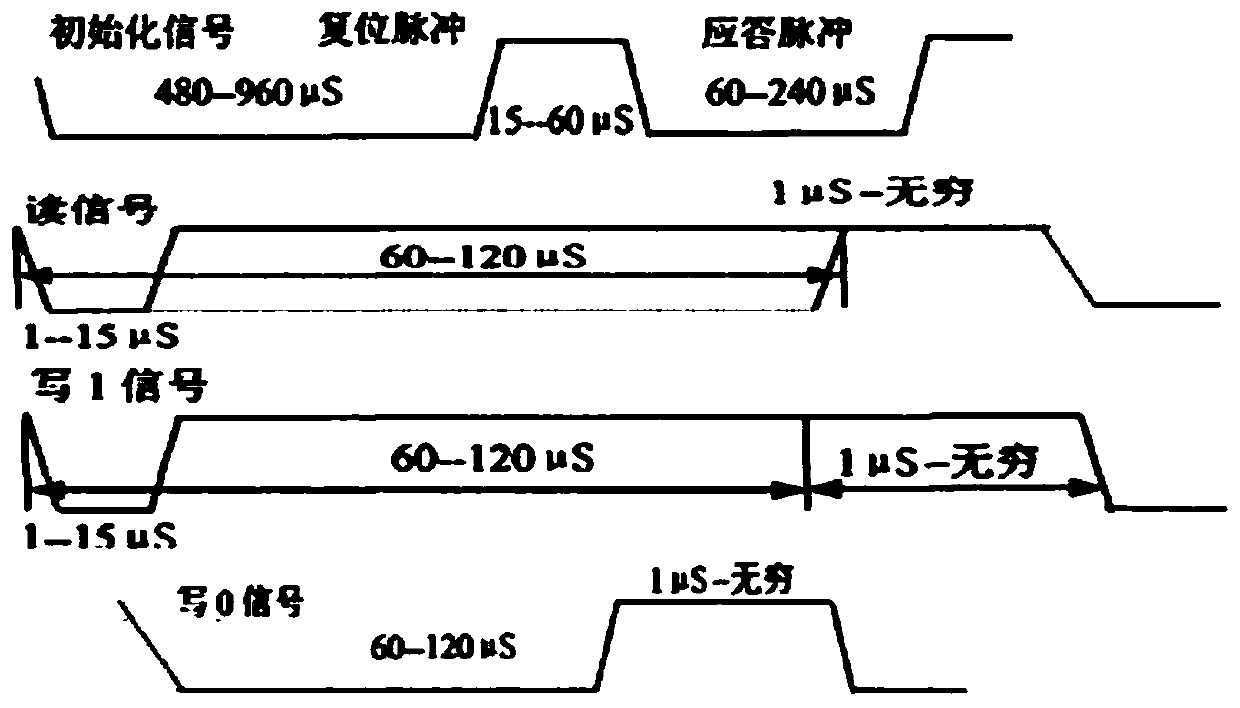

[0052]The temperature sensor in the distributed power cable joint temperature monitoring system of this embodiment is a single-bus digital temperature sensor, more preferably a digital temperature sensor DS18B20 from DALLAS Semiconductor Company, which can directly convert the temperature into a serial digital signal and send it directly into the microcontroller for processing and control. Moreover, the physical and chemical properties of the chip are very stable, and the linearity is good when it is used as a temperature measuring element. At 0-100°C, the maximum linear deviation is less than 1°C. Single-bus data output is used, and the output value is a digital signal, so it can directly enter the single-chip microcomputer for digital processing without using an A / D converter and related interface chips. In this way, the structure of the temperature measurement system is relatively simple and the volume is not large. At the same time, it is controlled by a single-chip micr...

Embodiment 2

[0147] In the distributed power cable joint temperature monitoring system provided in this embodiment, the temperature sensor is a thermocouple sensor, and a thermocouple temperature difference circuit is used for temperature measurement. The temperature detection part can use a low-temperature thermocouple, and the thermocouple is composed of two welded together Composed of metal wires, the thermoelectric potential generated by the thermocouple is composed of the contact potential of the two metals and the temperature difference potential of a single conductor. By keeping the reference junction at a known temperature and measuring this voltage, the temperature of the sense junction can be inferred. The data acquisition part adopts a single-chip microcomputer with A / D channel, and then collects the voltage or current signal that changes with the measured temperature. The multi-channel sampling signal obtained in this way is passed through the amplifier, multi-channel analog sw...

Embodiment 3

[0149] In the distributed power cable joint temperature monitoring system provided in this embodiment, the temperature sensor adopts a two-terminal semiconductor integrated temperature sensor. Specifically, a two-terminal semiconductor integrated temperature sensor AD590, LM35, etc. can be selected, and the collected current signal is passed through The multi-channel A / D converters are sent to the single-chip microcomputer, and the single-chip microcomputer controls the data collection and conversion. Taking AD590 as an example, its temperature measurement range is -55 ~ +l50°C, and its working voltage is +4 ~ +30V. Most of the traditional multi-point temperature detection systems use analog temperature sensors (such as AD590), which generally go through the processes of front-end amplification, A / D conversion and data correction. The two-terminal semiconductor integrated temperature sensor has high anti-interference ability and is suitable for remote temperature measurement a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com